Patents

Literature

37results about How to "Overcome displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photocuring and thermocuring conductive adhesive and preparation method

ActiveCN102127386ALiquidConnectivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses a photocuring and thermocuring conductive adhesive, which is prepared by mixing photosensitive high polymer, diluent monomer, conducting particles, photoinitiator, polymerization inhibitor, epoxy resin, epoxy active diluting agent, latent curing agent and latent promoting agent, grinding the mixture, and stirring and dispersing in a planetary manner. The curing temperature of the product is low, and deep curing can be realized; after being cured, the adhesive has high adhesiveness and high solvent resistance; and the adhering strength is high, the resistivity is low, and the requirements of microelectronic packaging technique for LED chips, liquid crystal materials, glass substrates, thin film circuits, PCB circuit boards and the like can be met.

Owner:东莞市新懿电子材料技术有限公司

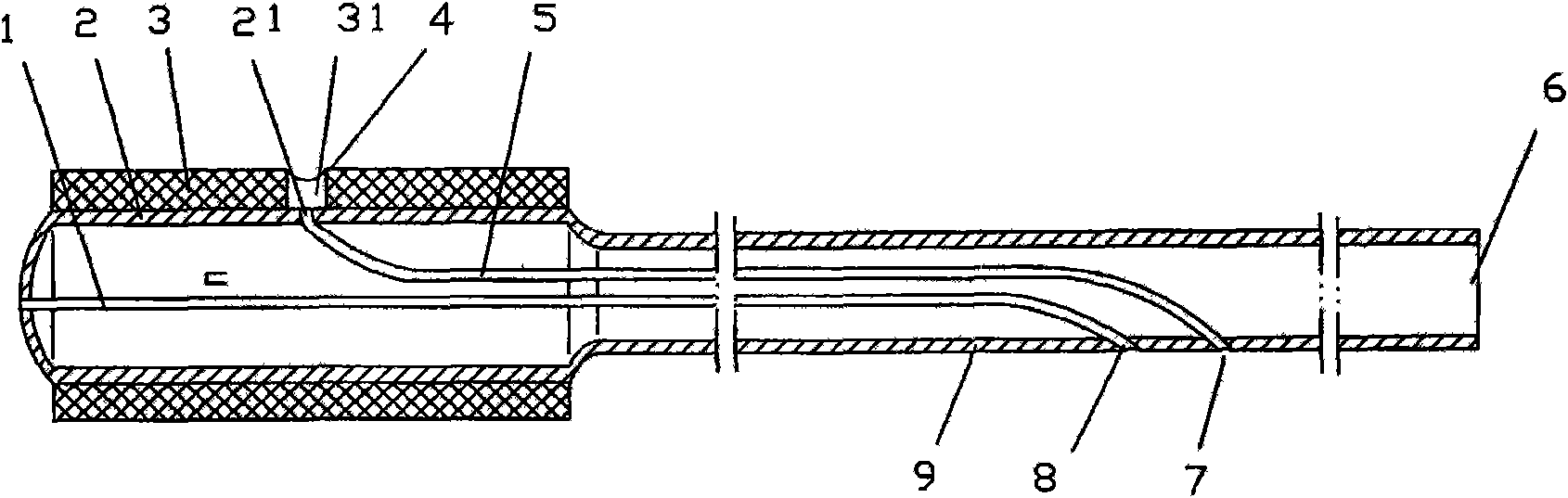

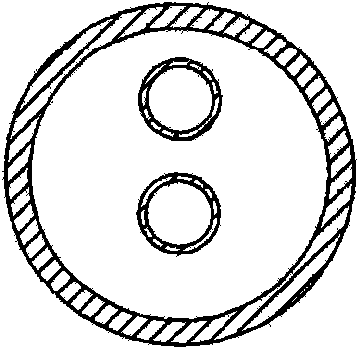

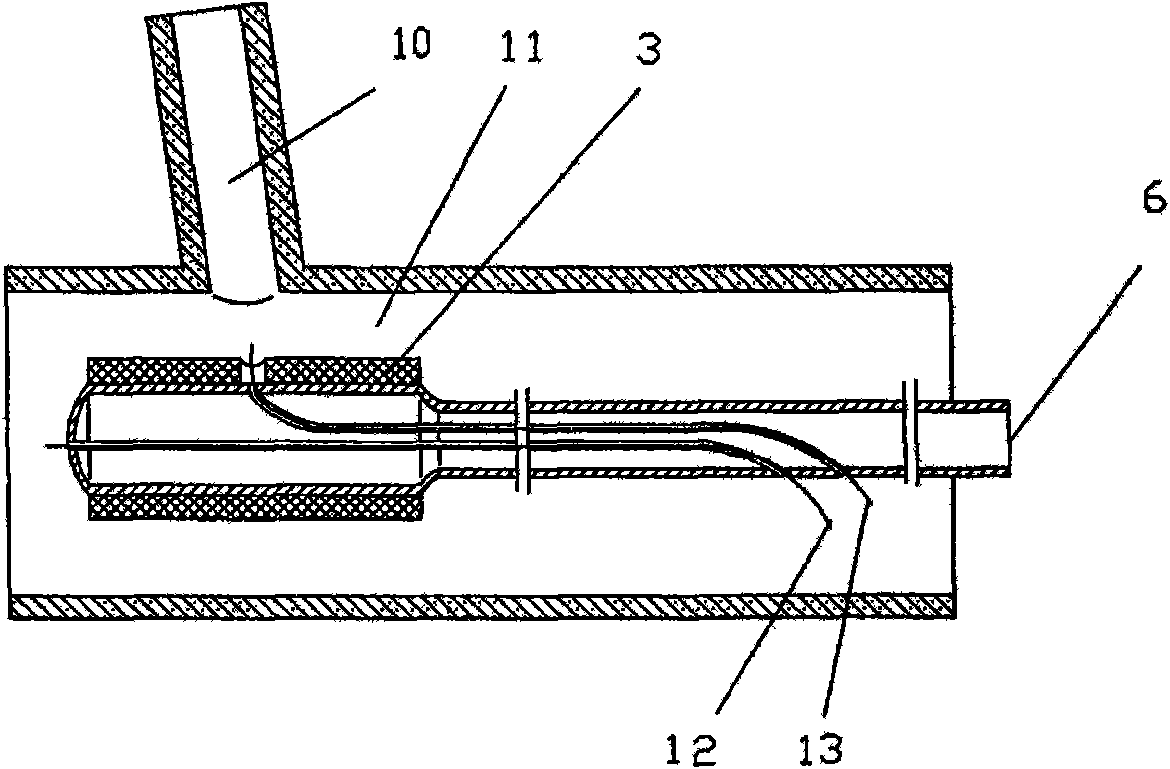

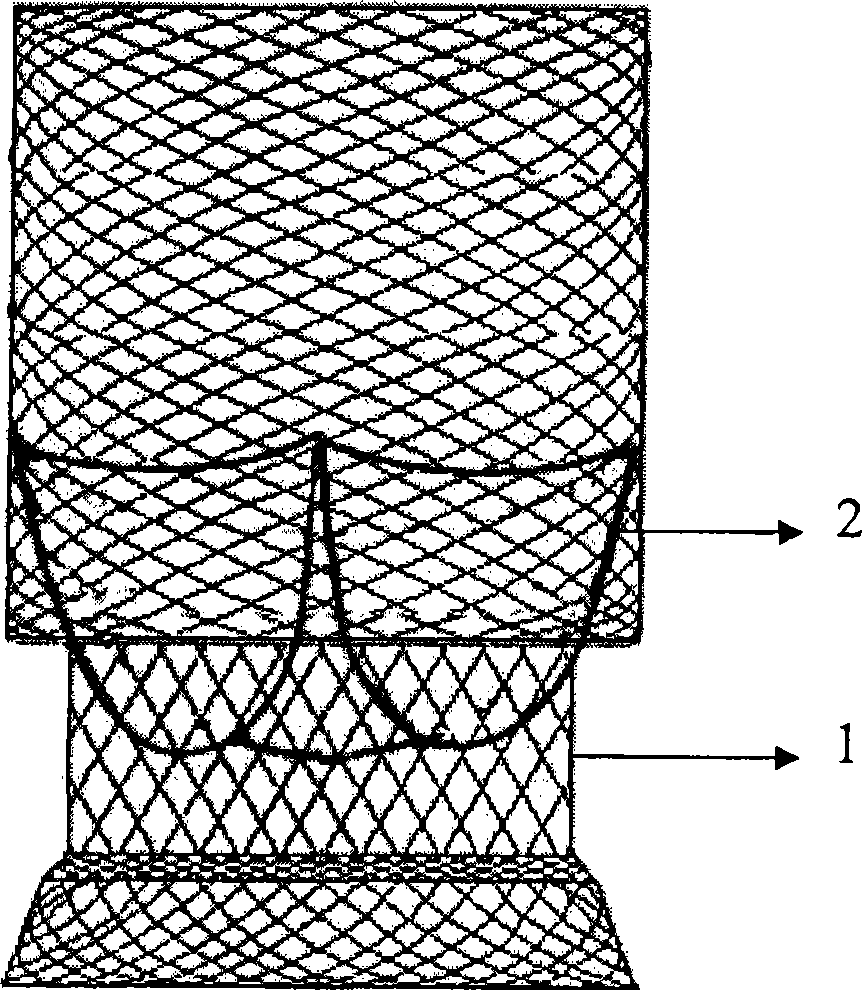

Balloon expandable stent with side-hole channel

InactiveCN101569570AOvercome displacementSolve operational difficultiesStentsMedical devicesCoronary bifurcationGuide tube

The invention relates to a balloon expandable stent with a side-hole channel, which belongs to the technical field of medical devices implantable into the blood vessel of human body. One end of the balloon is communicated with a balloon catheter that can inject and suck out contrast agent; an expandable compression stent is arranged outside the balloon; a main intracavity channel and an intracavity sub-channel are respectively arranged in the balloon and the balloon catheter; one opening of the main intracavity channel is positioned at the side wall of the balloon catheter, and the other opening is positioned at the top of the balloon; one opening of the intracavity sub-channel is positioned at the side wall of the balloon catheter, and the other opening is positioned at the side wall of the balloon; the expandable compression stent is provided with a side hole opposite to the side-wall hole of the balloon. The invention has the characteristics of simple structure, convenient operation and use, time saving and safety; meanwhile, the stent can break through the forbidden zone that the interventional therapy can not proceed due to the bifurcation and lesion of the blood vessel of brain, can simplify the steps of treating the bifurcation and lesion of the coronary artery, lower the operation risk and difficulty of stent-aiding embolism operation for wide-necked aneurysms, enhance interventional embolism / surgical clipping ratio, and alleviate patients' wound and pain.

