Backlight module and method for assembling the same, and display device

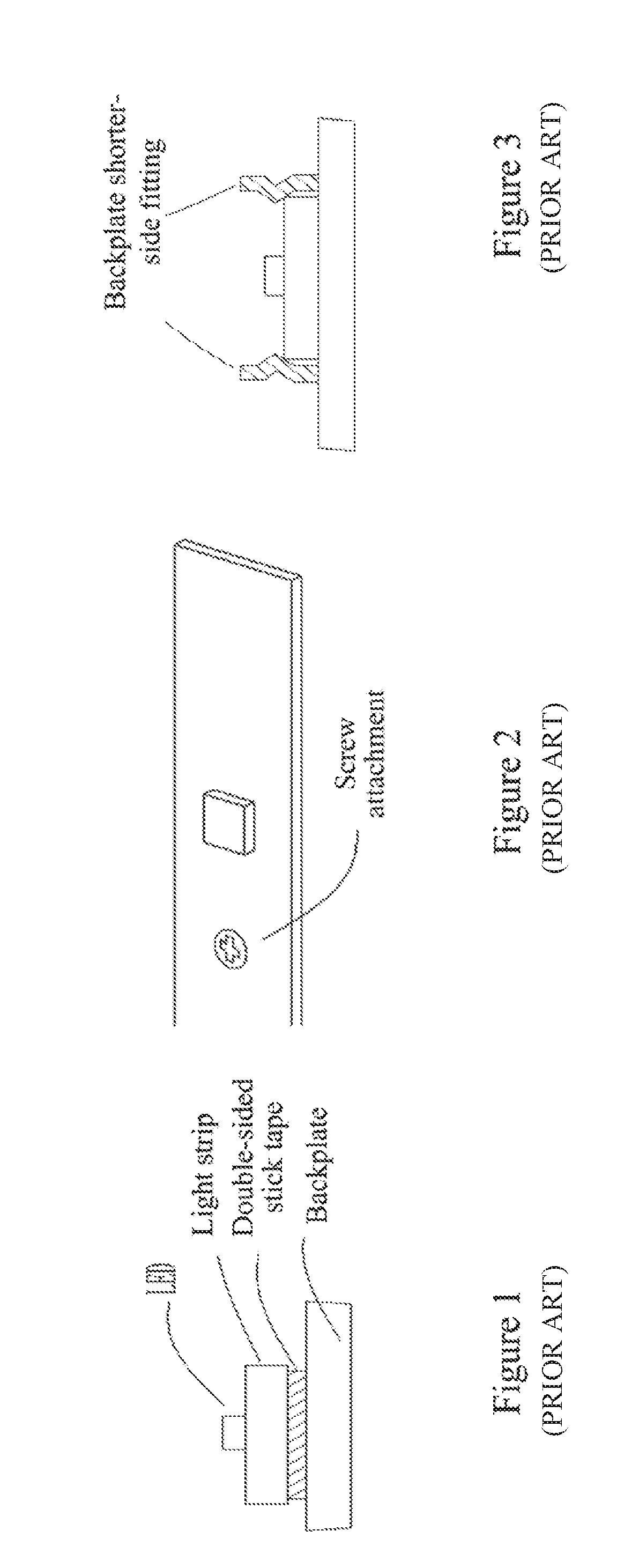

a backlight module and display device technology, applied in non-linear optics, instruments, optics, etc., can solve the problems of difficult fundamentally solving, high cost of working hours, and prone to iron dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

