Hot pressing method for preparing ceramic coating

A technology of ceramic coating and hot pressing method, which is applied in the field of preparation of ceramic coating, which can solve the problems of affecting the uniformity of the coating, the displacement of the coating substrate, and the displacement easily occurring on the surface parallel to the direction of the applied force. , to achieve the effects of improving various performances, overcoming friction, and improving the effect of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

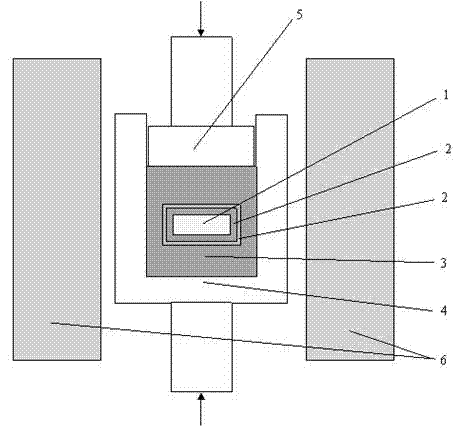

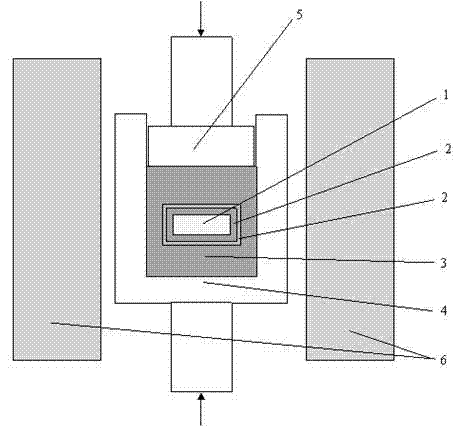

Image

Examples

Embodiment 1

[0025] Example 1. Al on the surface of cuboid sample 2 o 3 ceramic coating

[0026] Prepare 1mol / L Al(NO 3 ) 3 Aqueous solution, then add ammonia water dropwise to the solution and vigorously stir until the pH value of the solution is approximately equal to 10, and continue to stir with a magnetic stirrer for 2h to obtain Al 2 o 3 The colloidal solution is heated to evaporate the water to form a slurry. Coat this slurry on the surface of a cuboid 1Cr18Ni9Ti stainless steel with a size of 15×10×2, and bury it in 800-mesh Al 2 o 3 ·SiO2 2 In ceramic microbeads, apply 20MPa / cm 2 The pressure was kept at 90°C for 60 minutes, then raised to 400°C, held for 180 minutes, and then cooled to room temperature. The surface of the sample obtained a uniform and dense Al layer with a thickness of 20 μm. 2 o 3 Nano ceramic coating.

Embodiment 2

[0027] Example 2. ZrO on the surface of cube sample 2 ceramic coating

[0028] Prepare 1mol / L Zr(NO 3 ) 4 Aqueous solution, then add ammonia water dropwise to the solution and stir vigorously until the pH value of the solution is approximately equal to 10, and continue to stir with a magnetic stirrer for 2h to obtain ZrO 2 The colloidal solution is heated to evaporate the water to form a slurry. Coat this slurry on the surface of a cube 1Cr18Ni9Ti stainless steel with a size of 8×8×8, and bury it in 1250 mesh Al 2 o 3 ·SiO2 2 In ceramic microbeads, apply 20MPa / cm 2 The pressure was kept at 90°C for 60 minutes, then the temperature was raised to 400°C, held for 180 minutes, and then cooled to room temperature. The surface of the sample obtained uniform and dense ZrO with a thickness of 20 μm. 2 Nano ceramic coating.

Embodiment 3

[0029] Example 3. Al on the surface of a cylindrical sample 2 o 3 -Y 2 o 3 ceramic coating

[0030] Prepare an aqueous solution of 1mol / LAl(NO3)3+1wt%Y(NO3)3, then add ammonia water dropwise to the solution and stir vigorously until the pH value of the solution is approximately equal to 10, and continue stirring with a magnetic stirrer for 2h, then A colloidal solution of Al2O3-Y2O3 can be obtained, and the colloidal solution is heated to evaporate water to form a slurry. Coat this slurry on the surface of a cube 1Cr18Ni9Ti stainless steel with a size of 8×8×8, embed it in 1250-mesh Al2O3??SiO2 ceramic microbeads, apply a pressure of 20MPa / cm2, keep it at 90°C for 60 minutes, and then raise the temperature To 400 ℃, heat preservation for 180 minutes, and then cooled to room temperature, the surface of the sample obtained a uniform and dense Al2O3-Y2O3 nano-ceramic coating with a thickness of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com