Gasketless Closure For Open-Top Pails

a gasketless, open-top technology, applied in the field of lids, can solve the problems of adding more cost and complexity to the manufacturing process, and reducing the recycling rate of the closure, so as to achieve the effect of leakage of fluids from the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

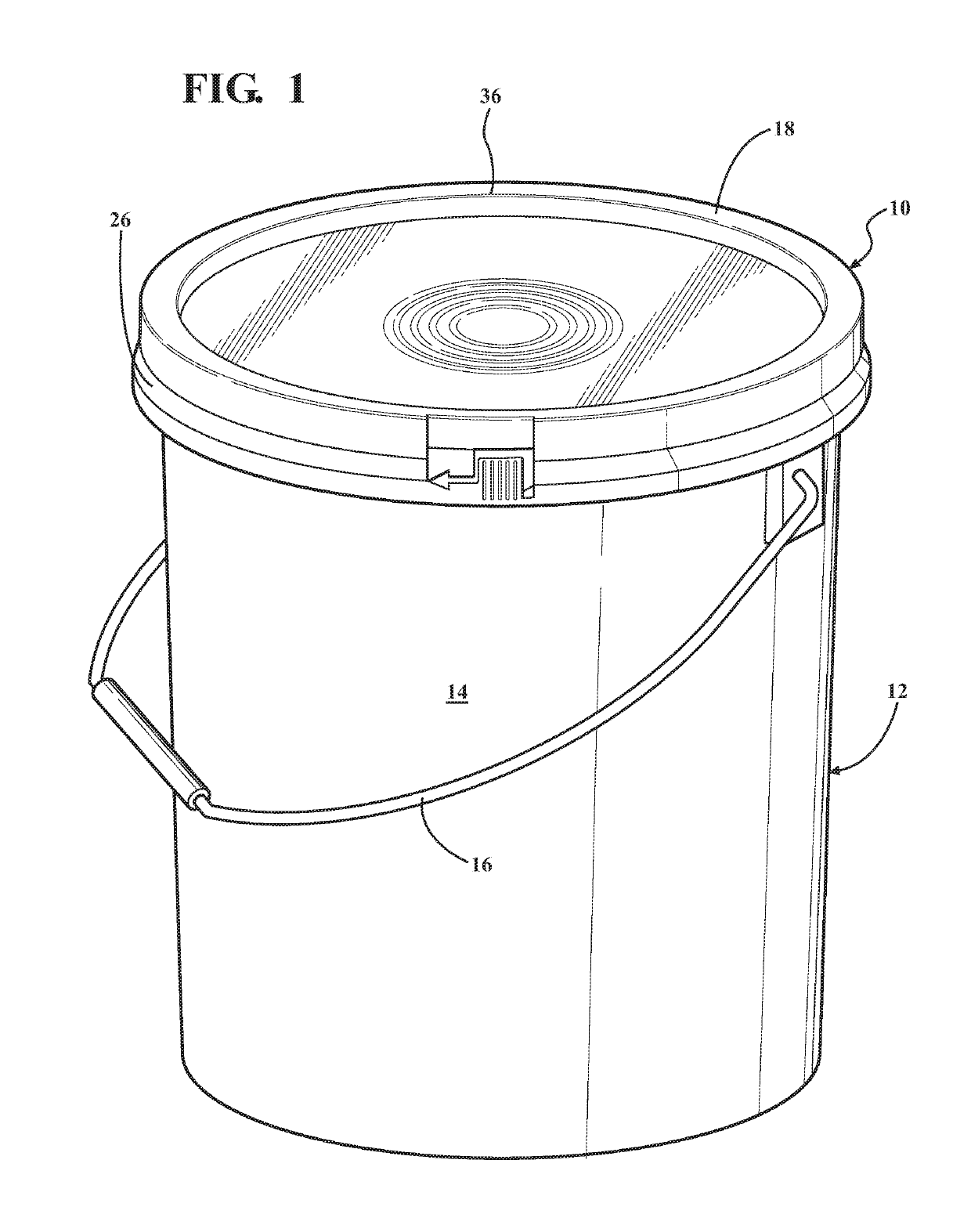

[0018]Referring to FIG. 1 there is shown a molded plastic closure 10 for a five-gallon open-top molded plastic pail 12 having a tapered sidewall 14 and a wire bail 16. Both the closure 10 and the pail 12 are preferably injection molded from HDPE. Other plastics, such as polypropylene, can also be used.

[0019]The closure 10 has an annular peripheral portion 18 surrounding a generally circular inner deck portion 20 and is sized to fit on the pail 12 in such a way as to “lock” onto the pail and provide a seal to prevent both the ingestion of air into the pail 12 as well as to prevent leakage from any fluid carried by the pail in the fully closed condition. This representation is intended to be generic in nature; i.e., it shows a typical pail / closure configuration wherein the closure has a “plug fit” on the pail rim, and also has a “tear strip” on the outer skirt, details of which are omitted here but can be found in the Schwarz patent identified above, incorporated herein by reference.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com