A high-vacuum shut-off fan

A technology of closing the fan and high vacuum, applied in the direction of conveyor, conveying bulk materials, transportation and packaging, etc., can solve the problems of weakened sealing ability, failure to achieve sealing effect, stuck high-vacuum fan, etc., to prevent adhesion , Improve surface finish, good machining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

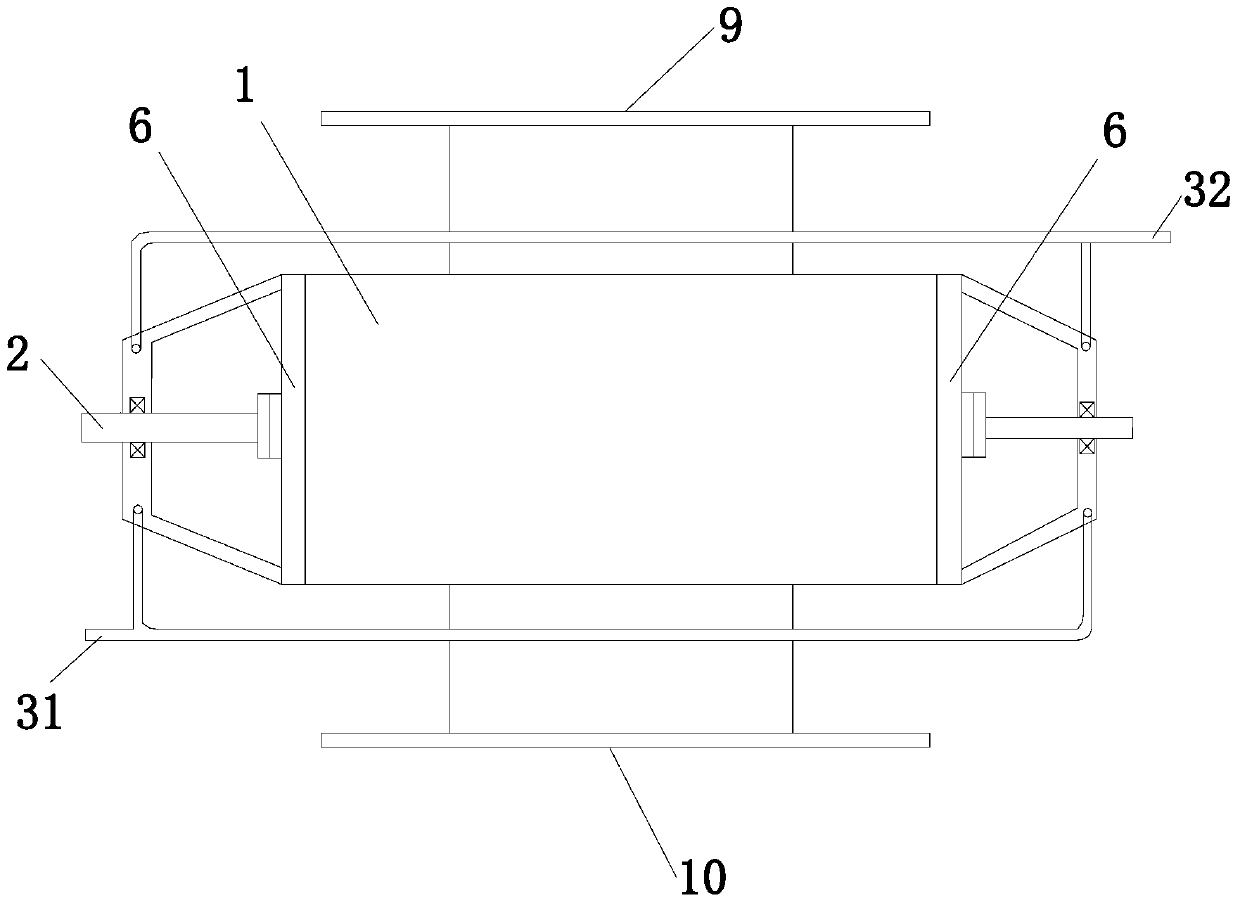

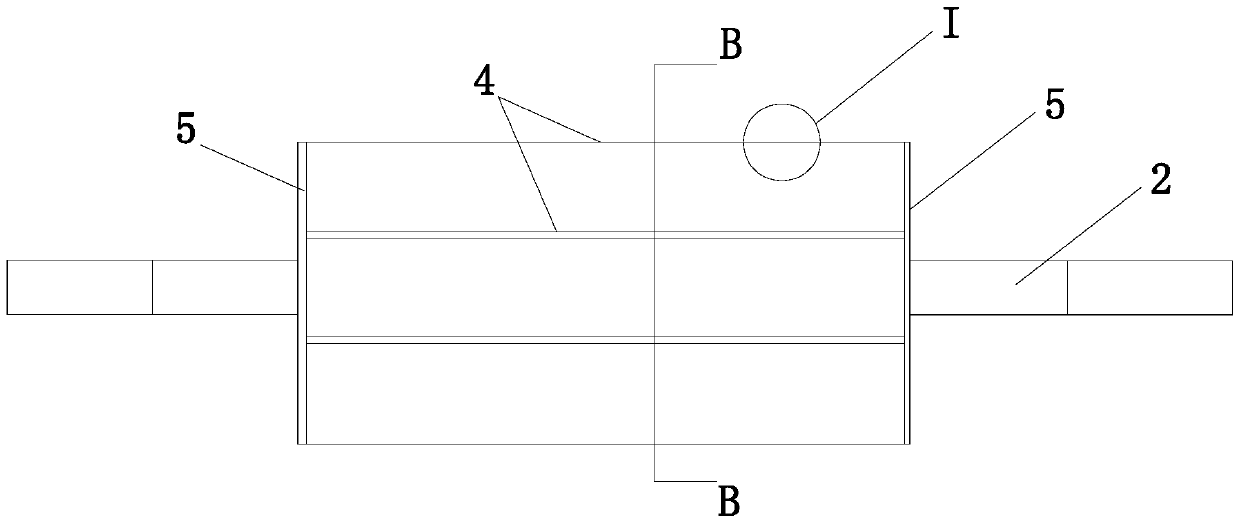

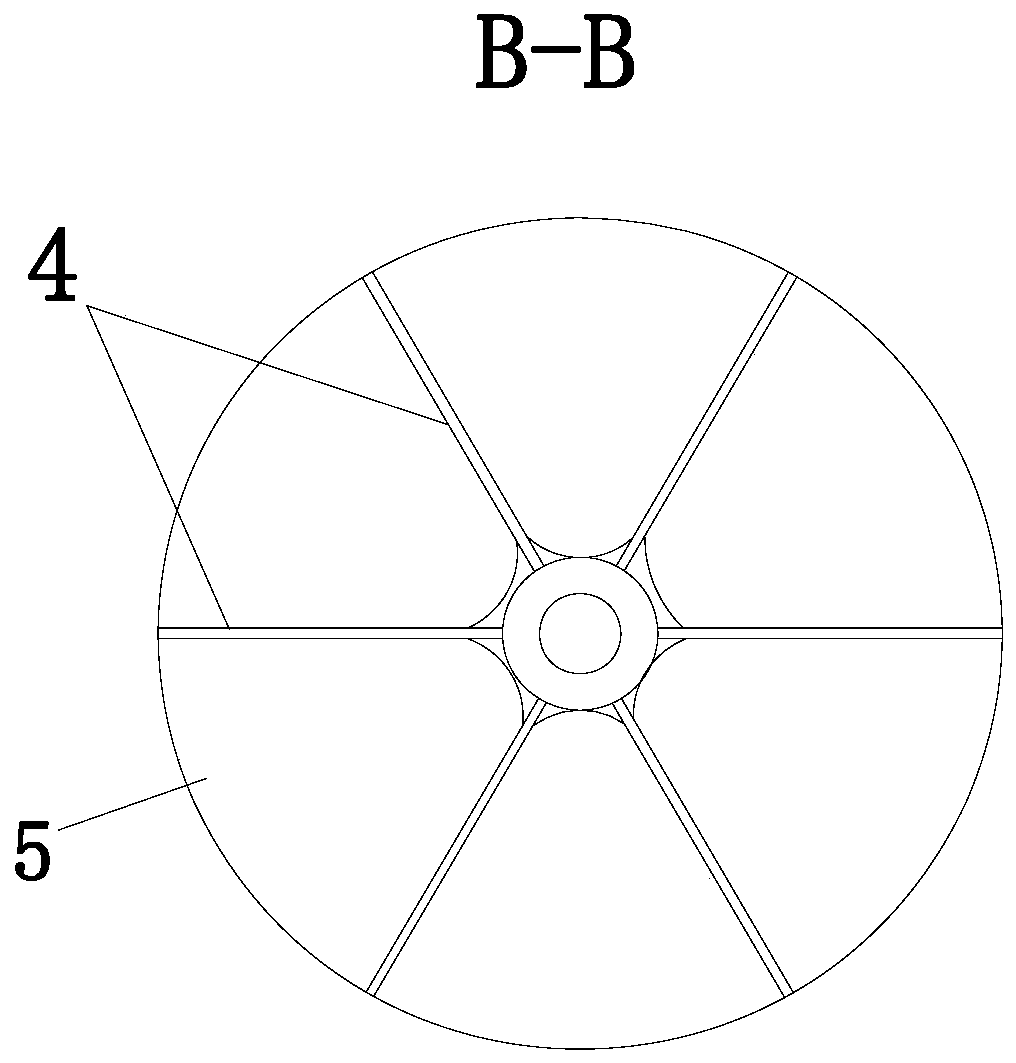

[0023] The air-to-high vacuum type shut-off fan of this embodiment includes: a cylindrical hollow housing 1 with an inner wall layer, the rotating shaft 2 runs through the housing 1 and the bearings are fitted on the end covers 6 on the left and right sides of the housing 1, the housing 1, and radially distributed on the rotating shaft 2, there are a plurality of wind-shielding plates 4, and the left and right ends of each wind-shielding plate 4 are respectively connected on a disc-shaped end plate 5, and the surroundings of the end plate 5, the The outer edge of the wind plate 4 is provided with a sealing strip that is sealingly matched with the inner wall of the housing 1 . The sealing strip includes: graphite: 20wt%; carbon fiber: 10wt%; PTFE: balance. Or, the sealing strip includes: 3-10wt% graphene, PTFE melts and wraps graphene under normal pressure and 330-340°C (the preferred solution is: graphene has multiple layers, and the phases are arranged in parallel and covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com