Owner:赵林

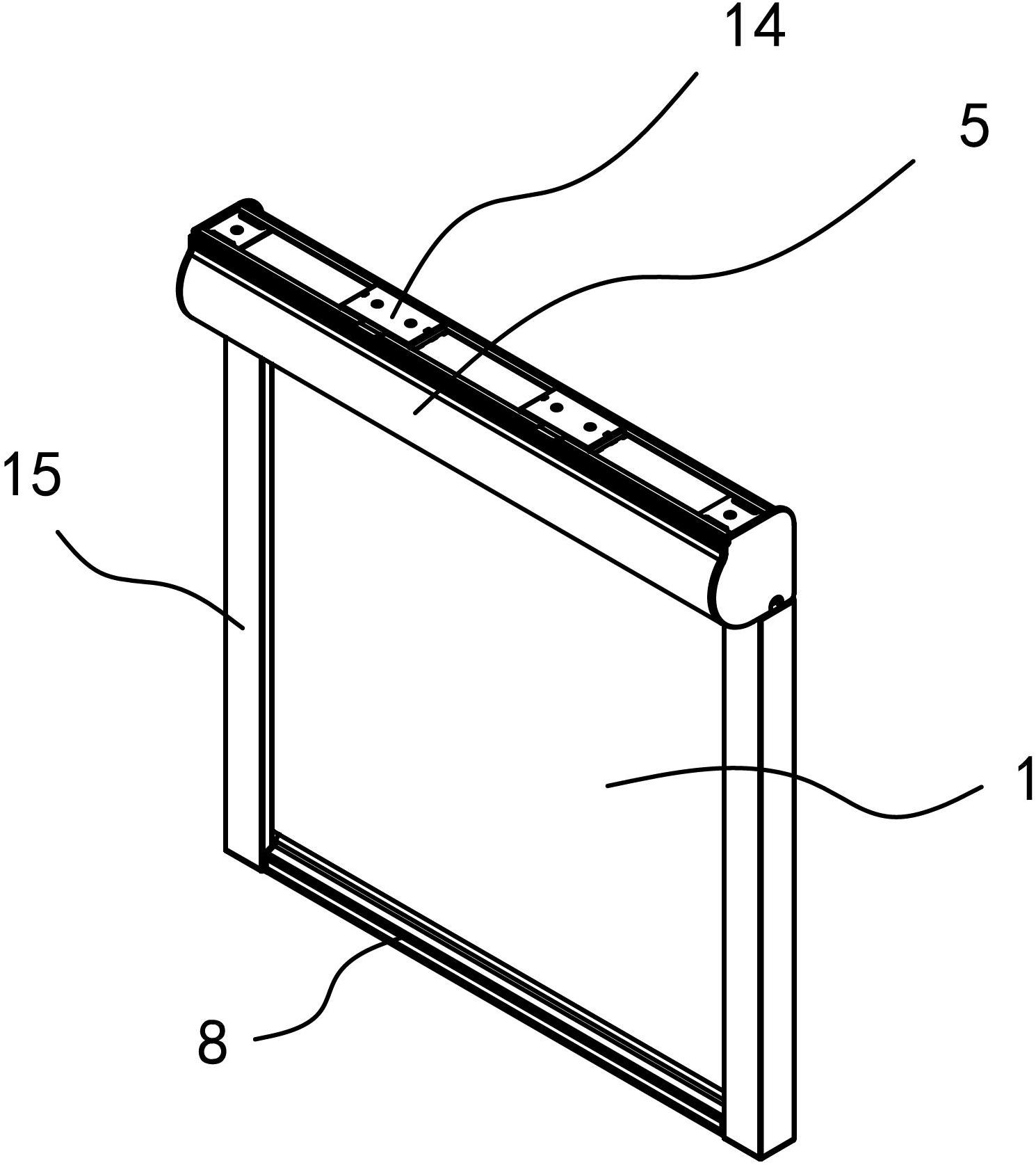

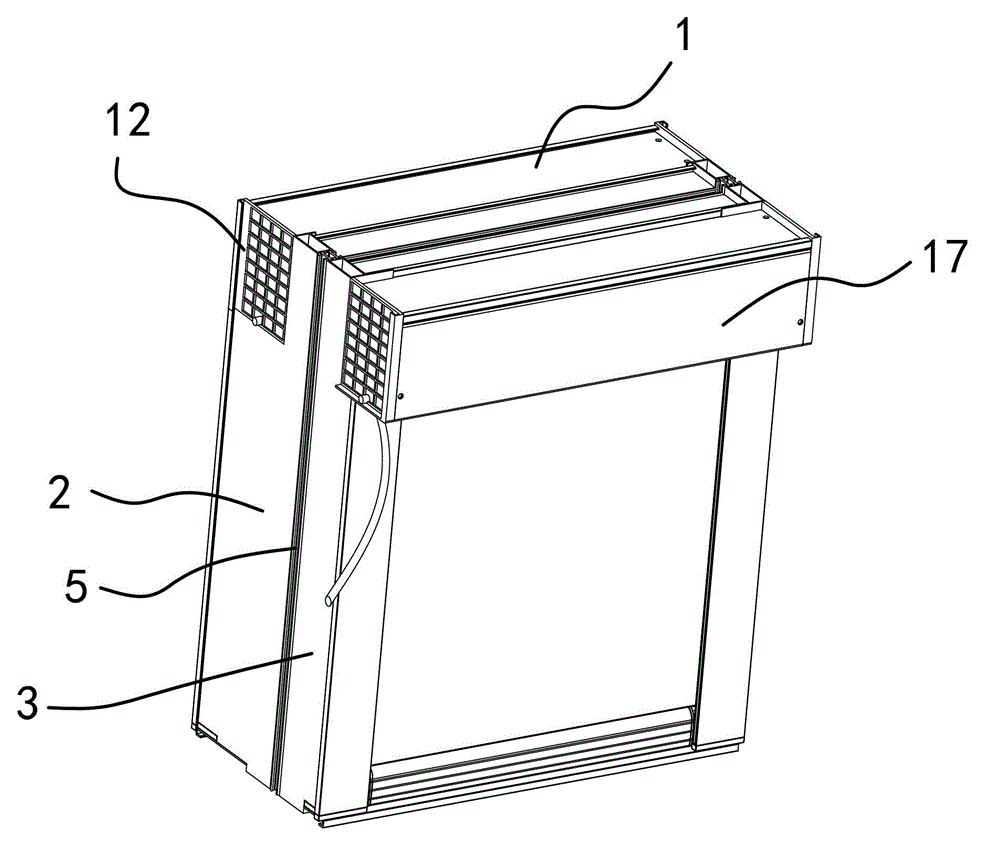

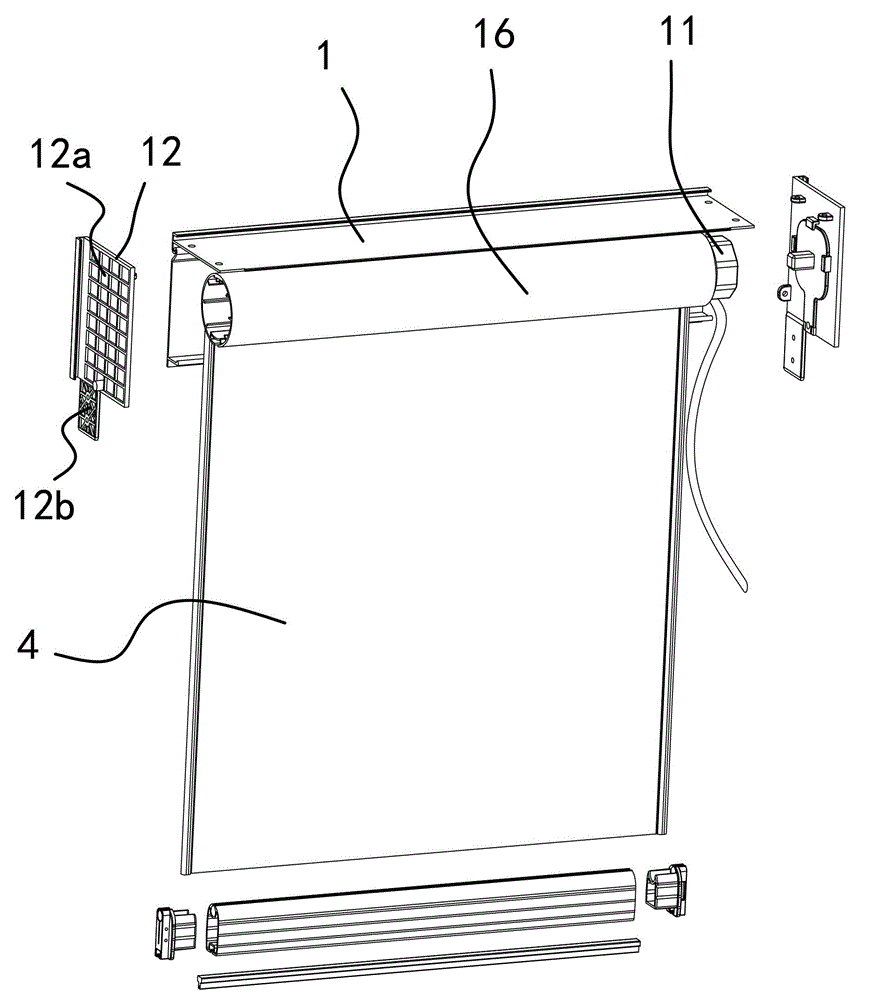

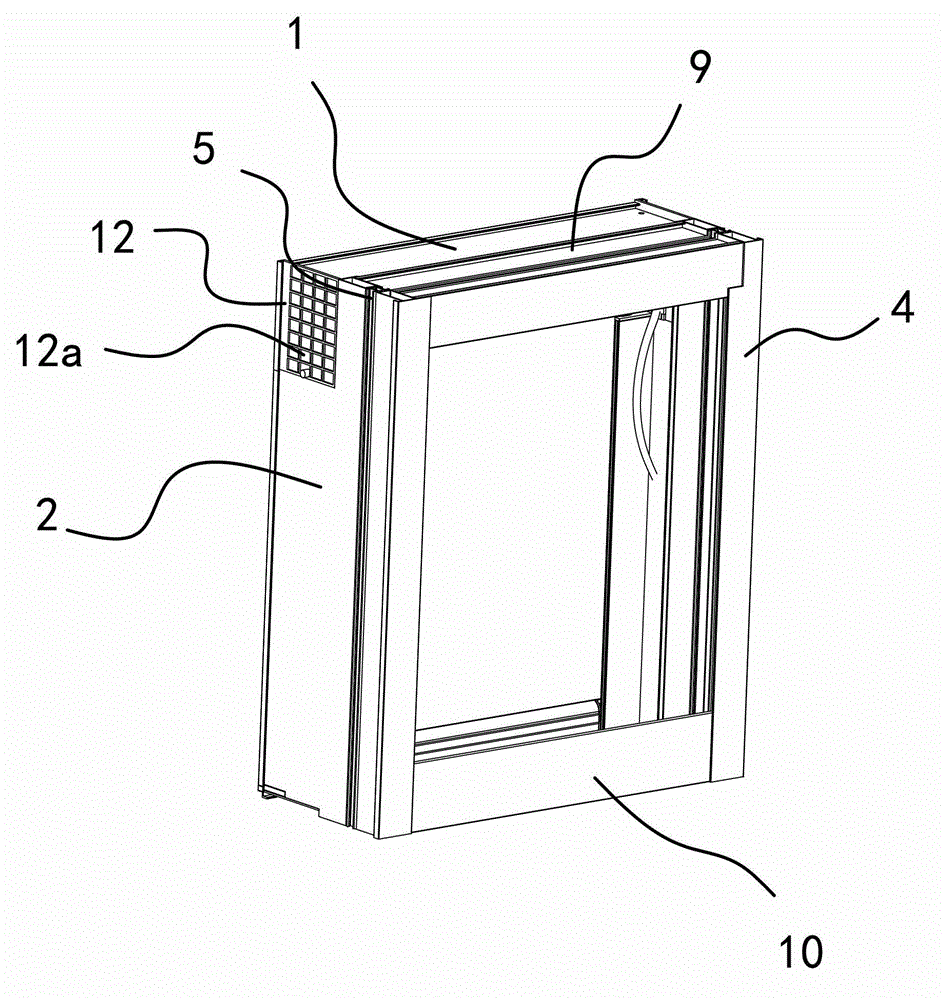

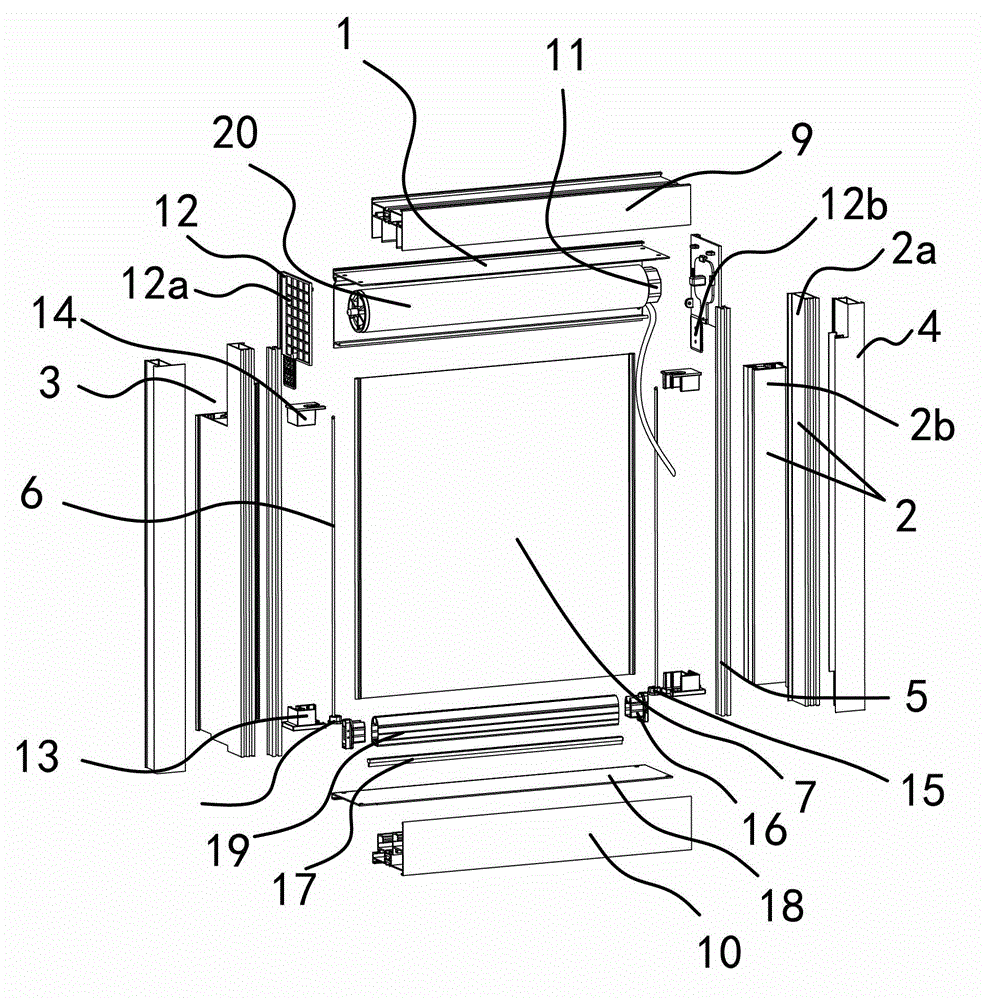

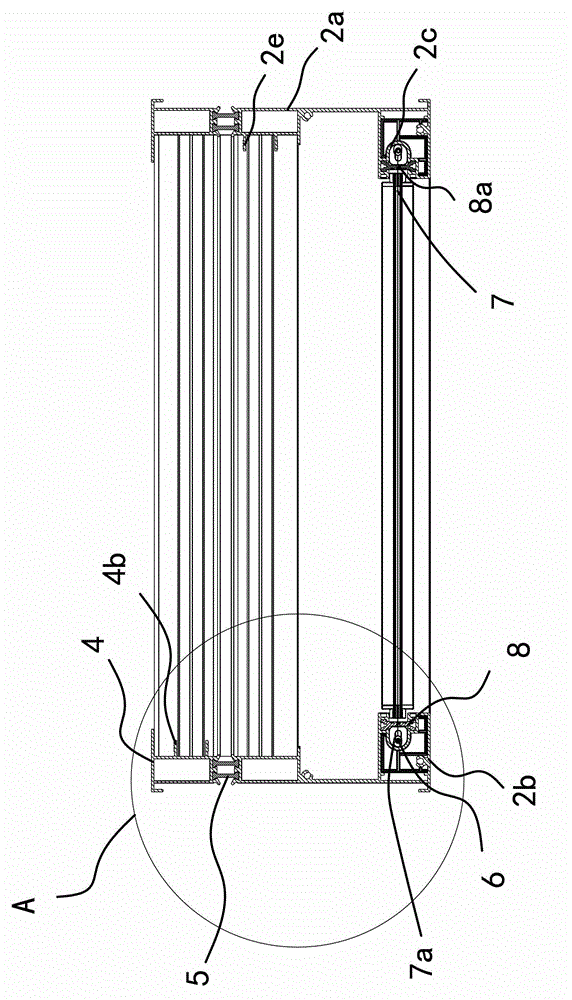

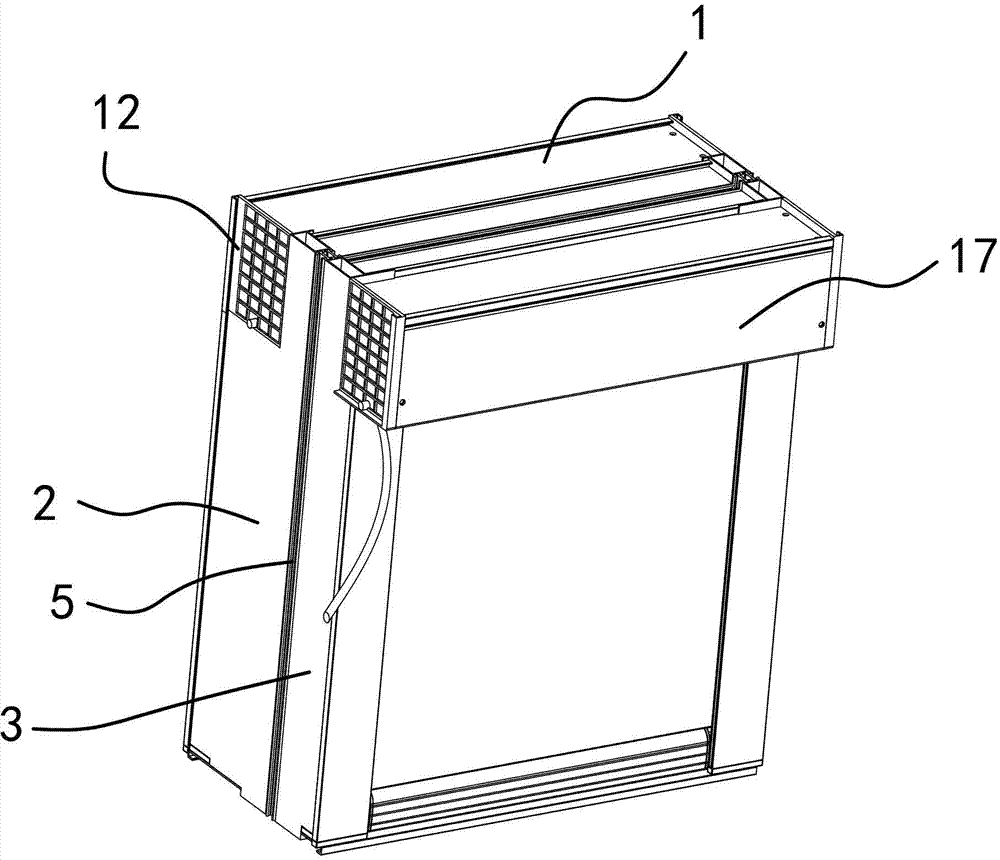

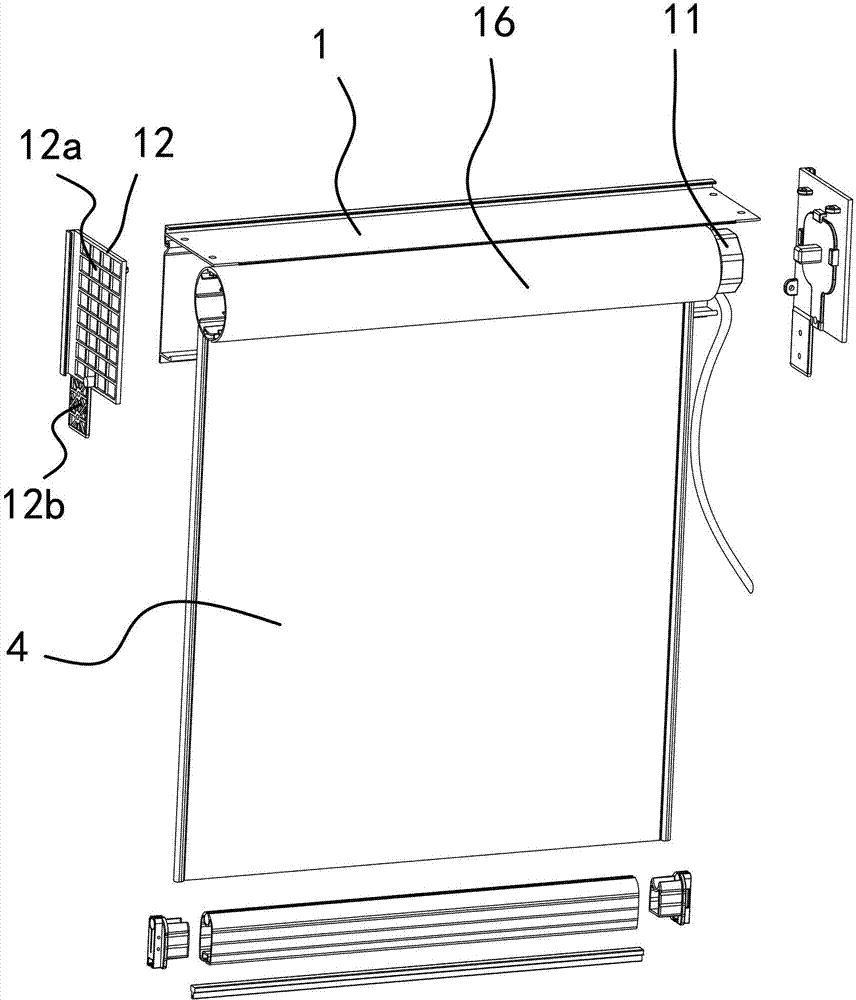

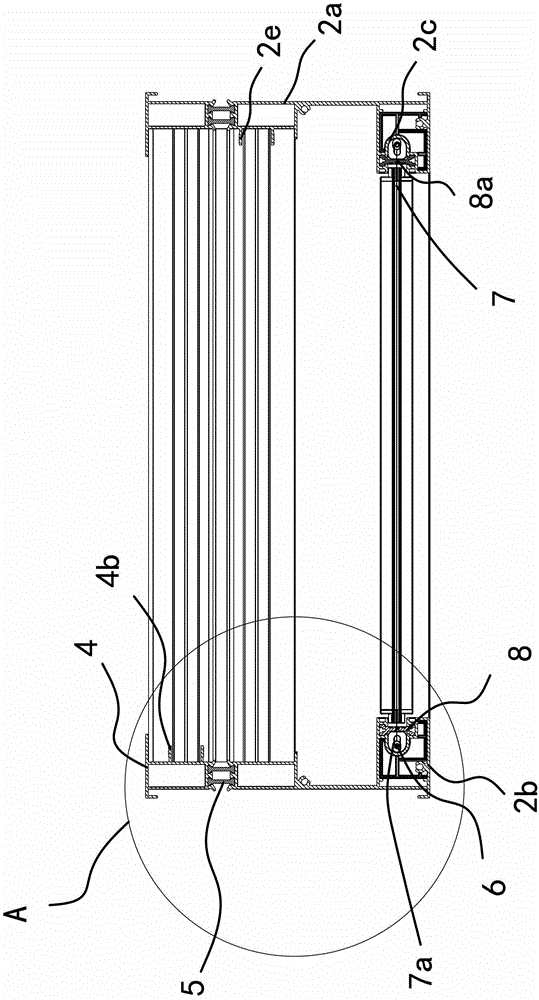

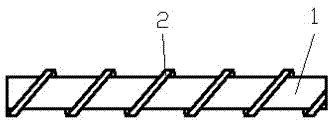

Window curtain and wind resisting component thereof

ActiveCN102691471AImprove cleanlinessPrevent difficult liftingLight protection screensEngineeringDaily living AIDS

The invention belongs to the technical field of articles for daily life, and provides a window curtain and a wind resisting component of the window curtain, comprising a curtain cloth, a window cover, a reel pipe arranged in the window cover, side rails arranged at two sides of the curtain cloth and a lower bar fixed at the lower end parts of the two side rails. The upper end of the window curtain cloth is fixed on the reel pipe, tracks are arranged in the side rails, and the wind resisting components for the window curtain are arranged between the tracks and the two sides of the curtain cloth; and the wind resisting component of the window curtain comprises a guide column arranged in each track and skirt edges fixedly connected with the sides of the curtain cloth, the outer diameter of the guide column is larger than the diameter of an opening of an open slot, and the skirt edges are sleeved on the guide columns and can move up and down along the guide columns. The window curtain and the wind resisting component of the window curtain have the advantages that the guide columns in the tracks can not separate from the tracks, and the curtain cloth is pulled straightly by the guide columns at two sides of the curtain cloth by utilizing the skirt edges which are arranged on the guide column so that the curtain cloth can not be blown up even blown away by big wind; and the skirt edges are pressed flatly when being wound by the reel pipe along with the curtain cloth, and the curtain cloth is flatly wound on the reel pipe to avoid deviation.

Owner:NINGBO XIANFENG NEW MATERIAL

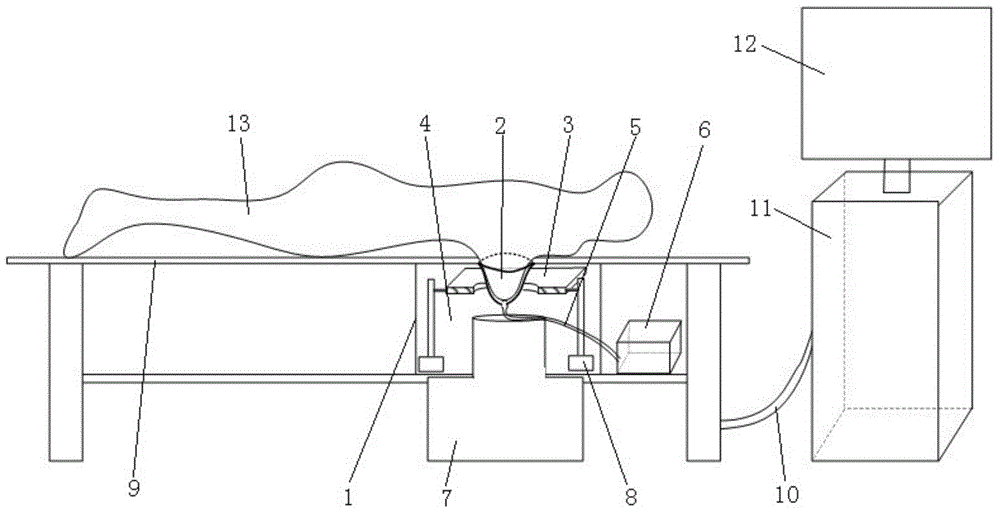

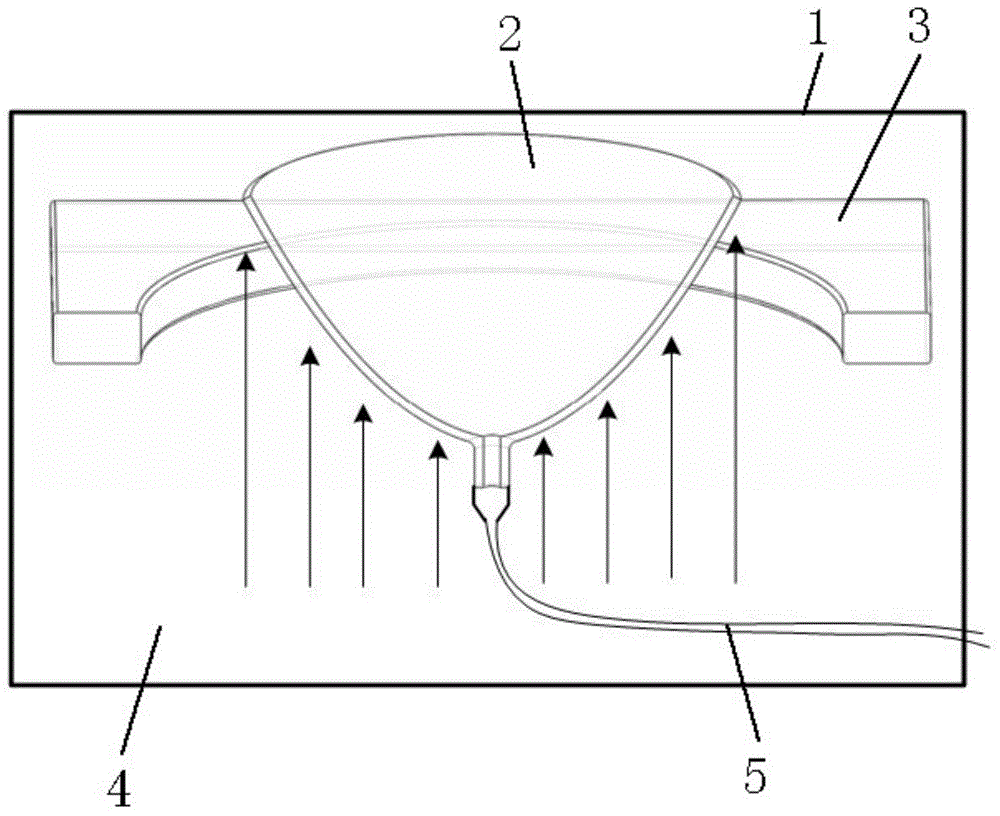

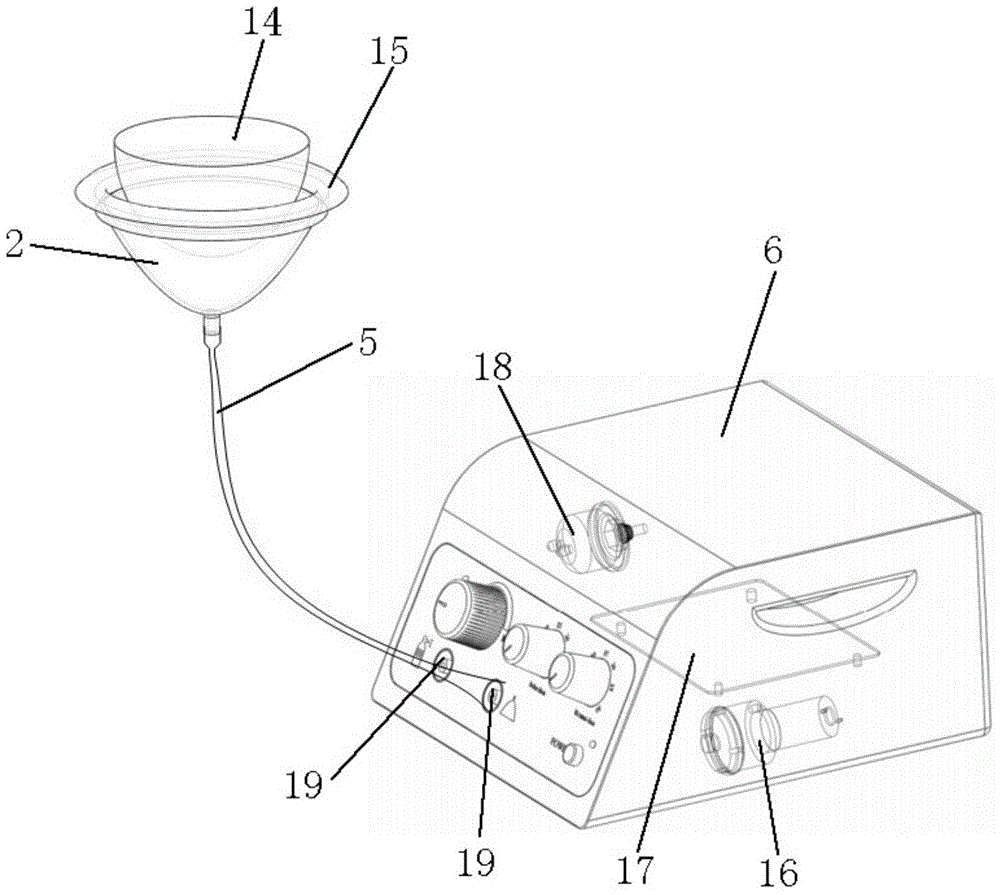

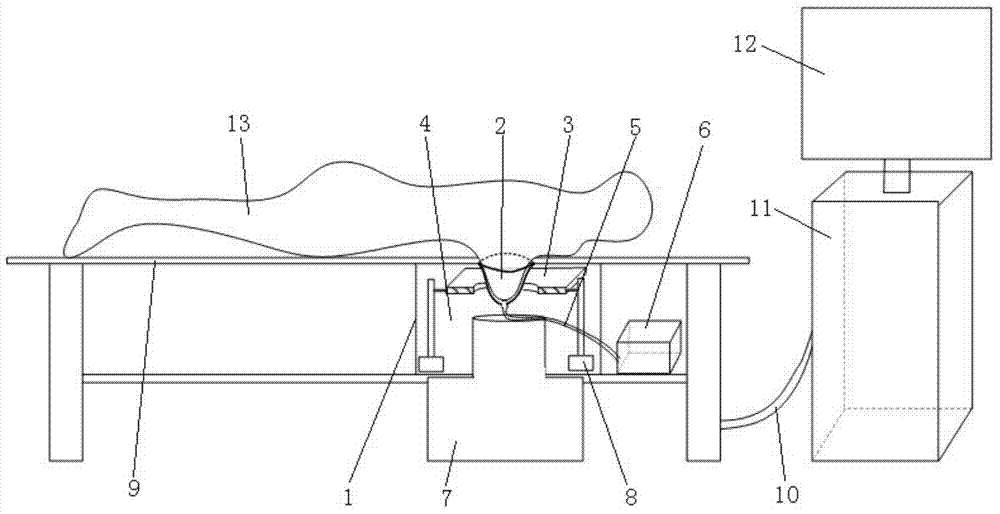

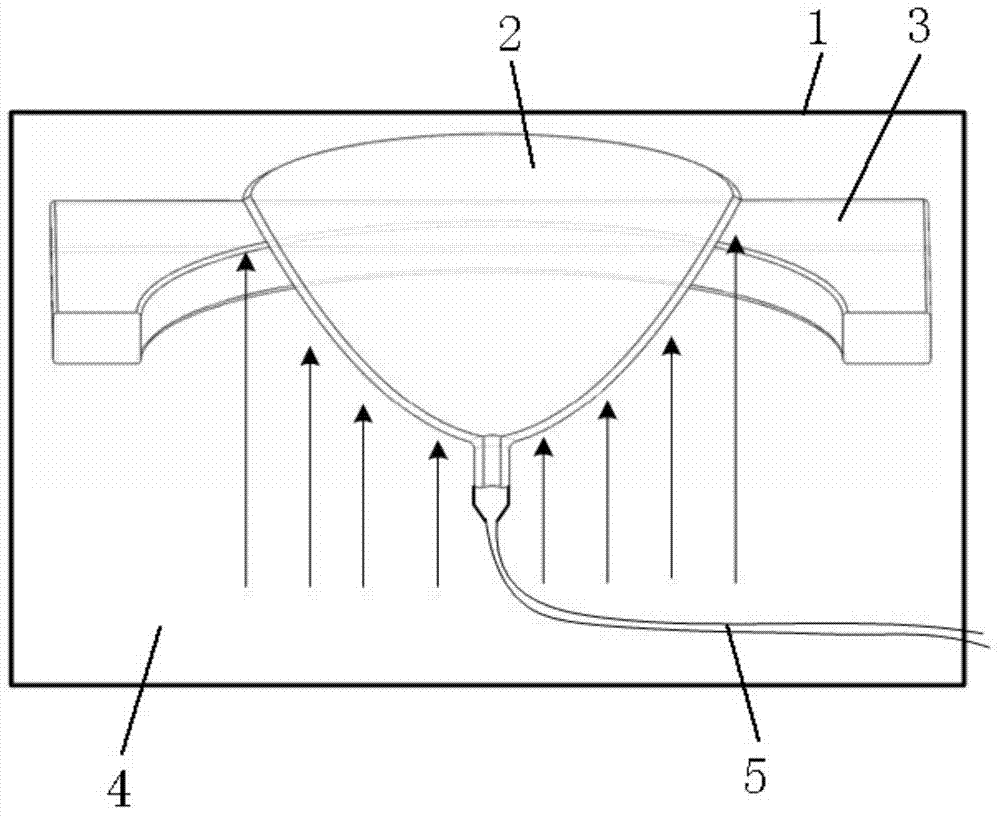

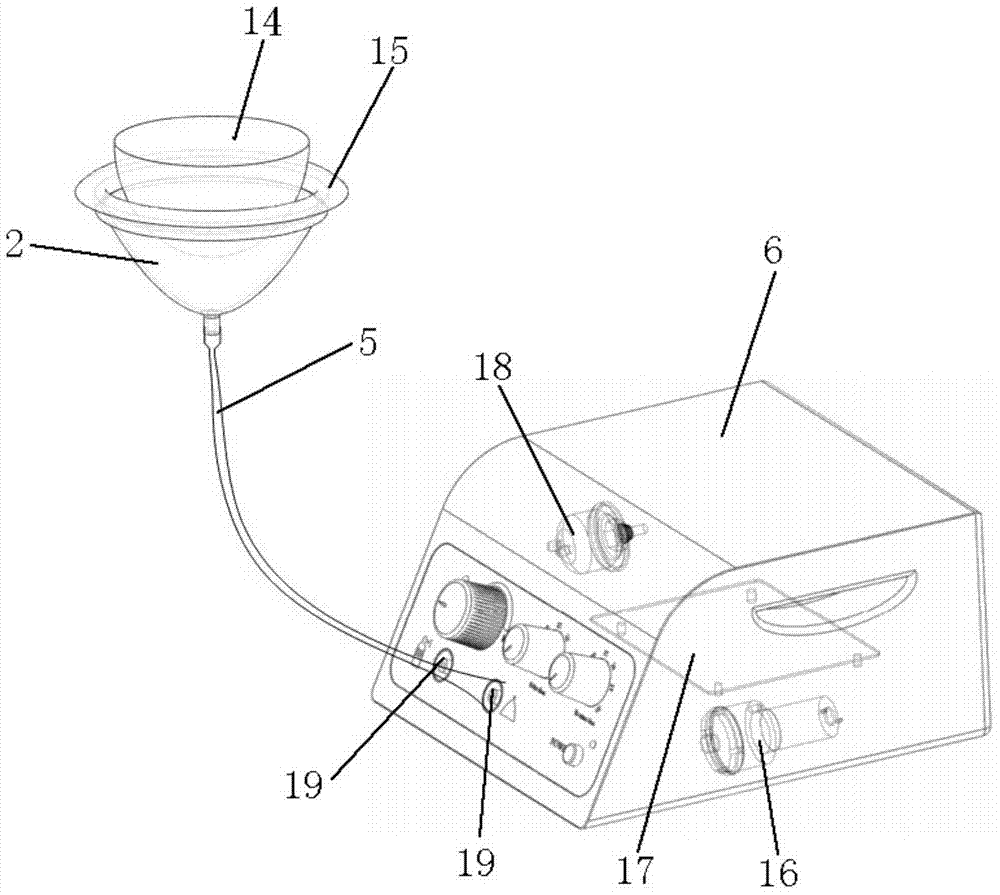

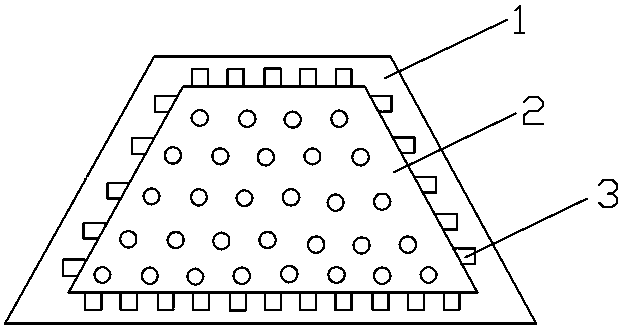

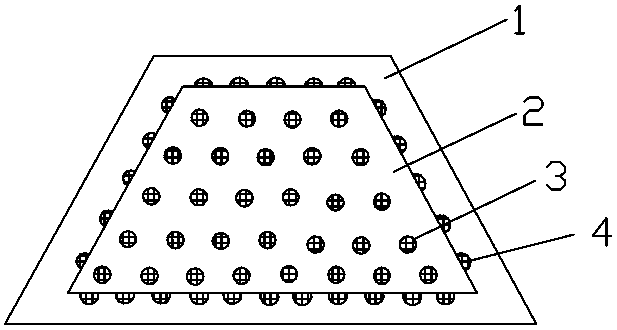

Close-contact ultrasonic coupling adaptive device for photoacoustic/thermoacoustic mammary gland imaging detection, and detection method of adaptive device

ActiveCN103549939ANo toxicityOvercoming coupling and easy deformationUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationDEFLATE

The invention relates to a close-contact ultrasonic coupling adaptive device for photoacoustic / thermoacoustic mammary gland imaging detection, and belongs to the technical field of photoacoustic / thermoacoustic imaging. The adaptive device comprises a detection cup, a coupling liquid spray device and an air pressure regulating device, wherein a to-be-detected breast is placed in the detection cup with the shape and the size corresponding to the breast; the coupling liquid spray device is connected with the detection cup, and can spray ultrasonic coupling liquid between the to-be-detected breast and the detection cup; and the air pressure regulating device is connected with the detection cup by an air guide tube, and inhales or deflates between the to-be-detected breast and the detection cup. The adaptive device has the advantages that the adaptive device is good in matching degree, safe, comfortable, easy to replace, and high in automation degree.

