Battery pack temperature control method and device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

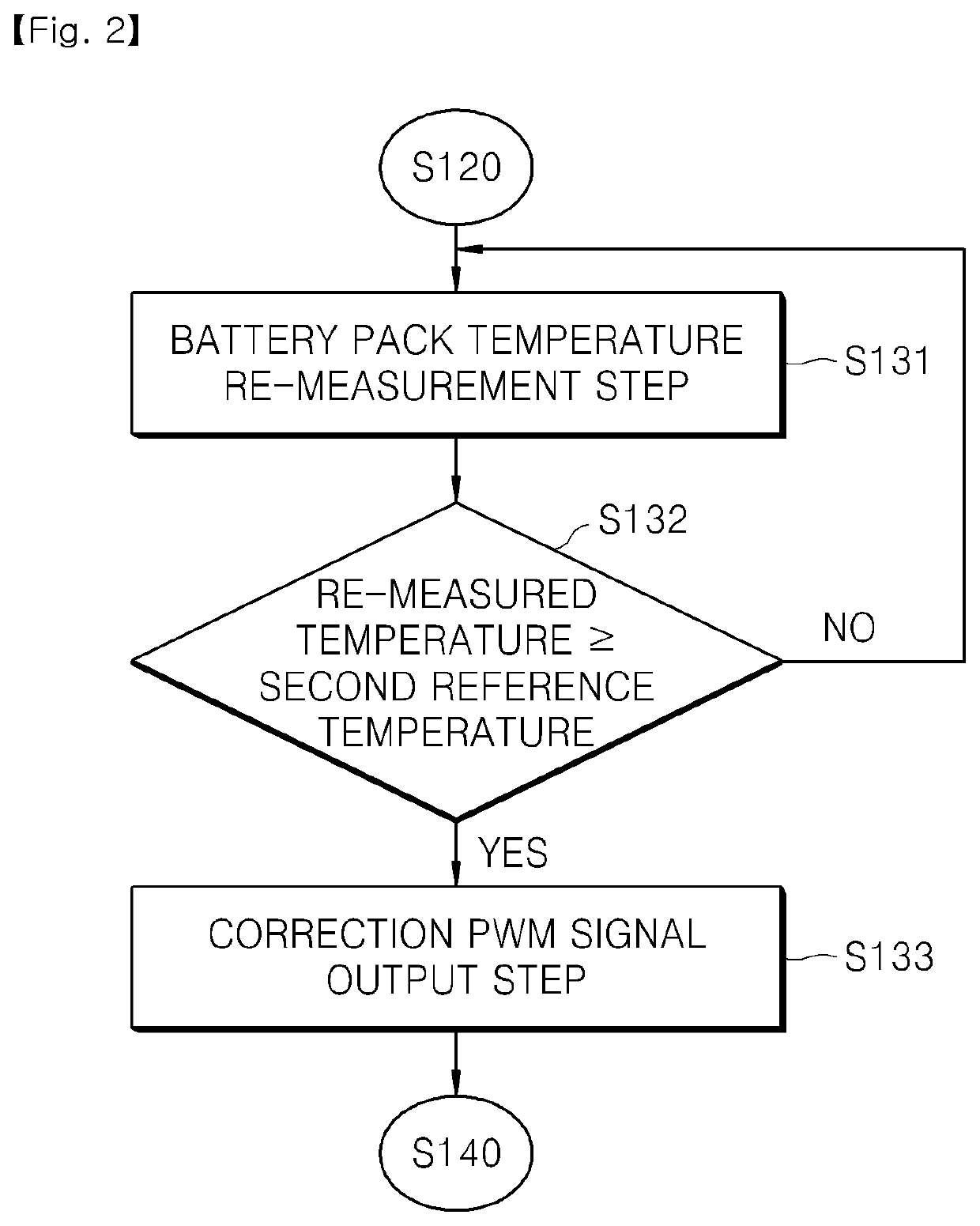

[0031]Next, a method for controlling a temperature of a battery pack according to an embodiment of the present invention will be described.

