Battery pack with reduced magnetic field emission

a battery pack and magnetic field technology, applied in the direction of batteries, cell components, conductors, etc., can solve the problems of inability to reliably autonomously fly, interference with the proper function of the device, and the magnetic field generated by the flow of electrical current, so as to reduce the magnetic field generated by the battery pack, reduce the magnetic field, and reduce the effect of magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

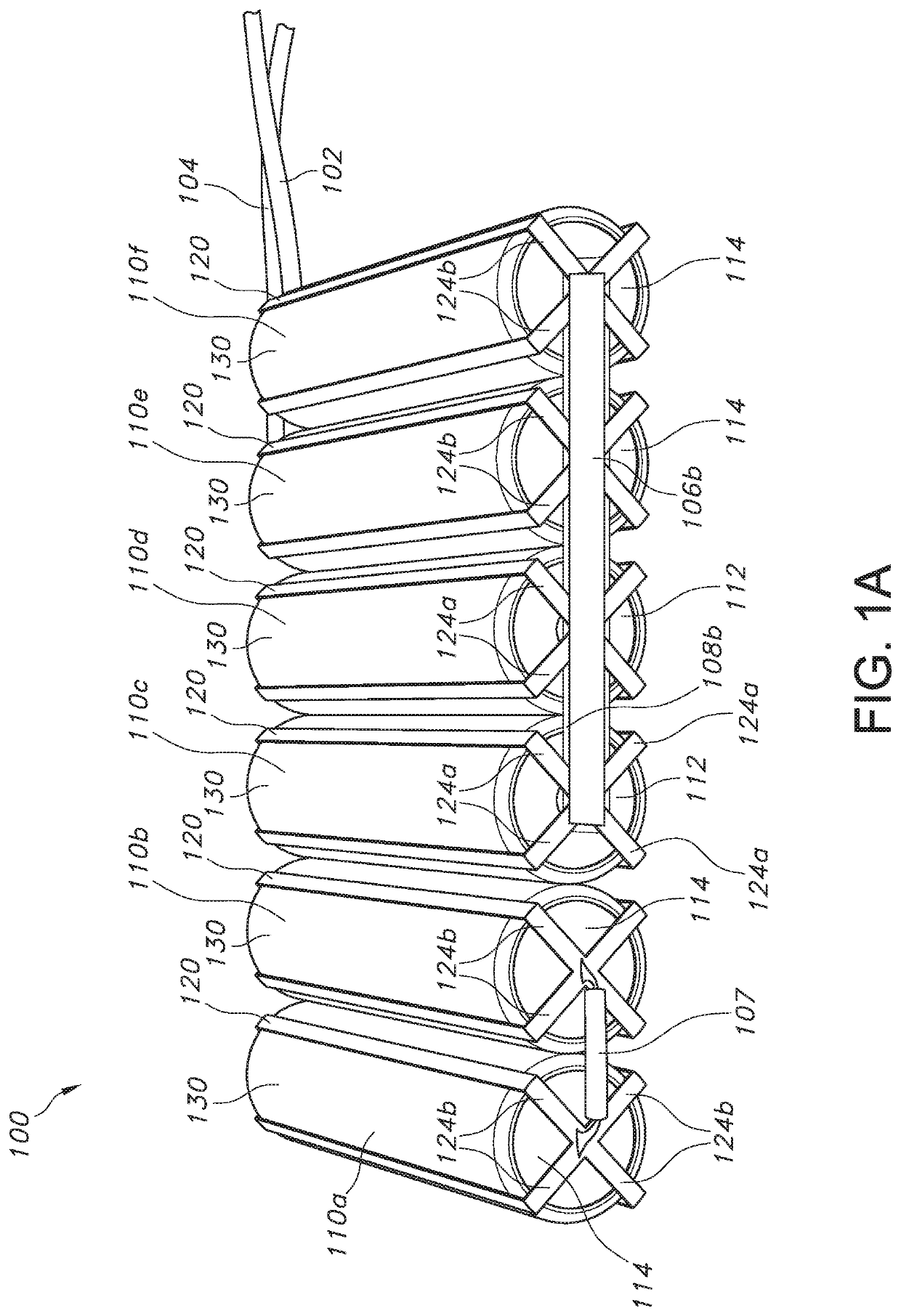

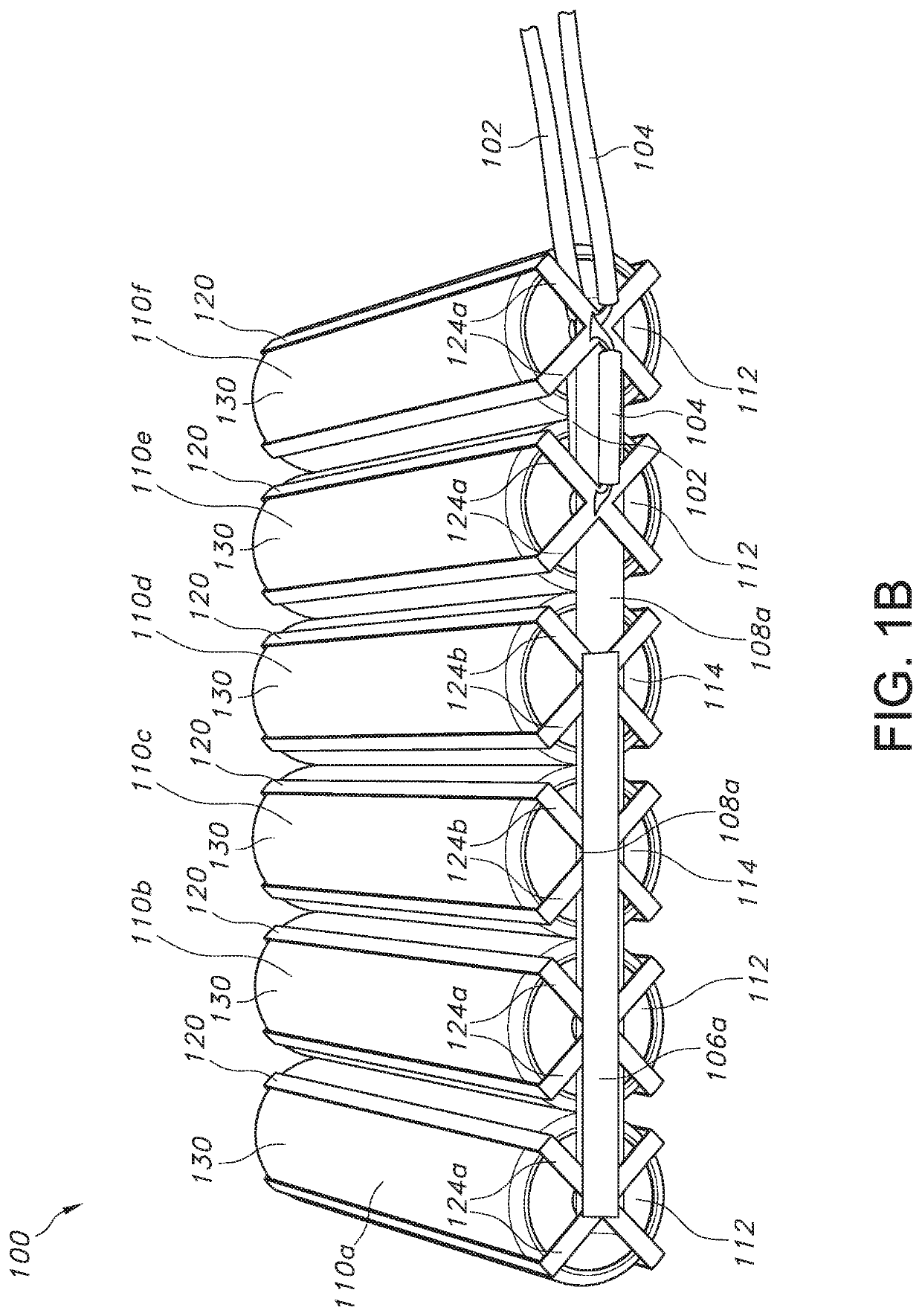

