Engine that includes blow-by-gas returning system

a technology of blow-by gas and engine, which is applied in the direction of machines/engines, functional valve types, combustion air/fuel air treatment, etc., can solve the problems of frozen moisture clogging the outlet of the pipe, the pipe is likely to be affected by coldness,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

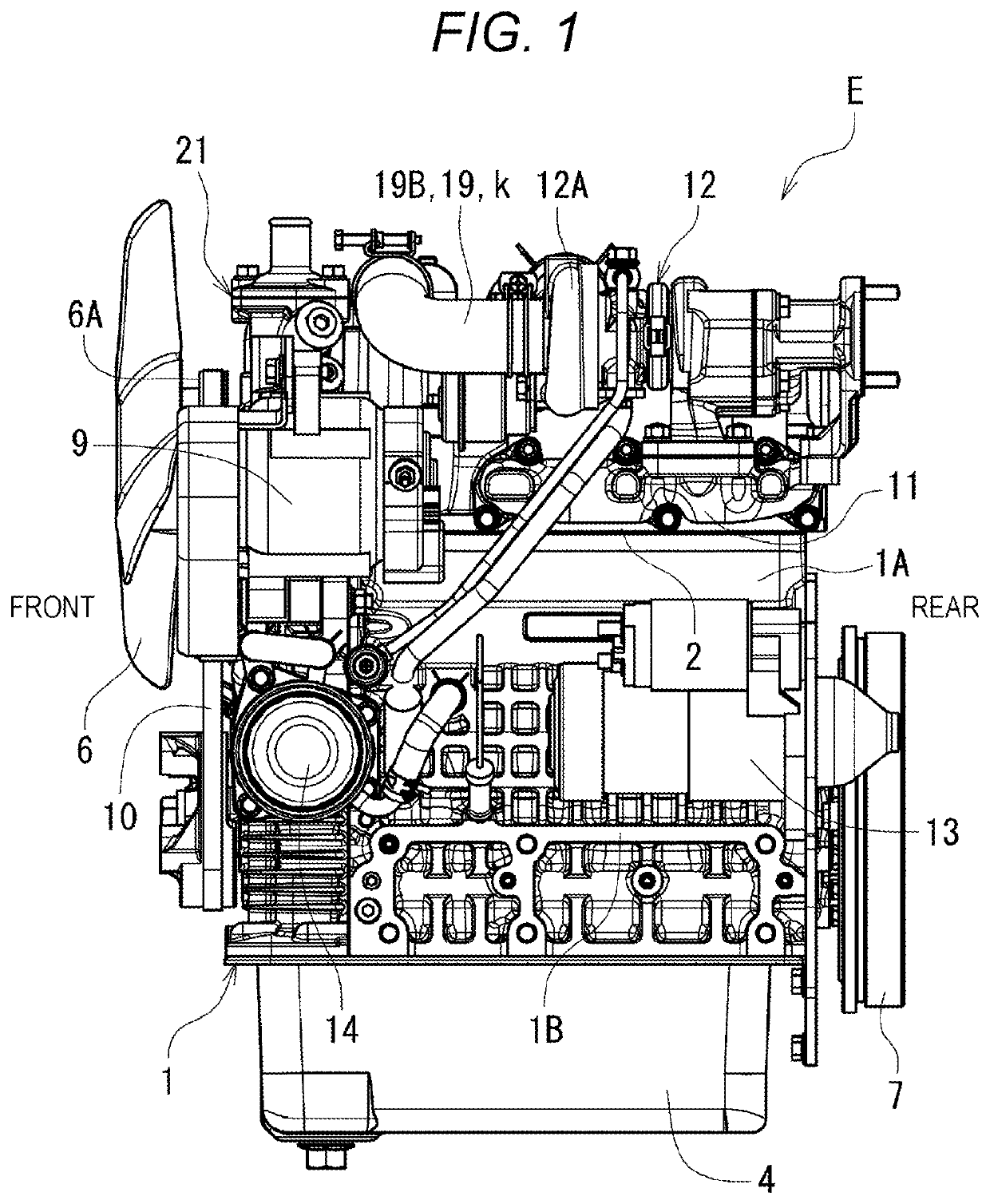

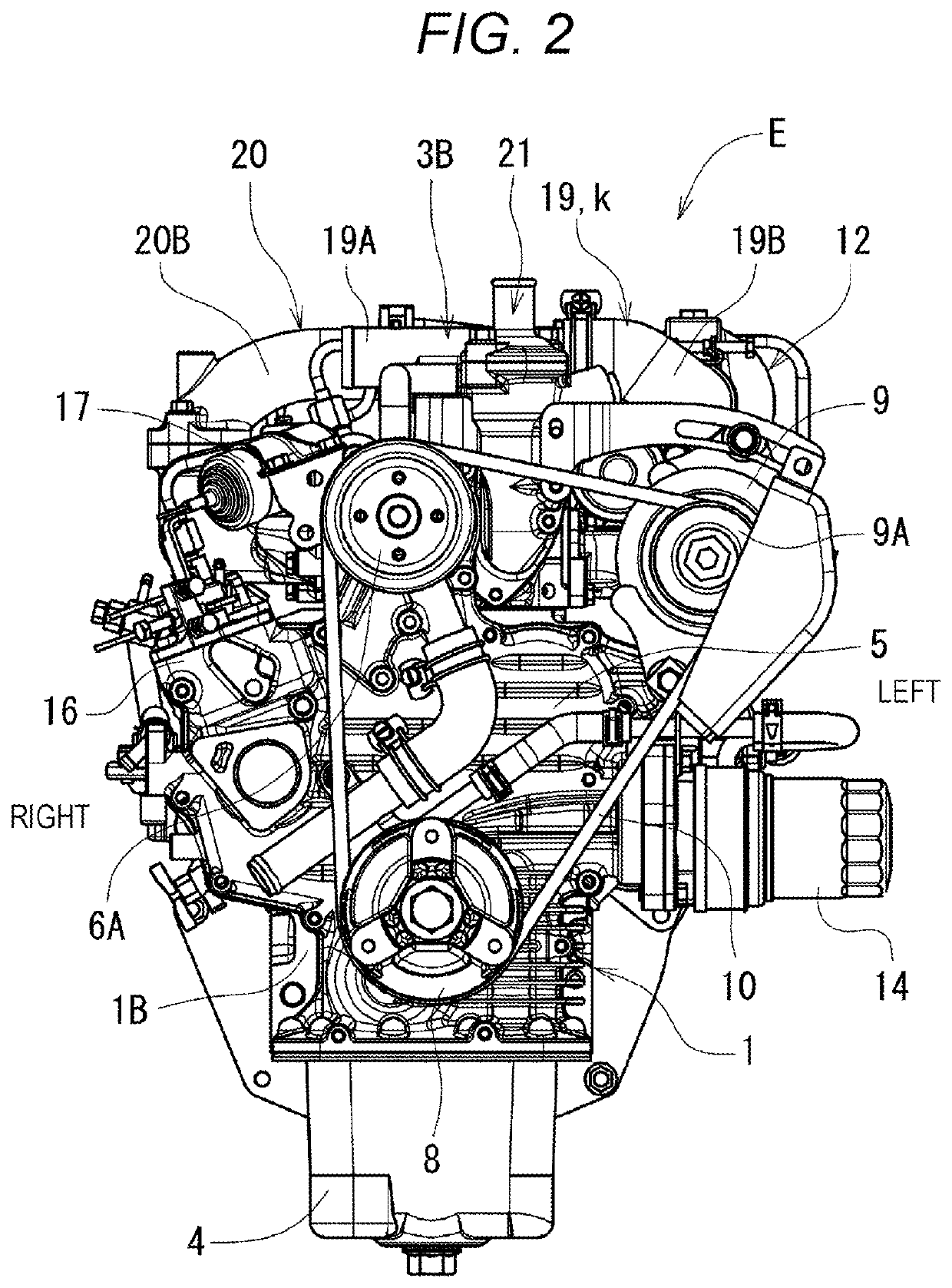

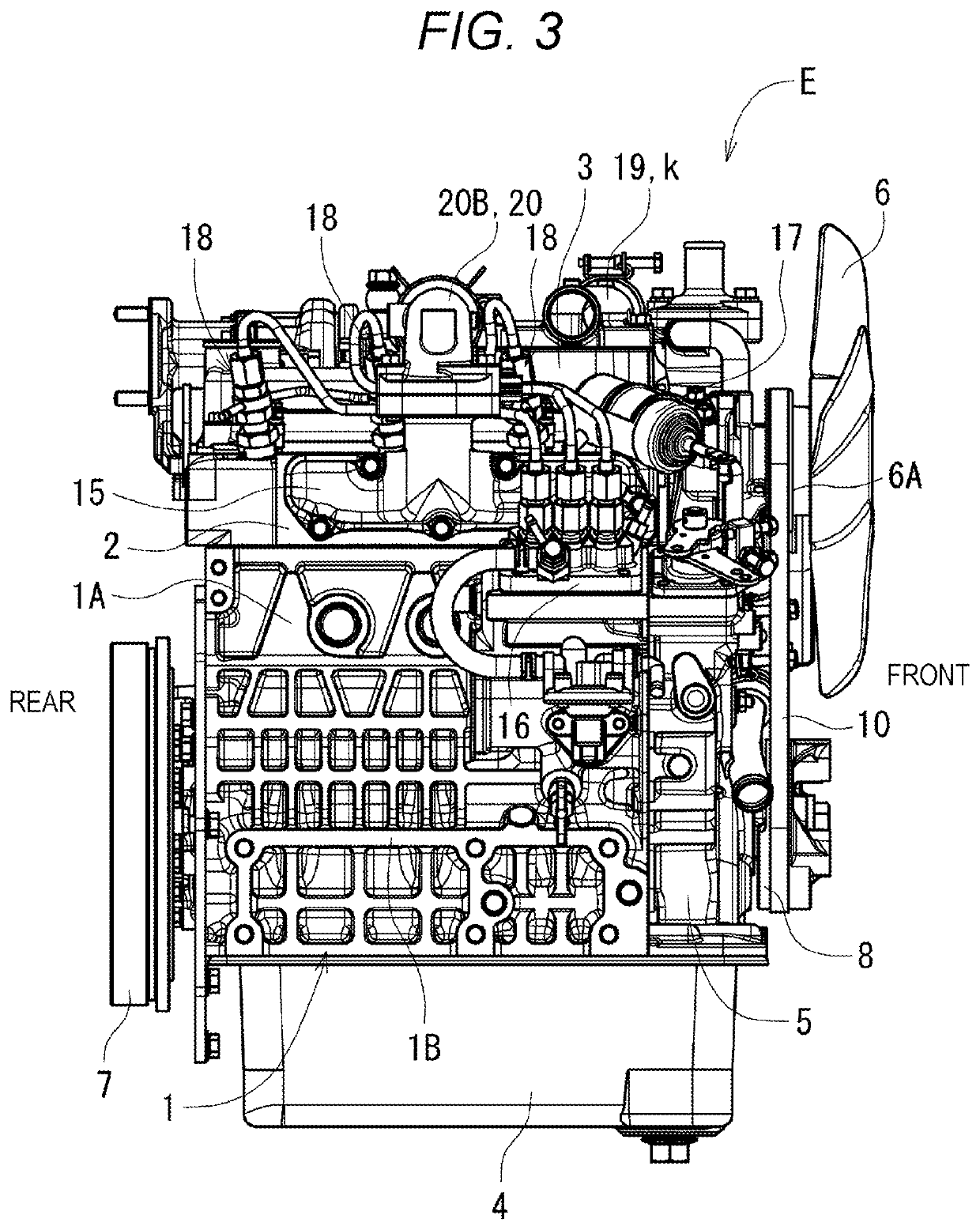

[0030]Hereinafter, an engine that includes a blow-by-gas returning system according to a preferred embodiment of the present invention will be described with reference to the drawings. In the preferred embodiment, the engine is applied to an industrial diesel engine.

[0031]As illustrated in FIGS. 1 to 5, an industrial diesel engine (hereinafter simply referred to as the engine) E includes a cylinder block 1, a cylinder head 2 attached to a top of the cylinder block 1, a head cover 3 attached to a top of the cylinder head 2, and an oil pan 4 attached to a bottom of the cylinder block 1. A power transmitting case 5 is attached to a front end of the cylinder block 1. An engine cooling fan 6 is disposed in front of the power transmitting case 5. A flywheel 7 is disposed behind the cylinder block 1. An upper half of the cylinder block 1 forms cylinders 1A. A lower half of the cylinder block 1 forms a crankcase 1B.

[0032]For example, a power transmitting belt 10 and a water flange 21 are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com