Buoy fixing mound and preparation method thereof

A technology for fixing piers and buoys, which is applied to buoys, special-purpose ships, ships, etc., can solve the problems of high inspection costs and maintenance costs, heavy workload of staff, and complicated production processes, so as to save inspection costs and reduce costs. The effect of workload and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

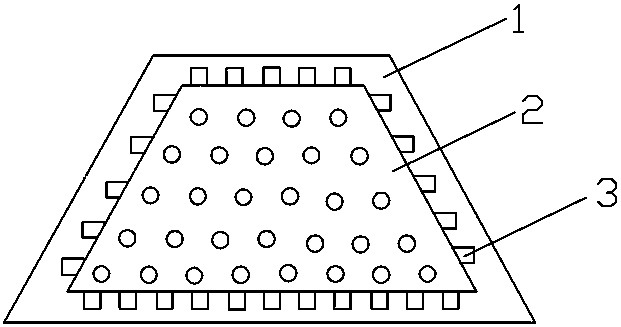

[0036] A nickel-clad iron buoy fixed pier, including a pier body 1 and an outer packaging layer 2, on the outer surface of the pier body 1 formed by melting and casting scrap iron, there are fifty protrusions exposed on the outer surface of the pier body 1 The outer surface of the pier body 1 is wrapped with an outer packaging layer 2 made of nickel-iron double metallization casting, and the outer packaging layer 2 wraps the protrusions 3 exposed on the outer surface of the pier body 1 therein.

[0037] The protrusion 3 is a rebar with a diameter of 6 mm, and the length of the rebar exposed on the outer surface of the pier is 12 mm.

[0038] The thickness of the outer packaging layer is 20 mm. The shapes of the pier body and the outer packaging layer are both square trusses.

[0039] A method for preparing a nickel-clad iron buoy fixed pier, the specific steps are as follows:

[0040] A. Make the pier mold first, and fix fifty pieces of rebar with a diameter of 6 mm on each ...

Embodiment 2

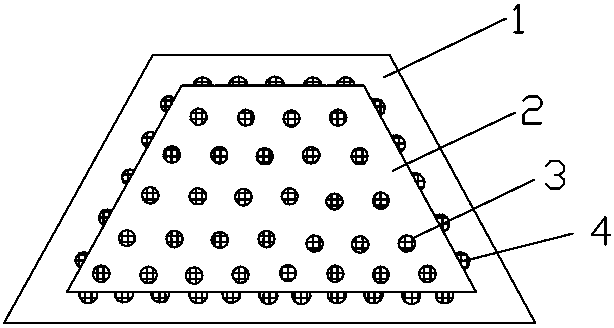

[0045] A nickel-clad iron buoy fixed pier, including a pier body 1 and an outer packaging layer 2, and ten protrusions exposed on the outer surface of the pier body 1 are arranged on the outer surface of the pier body 1 formed by melting and casting scrap iron 3. The outer surface of the pier body 1 is wrapped with an outer packaging layer 2 made of nickel-iron double metallization casting, and the outer packaging layer 2 wraps the protrusions 3 exposed on the outer surface of the pier body 1 .

[0046] The protrusion 3 is a rebar with a diameter of 26 mm, and the length of the rebar exposed on the outer surface of the pier is 30 mm.

[0047] The thickness of the outer wrapping layer is 40 mm. The shapes of the pier body and the outer packaging layer are both circular frustums.

[0048]A method for preparing a nickel-clad iron buoy fixed pier, the specific steps are as follows:

[0049] A. Make the pier mold first, and fix ten pieces of rebar with a diameter of 26 mm on each...

Embodiment 3

[0054] A nickel-clad iron buoy fixed pier, including a pier body 1 and an outer packaging layer 2, on the outer surface of the pier body 1 formed by melting and casting scrap iron, there are thirty protrusions exposed on the outer surface of the pier body 1 The outer surface of the pier body 1 is wrapped with an outer packaging layer 2 made of nickel-iron double metallization casting, and the outer packaging layer 2 wraps the protrusions 3 exposed on the outer surface of the pier body 1 therein.

[0055] The protrusion 3 is a rebar with a diameter of 16 mm, and the length of the rebar exposed on the outer surface of the pier is 15 mm.

[0056] The thickness of the outer wrapping layer is 30 mm. The shapes of the pier body and the outer packaging layer are both cubes.

[0057] A method for preparing a nickel-clad iron buoy fixed pier, the specific steps are as follows:

[0058] A. Make the pier body mold first, and fix 30 rebars with a diameter of 16 mm on each face of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com