Owner:SOUTH CHINA NORMAL UNIVERSITY

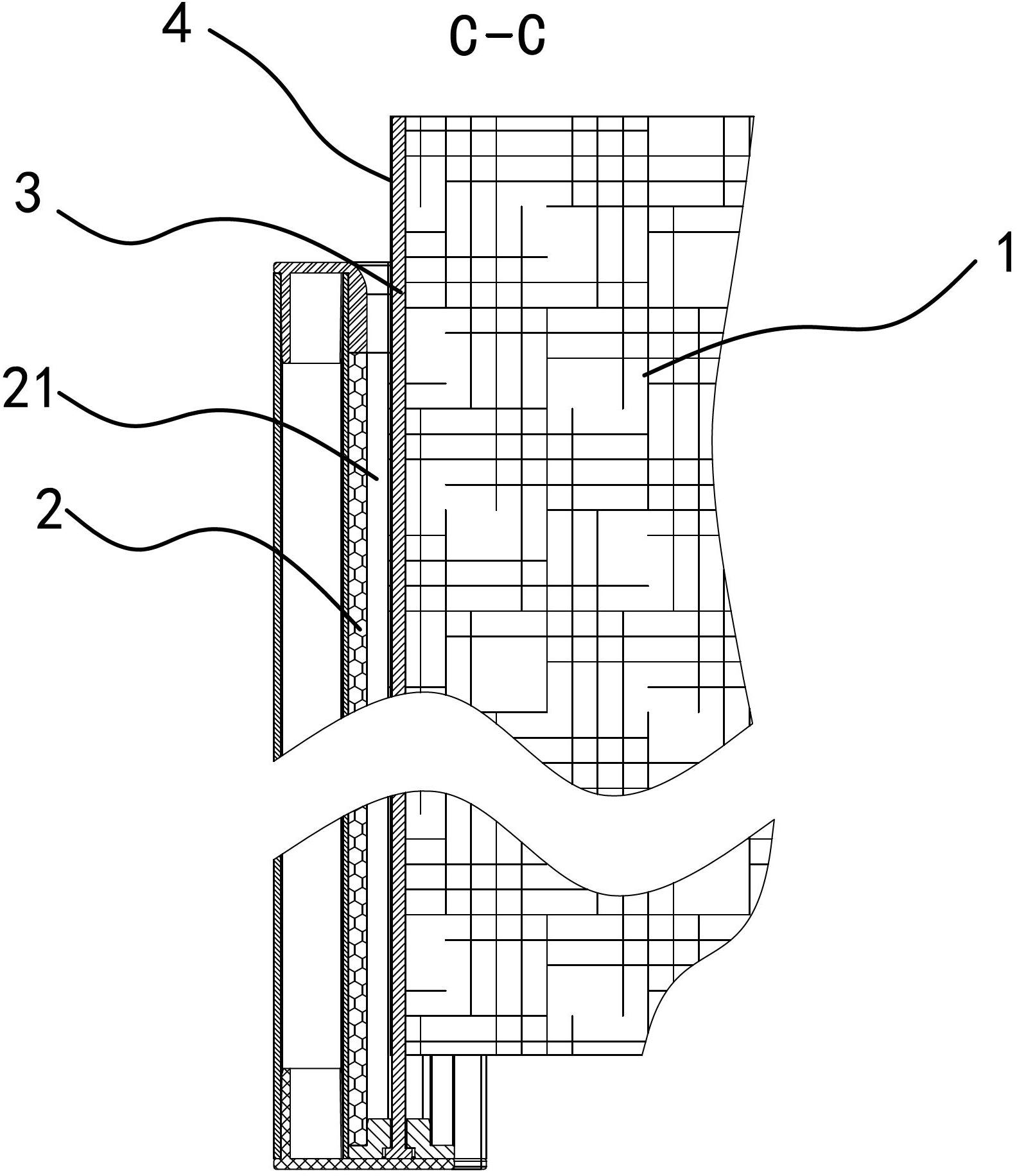

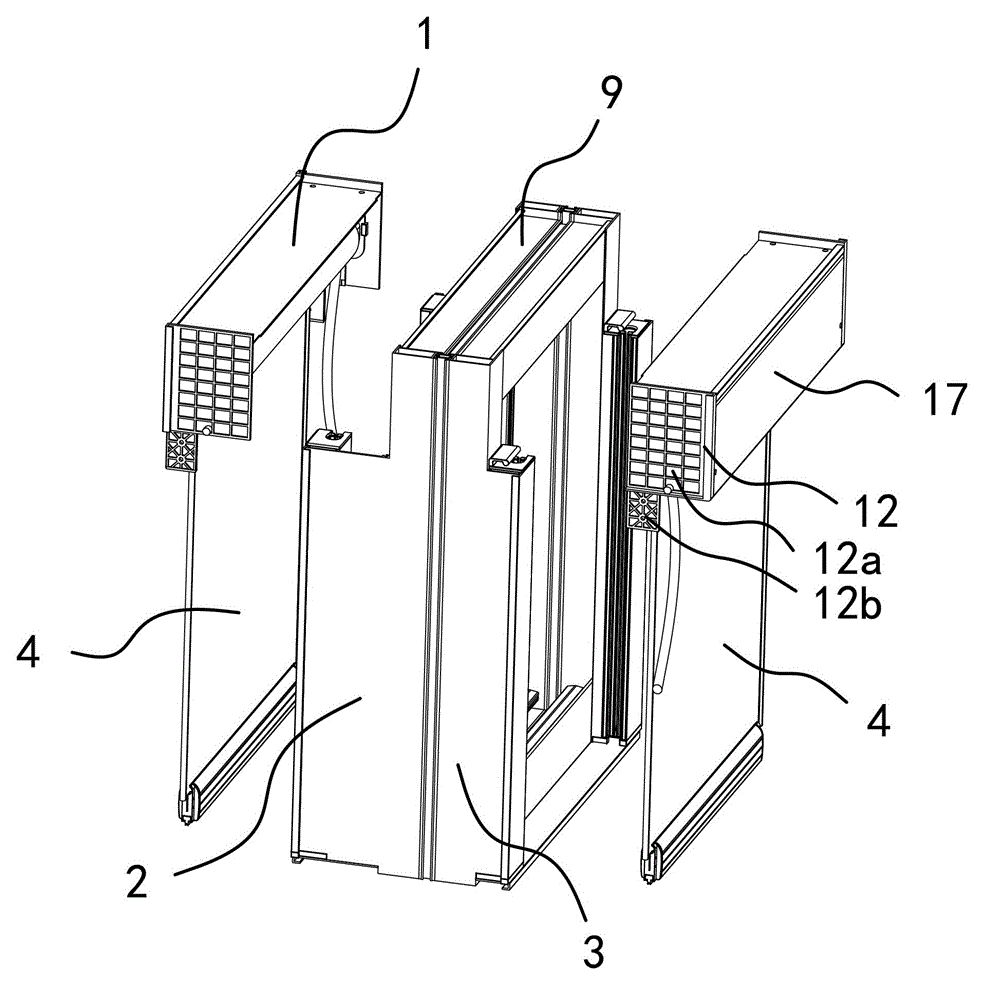

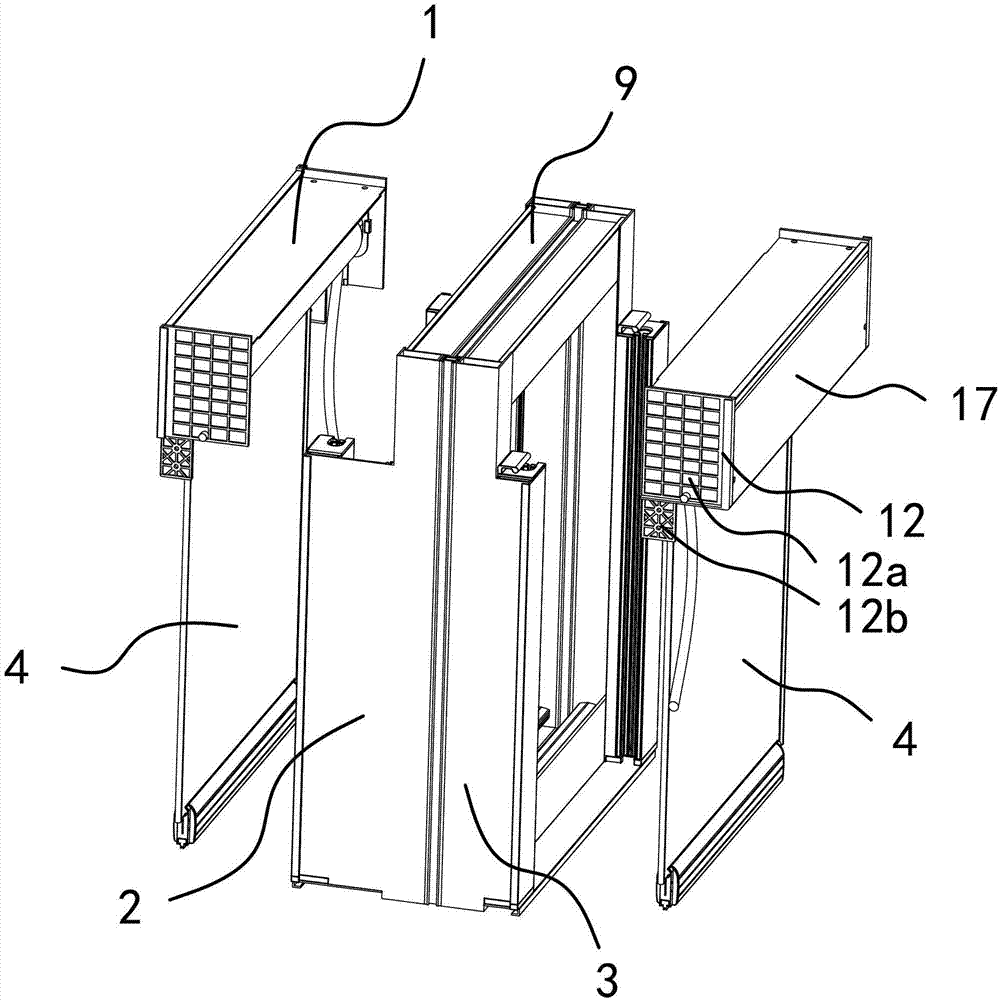

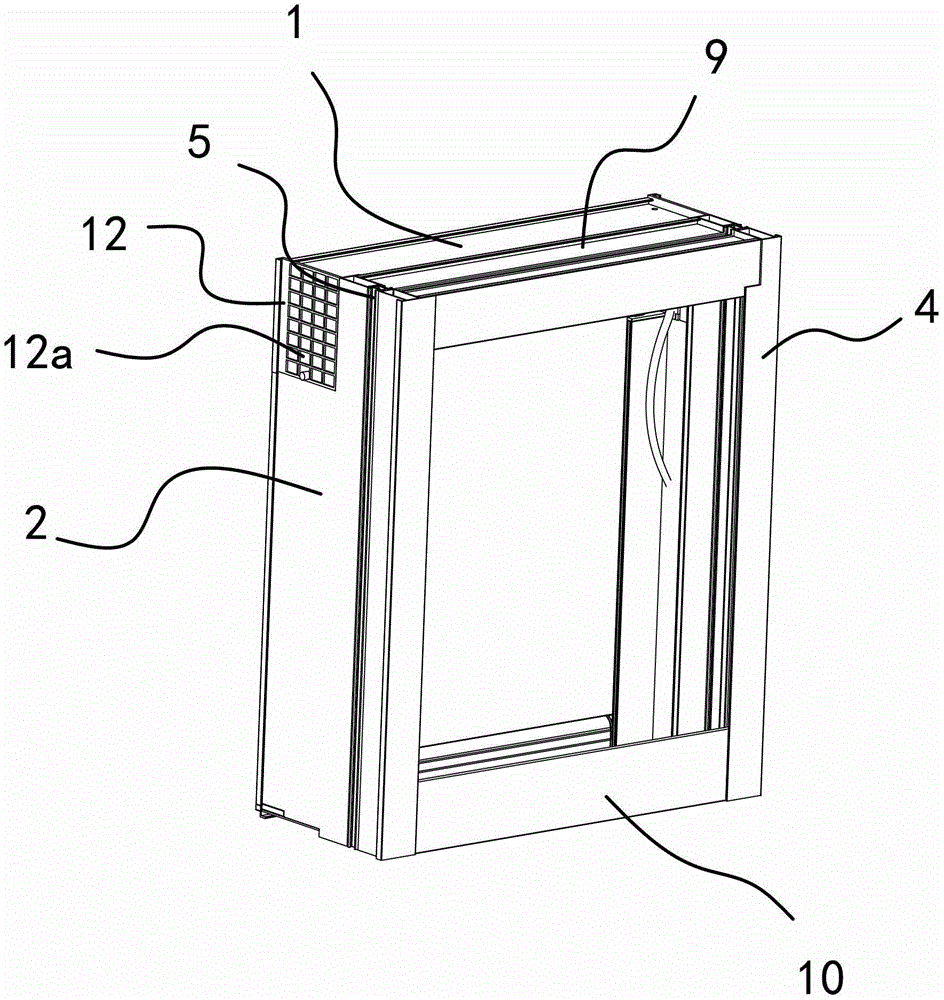

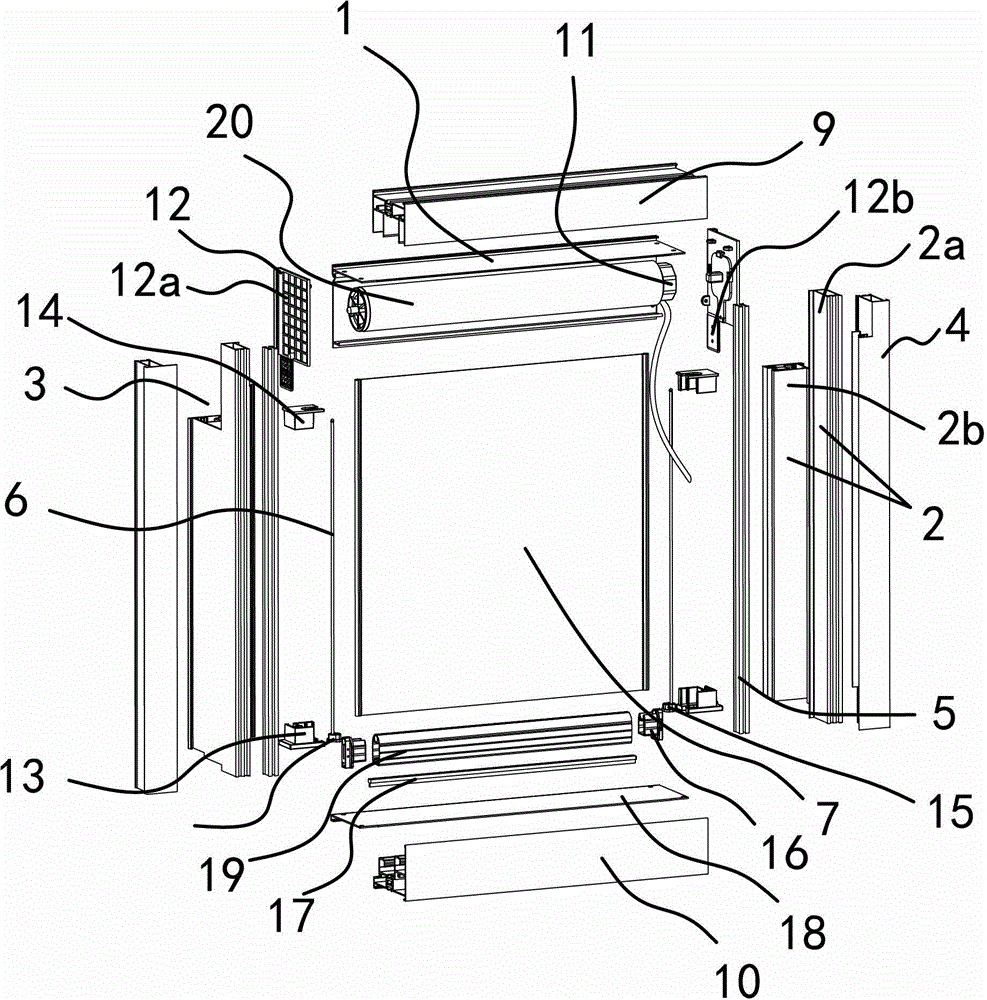

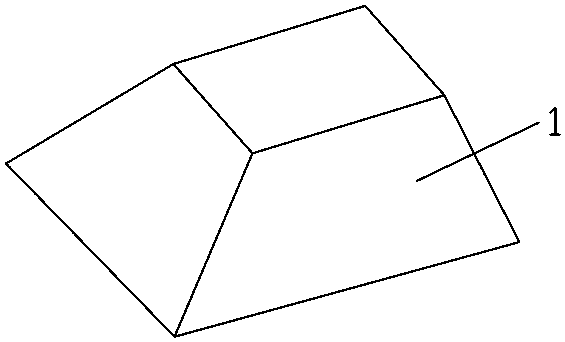

Window frame with front window cover and rear window cover and window with same

ActiveCN102747926AGuaranteed smoothnessOvercome displacementInsect protectionLight protection screensEngineeringMechanical engineering

The invention belongs to the technical field of a building material, and provides a window frame with a front window cover and a rear window cover and a window with the window frame. The window comprises a window frame and two pieces of curtain cloth, wherein the window frame comprises a front frame body and a rear frame body which are symmetrical with each other left and right, the front frame body is provided with a front support part and a front guide part, the rear frame body is provided with a rear support part and a rear guide part, the front support part is fixedly connected with the rear support part by a plastic stripe, the upper part of the front frame body is provided with the front window cover, the upper part of the rear frame body is provided with the rear window cover, and the two pieces of curtain cloth are respectively arranged on the front window cover and the rear window cover, the front window cover and the rear window cover are internally and respectively provided with a curtain cloth rolling mechanism, the front guide part and the rear guide part are internally and respectively provided with a rail which is internally provided with a guide rod, and two sides of the two pieces of curtain cloth are fixedly connected with skirts which are respectively sleeved on the corresponding guide rod and can move along with the guide rods. The window frame and the window have the advantages that the two pieces of curtain cloth are arranged on the front window cover and the rear window cover, the window frame and the window are convenient to install, economical and practical, and convenient to manufacture as the guide parts are integrated with the support parts.

Owner:NINGBO XIANFENG NEW MATERIAL

Window frame provided with window hood and window with window frame

ActiveCN102747925AGuaranteed smoothnessOvercome displacementInsect protectionLight protection screensComputer scienceBuilding material

Owner:NINGBO XIANFENG NEW MATERIAL

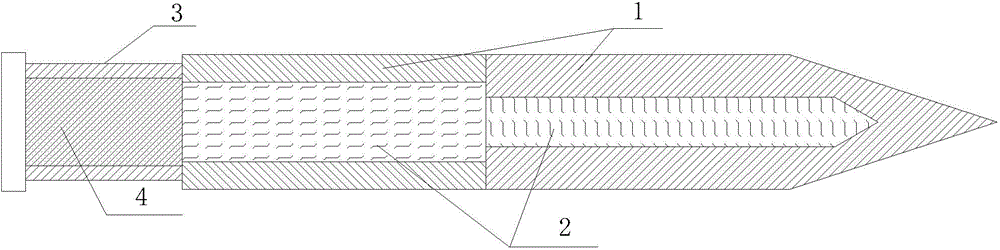

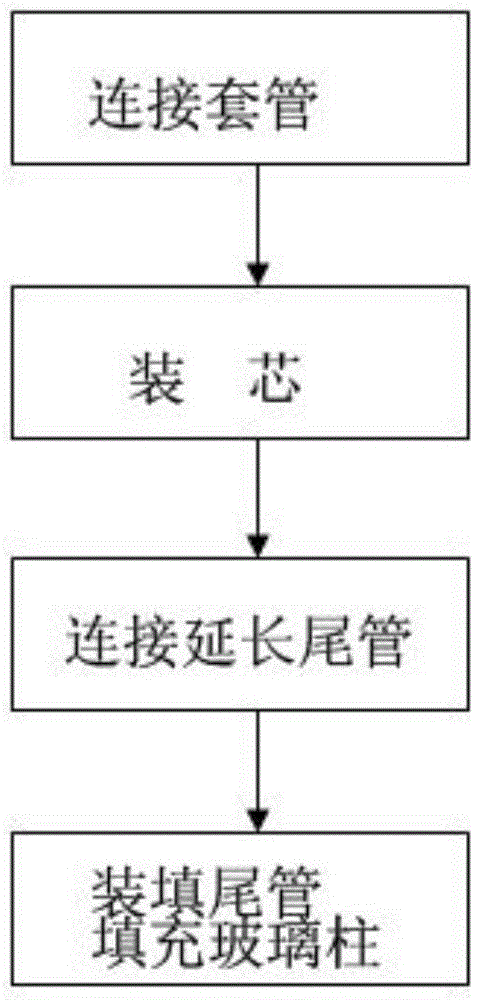

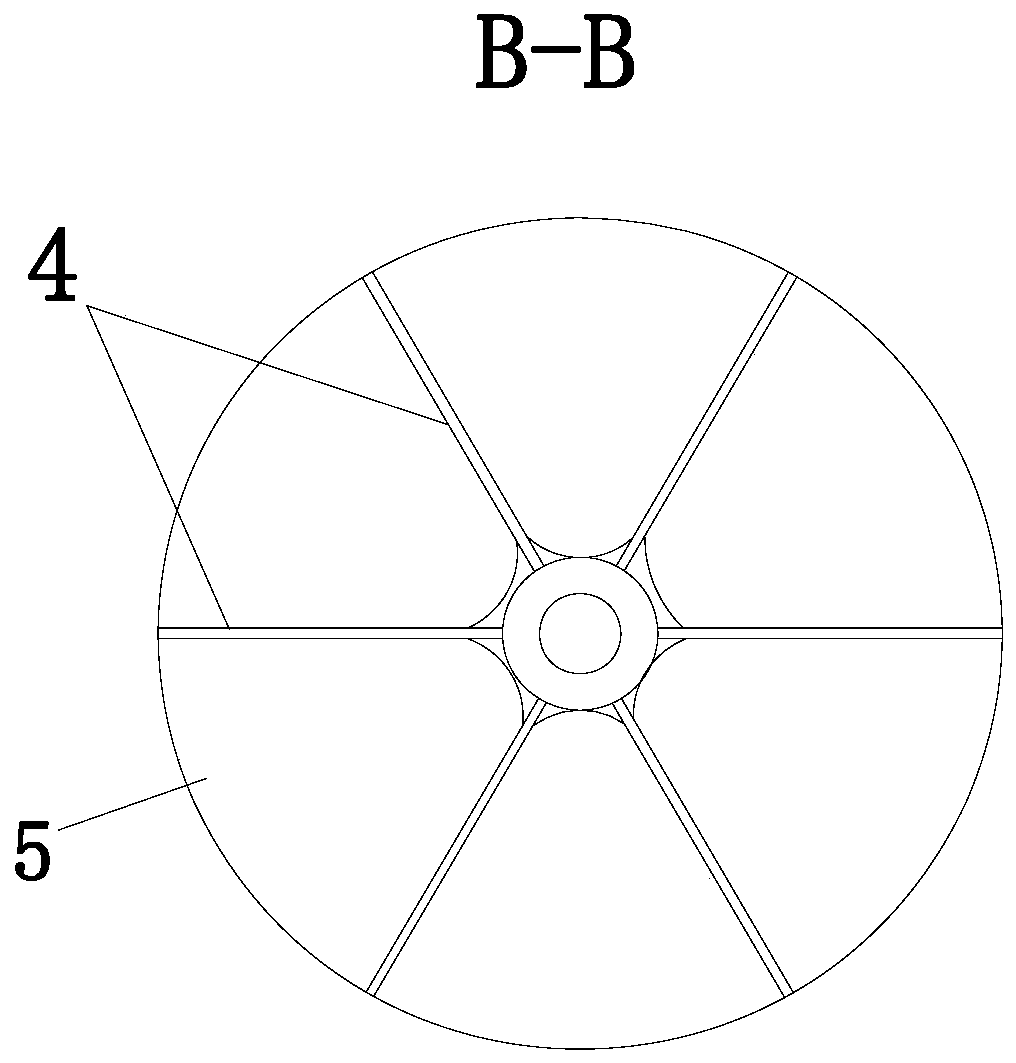

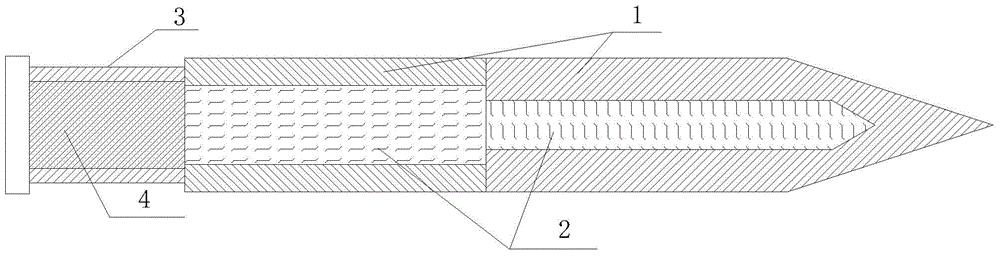

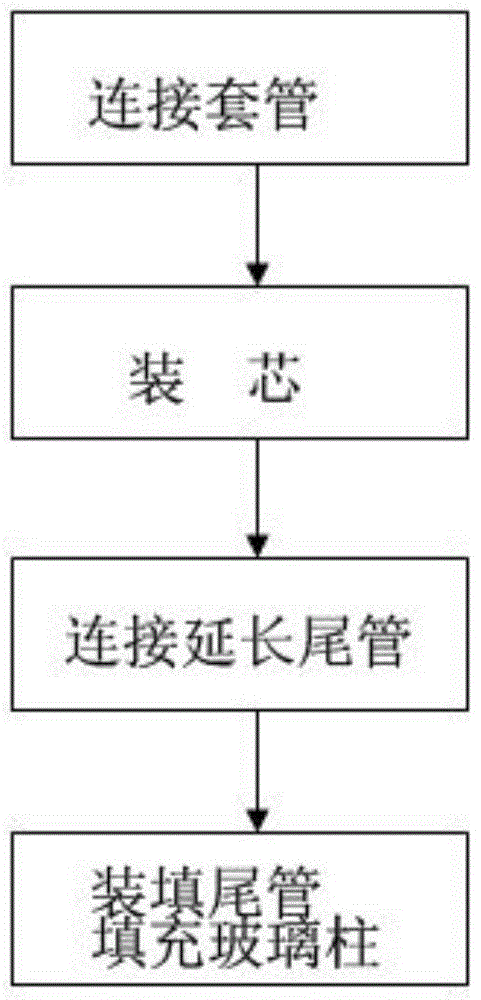

Six-meter super-long optical fiber preform bar and manufacturing process

ActiveCN104860530AIncrease the lengthImprove utilization efficiencyGlass making apparatusGlass productionEngineeringOptical fiber

