Recording apparatus and recording method

a recording apparatus and recording method technology, applied in electrical equipment, printing, pictoral communication, etc., can solve the problems of image quality decline etc., to reduce granular impression, image quality decline, and image quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

[0035]Hereinafter, a first exemplary embodiment of the present invention will be described in detail with reference to the drawings.

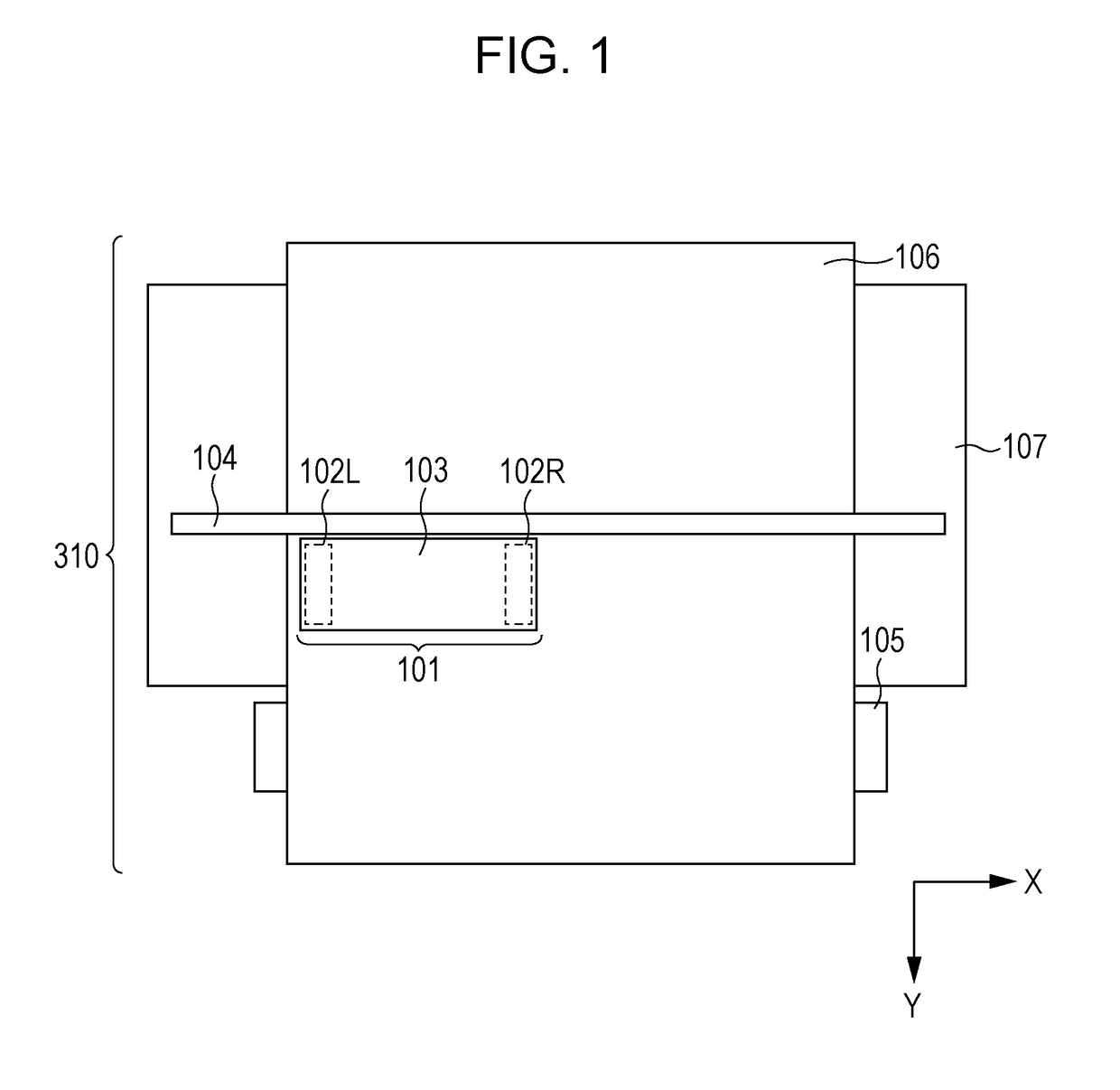

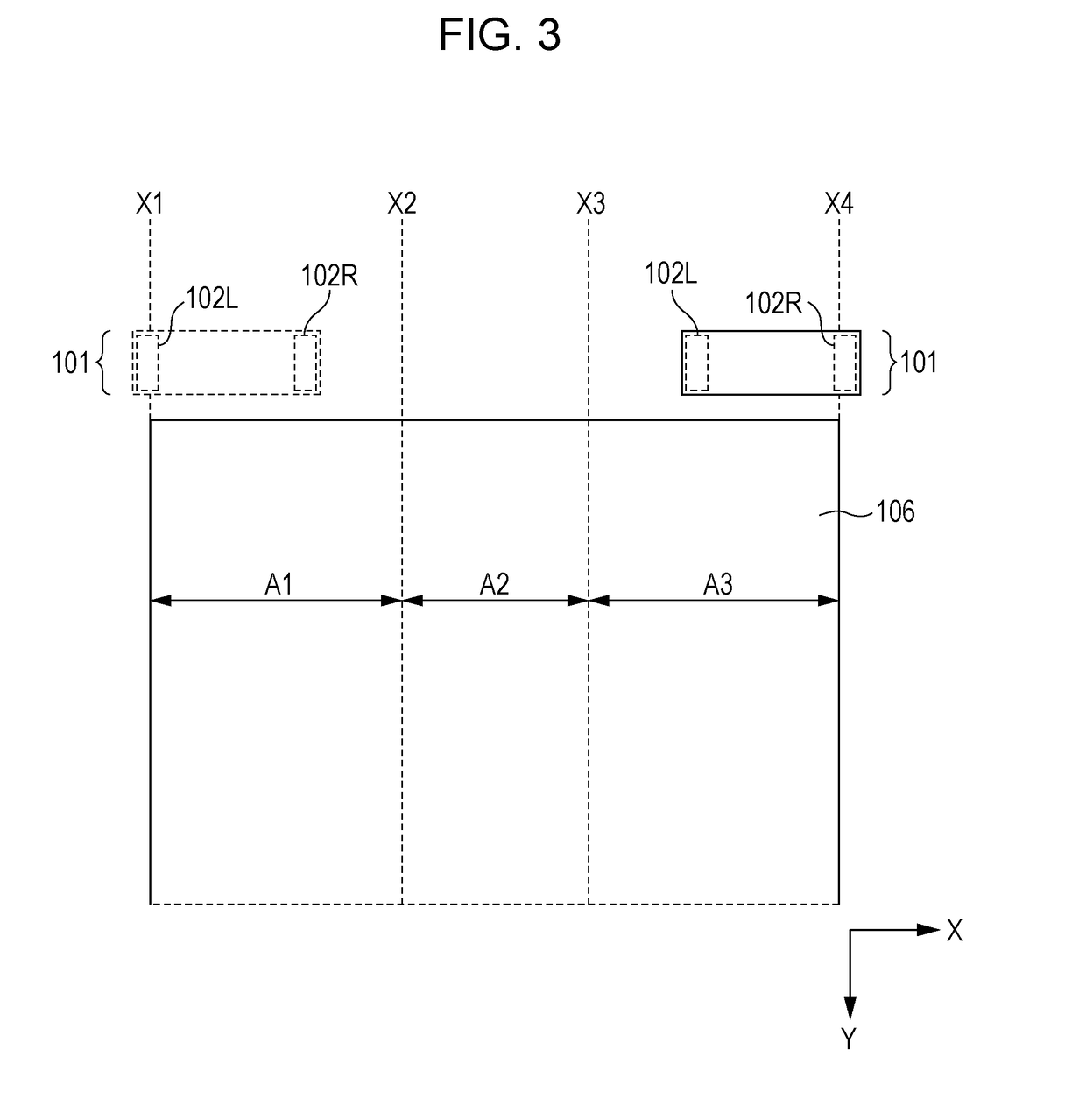

[0036]FIG. 1 is a schematic diagram illustrating an internal configuration of an inkjet recording apparatus 310 according to the present exemplary embodiment.

