Rubber assembly, comb and method for manufacturing comb

a technology of comb and rubber body, which is applied in the direction of brushes, hair cleaning, hair equipment, etc., can solve the problems of weakened massage effect, increase in and increase the structural complexity of the structure, so as to achieve the effect of not affecting the overall use effect of the air-cushion comb, not increasing the thickness of the rubber body, and sufficient arrangement spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order that those skilled in the art better understand the invention to clearly define the claimed scope of the invention, the invention will be described below in detail with reference to some particular embodiments of the invention.

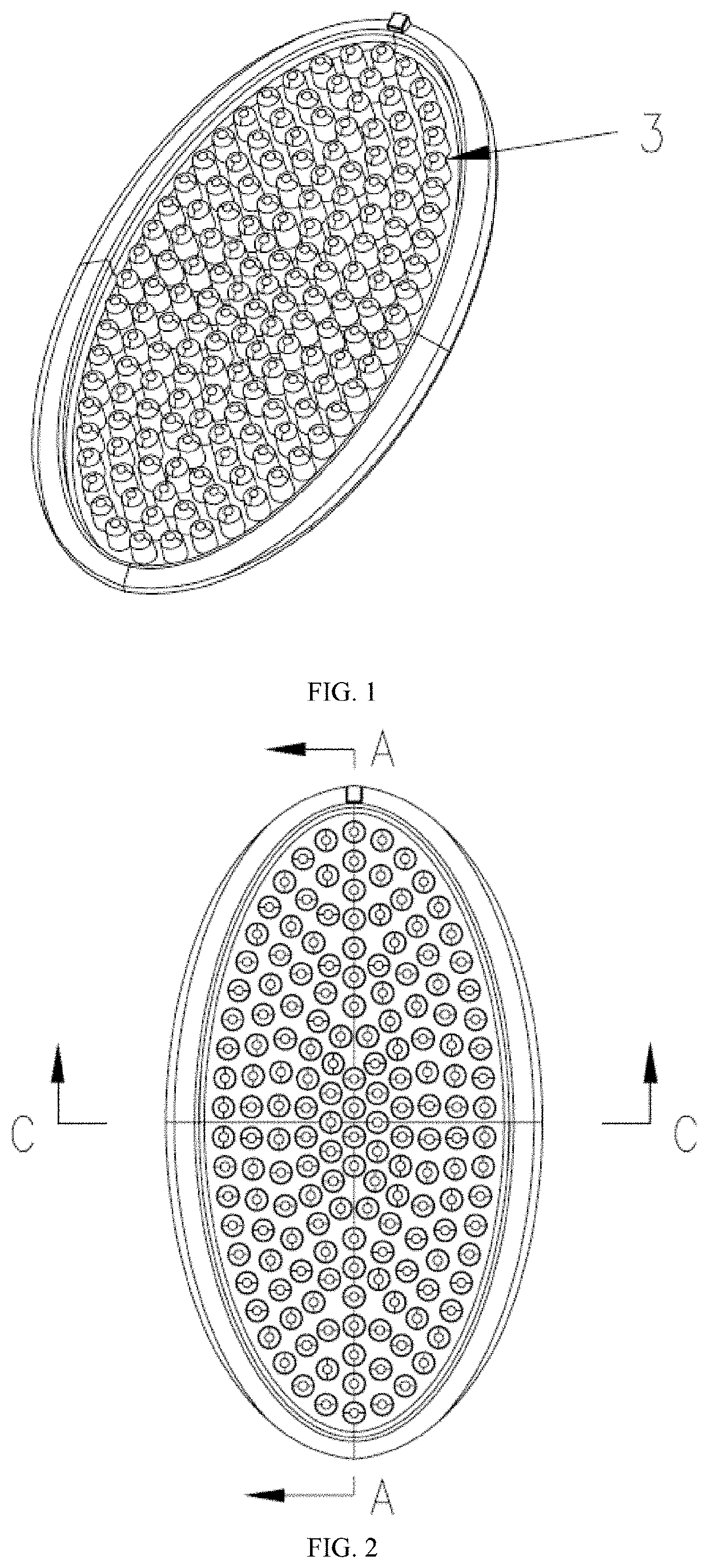

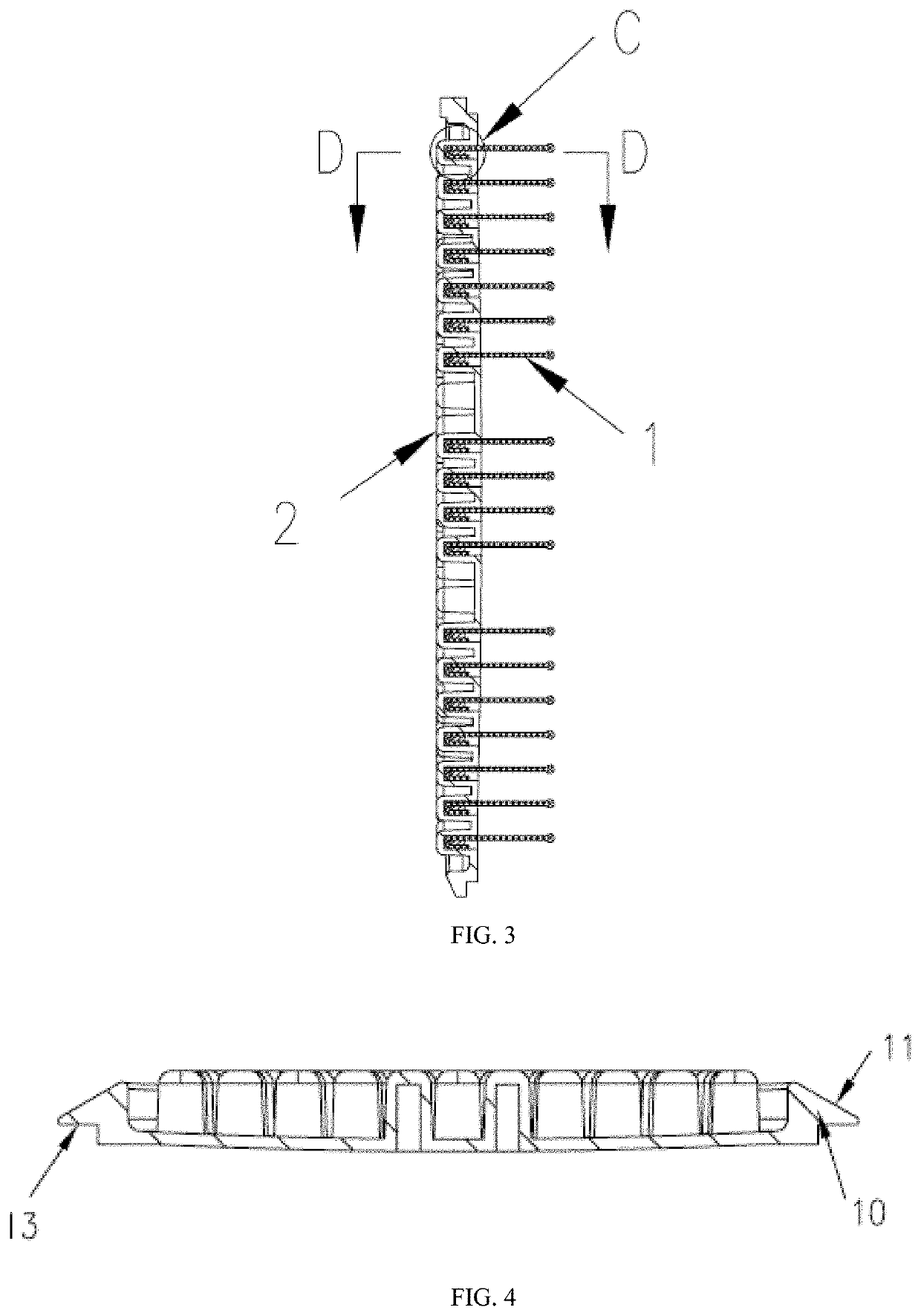

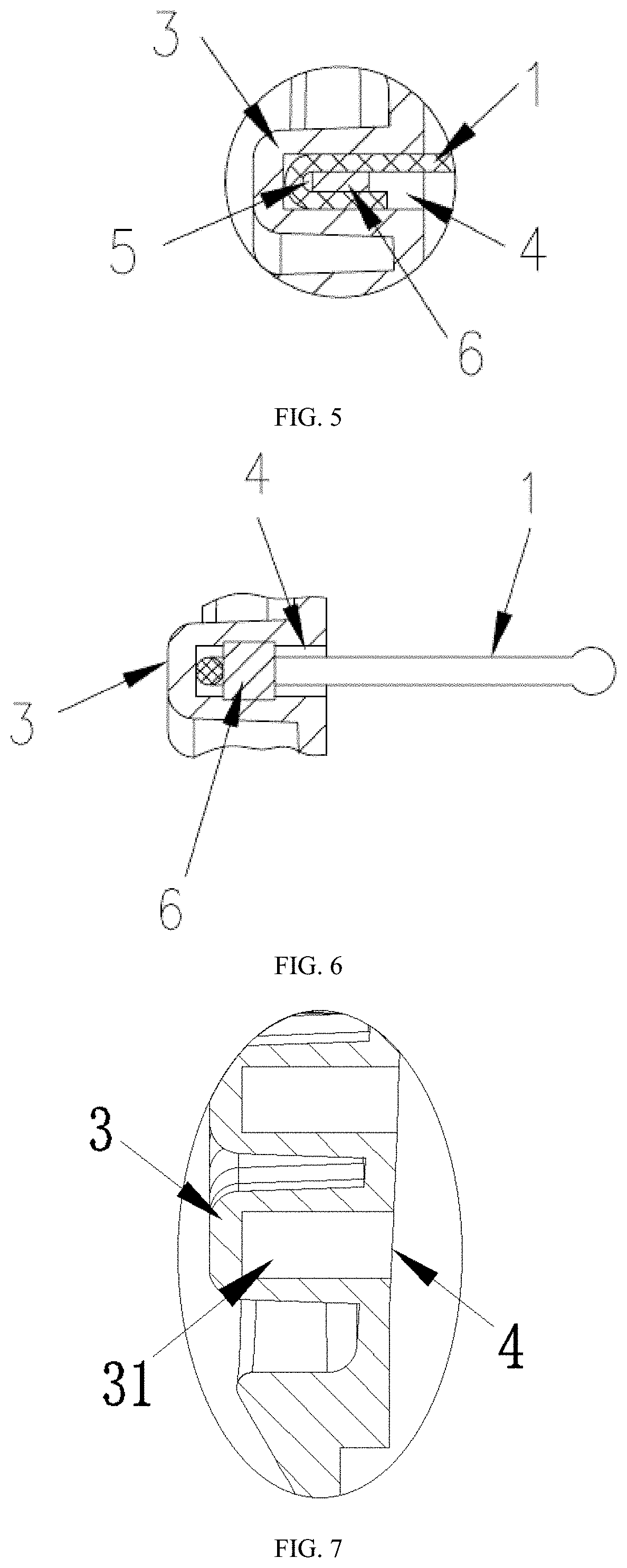

[0035]As shown in FIGS. 1 to 8, a rubber assembly comprises comb teeth 1 and a rubber 2, and the comb teeth 1 are directly or indirectly fitted on the rubber 2 to form the rubber assembly. A plurality of raised columns 3 are also arranged at a back side of the rubber 2, and the raised columns 3 are arranged independently of each other and spacedly. As shown in FIGS. 1 and 2, the raised columns 3 have a certain interstitial space among each other so that the overall thickness of the rubber assembly in use is not increased due to the arrangement of the raised columns 3. In fact, excessively dense raised columns 3 cause such problem to some extent, thus the thickness of the rubber 2 and the parameters and distribution density of the raised columns ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com