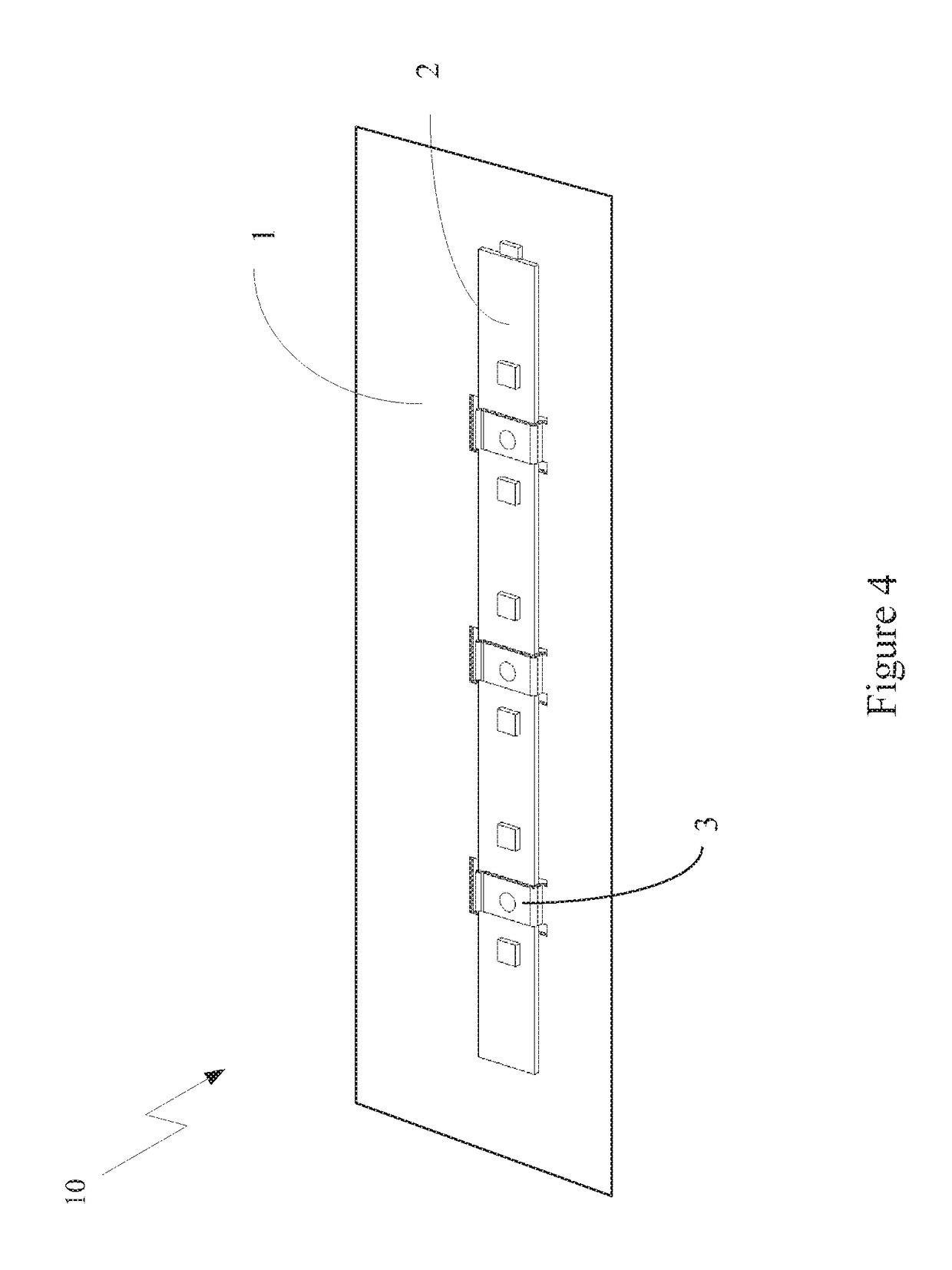

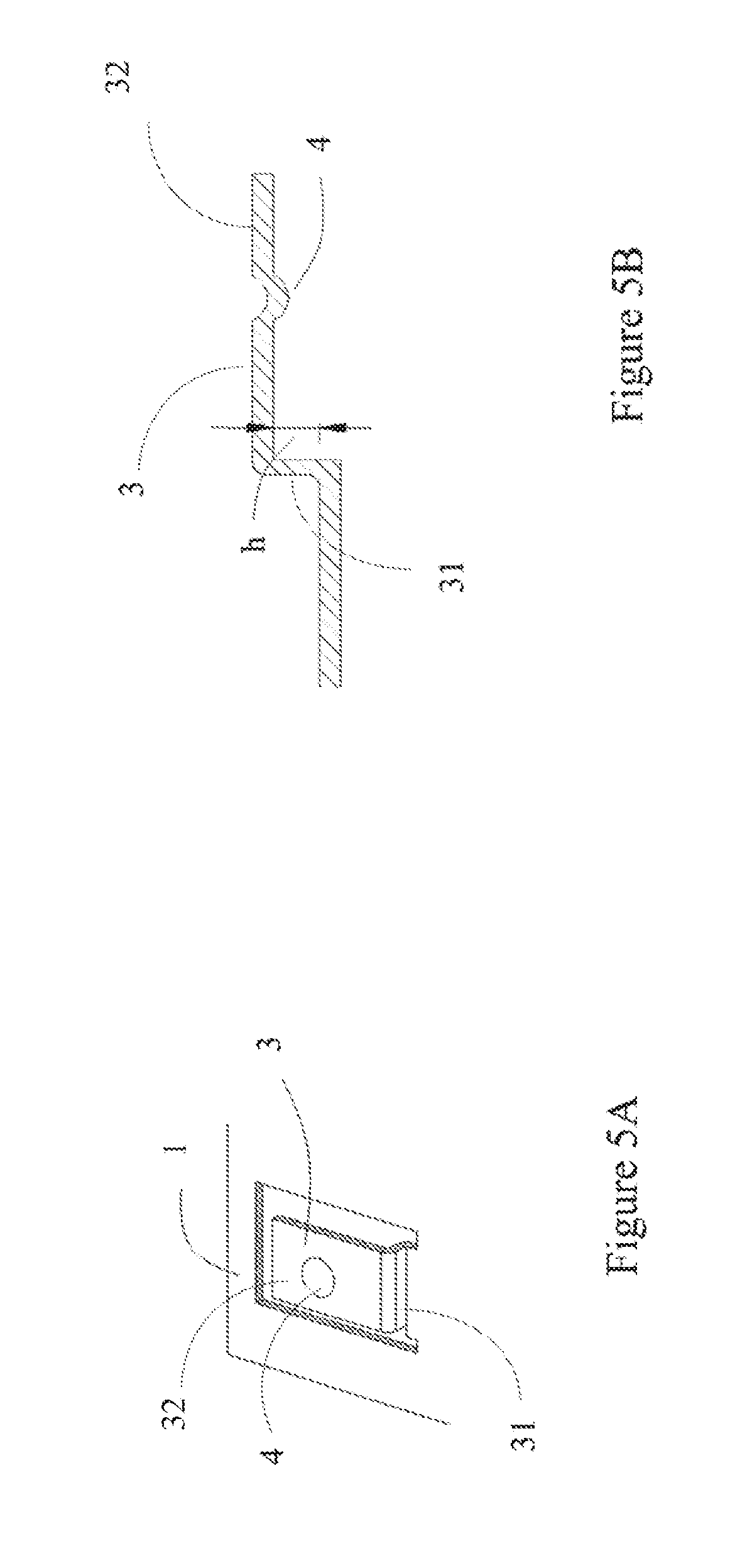

[0021]The technical solution of the present disclosure provides an effective fixing method for the light strip and the backplate, and has the advantages of simple structure, convenient assembling, convenient re-work, low material and labor cost, overcoming deformation of the light strip, material waste, assembly and re-work inconvenience, high labor costs and other shortcomings of the prior art.

[0022]In order to provide a better understanding of the solution of the present disclosure to those skilled in the art, a backlight module and a method for assembling the same, and a display device according to embodiments of the present disclosure will now be described in greater detail with reference to the accompanying drawings and specific embodiments of the present disclosure. It is obvious that the described embodiments are part of the present application, not all embodiments. All other embodiments obtained based on the described embodiments of the present disclosure by one of ordinary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com