Contact probe and inspection jig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

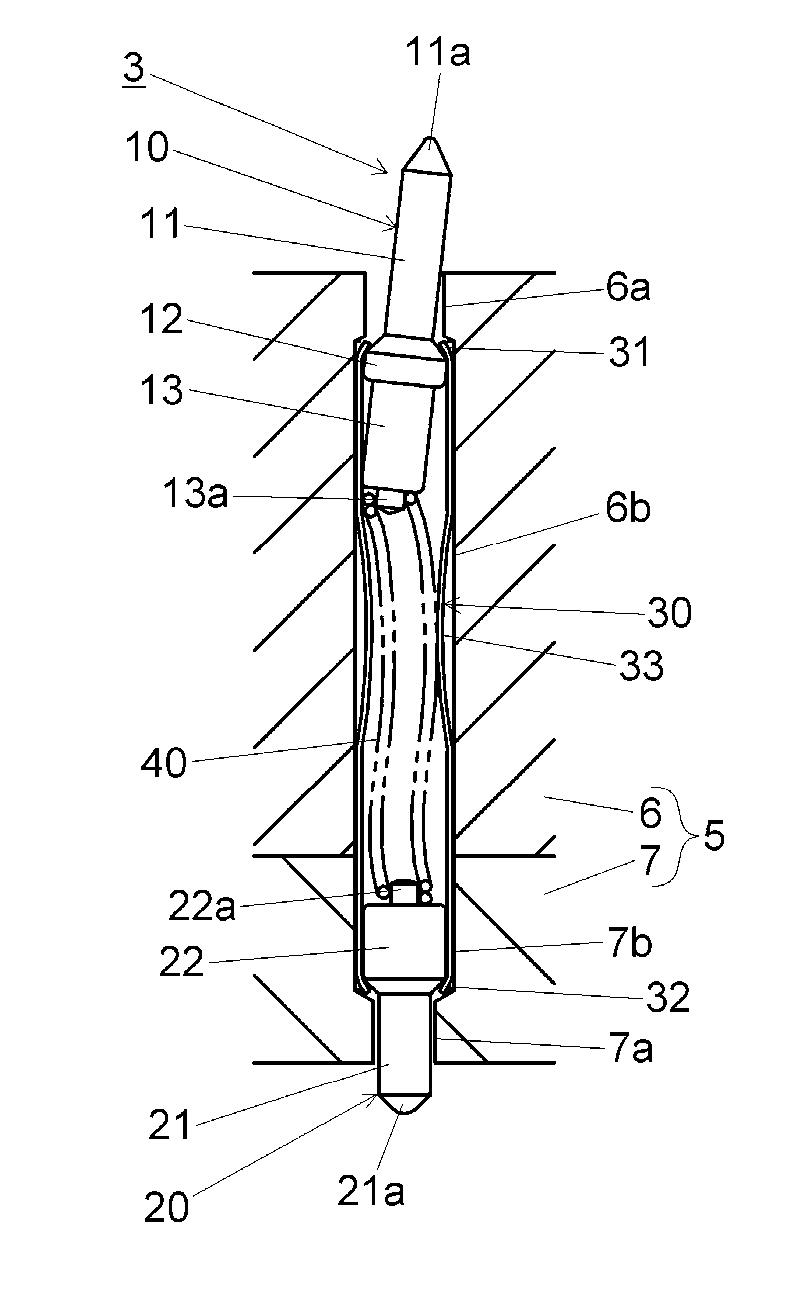

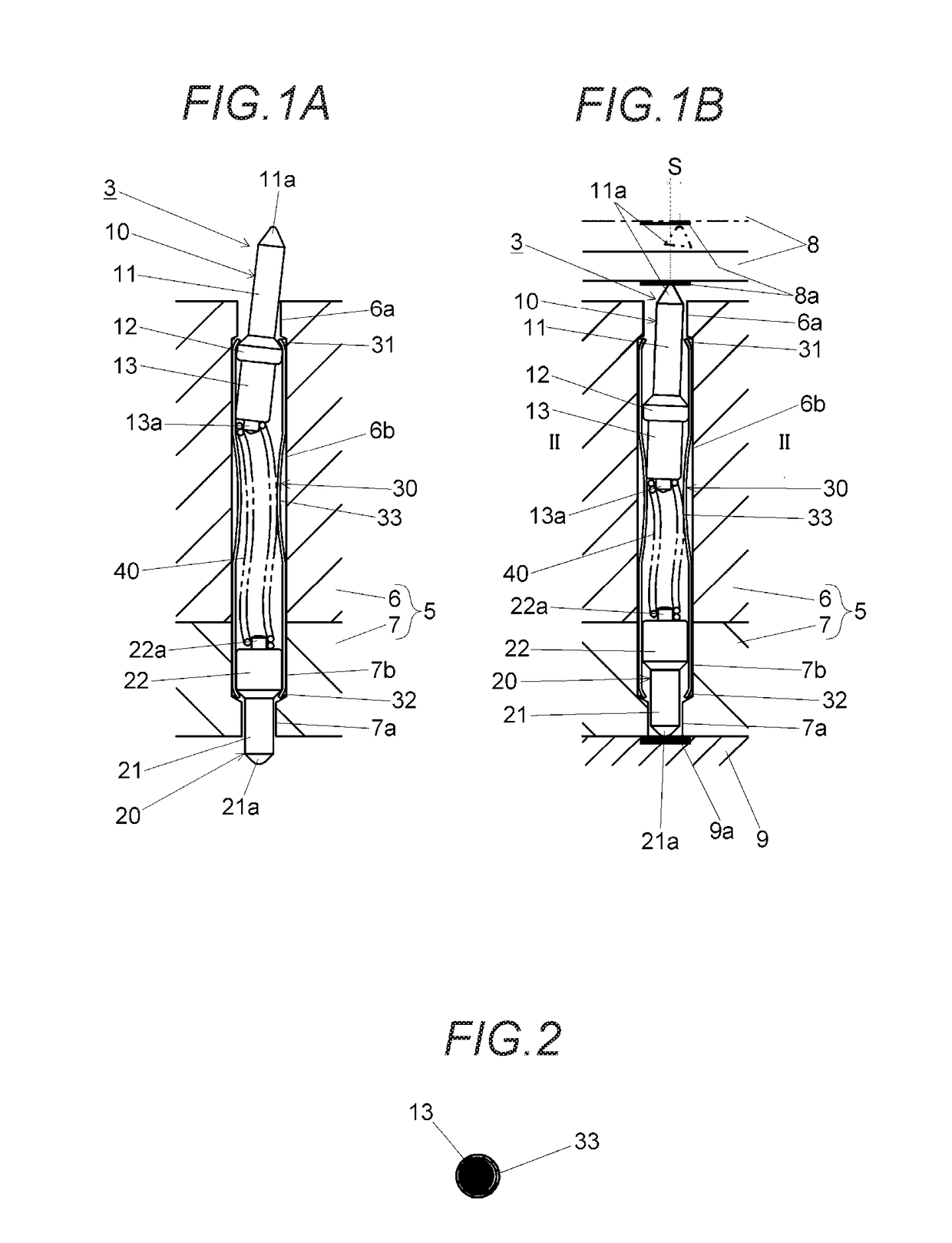

[0025]FIG. 1A is a sectional view of an inspection jig 1A according to a first embodiment, and FIG. 1B is a sectional view showing how an inspection is conducted using the inspection jig 1A. The inspection jig 1A is equipped with a contact probe 3 and an electrically insulative socket 5 which holds the contact probe 3 penetrating through it. Although in the illustrated example only one contact probe 3 is supported by the socket 5, plural contact probes 3 may be supported by the socket 5. The socket 5 is formed by combining a first socket 6 and a second socket 7 together and screwing them on each other into an integral body. A small-diameter hole 6a and a large-diameter hole 6b of the first socket 6 and a small-diameter hole 7a and a large-diameter hole 7b of the second socket 7 constitute a through-hole in which the contact probe 3 is set.

[0026]The contact probe 3 has a first plunger 10, a second plunger 20, a tube 30, and a spring 40. The first plunger 10 is a component for connect...