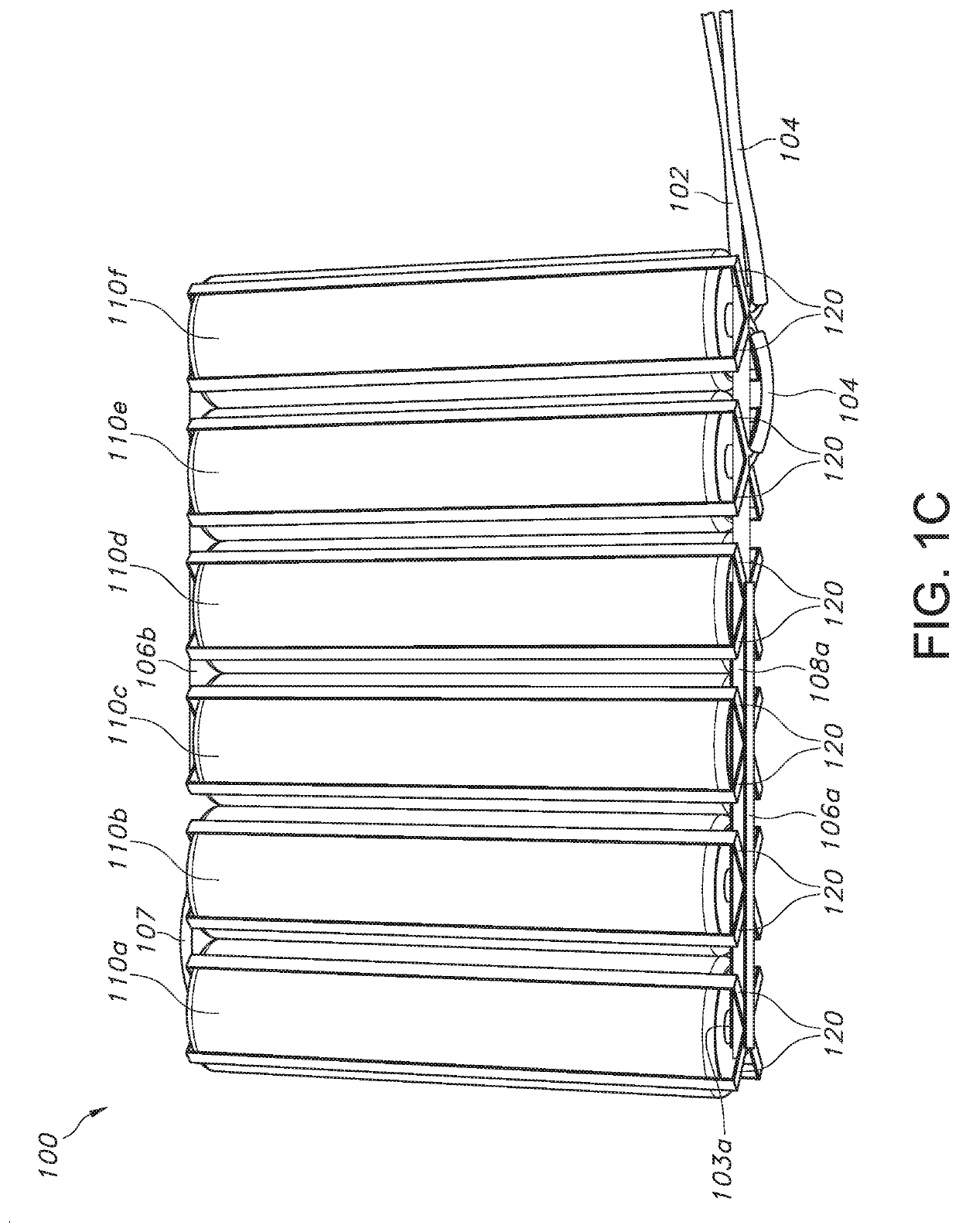

[0020]FIGS. 1A-1C illustrate an example battery pack with reduced magnetic field emission 100 according to the principles of the present disclosure. In some implementations, the battery pack 100 may be configured to reduce and / or eliminate the magnetic field normally generated while electrical current is being drawn from one or more cylindrical-steel electrochemical cells (e.g., AA batteries) by a connected electrical device. In some implementations, the magnetic field generated by the battery pack 100 may be reduced by minimizing or eliminating the loop area of the electrical conductors (e.g., wires or other conductive elements) used to complete the supply path and the return path thereof. In some implementations, the supply path and the return path of a battery pack 100 may be placed into a coaxial arrangement in which only a thin layer of insulating material is positioned therebetween. In this way, the loop area of the electrical conductors is minimized.

[0021]As shown in FIGS. 1A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| magnetic interference | aaaaa | aaaaa |

| magnetic field interference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com