Method to operate a combustor of a gas turbine

A technology of gas turbines and burners, applied in combustion methods, gas turbine devices, fuel control of turbine/propulsion devices, etc., to achieve the effect of avoiding high emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

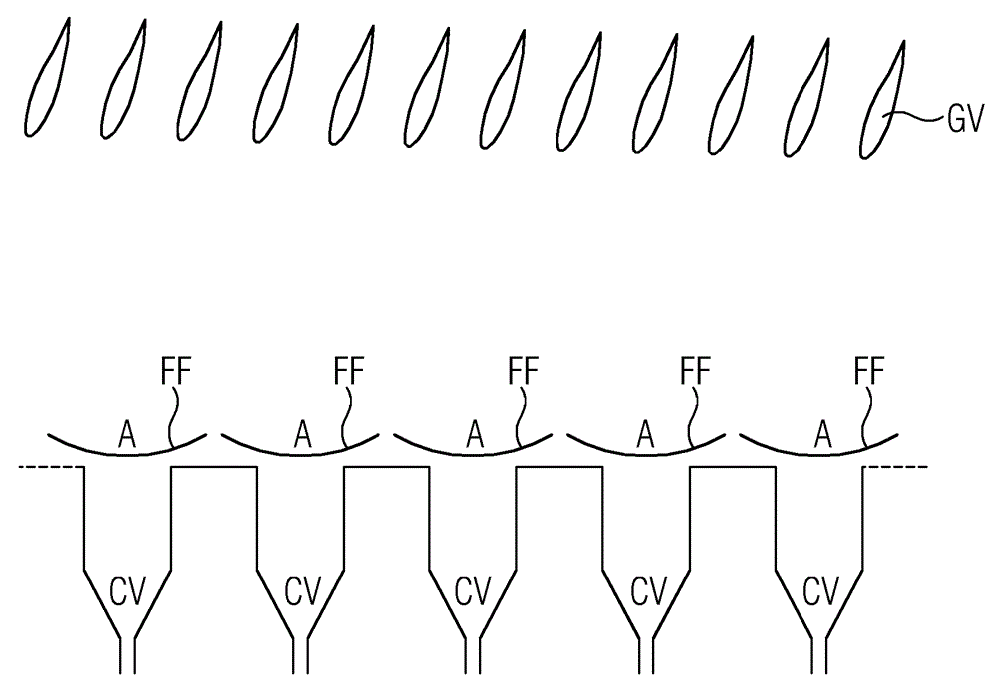

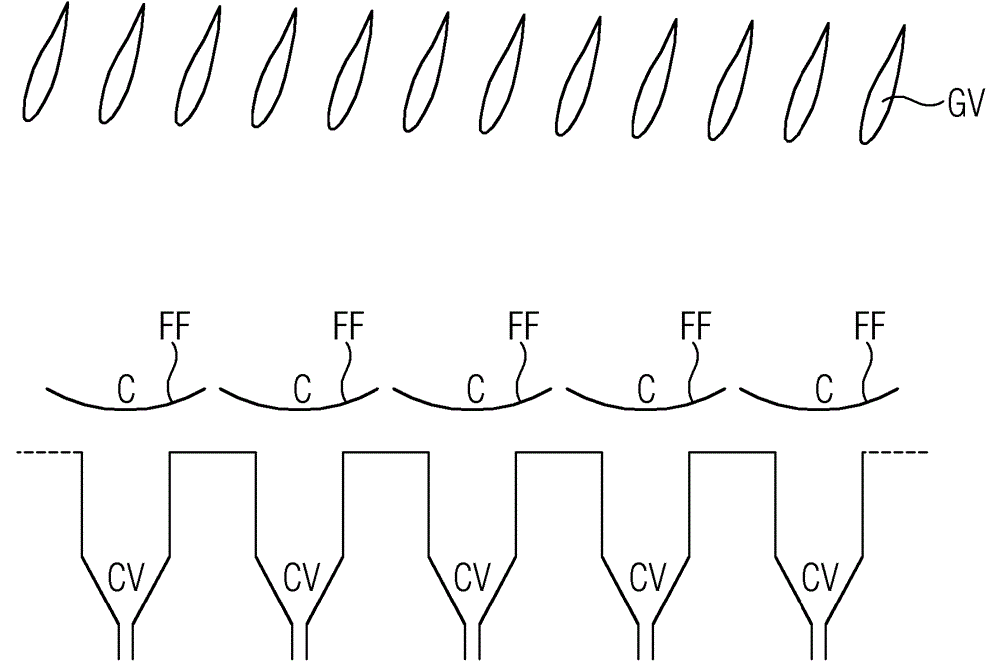

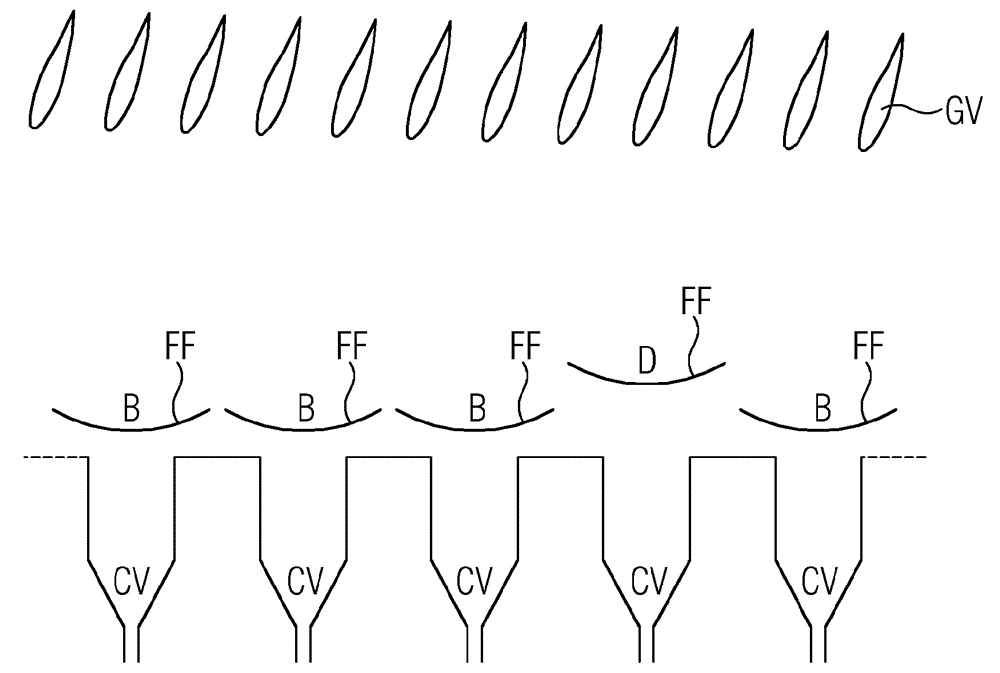

[0024] figure 1 A two-dimensional depiction of a gas turbine GT to be controlled by the method according to the invention is schematically shown. The basic elements of a gas turbine GT include a compressor CO, a combustor CB and a turbine TB. Said compressor CO compresses an oxygen-containing gas OCG, preferably air, and delivers it downstream to said burner CB to be mixed with gaseous fuel F and combusted by a plurality of burners B1 , B2 , . . . , Bn. The burners B1, . . . , Bn respectively receive fuel F through undepicted fuel lines, and inject the fuel F into In the first cavity CV of said corresponding burner B1, B2, . . . , Bn. The burners B1, B2, . . . , Bn also include swirlers SW. Said swirler SW is positioned circumferentially around said central axis CX and injects into said cavity CV oxygen-containing gas OSG optionally mixed with fuel F inclined to said central axis CX.

[0025] Downstream of the flow of the mixture of oxygen-containing gas OCG and fuel F, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com