embodiment 2

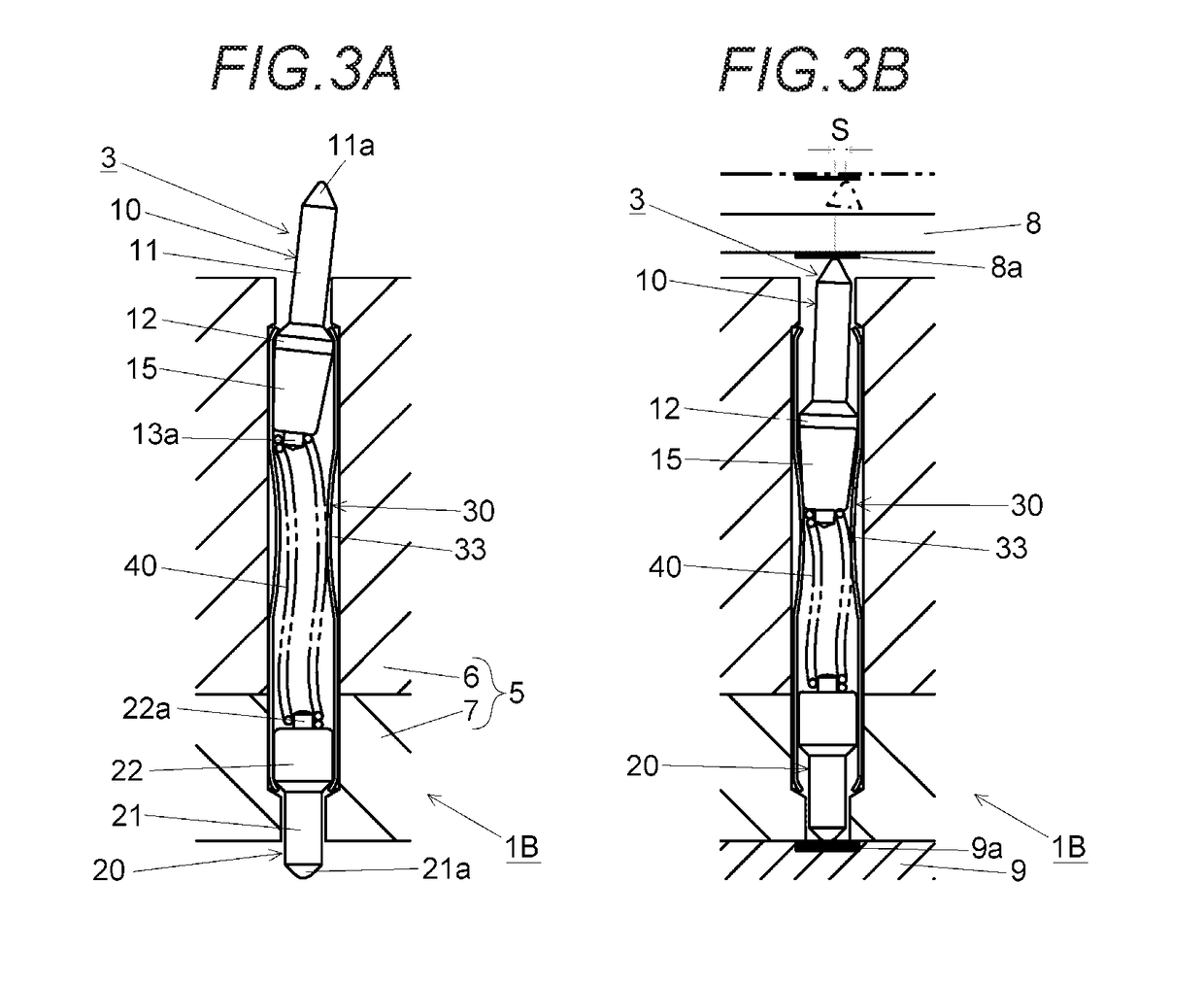

[0050]FIG. 3A is a sectional view of an inspection jig 1B according to a second embodiment.FIG. 3B is a sectional view showing how an inspection is conducted using the inspection jig 1B. The inspection jig 1B according to this embodiment is the same as the inspection jig 1A according to the first embodiment except that the base-side cylinder portion 13 of the first plunger 10 is replaced by a base-side truncated-cone portion 15. The outer circumferential surface of the base-side truncated-cone portion 15 is part of the side surface of a cone, and hence its outer diameter decreases as the position goes from the side of the flange portion 12 to the side of the spring 40. The outer diameter of the end of the base-side truncated-cone portion 15 on the side of the flange portion 12 is the same as that of the flange portion 12. This embodiment would provide the same advantages as the first embodiment.

embodiment 3

[0051]FIG. 4A is a sectional view of an inspection jig 1C according to a third embodiment. FIG. 4B is a sectional view showing how an inspection is conducted using the inspection jig 1C. The inspection jig 1C according to this embodiment is the same as the inspection jig 1A according to the first embodiment except that the projection 13a formed on the base surface of the base-side cylinder portion 13 of the first plunger 10 is absent and the base surface (slant surface 13b) is inclined with respect to the longitudinal direction of the first plunger 10 and that the two end surfaces of the spring 40 being in a free state are flat surfaces that are perpendicular to the longitudinal direction of the spring 40. This embodiment would provide the same advantages as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap