Counter flow heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]A detailed description of one or more embodiments of the disclosed apparatus and method are presented herein by way of exemplification and not limitation with reference to the Figures.

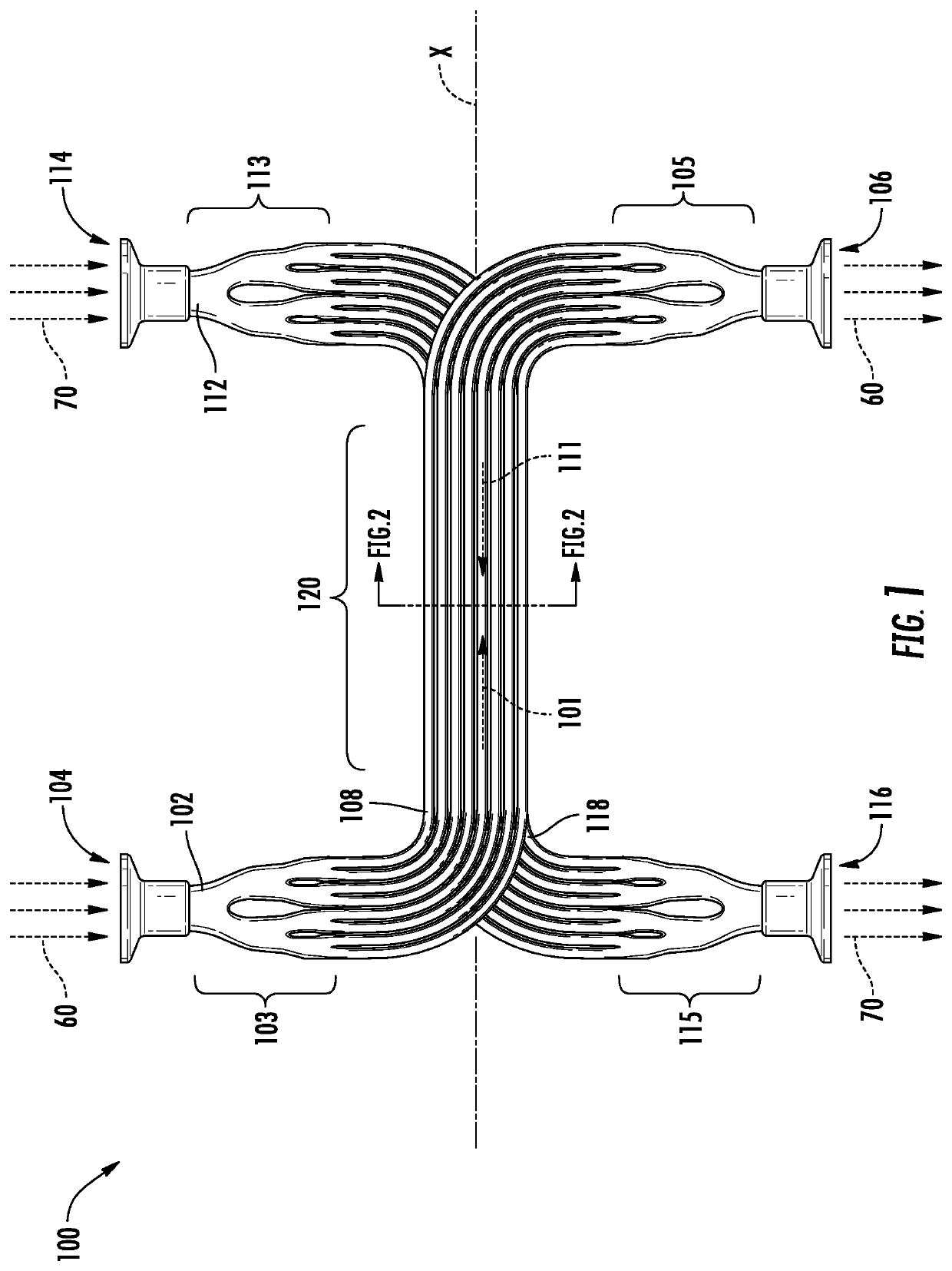

[0028]FIG. 1 is a top view of a counter-flow heat exchanger 100, according to an embodiment of the present disclosure. The counter-flow heat exchanger 100 may be utilized in a variety of applications requiring thermal dynamic transfer of heat including but not limited to an aircraft, a combustion engine, a car, a space craft, a powerplant, a satellite, satellite, etc. In an embodiment, the counter-flow heat exchanger 100 may be utilized in an aircraft. In another embodiment, the counter-flow heat exchanger 100 may be utilized in an aircraft air conditioning system.