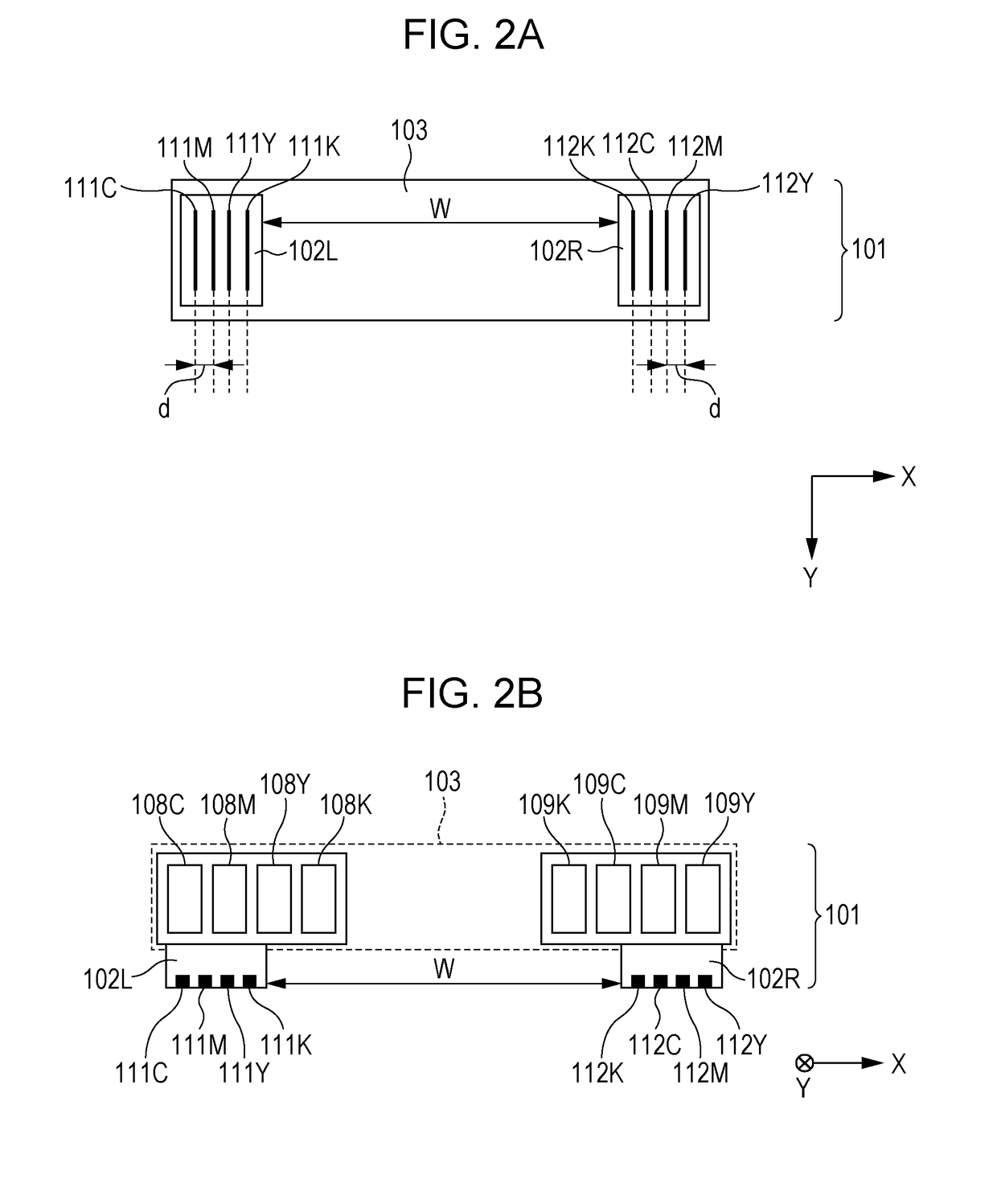

[0037]The inkjet recording apparatus according to the present exemplary embodiment (hereinafter, which will be also referred to as a printer or a recording apparatus) 310 is provided with a recording unit 101. The recording unit 101 includes a recording head 102L and a recording head 102R, and the recording heads 102L and 102R are held by a single holding part 103. Each of the recording heads 102L and 102R is provided with an ejection nozzle array for ejecting black ink, an ejection nozzle array for ejecting cyan ink, an ejection nozzle array for ejecting magenta ink, and an ejection nozzle array for ejecting yellow ink. A detail thereof will be described below.

[0038]The recording unit 101 can rela...

second exemplary embodiment

[0127]According to the present exemplary embodiment, a dither pattern 80 which will be described below is used instead of the dither pattern 70 used according to the first exemplary embodiment, and a dither pattern 81 which will be described below is used instead of the dither pattern 71 to perform the quantization processing. The dither patterns 80 and 81 indicate a spatial frequency characteristic in which the number of low frequency components is low.

[0128]It should be noted that descriptions of parts similar to the above-described first exemplary embodiment will be omitted.

[0129]FIGS. 13A to 13D illustrate the dither pattern 80 used according to the present exemplary embodiment. As illustrated in FIG. 13A, the dither pattern 80 according to the present exemplary embodiment has a size of 512 pixels×512 pixels. It should be noted that, for simplicity, although omitted in FIG. 13A, one of thresholds 1 to 256 is set in each of the pixels having a size of 512 pixels×512 pixels in act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com