Injection molding machine screw extrusion rod structure

A technology of screw extrusion and rod structure, applied in the field of pipe structure, can solve the problems of difficult control of axial deformation, cumbersome operation, high cost, etc., and achieve the effect of low design and manufacturing cost, broad market prospect, and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

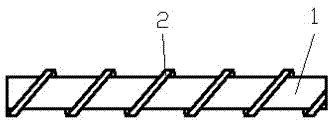

[0019] This embodiment provides a screw extrusion rod structure for an injection molding machine, which is characterized in that: the screw extrusion rod structure for an injection molding machine includes a tube body 1 and a hard fixing structure 2 on the outer surface of the tube, and the hard fixing structure 2 is connected to the outer surface of the tube. The pipe body 1 is an integral structure.

[0020] The fixing structure 2 is helically wound on the outer surface of the pipe body 1 .

[0021] The structure of the screw extruded rod of the injection molding machine according to the invention is mainly embodied in the pipe material of non-metallic material, and can be used for burying the ground. It can control the axial deformation of the pipe after being cooled and heated to a certain extent, and can solve a lot of practical problems in engineering; when wrapping the outer layer of insulation material, the fixed structure 2 can effectively ensure that the softer insul...

Embodiment 2

[0024] This embodiment provides a screw extrusion rod structure for an injection molding machine, which is characterized in that: the screw extrusion rod structure for an injection molding machine includes a tube body 1 and a hard fixing structure 2 on the outer surface of the tube, and the hard fixing structure 2 is connected to the outer surface of the tube. The pipe body 1 is an integral structure.

[0025] The fixing structure 2 is ring-shaped and arranged equidistantly on the outer surface of the pipe body 1 .

[0026] The screw extrusion rod structure of the injection molding machine of the present invention is mainly embodied in the pipe material of non-metallic material, and can be used above ground and underground. It can effectively ensure the compressive strength of the pipe, and can control the axial deformation of the pipe after being cooled and heated to a certain extent, which solves the requirements in the specification; when the outer layer is wrapped with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com