Six-meter super-long optical fiber preform bar and manufacturing process

A technology of optical fiber preform and manufacturing process, which is applied in the field of optical fiber production and processing, can solve the problems of difficult control of connection node quality, poor product quality stability, low drawing production efficiency, etc., to overcome the phenomenon of displacement and slide, and improve product quality stability Good performance, controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

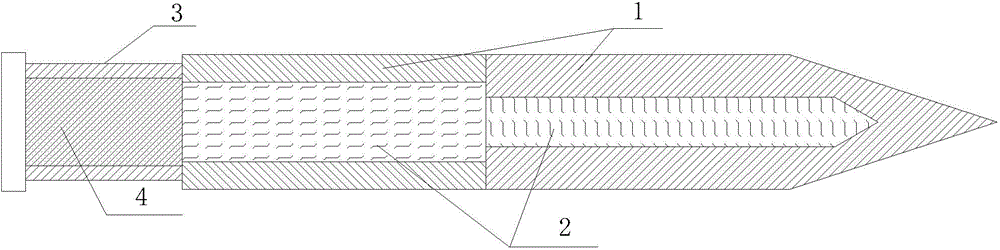

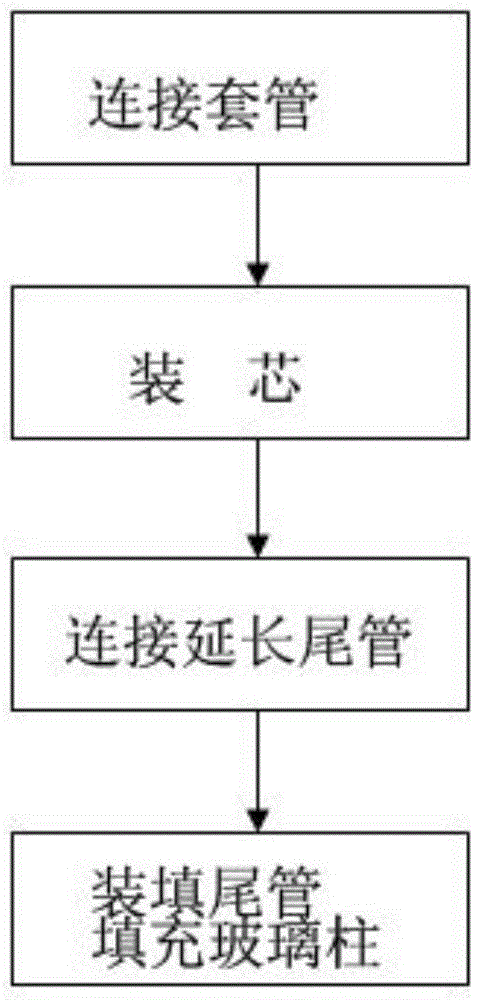

[0024] Such as figure 2 A manufacturing process of a 6-meter ultra-long optical fiber preform shown includes the following steps:

[0025] The first step is to connect the casing, choose two lengths of 3 meters, the outer diameter is 200mm, and the inner diameter of the front casing of the two casings is 49mm, and the rear casing is 52mm, and then the casing is placed in the horizontal working On the table and positioned by the fixture, so that the axes of the two casings are in the same straight line direction, then use a blowtorch to weld the contact surface of the two casings, and smooth the welding surface with graphite at the welding place of the two casings at the same time ;

[0026] The second step is to install the core. After the casing is connected and cooled, the casing and mandrel are cleaned in hydrofluoric acid for 30 minutes and dried for 3 hours, and then the two mandrels are placed inside the casing in turn. And through the positioning fixture, the mandrel...

Embodiment 2

[0033] Such as figure 2 A manufacturing process of a 6-meter ultra-long optical fiber preform shown includes the following steps:

[0034] The first step is to connect the sleeves, choose 3 lengths of 2 meters, the outer diameter is 200mm, and the inner diameter of the front sleeve of the two sleeves is 55 mm, and the rear sleeve is 60 mm, and then the sleeves are placed in the horizontal working On the table and positioned by the fixture, so that the axes of the two casings are in the same straight line direction, then use a blowtorch to weld the contact surface of the two casings, and smooth the welding surface with graphite at the welding place of the two casings at the same time ;

[0035] The second step is to install the core. After the casing is connected and cooled, the casing and mandrel are cleaned in hydrofluoric acid for 40 minutes and dried for 4 hours, and then the two mandrels are placed inside the casing in turn. And the mandrel is coaxially distributed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com