The invention provides a six-meter super-long optical fiber preform bar which comprises at least two sleeve pipes, at least two core bars, a prolonged tail pipe and a tail pipe filling glass column, wherein the core bars are all arranged in the two sleeve pipes in a sleeving manner; the adjacent sleeve pipes are connected in a welding manner; the prolonged tail pipe is connected with the tail end of the connected sleeve pipes; the prolonged tail pipe and the sleeve pipes are coaxially distributed; the tail pipe filling glass column is embedded in the prolonged tail pipe and propped against the core bars. A manufacturing process for the six-meter super-long optical fiber preform bar comprises four steps of connecting the sleeve pipes, mounting the core bars, connecting the prolonged tail pipe and filling the tail pipe filling glass column. On one hand, the wire-drawing length of a single optical bar can be increased, the utilization efficiency of the optical bar and the production efficiency of wire-drawing equipment can be improved, the wire-drawing length of the single optical bar can reach 15,000 km, and the manufacturing cost can be reduced by about 3-5% in comparison with a conventional process; on the other hand, the phenomena of high possibility of displacement and downward slide of a conventional six-meter super-long core bar in the sleeve pipes during a wire-drawing process are effectively avoided, so that the quality stability of a product produced by wire-drawing of the single optical bar can be improved.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

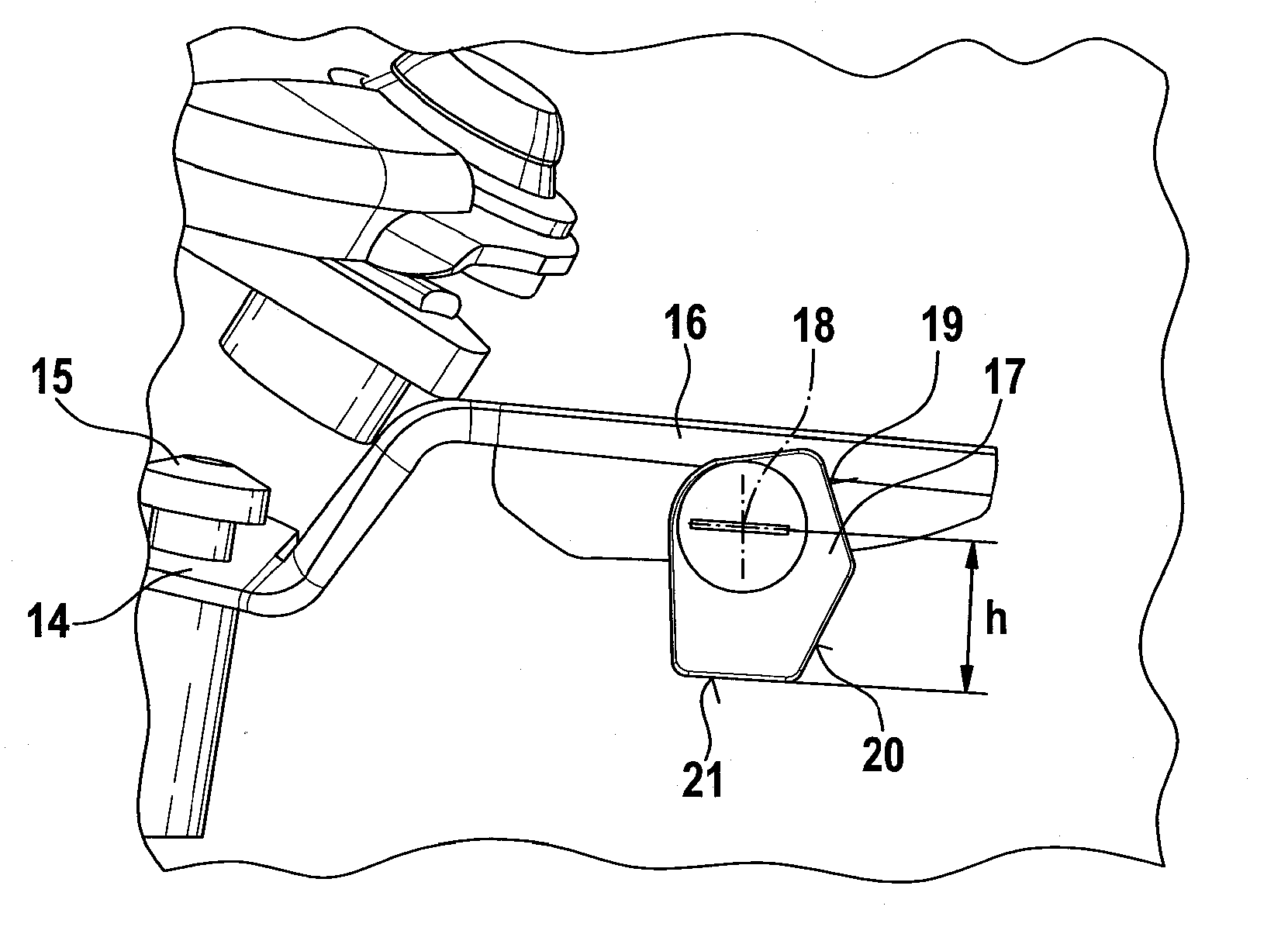

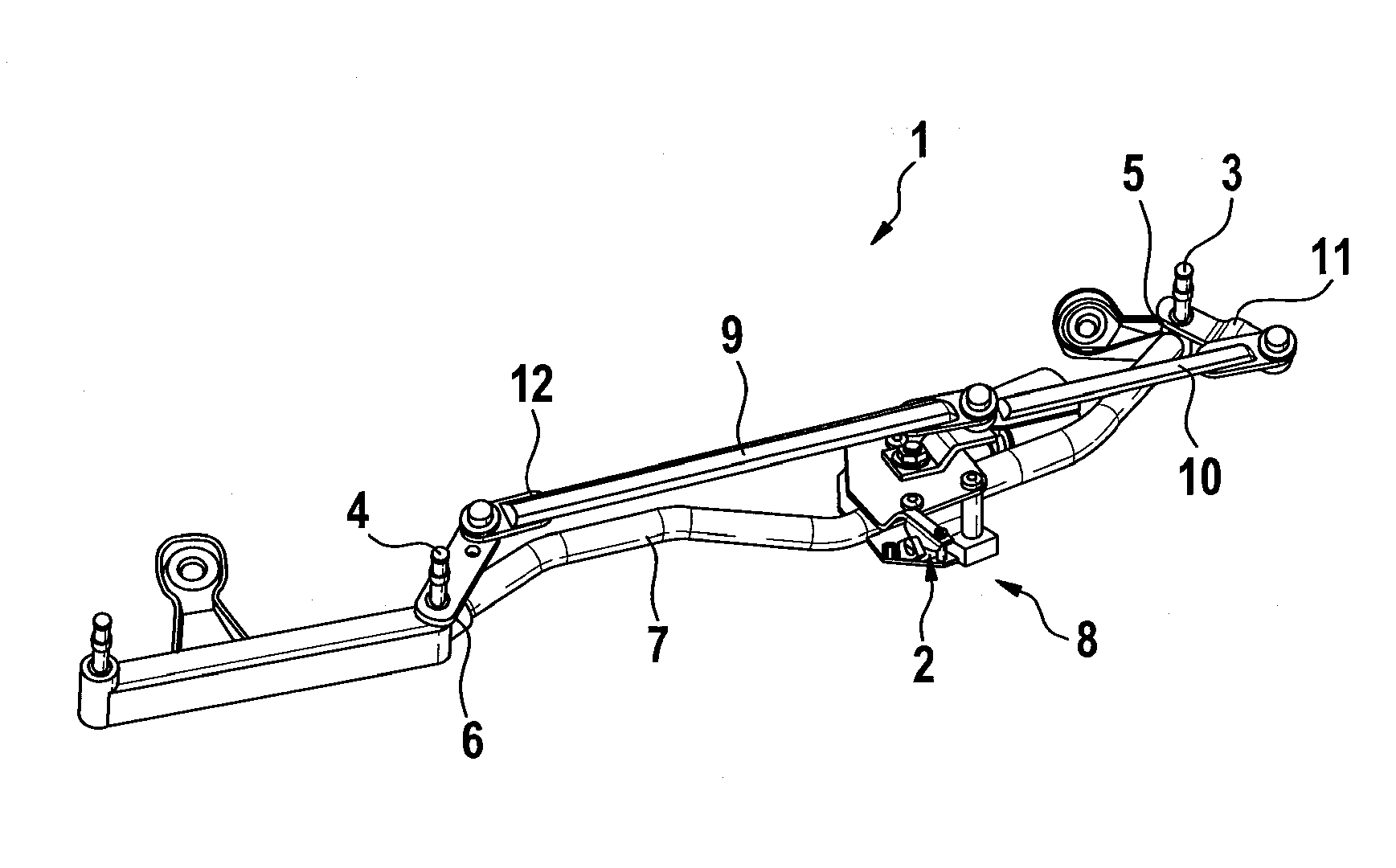

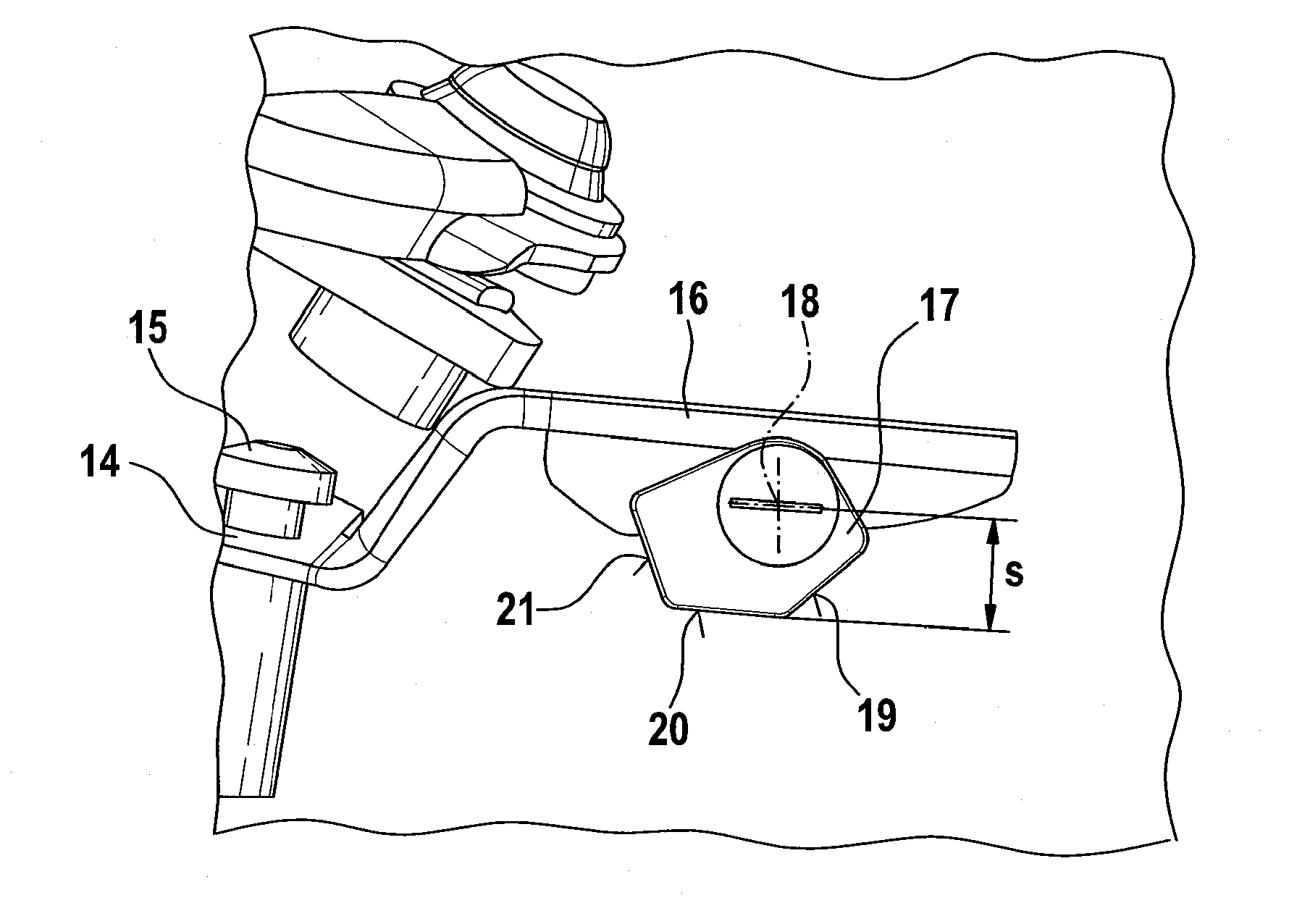

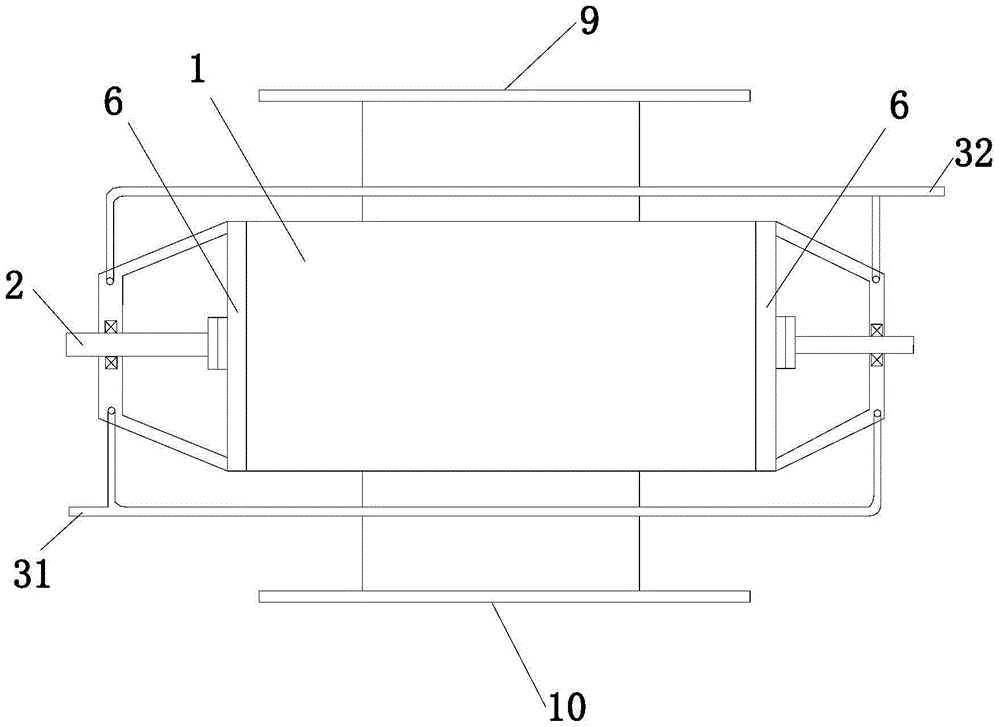

Windshield wiping device

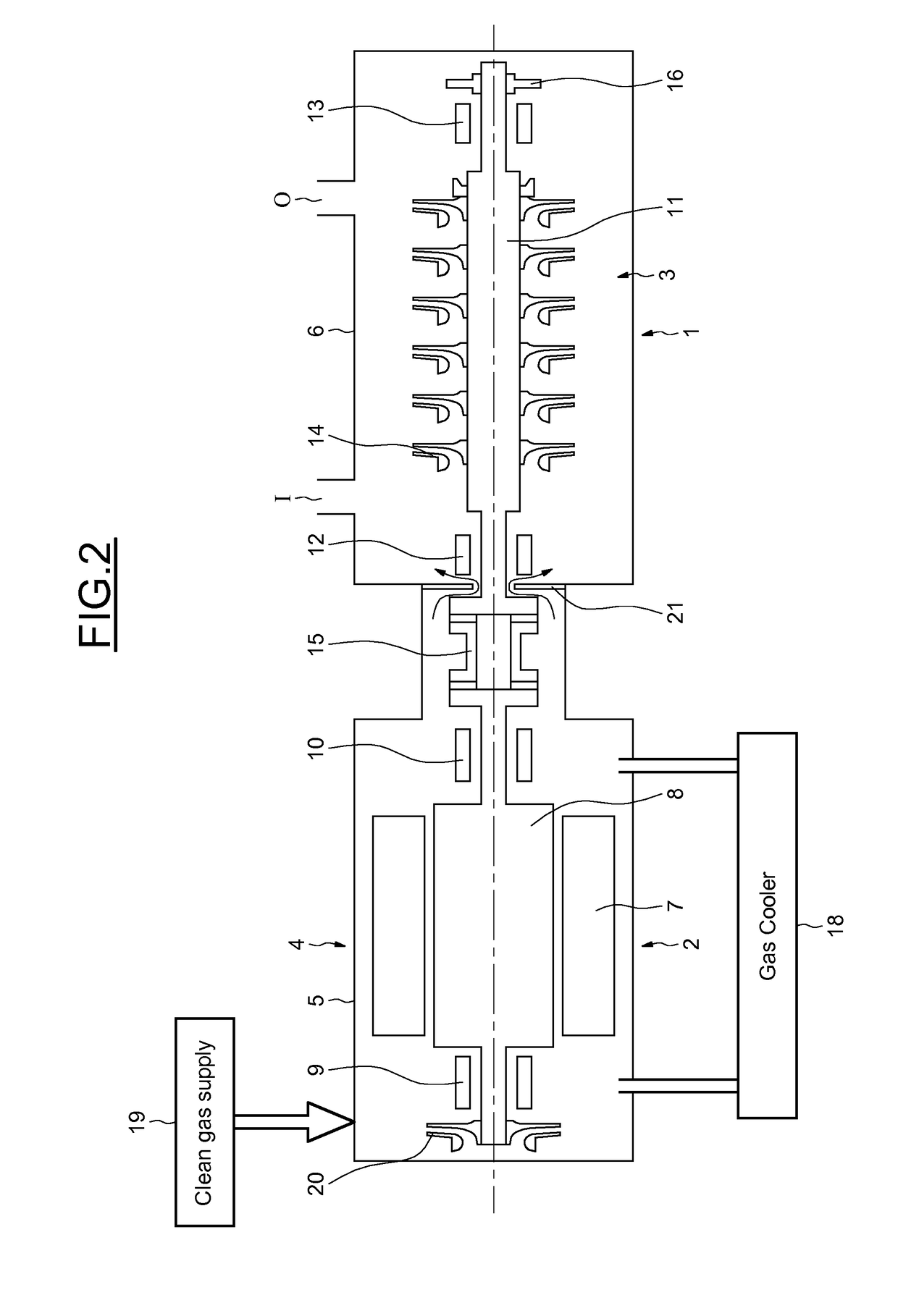

The invention relates to a windshield wiping device (1) for a motor vehicle, comprising a wiper motor (8) and at least one wiper mounting (5, 6) in which a wiper shaft (3, 4) is mounted, said wiper shaft being drivable by means of the wiper motor (8) in order to actuate at least one wiper arm that is connected to the wiper shaft (3, 4), and comprising a fixing arrangement for connecting the windshield wiping device (1) to a body (13) of the motor vehicle. The fixing arrangement comprises a motor support (14) to which the wiper motor (8) can be fixed. The fixing arrangement comprises an adjusting mechanism (17, 22) that is rotatably connected to the motor support (14) in order to adjust a space between the motor support (14) and the vehicle body (13) in stages by simple twisting of the adjusting mechanism (17, 22) in order to correct an orientation of the wiper mounting (5, 6) relative to a windshield of the motor vehicle by means of the adjusting mechanism (17, 22).

