Water Assisted Toilet Plunger

a technology of assisted toilets and plungers, which is applied in water installations, domestic plumbing, construction, etc., can solve the problems of the shut-off valve moving away from the seat, and achieve the effect of quick and simple improvemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

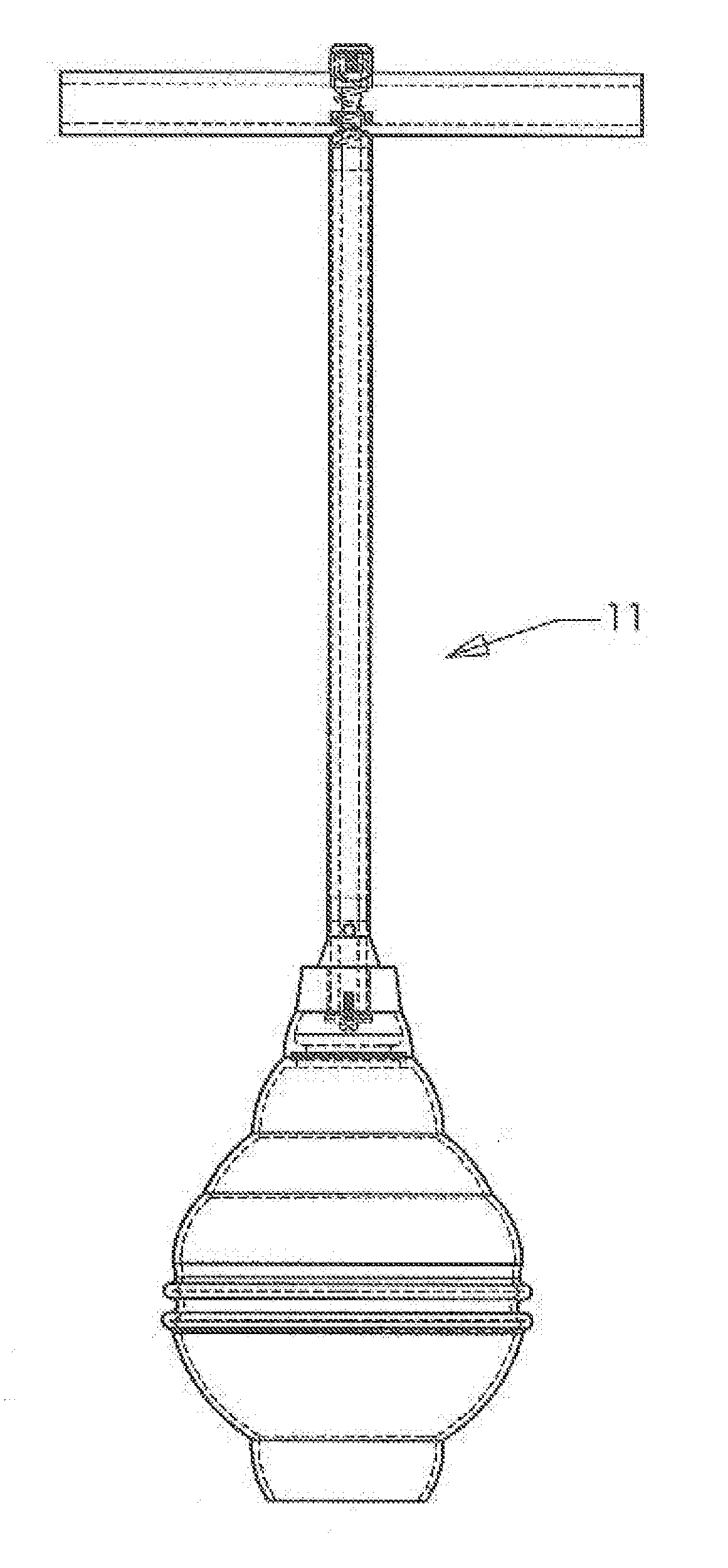

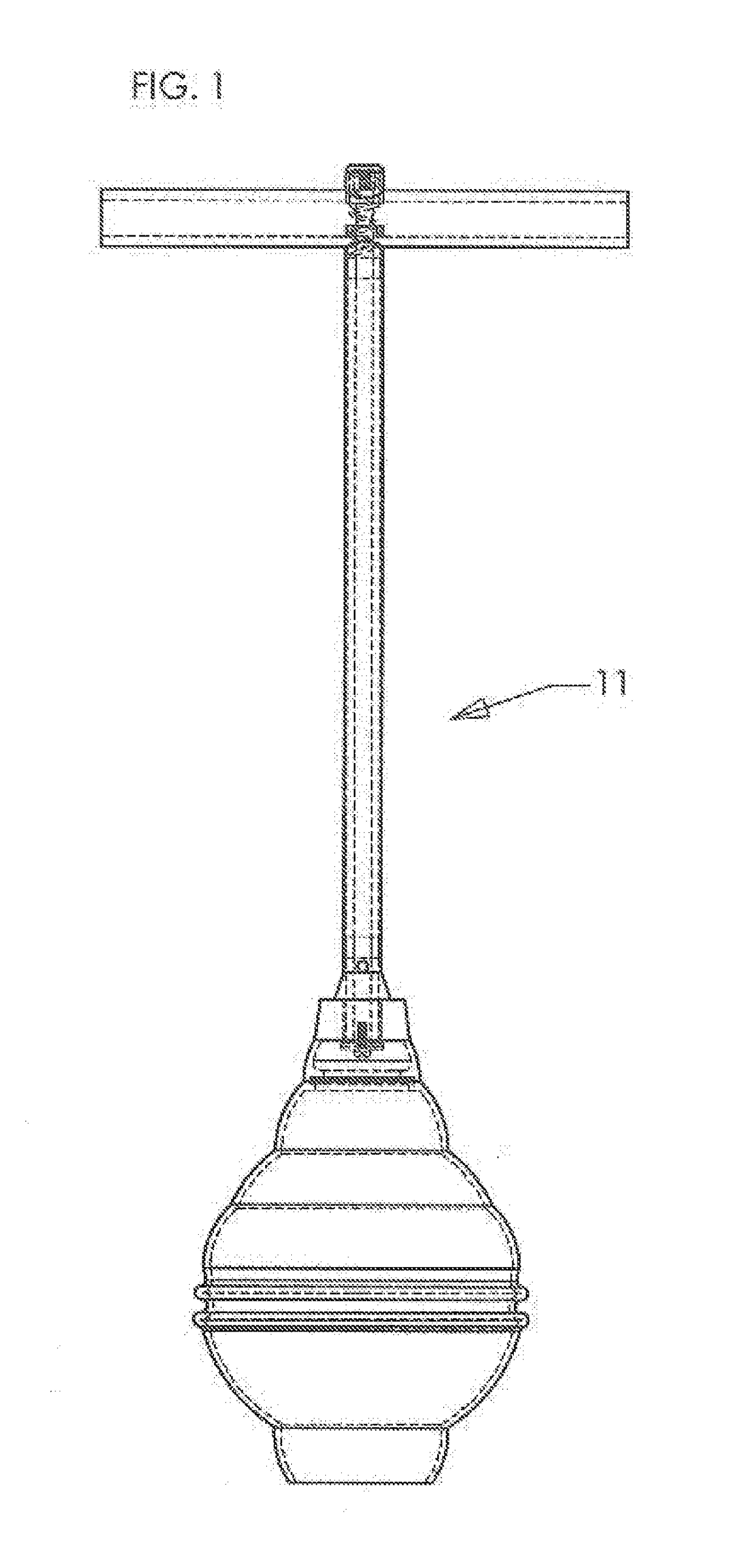

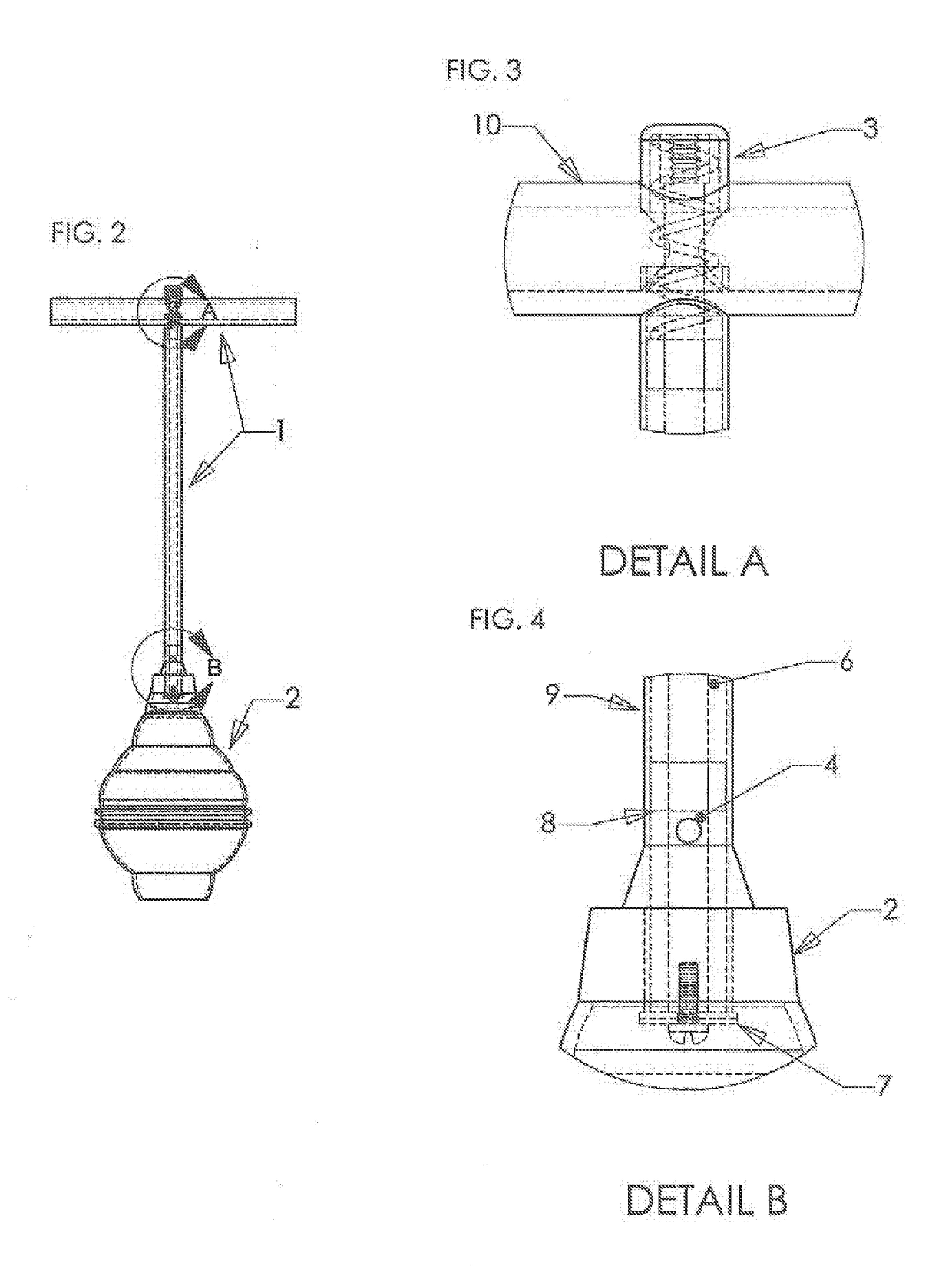

[0016]Referencing the drawings, in particular, FIGS. 2 through 8, an improvement to a typical / conventional toilet plunger (such plunger designed generally by the reference numeral 11 (in the drawings), is embodied in the concepts and principles of an embodiment of the disclosure, and will be described.

[0017]FIG. 2 illustrates a typical / conventional toilet plunger 11 with a handle / shaft assembly 1 and in this representation, a bellows 2, attached to the handle / shaft assembly 1. FIG. 2 also shows the two principle areas circled where the improvement is located: at the handle 10 and the opposite end of the hollow shaft 9 from the handle 10. FIG. 3 shows a depressible button 3 protruding out the top of a concentric hole in the handle 10. FIG. 4 shows the vent 4, two circular holes in the shaft 9, directly across from each other, located below the lower of two bearings 8 attached to the inside diameter of the hollow shaft 9 as the plunger 11 is situated in a vertical position as is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com