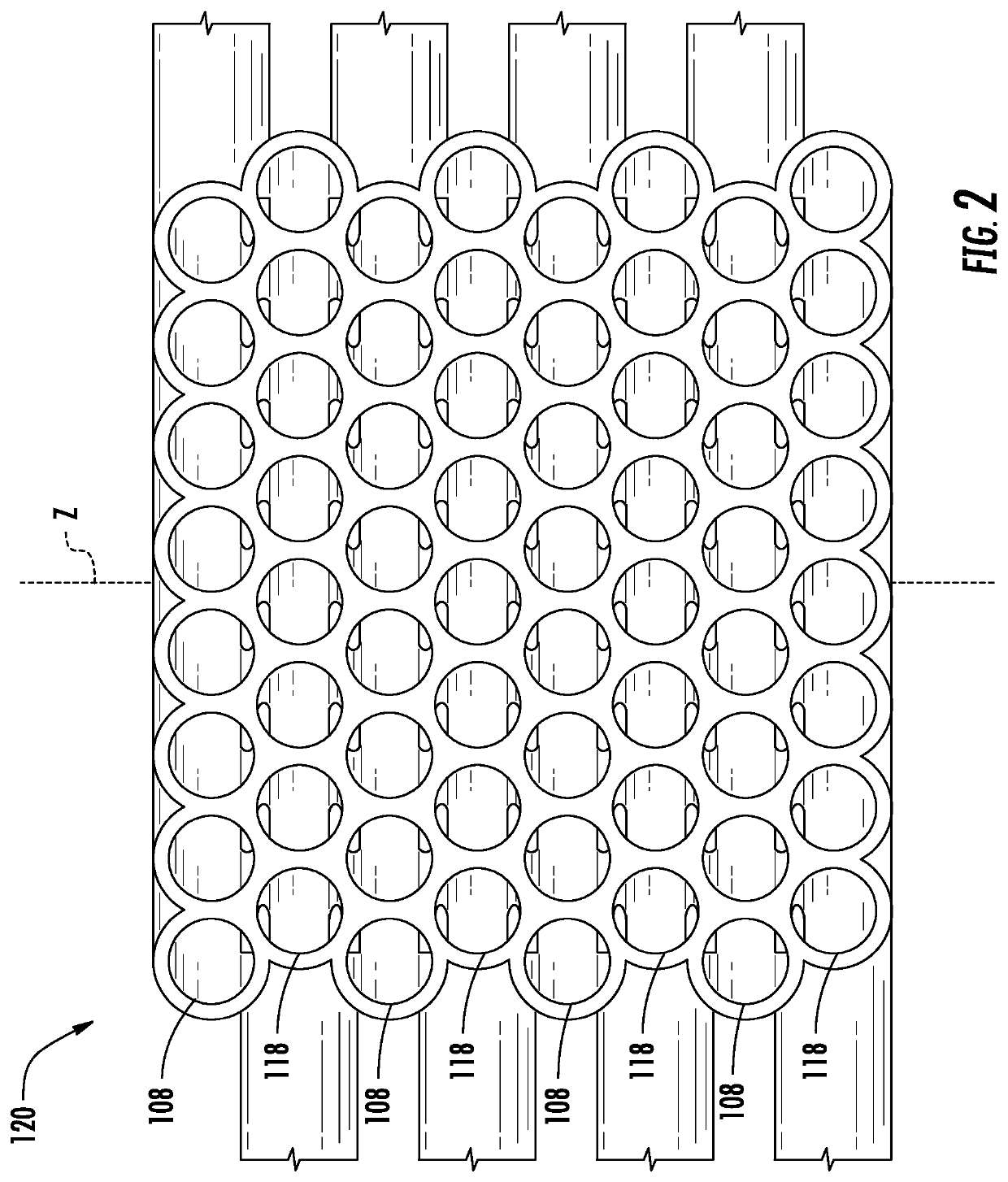

[0029]The counter-flow heat exchanger 100 includes a heat exchanger core 120 that may be oriented along a longitudinal axis X. The counter-flow heat exchanger 100 includes a primary flow passageway 102 and a secondary flow passageway 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com