Owner:ROBERT BOSCH GMBH

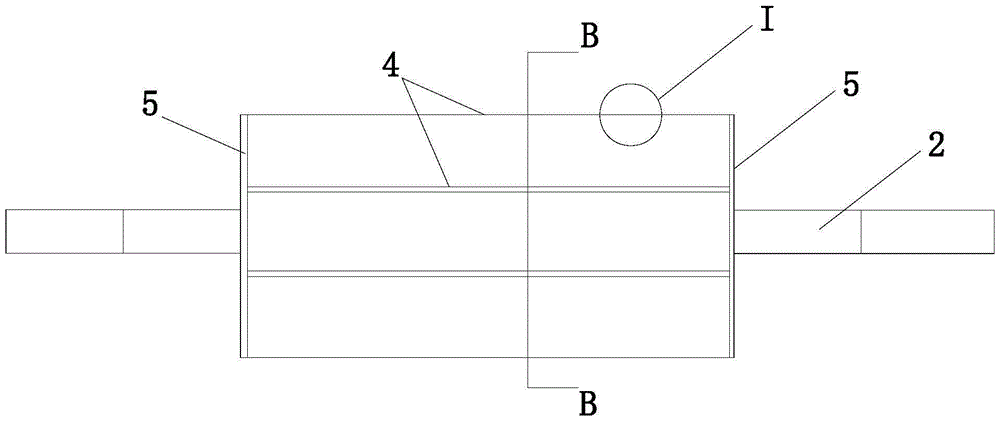

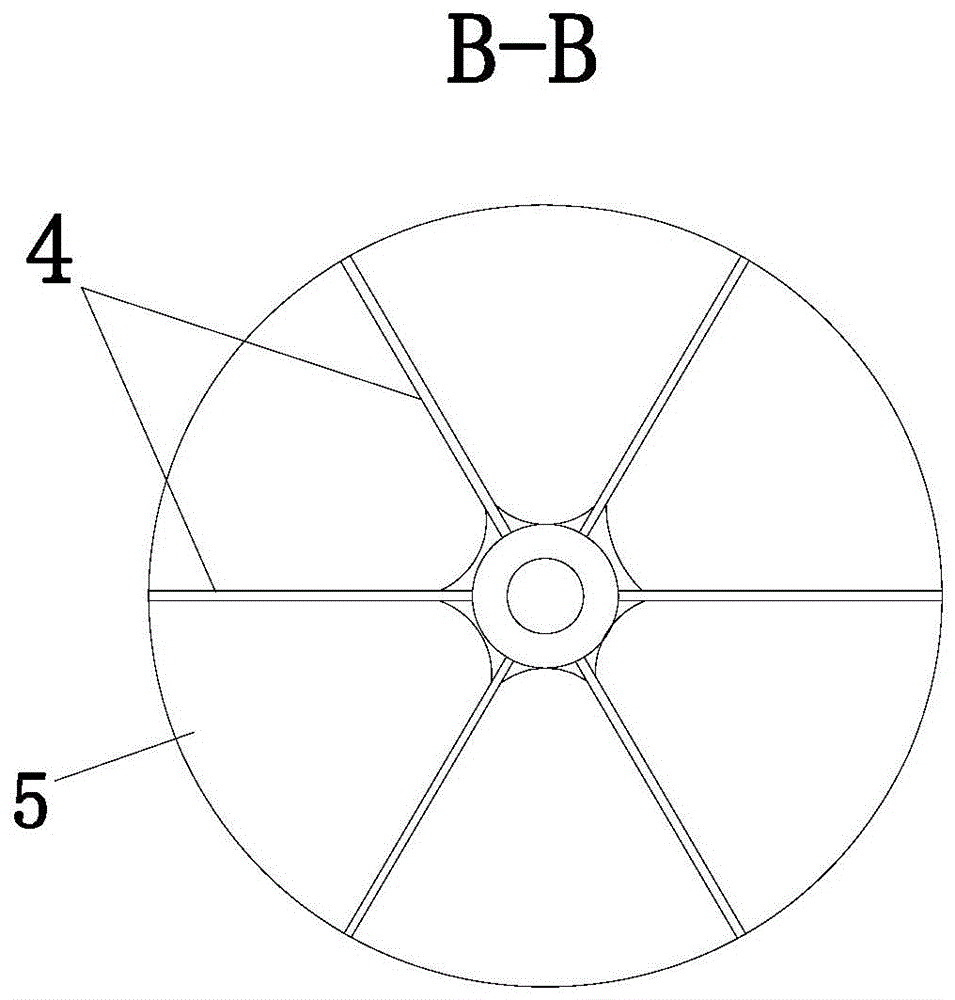

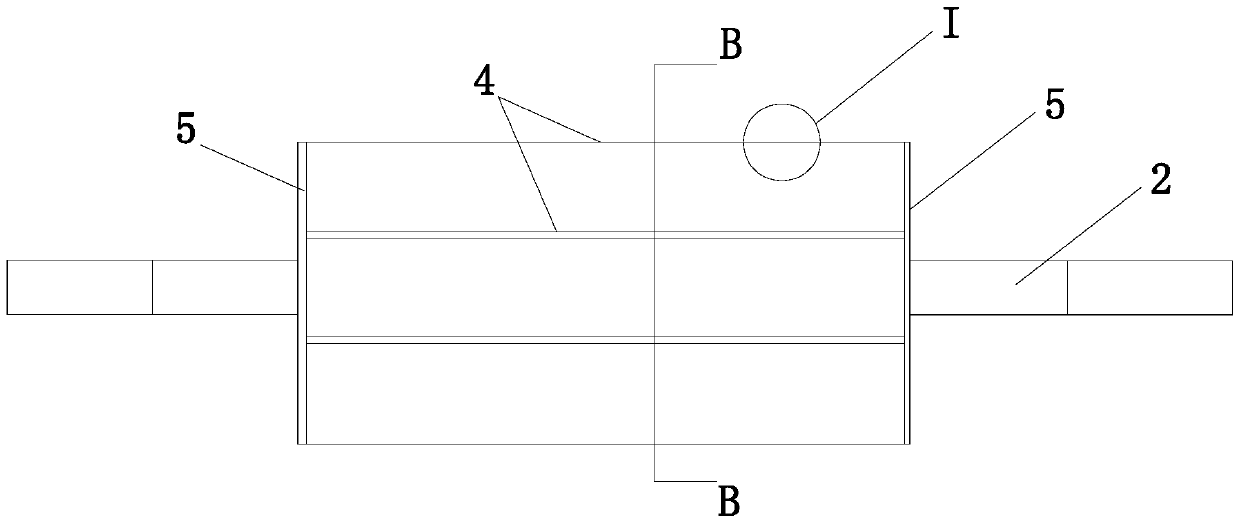

High vacuum type air lock

The invention relates to a high vacuum type air lock. The high vacuum type air lock comprises a hollow shell with a cylindrical inner wall layer. A rotary shaft penetrates the shell and is matched with end caps on the left and right sides of the shell through bearings. A plurality of air partition plates are distributed in the shell and on the rotary shaft in the radial direction. The left and right ends of each air partition plate are connected to disc-shaped end plates respectively. Sealing strips in seal fit with the inner walls of the shell are arranged on the peripheries of the end plates and the outer edges of the air partition plates. Each sealing strip comprises 18-22 wt% of graphite, 8-12 wt% of carbon fibers and the balance PTFE. The sealing strips have a better machining property by being added with the carbon fibers, and the abrasion resistance of the sealing strips is improved; and meanwhile, as the graphite has the self-lubrication function, by means of combination of the graphite and the PTFE, the vacuum degree and the service life can be further ensured.

Owner:CHANGZHOU YUTONG DRYING EQUIP

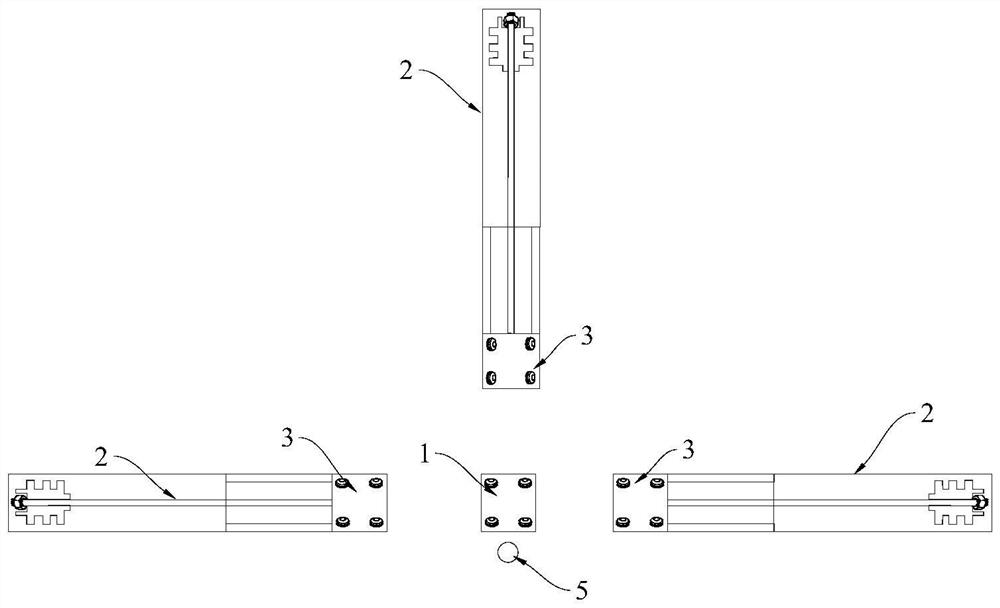

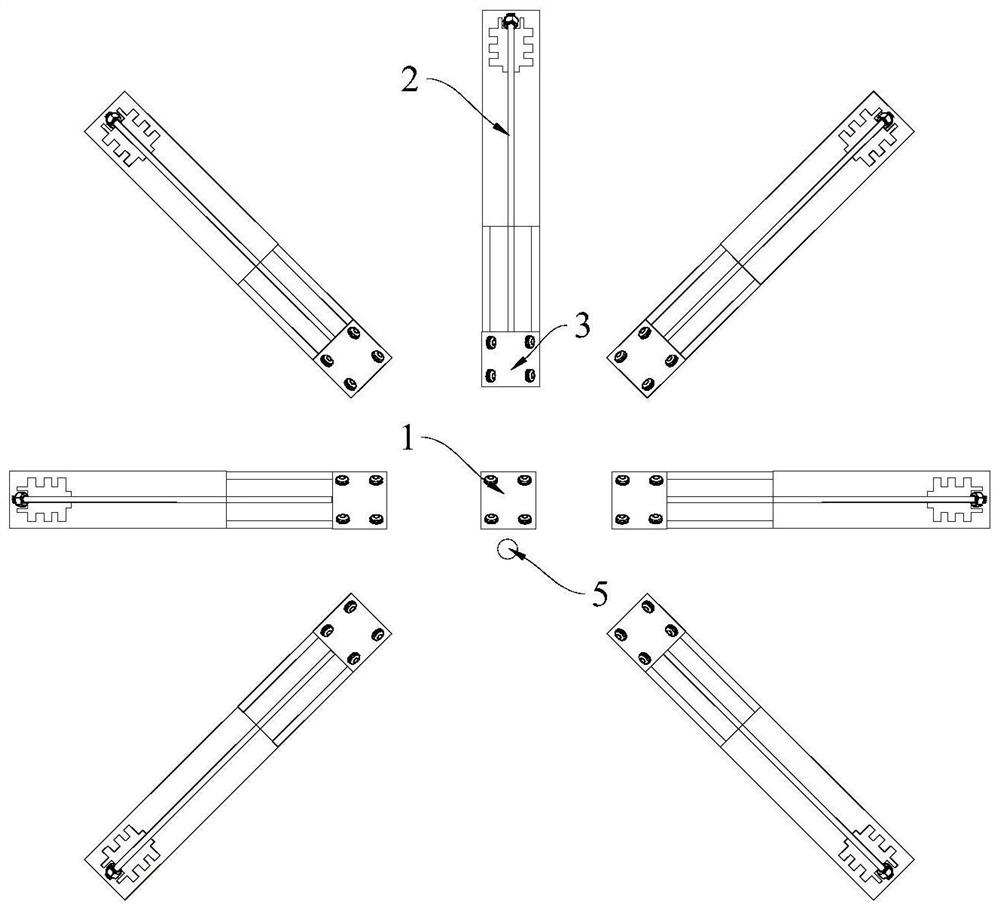

Multifunctional general tool for curved surface coating

InactiveCN103863634AReduce manufacturing costReduce stretchLabelling machinesPrinting inkEngineering

The invention belongs to the technical field of auxiliary tools for curved surface coating, and concretely discloses a multifunctional general tool for curved surface coating. The multifunctional general tool comprises an umbrella-shaped skeleton mechanism capable of vertically telescoping and horizontally opening and furling, and a plurality of workpiece fixing mechanisms for grabbing or installing a workpiece, and the workpiece fixing mechanisms are connected to all lower end portions of the umbrella-shaped skeleton mechanism respectively, and can be adjusted around the lower end portions at an arbitrary angle. The tool is suitable for a variety of workpieces with different dimensions, and can reduce the tensile deformation of a coating film material in the use process in order to reduce the displacement and the chromatic aberration of a printing ink image.

Owner:黄北江

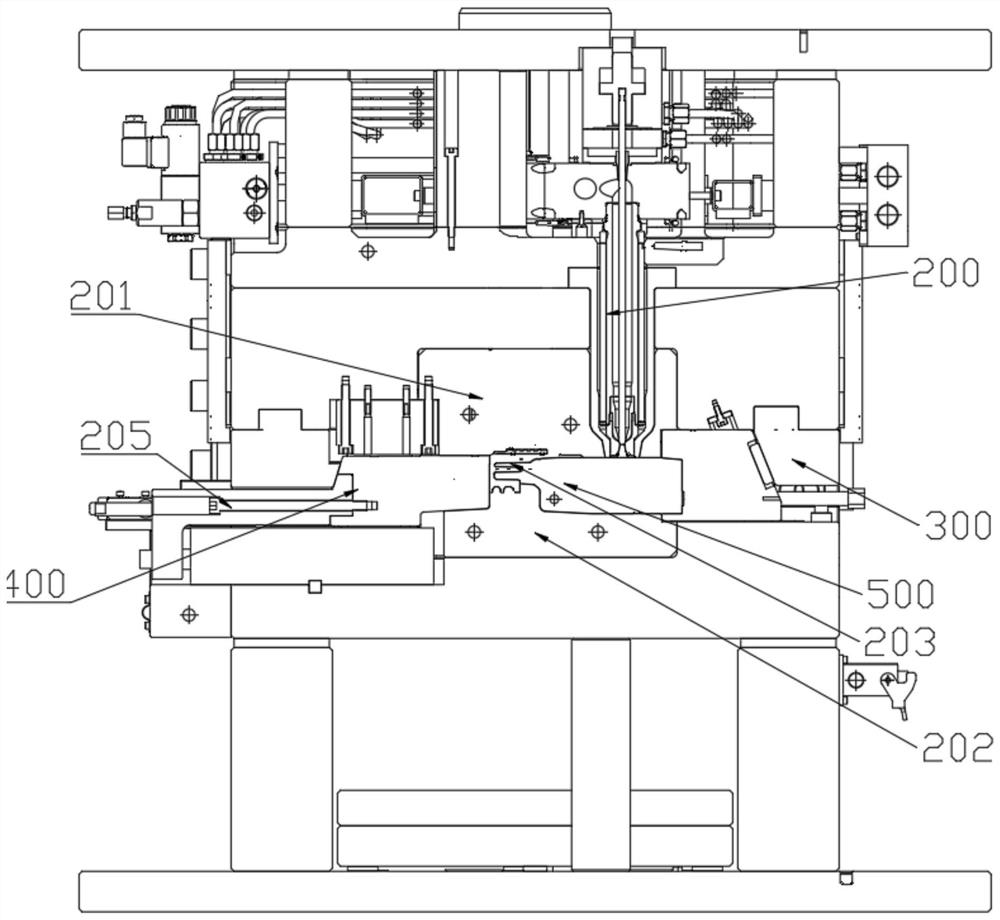

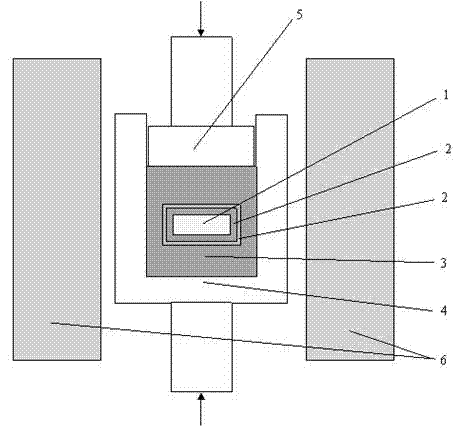

Injection mold for automobile battery assembly insert product and method

PendingCN113320079APrecise positioningOvercome displacementCoatingsAutomotive batteryInjection moulding

The invention discloses an injection mold for an automobile battery assembly insert product. The injection mold comprises a primary injection molding mold and a secondary injection molding mold which are arranged in sequence, the primary injection molding mold and the secondary injection molding mold are both provided with injection molding channels, meanwhile, the invention provides the injection method for the automobile battery assembly insert product, a problem that in the production process of the automobile battery assembly insert product, the product cannot be positioned, and consequently production efficiency of the product is low is solved.

Owner:QINGDAO INJELIC PRECISION MOLD +1

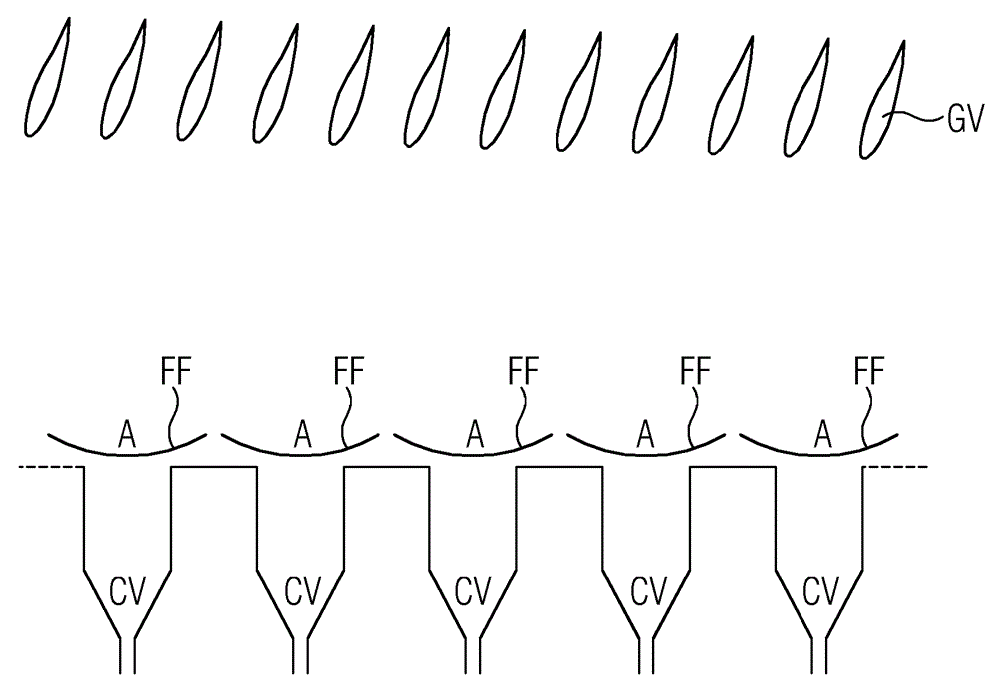

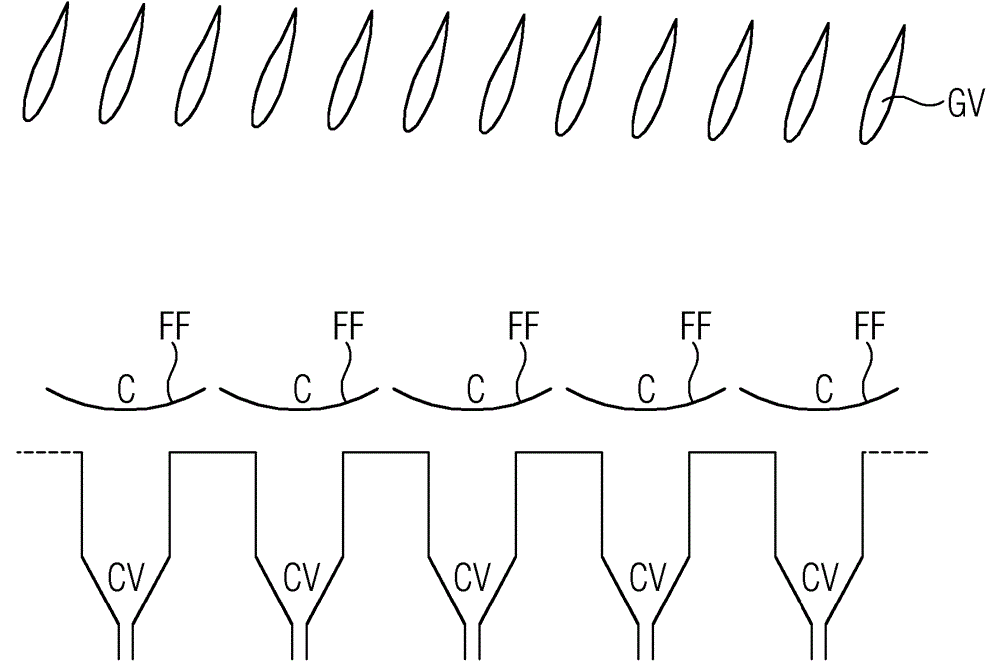

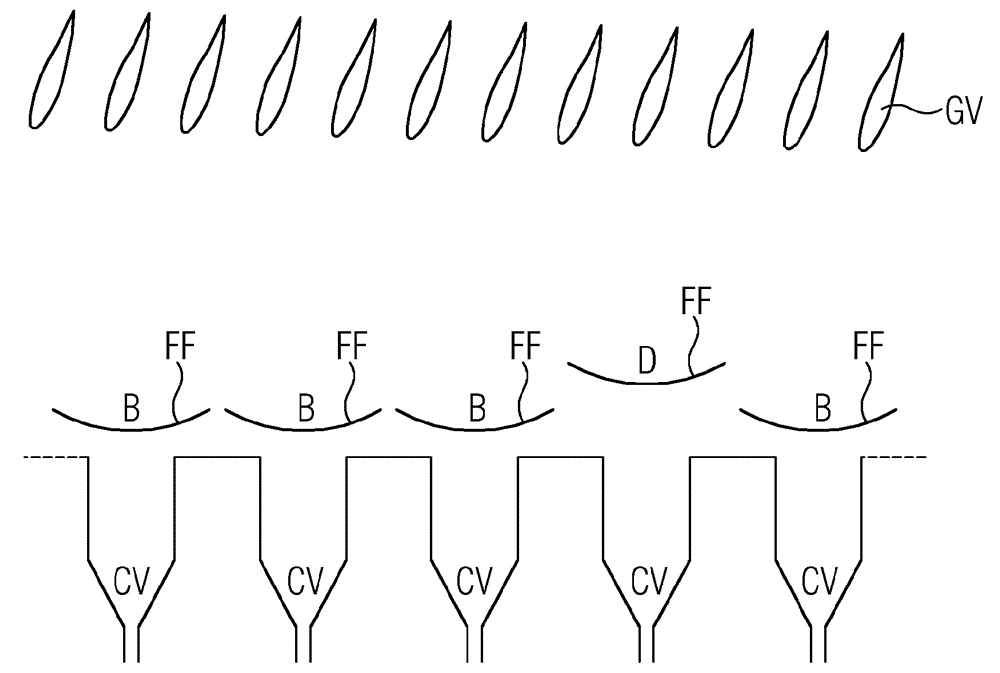

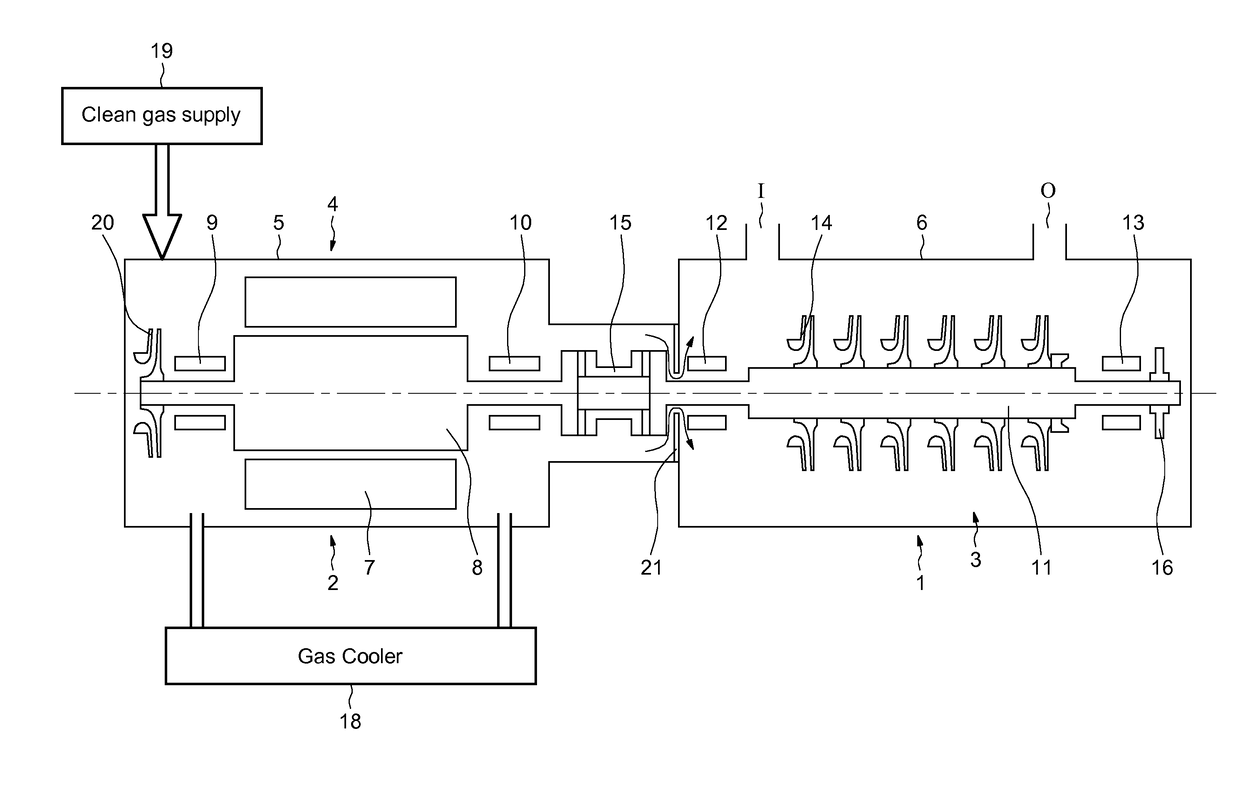

Method to operate a combustor of a gas turbine

ActiveCN104919250AAvoid high emissionsAccelerate emissionsContinuous combustion chamberAir supply regulationCombustion chamberCombustor

Method to operate a combustor (CB) of a gas turbine (GT), wherein the gas turbine (GT) comprises a compressor (CO) said combustors (CB) and the turbine (TB) and at least two temper- ature measurements (TN1, …, TNX, …, TNY, …, TNN) downstream said combustor (CB) to measure a respective combustion gas (CG) temperature, wherein said compressor (CO) delivers an oxygen containing gas (OCG) to said combustor (CB), wherein said combustor (CB) comprises at least two burners (B1, …, B2) and at least one main combustion chamber (MCC) downstream said burners (B1, …, B2), wherein at least two of said burners (B1, …, B2) join commonly into said at least one main combustion chamber (MCC) to generate said combustion gas (CG) from burning fuel (F) and said oxygen containing gas (OCG), wherein one extraction (EX) is provided to tap off at least a portion of the oxygen containing gas (OSG) downstream said compressor (CO) and upstream of said combustors (CB), wherein said extraction (EX) comprises a valve (BV) to control the portion of the oxygen containing gas (OSG) to be tapped off. To reduce emissions it is proposed that said method comprises the steps of: - monitoring the combustion gas temperature by said tem- perature measurements (TN1, …, TNX, …, TNY, …, TNN) at different locations at respectively equal flow-distances to the burner of the combustion gas (CG), - comparing said temperature measurements (TN1, …, TNX, …, TNY, …, TNN), opening said valve (BV) or increasing the opening position of said valve (BV) when said comparison reveals that a difference between said temperature measurements exceeds a temperature difference threshold ∆T1.

