Sensor and method for identifying a mechanical deformation of a housing of a charging column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

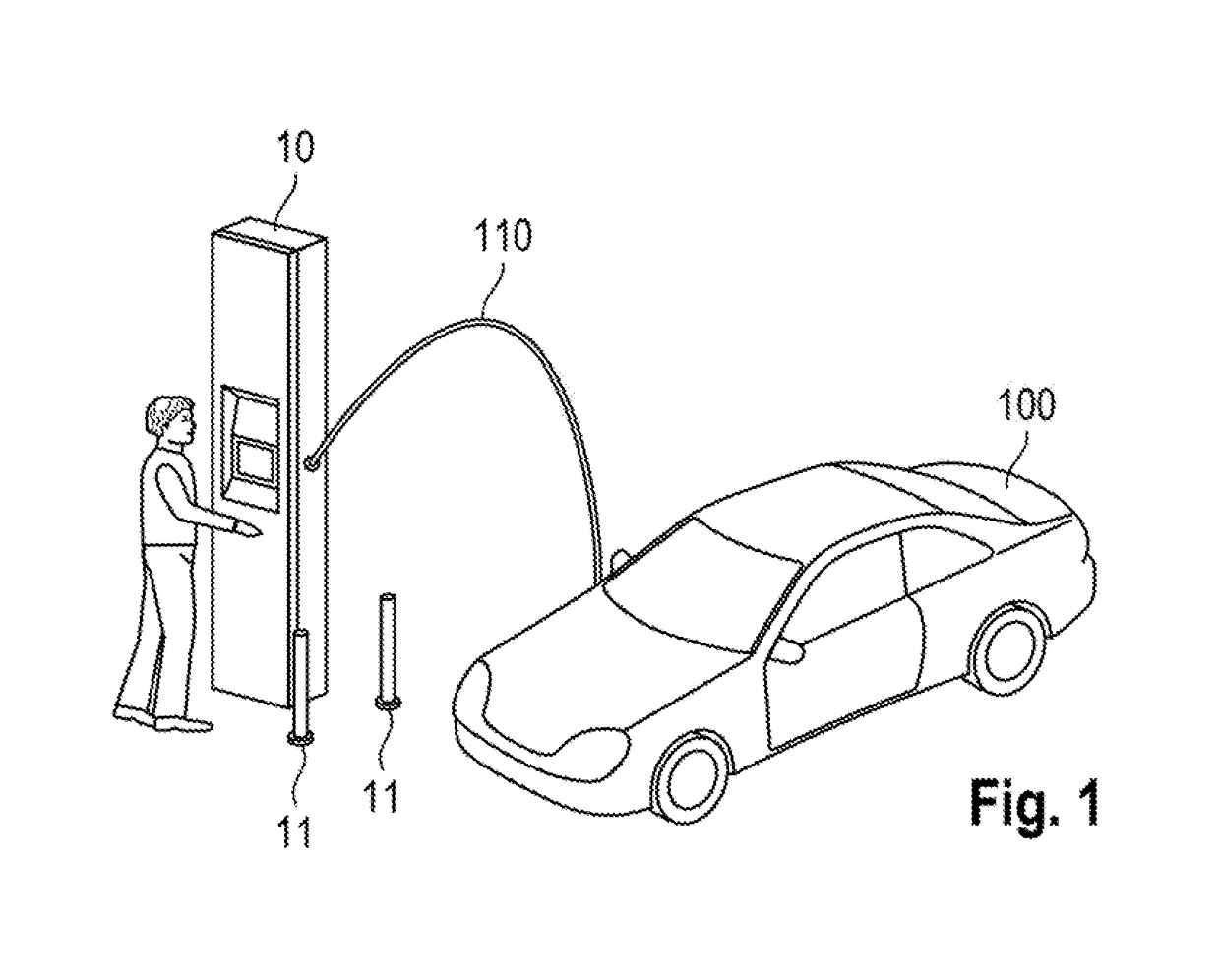

[0037]FIG. 1 shows an electric vehicle 100, which is connected to a charging column 10 by a charging cable 110. In the case of an extensive installation of charging columns 10, it should be assumed that, on the one hand, the charging columns will no longer have in each case a canopy, like in conventional filling stations and, further, a plurality of said charging columns are generally installed in charging parks, which are intended to be freely accessible for the respective vehicles to be charged. As a result, the charging columns 10, the charging cable 110 and the electric vehicle 100 are always located in the open, where they are exposed to all conceivable external influences. Since it is sought, at the same time, to enhance vehicles to enable higher charging speeds from the previous 400 V to 800 V, charging columns, in particular fast DC charging columns, which use voltages of up to 1000 V are provided. On account of the high voltage, a higher power can be transmitted at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com