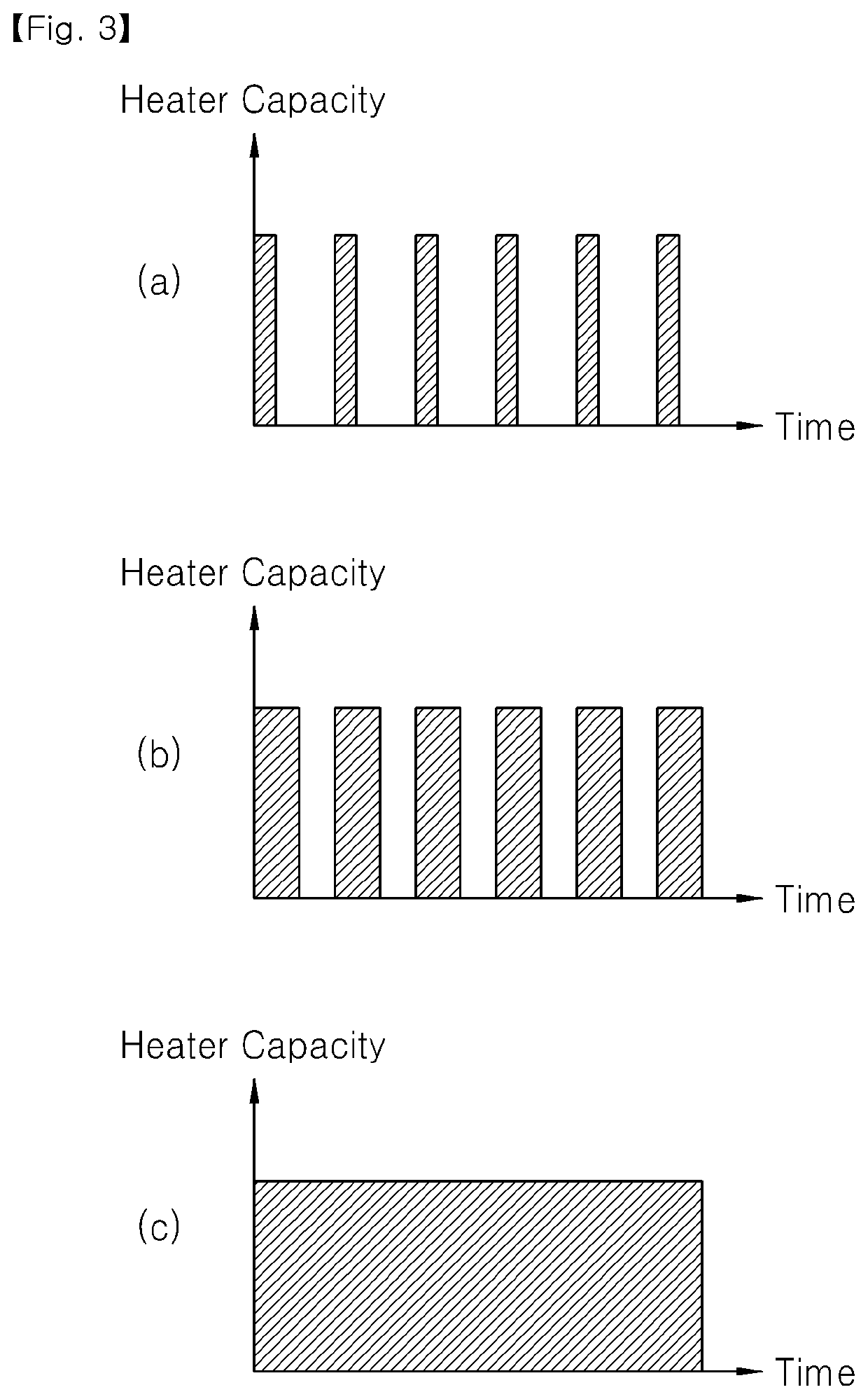

[0032]In the method for controlling the temperature of the battery according to the present invention, when the charging / discharging of the battery pack is performed at a low temperature, a PWM signal having a predetermined duty ratio may be outputted to drive a heat generating unit. Thus, the outputted duty ratio of the PWM signal increases as the battery pack increases in temperature so that a temperature value of the battery stably increases.