Owner:西门子能源全球两合公司

Hot pressing method for preparing ceramic coating

The invention discloses a hot pressing method for preparing ceramic coating. According to the method, a ceramic coating slurry coated sample is embedded into ceramic microspheres for hot pressing solidification to obtain a needed ceramic coating. Ceramic microspheres are used as a solid medium for heat transfer, force transmission and water loss to replace traditional coarse quartz sand to improve force transmission effect during presurrizing process, so that external forces can be transmitted uniformly to each surfaces of the ceramic coating under a certain pressure, besides displacements and frictions can be reduced at most to effectively improve a uniformity of the ceramic coating and to ensure integral uniformity of the ceramic coating. Therefore, performances of the ceramic coating can be enhanced effectively, and preparation quality of ceramic coatings for surfaces of samples with complicated shapes can be increased.

Owner:GUIZHOU UNIV

Grassland restoration ecological bag and application thereof

InactiveCN108029281AEasy to collectImprove water retentionExcrement fertilisersPlant cultivationMass ratioGrassland

The invention discloses a grassland restoration ecological bag and application thereof. The grassland restoration ecological bag comprises a ecological bag main body and seeds and a mixed substrate filled in the ecological bag main body, wherein the mixed substrate is a mixture prepared from soil, organic matters, a slow release fertilizer and grass powder according to the mass ratio of (65 to 70):(5 to 15):(5 to 10):(15 to 20); the mass ratio of the seeds to the mixed substrate is (2 to 3):(100 to 150). The substrates filled in the ecological bag main body can be conveniently collected; cow and sheep dung is used as organic matters and are used for providing nutrients for the plant growth together with the slow release fertilizer; particularly, withered grass ground powder filled in the ecological bag main body can further enhance the water holding performance of the substrate; the substrate and the seeds are put into the grassland restoration ecological bag; the seed flying and the damage can be prevented; the seed germination rate and the young seedling survival rate can be improved; a later stage plateau ecological bag main body material of non-woven fabric can be degraded. Thegrassland restoration ecological bag is particularly applicable to heavy-degraded high-cold grassland.

Owner:CHINA AGRI UNIV

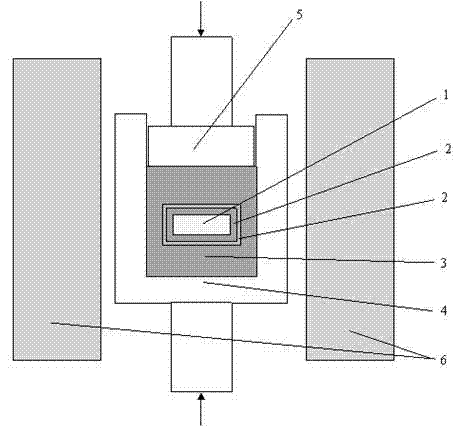

Subsea centrifugal compressor with horizontal shaft and with only one axial thrust bearing

InactiveUS20180209434A1Overcome displacementPump componentsPump installationsDrive shaftThrust bearing

A centrifugal compressor unit including a motor having a rotor, at least one compressor having a shaft driven by the rotor; and a set of bladed wheels fitted on the driven shaft, the motor and the compressor being mounted in a common watertight casing. It further includes cooling means for cooling the motor, the cooling means having a gas cooler outside the casing. In operation, the motor, the compressor and the casing having the motor and the compressor are arranged horizontally, one axial thrust bearing only being provided on a compressor side.

Owner:THERMODYN

Buoy fixing mound and preparation method thereof

The invention discloses a buoy fixing mound and a preparation method thereof. The buoy fixing mound comprises a mound body and an outer packaging layer. Multiple protrusions exposed out of the outer surface of the mound body are arranged on the outer surface of the mound body made of scrap iron in a melting and casting mode. The outer surface of the mound body is coated with the outer packaging layer made of ferronickel or ferrochromium duplex metal in a melting and casting mode. The outer packaging layer coats the protrusions exposed out of the outer surface of the mound body inside. The protrusions are screw-thread steel or protruding bags made of scrap iron in a melting and casting mode. The mound body on the inner layer and the ferronickel or ferrochromium outer packaging layer on theouter layer can be tightly attached together through the protrusions after being cast, are not layered and are free of gaps, and the practicability and the reliability of the product are enhanced. Thebuoy fixing mound has the beneficial effects that the buoy fixing mound can be stably arranged in the seabed of the water surface position, a buoy is prevented from being moved or lost, the size is small, the product cannot rust or rot forever, the service life is long, the mound body and the outer packaging layer are tightly attached together, are not layered and are free of gaps, the weight islarge, routing inspection cost and maintenance cost are saved, and the workload is reduced.

Owner:周国发

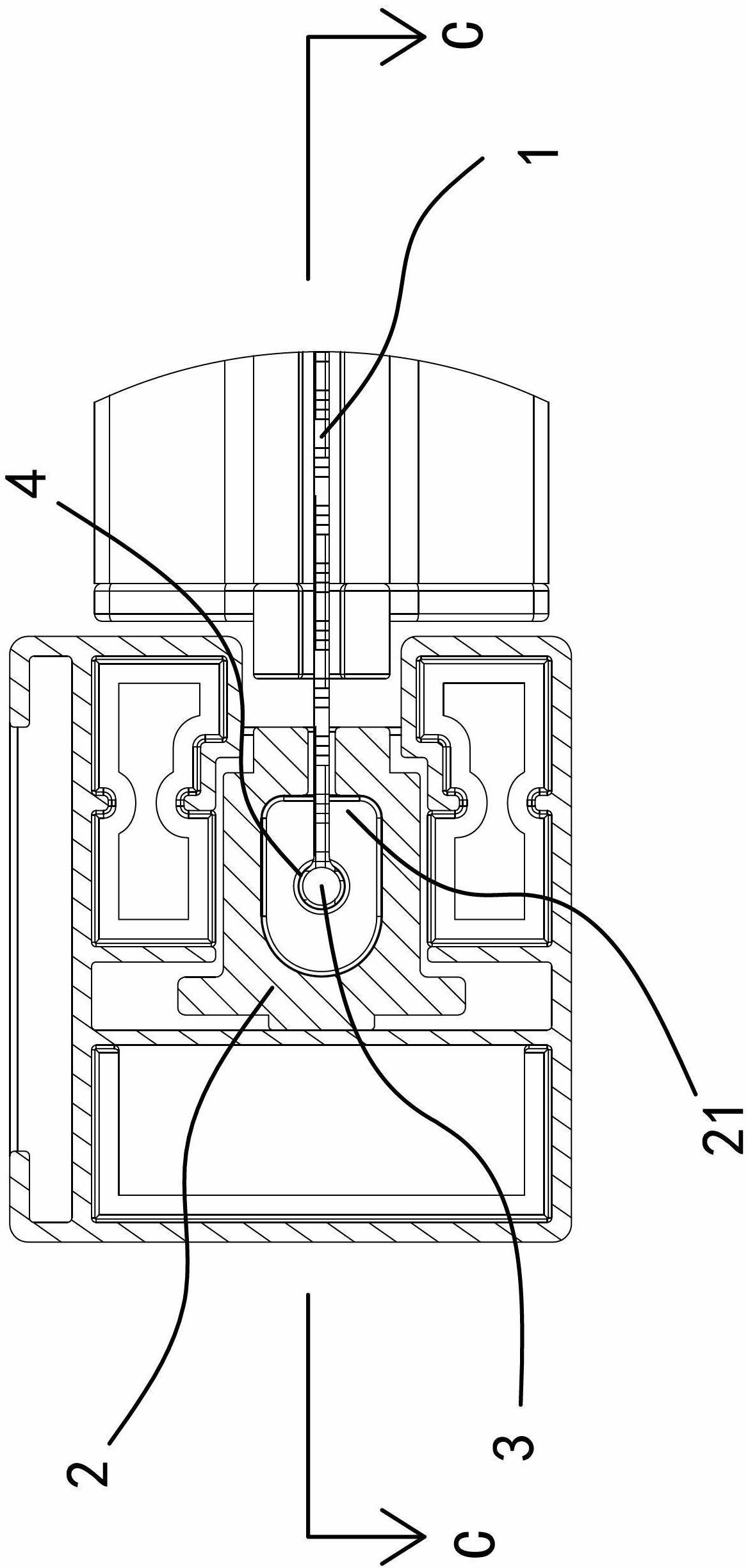

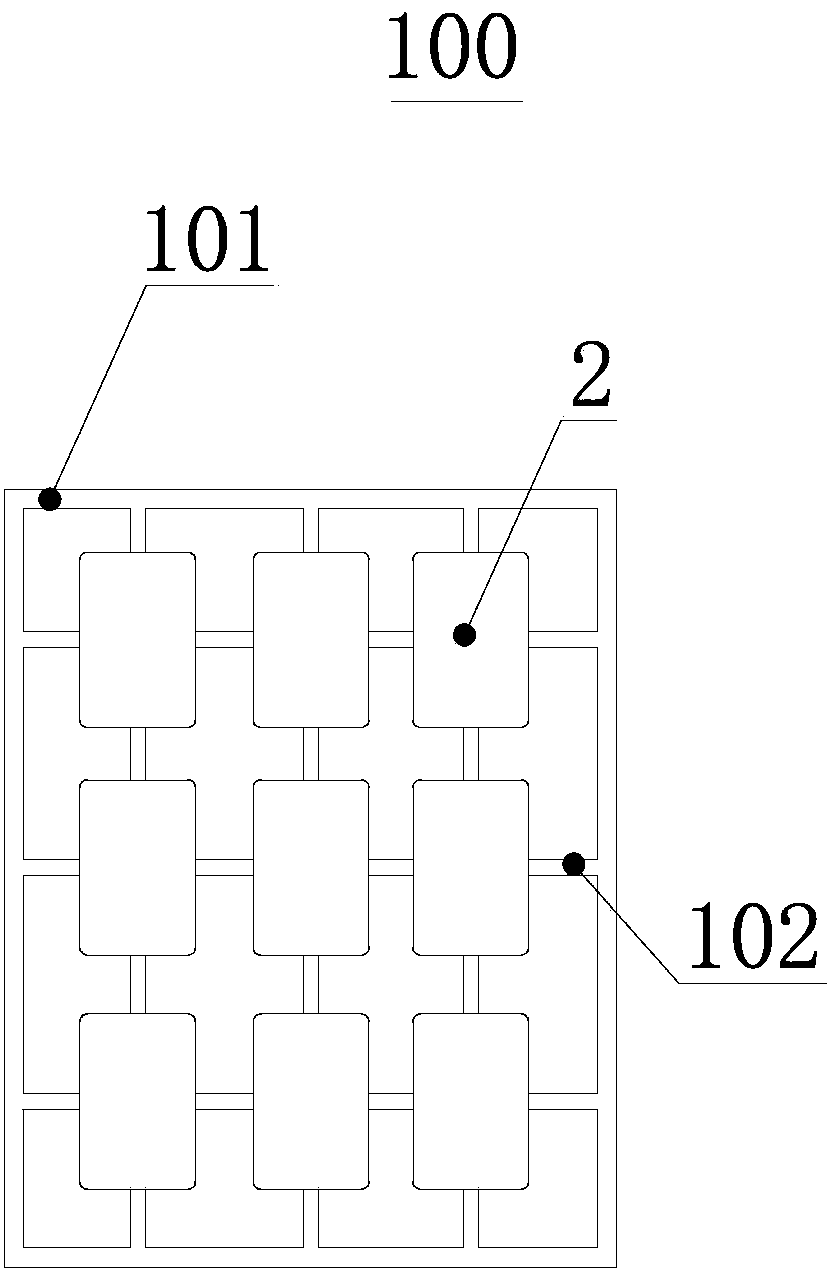

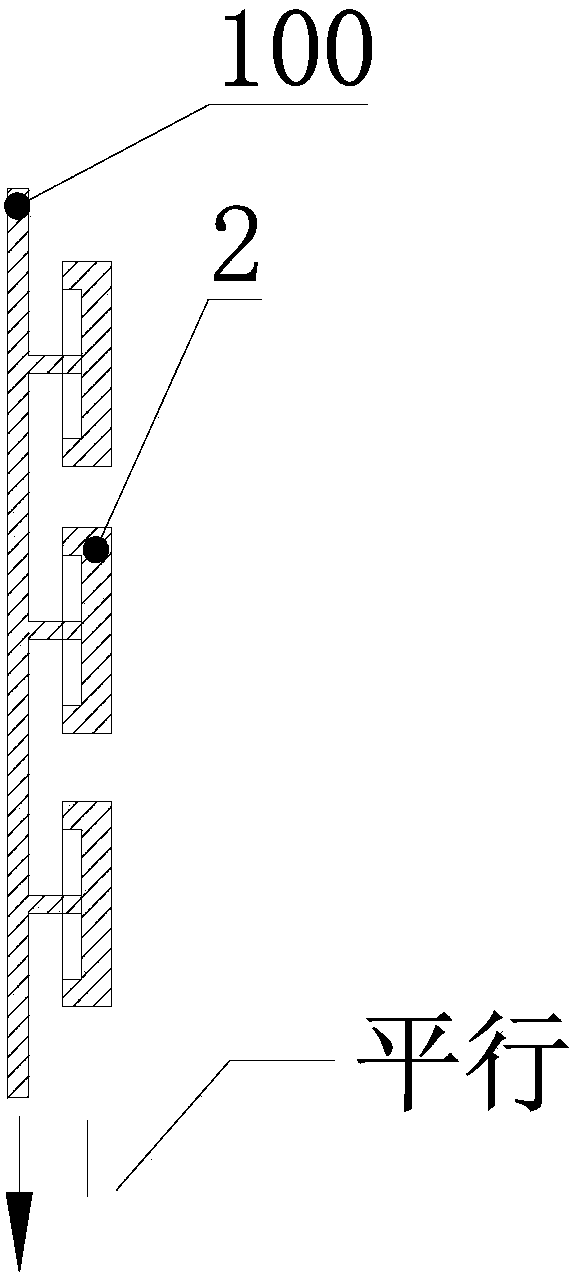

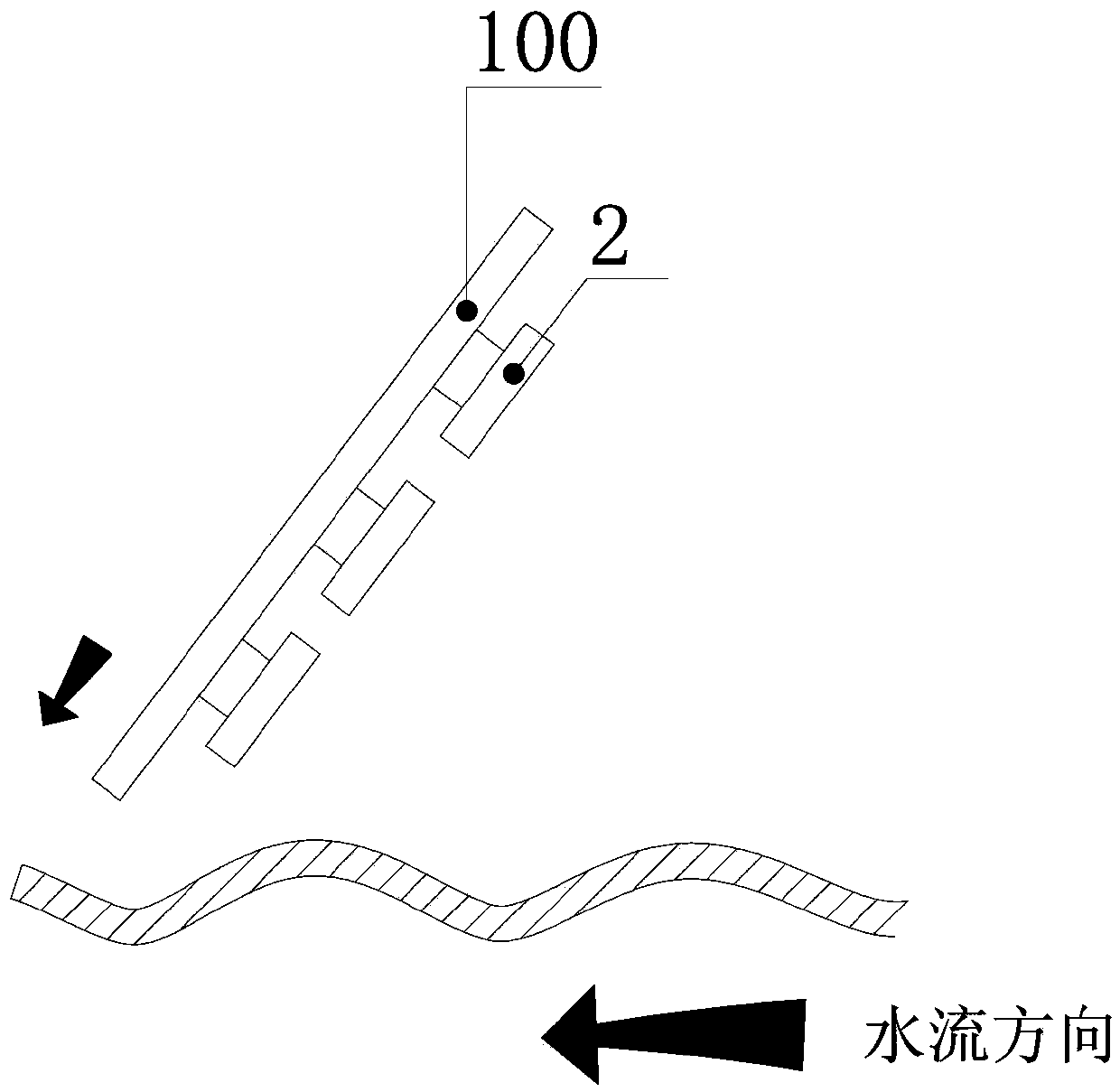

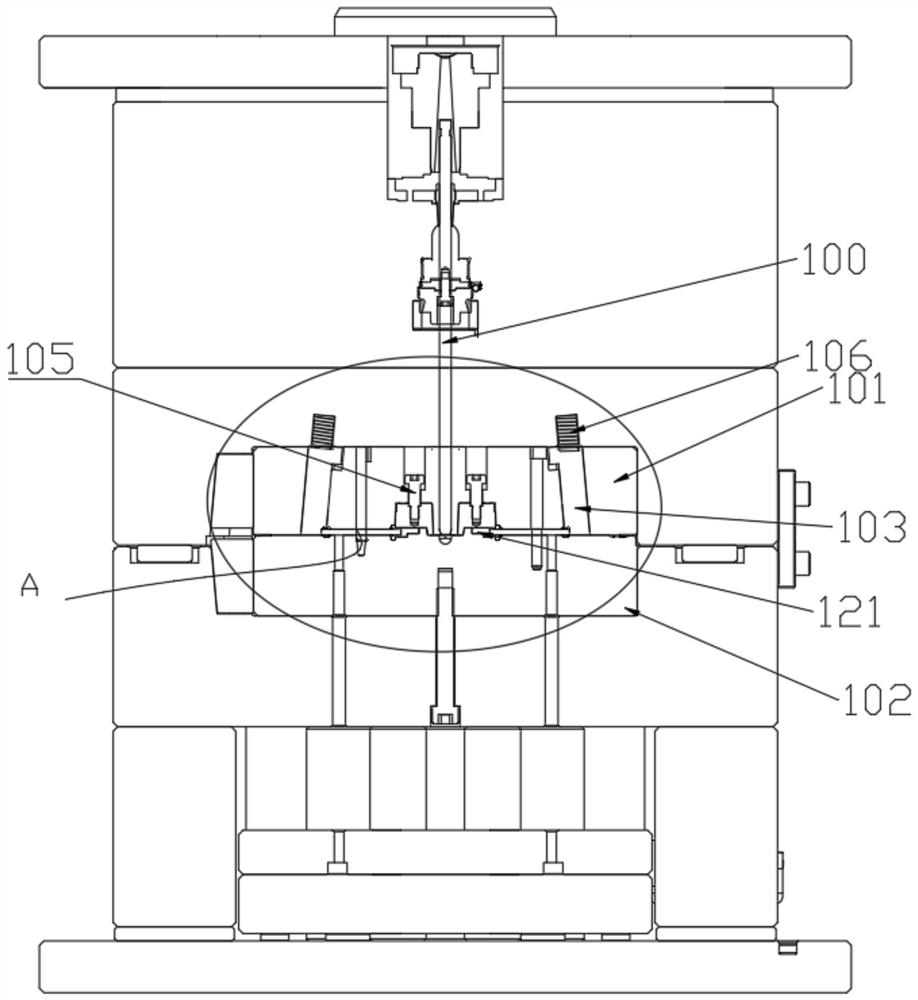

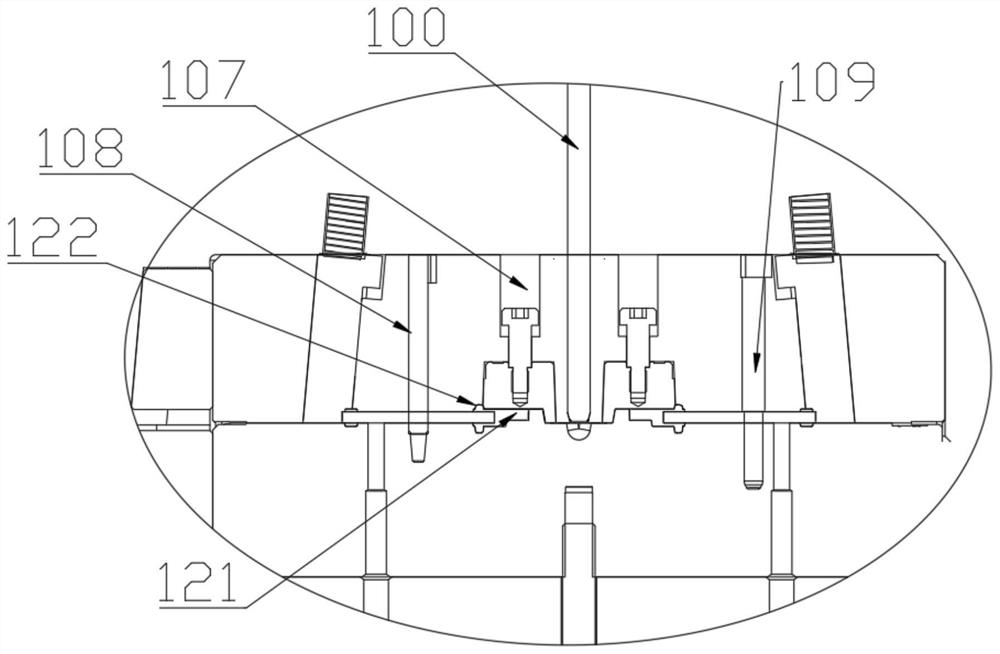

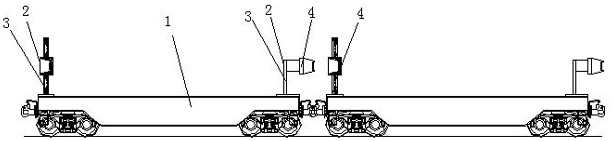

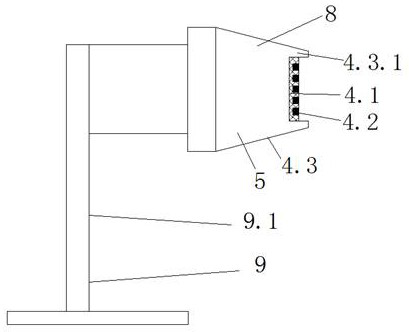

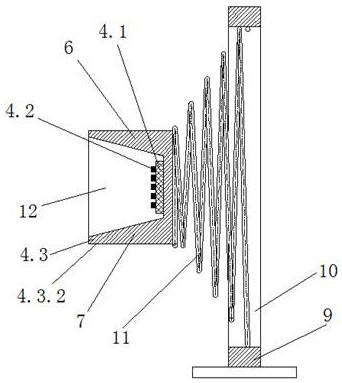

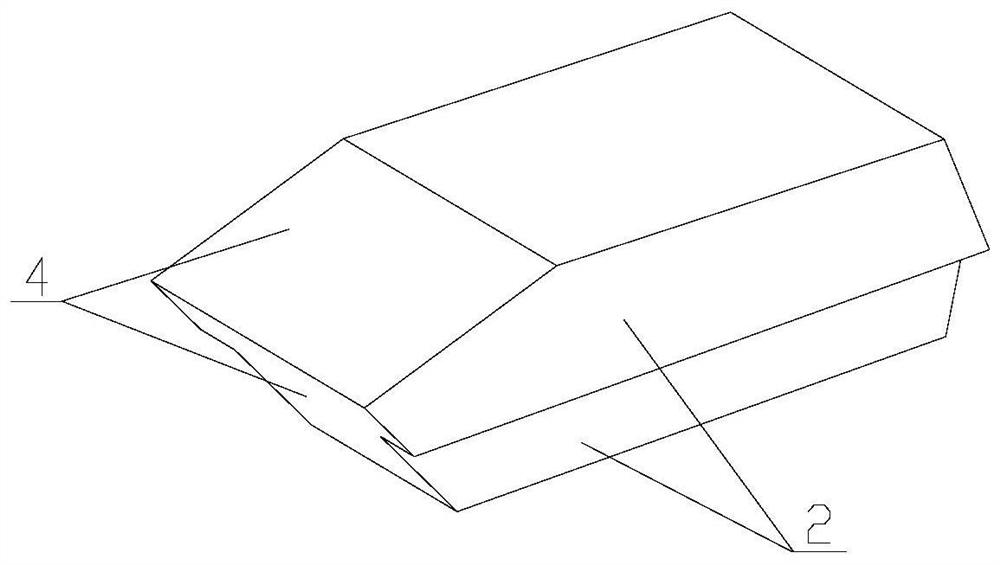

Multi-dimensional self-adaptive electric connection device of mobile device

PendingCN112201994AEnable connectivityAchieve separationCoupling device detailsStructural engineeringMobile device

The invention discloses a mobile device multi-dimensional self-adaptive electric connection device, and the device comprises a mobile device; cable connectors are arranged at the two ends of the mobile device respectively, each cable connector comprises an installation support and a power connection body assembly located on the installation support, and each power connection body assembly comprises an insulation block and an electric conductor located on the insulation block; the cable connector at one end of the mobile device is a cable connector male end, and the other end is a cable connector female end. One end or two ends of the moving device are floating connecting ends, and the insulating blocks on the cable connectors at the floating connecting ends are connected with the mountingsupport through floating supporting assemblies. Automatic connection and separation of the cable connectors at the ends of the two moving devices can be achieved, the insulation blocks at the floatingconnection ends and the installation support are connected through the floating supporting assemblies, displacement or tilting can be overcome when the moving devices are connected with the cable connectors of the moving devices, and it is guaranteed that the male ends and the female ends of the connectors are connected properly; and no manual intervention is required.

Owner:YIXING SAVE METALLURGICAL MACHINERY

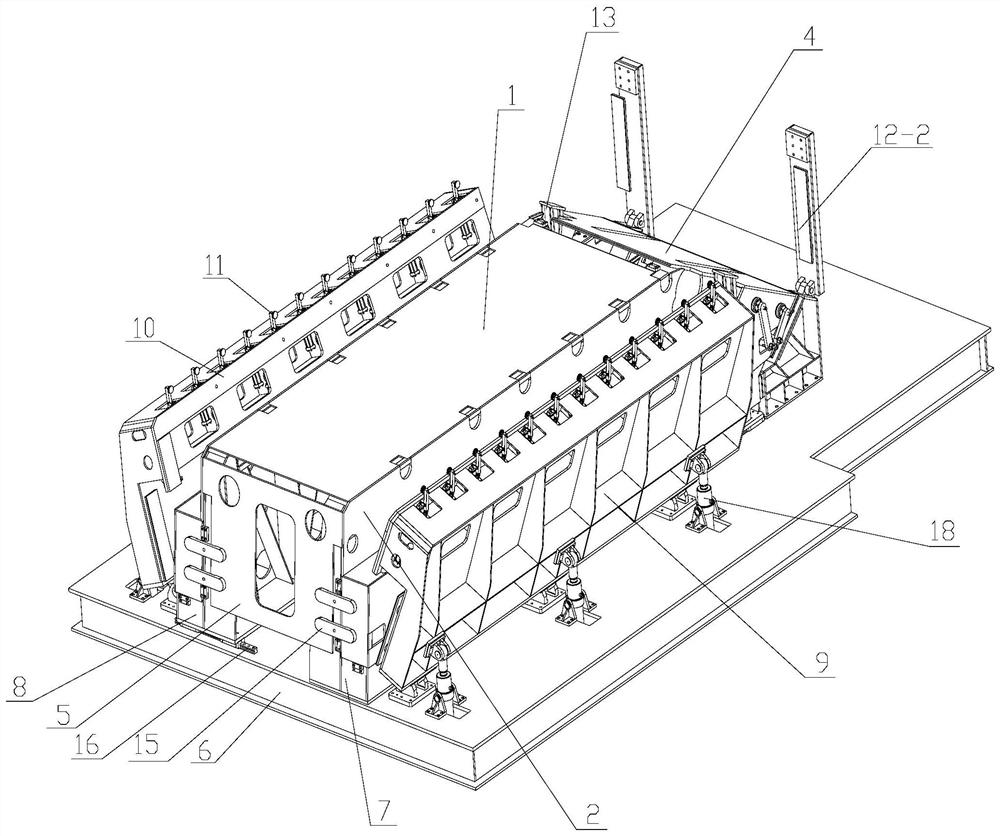

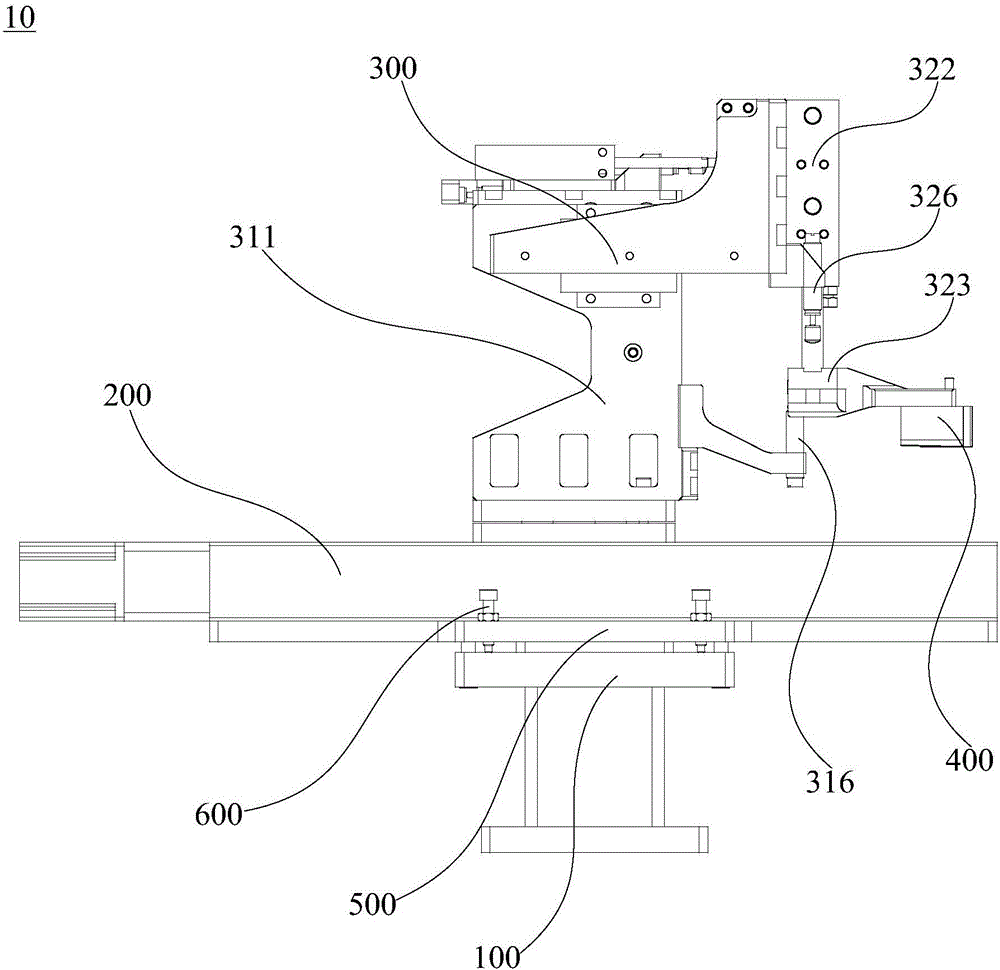

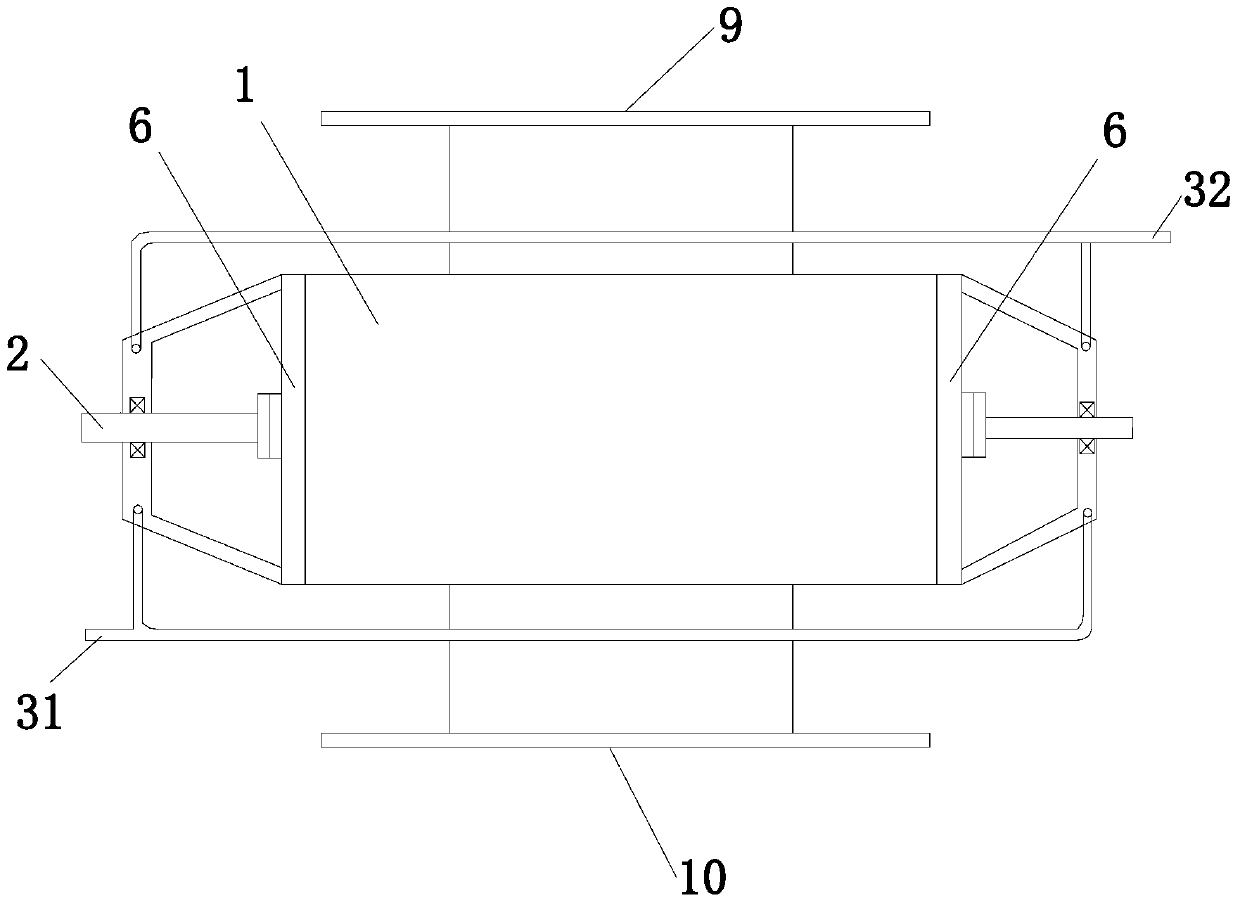

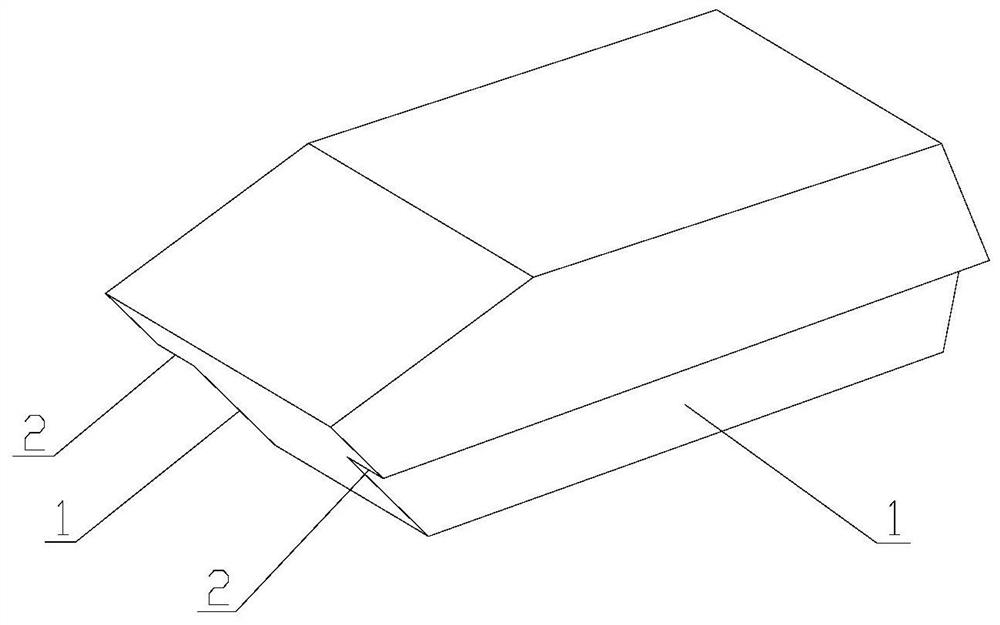

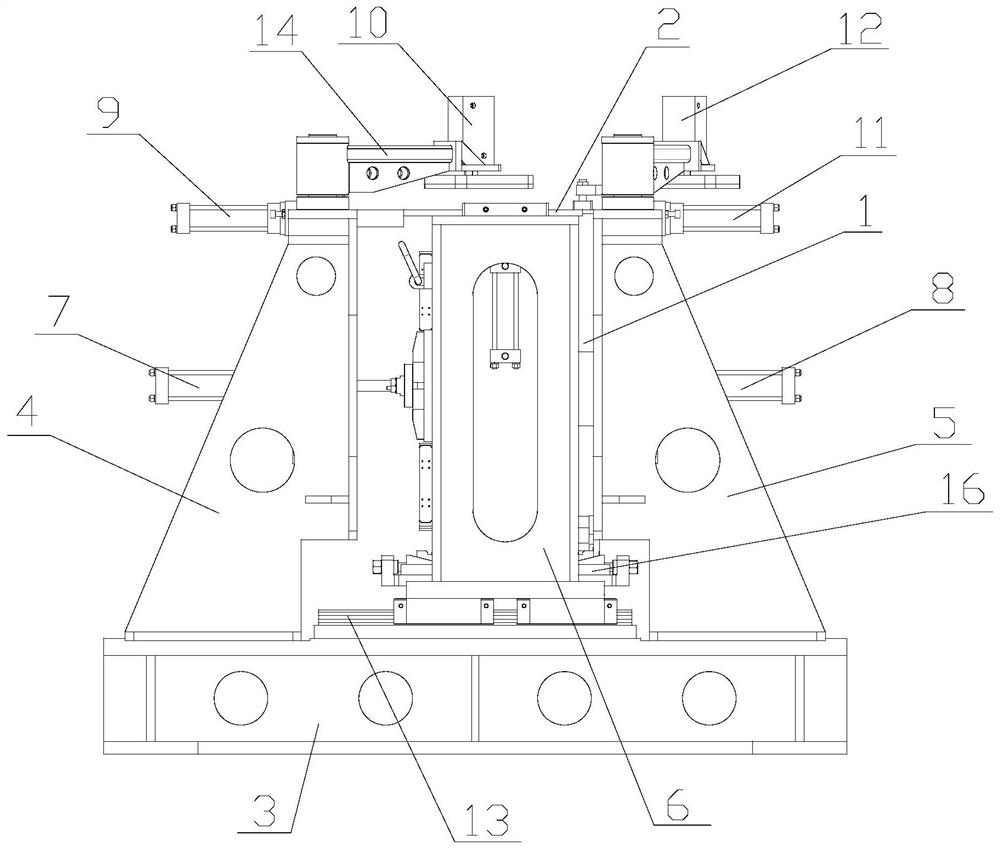

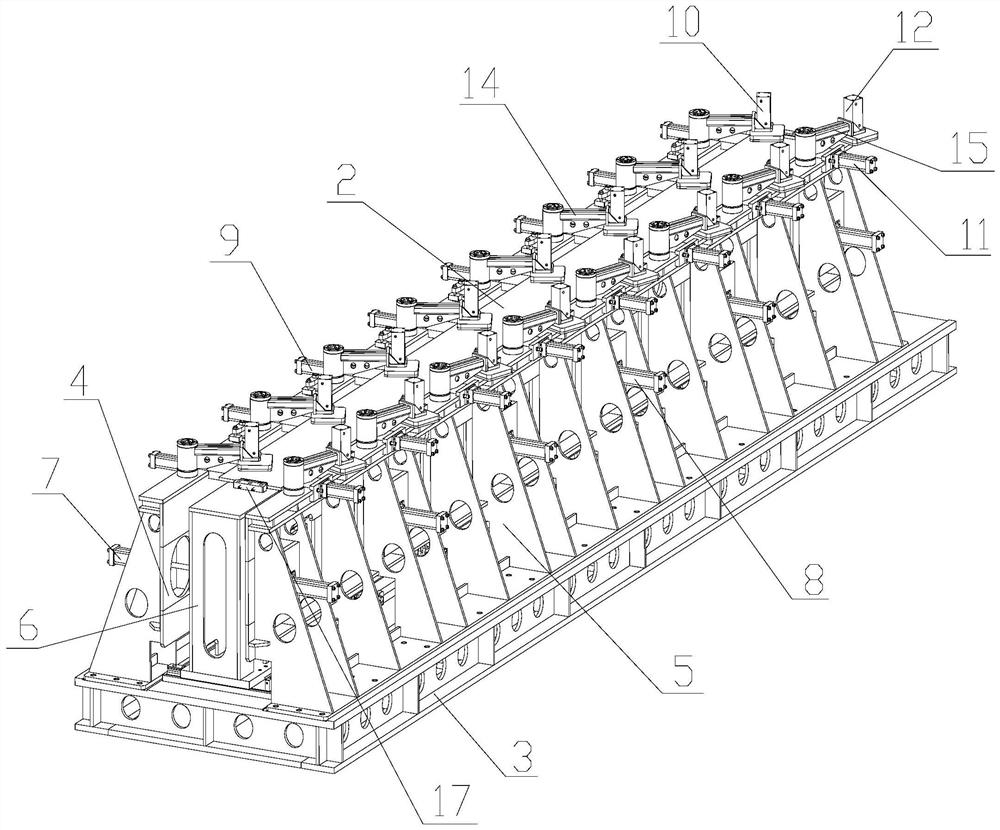

Armored car body welding tool

PendingCN113001011AHigh positioning accuracyOvercome displacementNon-electric welding apparatusArmored carEngineering

The invention relates to the technical field of tool tools, in particular to an armored car body welding tool. The welding tool which is high in automation degree and good in welding quality and is used in a friction stir welding method is provided. According to the solution, the tool is provided with a base, a left inner supporting base for supporting a left side plate and a right inner supporting base for supporting a right side plate are arranged on the base, a left turning plate and a right turning plate which can turn laterally and press the side plates on the supporting bases are arranged on the outer side of the left inner supporting base and the outer side of the right inner supporting base correspondingly, turning type pressing oil cylinders which press a bottom plate on the top face are arranged on the left turning plate and the right turning plate, a bracket for supporting the front top plate is arranged on the base, the bracket is provided with a first pressing portion and a second pressing portion which press the front top plate, one end of the second pressing part is hinged to the first pressing part, the other end of the second pressing part is detachably fixed to a stand column arranged on the base, a pushing and pressing device for positioning the side plates is also arranged on the base at the weld joints of the front top plate, and the side plates and tail clamping devices for clamping a tail plate are arranged on the rear end surfaces of the left turning plate and the right turning plate.

Owner:江苏锐成机械有限公司

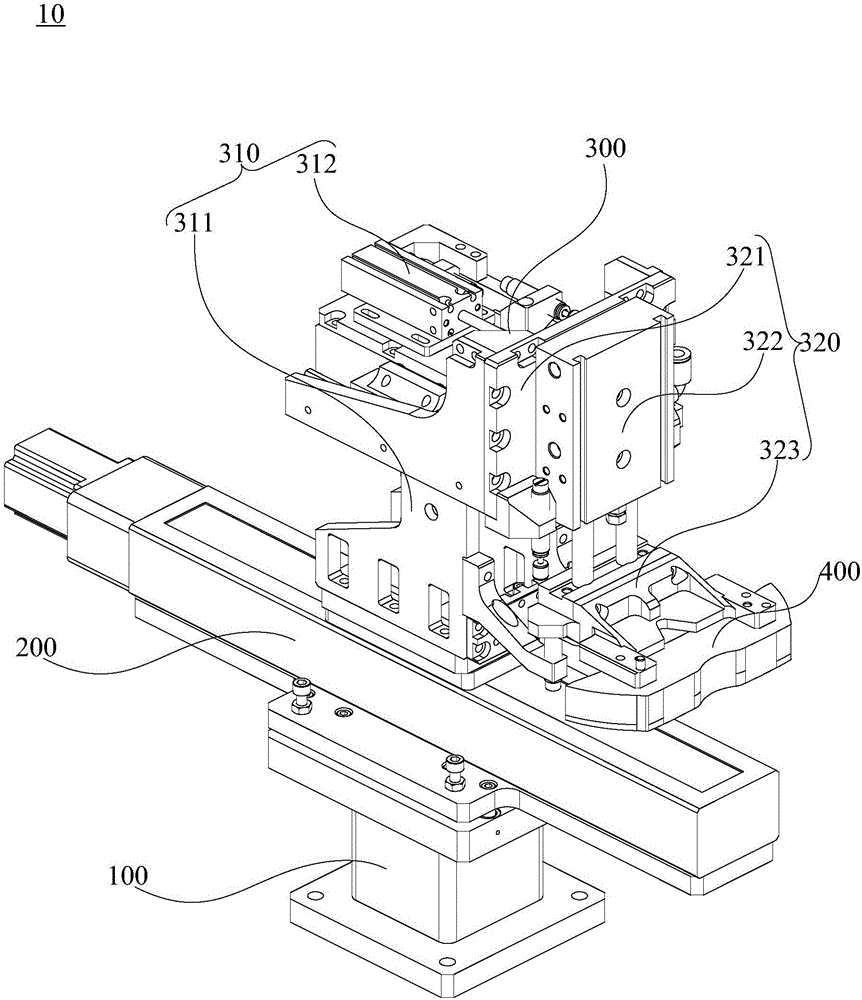

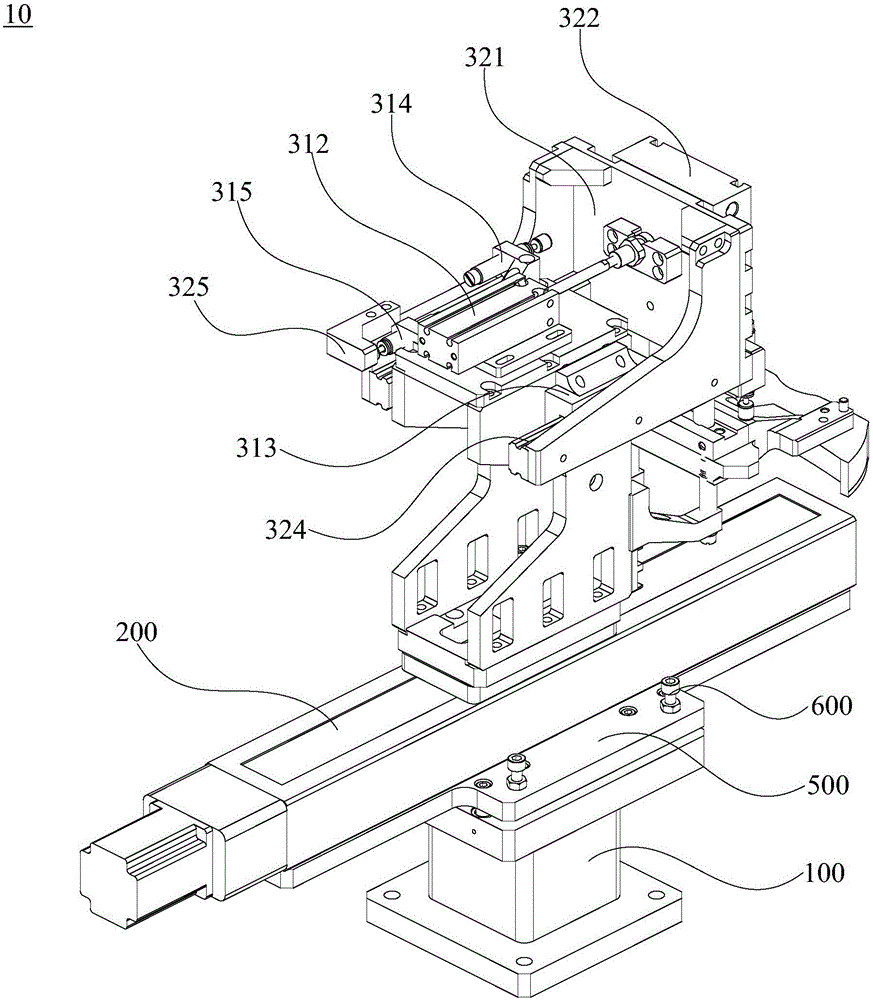

Pressing tool

The invention relates to a pressing jig. Wherein, the pressing jig includes: a base; a linear motion platform mounted on the base; a driving mechanism mounted on the linear motion platform, and the driving mechanism can move linearly along the linear motion platform; and The pressing piece used to press the workpiece to be welded is made of a light-transmitting material. The pressing piece is installed on the driving mechanism, and the driving mechanism can drive the pressing piece to approach and compress on the workpiece. The workpiece to be welded is compressed by using the driving mechanism to drive the pressing piece, so that the workpiece is welded under a certain pressure to overcome the displacement and deformation generated during the welding process. At the same time, the compression fixture can realize the compression of the workpiece without occupying a large space near the workpiece to be welded, so as to effectively avoid movement interference with other process steps.