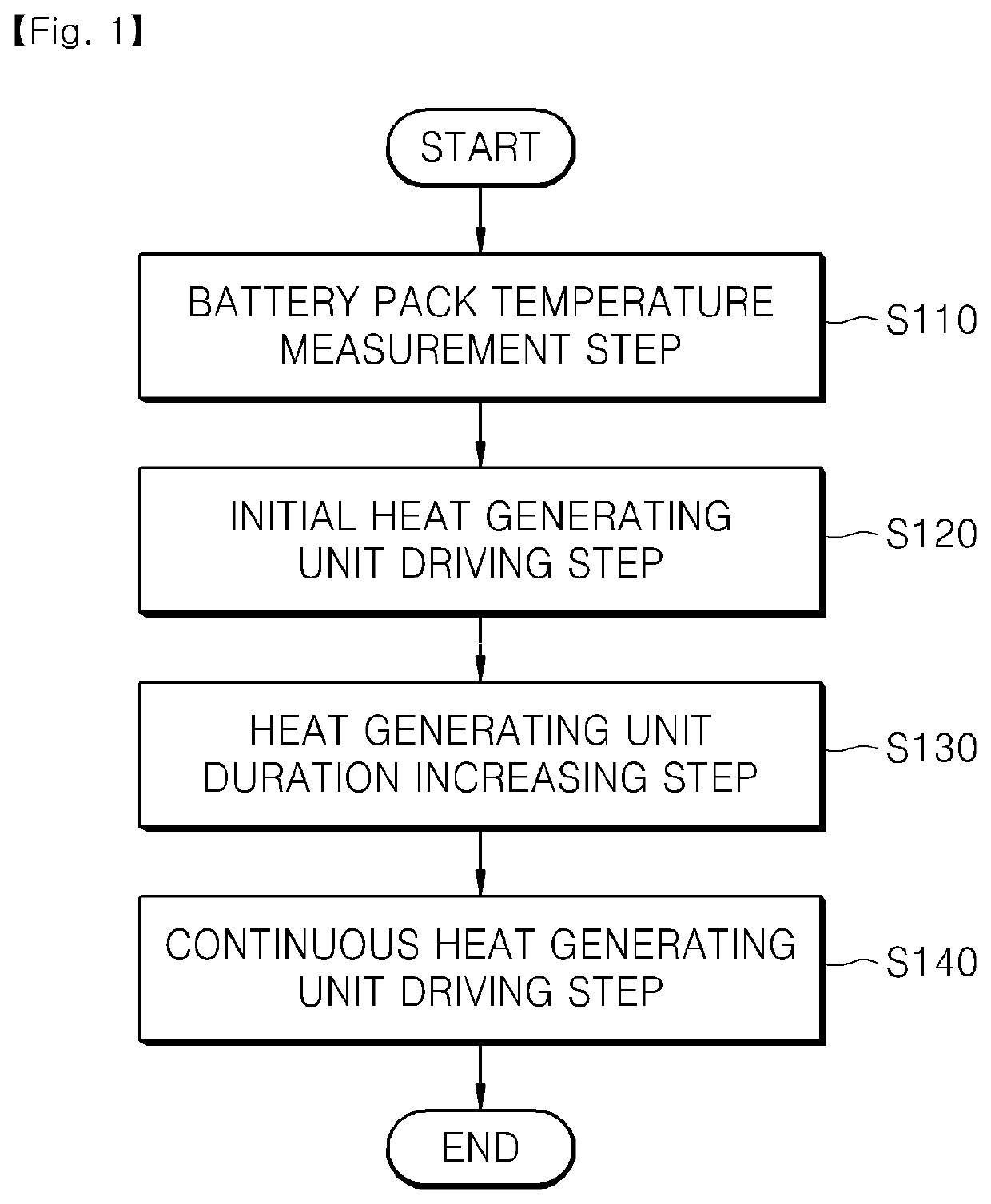

[0033]FIG. 1 is a flowchart illustrating a method for controlling a temperature of a battery pack according to an embodiment of the present invention.

[0034]Referring to FIG. 1, in a method for controlling a temperature of a battery pack according to an embodiment of the present invention, a temperature value of the battery pack is measured before charging / discharging is performed (a battery pack temperatur...

embodiment 2

[0075]Next, an apparatus for controlling a temperature of a battery pack according to an embodiment of the present invention will be described.

[0076]The apparatus for controlling the temperature of the battery pack of the present invention may control a heat generating unit switch to intermittently turn-on / off a heat generating unit attached to the battery pack under an extremely low temperature to stably safely perform charging / discharging of the battery pack.

[0077]FIG. 4 is a block diagram illustrating the apparatus for controlling the temperature of the battery pack according to an embodiment of the present invention.

[0078]Referring to FIG. 4, an apparatus 300 for controlling the temperature of the battery pack according to an embodiment of the present invention includes a heat generating unit 330 surrounding a battery pack 320 constituted by a plurality of battery cells, a heat generating unit switch 340 for turning on / off current supply to the heat generating unit 330, and a BM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com