Owner:HANS LASER TECH IND GRP CO LTD

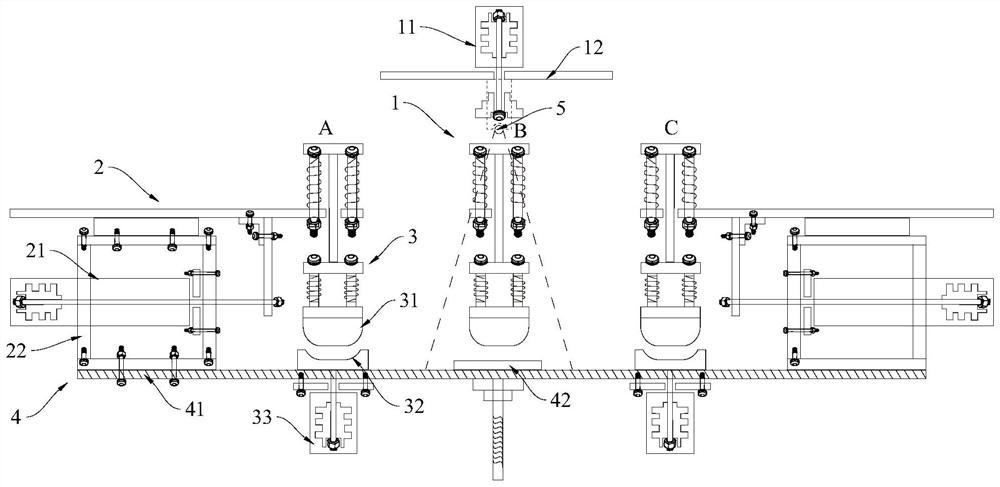

Multicolor ink transfer printing or thermal transfer printing machine

PendingCN112172329AOvercome displacementOvercome the defects of inaccurate plate alignment and poor effectTransfer printingTextile printerReciprocating motion

The invention provides a multicolor ink transfer printing or thermal transfer printing machine, and relates to the technical field of printing equipment. The printing machine comprises a vertical driving mechanism, horizontal driving mechanisms, transfer printing mechanisms and a workbench, wherein the vertical driving mechanism is located right above the workbench and drives the transfer printingmechanisms arranged below the vertical driving mechanism to move up and down in the vertical direction; and the number of the horizontal driving mechanisms is the same as that of the transfer printing mechanisms, the horizontal driving mechanisms and the transfer printing mechanisms are arranged on the workbench and surround the periphery of the vertical driving mechanism, and the horizontal driving mechanisms are in driving connection with the transfer printing mechanisms and drive the transfer printing mechanisms to move towards the direction right below the vertical driving mechanism and away from the direction right below the vertical driving mechanism. According to the multi-color ink transfer printing or thermal transfer printing machine, the defects that a printed object does reciprocating motion on a horizontal straight line, so that the displacement or the register of the printed object is not accurate, and the effect is poor are overcome.

Owner:QUANZHOU SHANGDE GARMENTS CO LTD +1

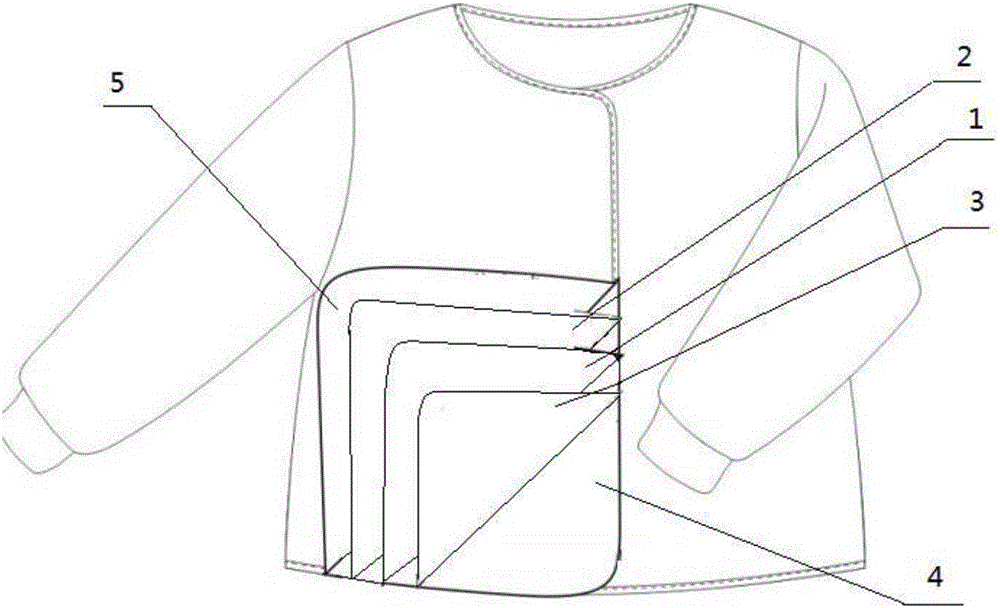

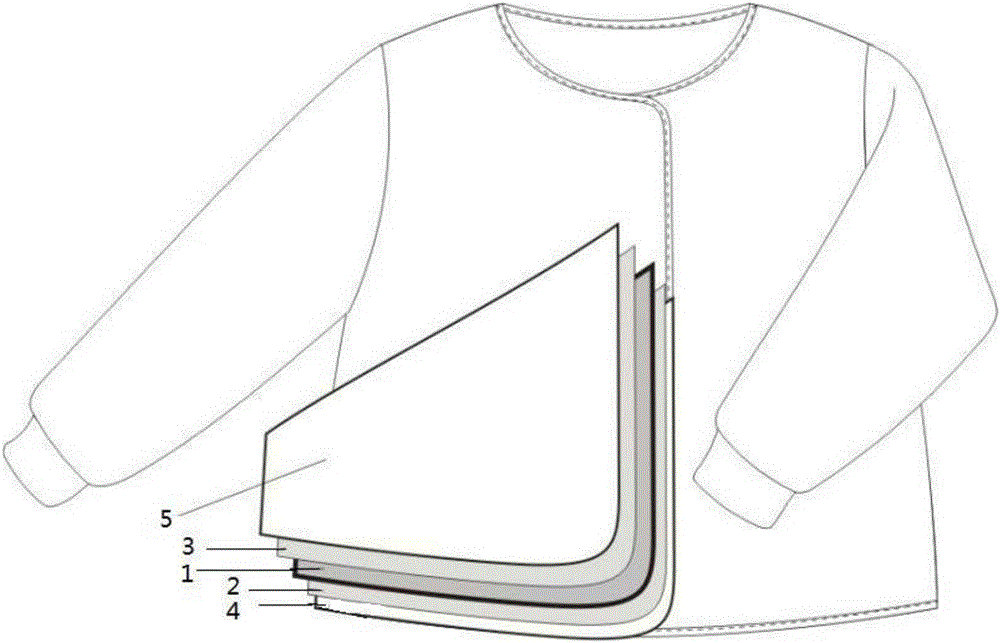

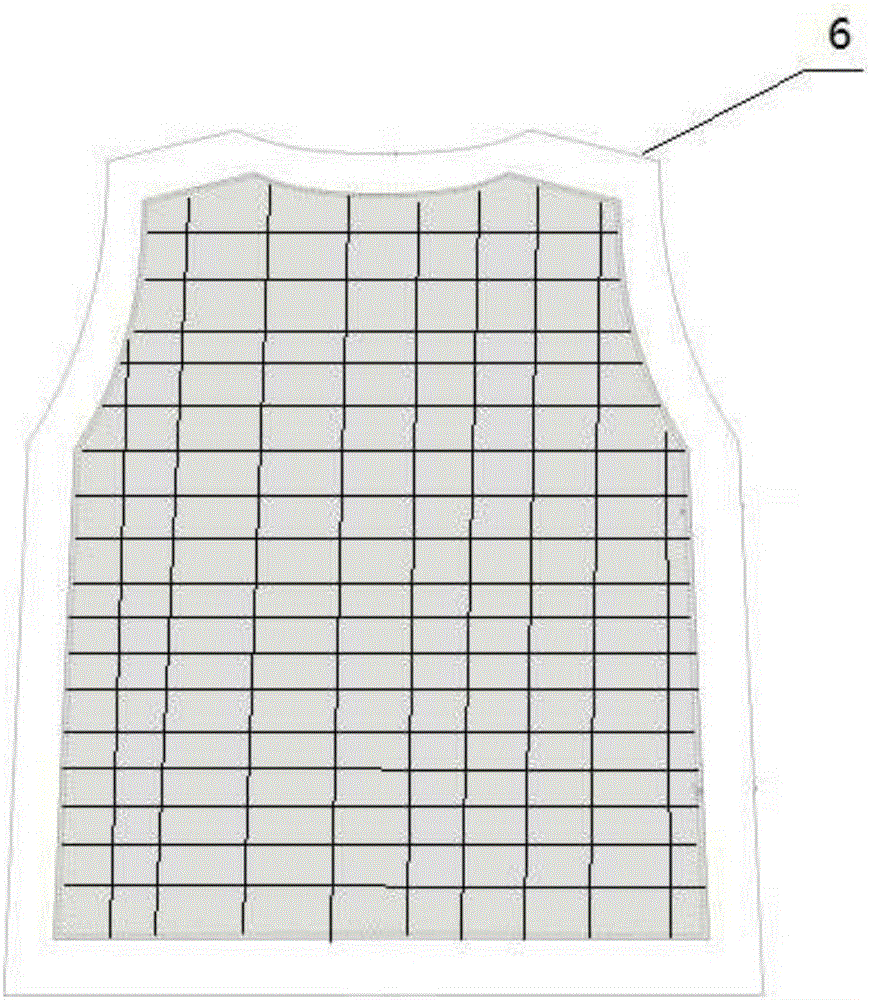

Turnover-free washable silk clothes

InactiveCN106165921AOvercome displacementOvercoming problems such as delaminationLayered productsOvergarmentsWaddingBiomedical engineering

The invention discloses turnover-free washable silk clothes. The clothes comprise a silk wadding liner, a first liner cutting garment piece layer and a second liner cutting garment piece layer; the first liner cutting garment piece layer, the silk wadding liner and the second liner cutting garment piece layer are sequentially sewn and fixed to form a turnover-free layer; a silk clothes body further comprises a first outer sleeve cutting garment piece layer and a second outer sleeve cutting garment piece layer, and the first outer sleeve cutting garment piece layer, the turnover-free layer and the second outer sleeve cutting garment piece layer are overall sewn. By adopting the turnover-free layer, the problems of silk displacement and delamination in traditional silk clothes due to direct washing are solved, and meanwhile the mode of washing the traditional silk clothes after taking the silk wadding liner down each time is changed.

Owner:浙江五世同堂真丝家纺股份有限公司

A high-vacuum shut-off fan

The invention relates to a high vacuum type air lock. The high vacuum type air lock comprises a hollow shell with a cylindrical inner wall layer. A rotary shaft penetrates the shell and is matched with end caps on the left and right sides of the shell through bearings. A plurality of air partition plates are distributed in the shell and on the rotary shaft in the radial direction. The left and right ends of each air partition plate are connected to disc-shaped end plates respectively. Sealing strips in seal fit with the inner walls of the shell are arranged on the peripheries of the end plates and the outer edges of the air partition plates. Each sealing strip comprises 18-22 wt% of graphite, 8-12 wt% of carbon fibers and the balance PTFE. The sealing strips have a better machining property by being added with the carbon fibers, and the abrasion resistance of the sealing strips is improved; and meanwhile, as the graphite has the self-lubrication function, by means of combination of the graphite and the PTFE, the vacuum degree and the service life can be further ensured.

Owner:CHANGZHOU YUTONG DRYING EQUIP

A 6-meter ultra-long optical fiber preform and its manufacturing process

ActiveCN104860530BIncrease the lengthImprove utilization efficiencyGlass making apparatusGlass productionEngineeringOptical fiber

The invention provides a six-meter super-long optical fiber preform bar which comprises at least two sleeve pipes, at least two core bars, a prolonged tail pipe and a tail pipe filling glass column, wherein the core bars are all arranged in the two sleeve pipes in a sleeving manner; the adjacent sleeve pipes are connected in a welding manner; the prolonged tail pipe is connected with the tail end of the connected sleeve pipes; the prolonged tail pipe and the sleeve pipes are coaxially distributed; the tail pipe filling glass column is embedded in the prolonged tail pipe and propped against the core bars. A manufacturing process for the six-meter super-long optical fiber preform bar comprises four steps of connecting the sleeve pipes, mounting the core bars, connecting the prolonged tail pipe and filling the tail pipe filling glass column. On one hand, the wire-drawing length of a single optical bar can be increased, the utilization efficiency of the optical bar and the production efficiency of wire-drawing equipment can be improved, the wire-drawing length of the single optical bar can reach 15,000 km, and the manufacturing cost can be reduced by about 3-5% in comparison with a conventional process; on the other hand, the phenomena of high possibility of displacement and downward slide of a conventional six-meter super-long core bar in the sleeve pipes during a wire-drawing process are effectively avoided, so that the quality stability of a product produced by wire-drawing of the single optical bar can be improved.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

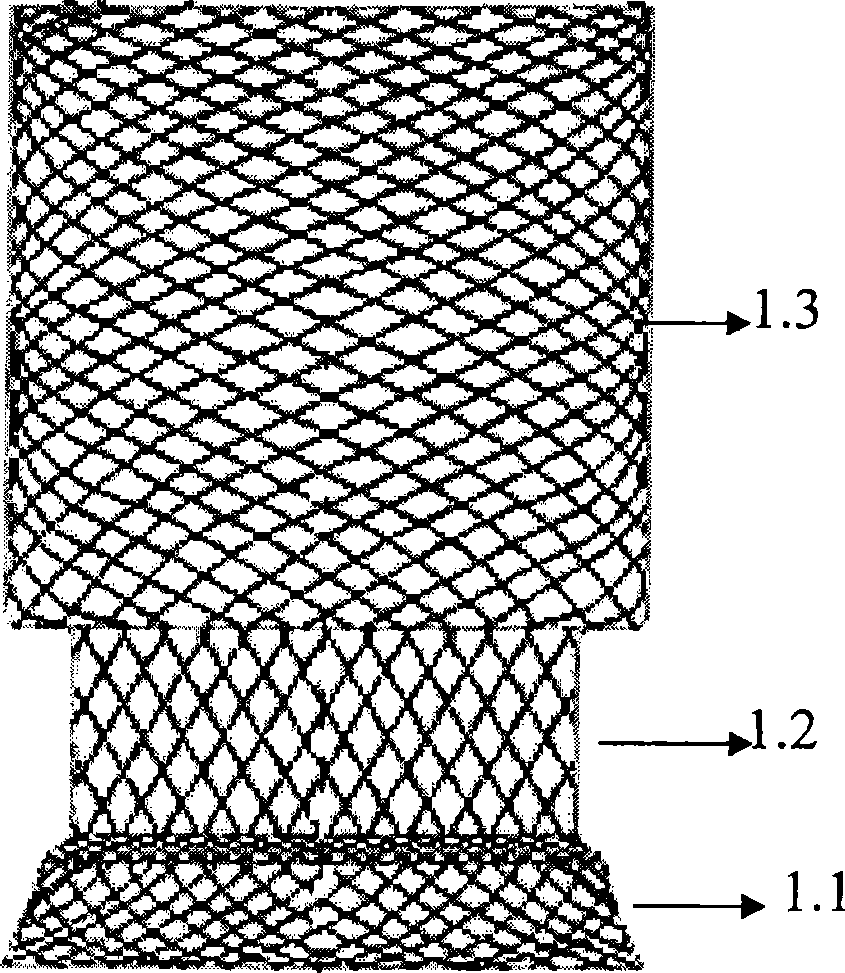

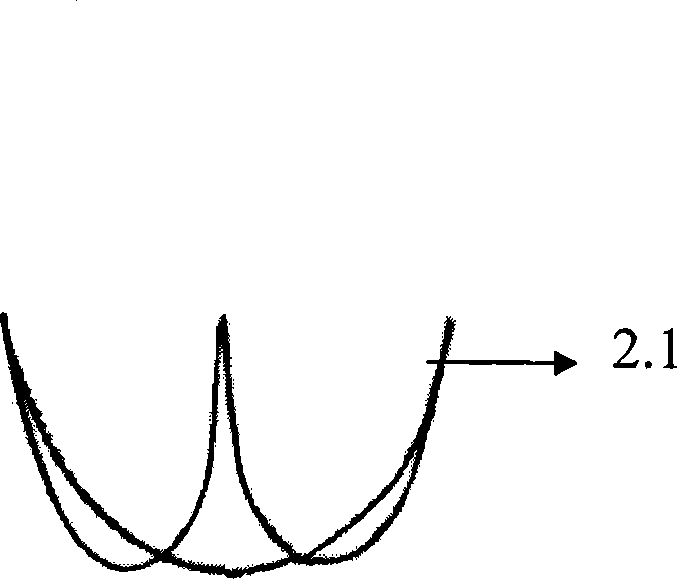

Lung arterial support with valve

The invention relates to the field of medical apparatus technique, which in detail is a cradle with valve pulmonary artery, comprising tubular cradle (1) and valve (2) inside it. The tubular cradle is braided with hyper-elastic shape memory alloy silk, and comprises head (1. 1), neck (1. 2) and body (1. 3). The head is near to heart and in horn shape, which matches to shape of pulmonary artery opening; the neck is a little narrower and connects head and body; the body is straight tube shape, the outer diameter is a little bigger than that of internal diameter of pulmonary artery. The valve comprises valve mount (2. 1) and valve leaf (2. 2), and the valve mount is made from hyper-elastic shape memory alloy silk. The wall of cradle is thin and soft, easy to compress, and it is convenient to put it into tube, thin conveying tube can be used to reduce injury. Because the valve leaf is fixed on valve mount, the sewing of tubular cradle is convenient and it will not move, and the curative effect is ensured.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Window frame with front window cover and rear window cover and window with same

ActiveCN102747926BGuaranteed smoothnessOvercome displacementInsect protectionWindow/door framesEngineeringMechanical engineering

The invention belongs to the technical field of a building material, and provides a window frame with a front window cover and a rear window cover and a window with the window frame. The window comprises a window frame and two pieces of curtain cloth, wherein the window frame comprises a front frame body and a rear frame body which are symmetrical with each other left and right, the front frame body is provided with a front support part and a front guide part, the rear frame body is provided with a rear support part and a rear guide part, the front support part is fixedly connected with the rear support part by a plastic stripe, the upper part of the front frame body is provided with the front window cover, the upper part of the rear frame body is provided with the rear window cover, and the two pieces of curtain cloth are respectively arranged on the front window cover and the rear window cover, the front window cover and the rear window cover are internally and respectively provided with a curtain cloth rolling mechanism, the front guide part and the rear guide part are internally and respectively provided with a rail which is internally provided with a guide rod, and two sides of the two pieces of curtain cloth are fixedly connected with skirts which are respectively sleeved on the corresponding guide rod and can move along with the guide rods. The window frame and the window have the advantages that the two pieces of curtain cloth are arranged on the front window cover and the rear window cover, the window frame and the window are convenient to install, economical and practical, and convenient to manufacture as the guide parts are integrated with the support parts.

Owner:NINGBO XIANFENG NEW MATERIAL

Close-contact ultrasonic coupling adaptive device for photoacoustic/thermoacoustic mammary gland imaging detection, and detection method of adaptive device

ActiveCN103549939BNo toxicityOvercome displacementUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationDEFLATE

Owner:SOUTH CHINA NORMAL UNIVERSITY

Window frame

ActiveCN102747925BGuaranteed smoothnessOvercome displacementInsect protectionWindow/door framesEngineeringBuilding material

Owner:NINGBO XIANFENG NEW MATERIAL

Injection molding machine screw extrusion rod structure

An injection molding machine screw extrusion rod structure is characterized by comprising a tube body and a hard fixed structure on the outer surface of the tube body, and the hard fixed structure is in overall or separate fixed connection with the tube body. The advantages are that when the outer layer is coated with a heat insulation material, a limiting structure fixes the heat insulation material external protective layer to effectively ensure that the soft heat insulation material and the tube body are not peeled and not squeezed and deformed. The injection molding machine screw extrusion rod structure has the advantages of simple structure, low design and manufacturing cost and wide market prospect. In a certain distance, annular or spiral artifacts and other accretion or additional links can be processed to enhance the pipeline friction to thrust and fix the pipeline.

Owner:张华君

Buoy fixing pier and preparation method thereof

ActiveCN108438148BExtended service lifeProportionally largeWaterborne vesselsBuoysStructural engineeringBuoy

The invention discloses a buoy fixing mound and a preparation method thereof. The buoy fixing mound comprises a mound body and an outer packaging layer. Multiple protrusions exposed out of the outer surface of the mound body are arranged on the outer surface of the mound body made of scrap iron in a melting and casting mode. The outer surface of the mound body is coated with the outer packaging layer made of ferronickel or ferrochromium duplex metal in a melting and casting mode. The outer packaging layer coats the protrusions exposed out of the outer surface of the mound body inside. The protrusions are screw-thread steel or protruding bags made of scrap iron in a melting and casting mode. The mound body on the inner layer and the ferronickel or ferrochromium outer packaging layer on theouter layer can be tightly attached together through the protrusions after being cast, are not layered and are free of gaps, and the practicability and the reliability of the product are enhanced. Thebuoy fixing mound has the beneficial effects that the buoy fixing mound can be stably arranged in the seabed of the water surface position, a buoy is prevented from being moved or lost, the size is small, the product cannot rust or rot forever, the service life is long, the mound body and the outer packaging layer are tightly attached together, are not layered and are free of gaps, the weight islarge, routing inspection cost and maintenance cost are saved, and the workload is reduced.

Owner:周国发

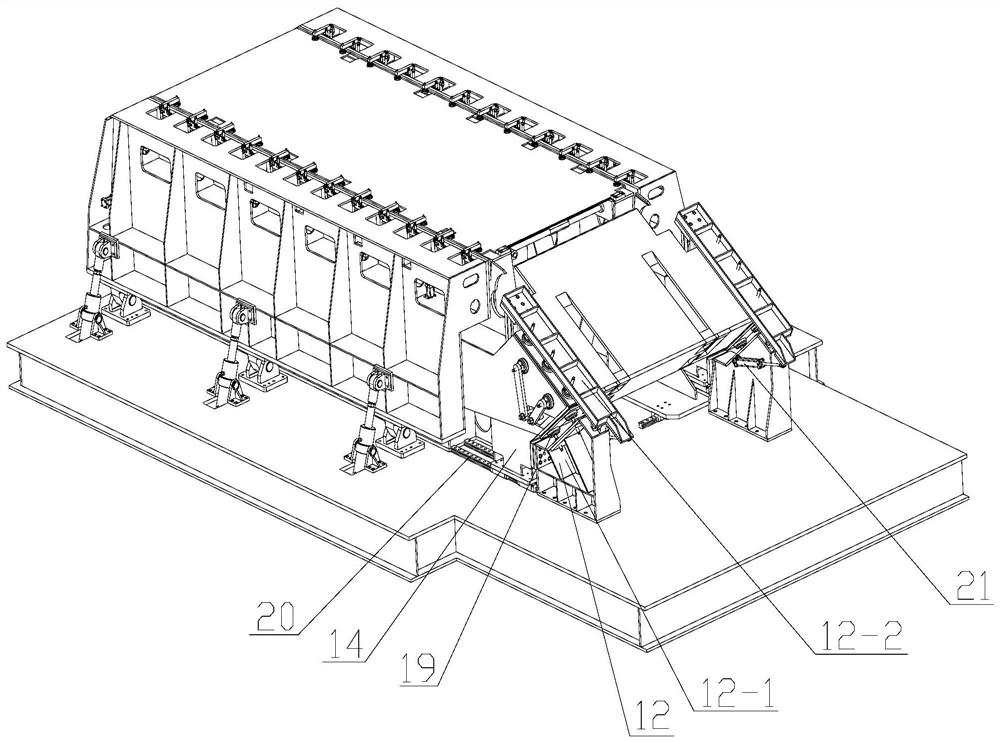

Welding tool for side lower plate and side flat plate of armored car

PendingCN113001010AHigh positioning accuracyOvercome the problem of easily causing workpiece displacementNon-electric welding apparatusMechanical engineeringFriction stir welding

The invention relates to the technical field of tool clamps, in particular to a welding tool for a side lower plate and a side flat plate of an armored car. The welding tool which is high in automation degree and good in welding quality under a friction stir welding method is provided, a vertical left clamping plate and a vertical right clamping plate are arranged on a tool bottom plate, an inner supporting frame moving left and right is arranged between the left clamping plate and the right clamping plate, the left side face of the inner supporting frame and the left clamping plate form a left side lower plate clamping space, the right side face of the inner supporting frame and the right clamping plate form a right side lower plate clamping space, the top face of the inner supporting frame is a bearing face for a left side flat plate or a right side flat plate, the left clamping plate is provided with a first oil cylinder pushing the inner supporting frame to move rightwards to clamp the right side lower plate, the right clamping plate is provided with a second oil cylinder pushing the inner supporting frame to move leftwards to clamp the left side lower plate, the top of the left clamping plate is provided with a third oil cylinder pressing a right side flat plate on the top face of the inner supporting frame rightwards and a fourth oil cylinder pressing downwards, and the top of the right clamping plate is provided with a fifth oil cylinder for leftwards pressing a left side flat plate on the top surface of the inner supporting frame and a sixth oil cylinder for downwards pressing.

Owner:江苏锐成机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com