Fin stabilized projectile and loading components

a stabilized and projectile technology, applied in the field of projectiles, can solve the problems of barrel heat up and projectile parts to be cold formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

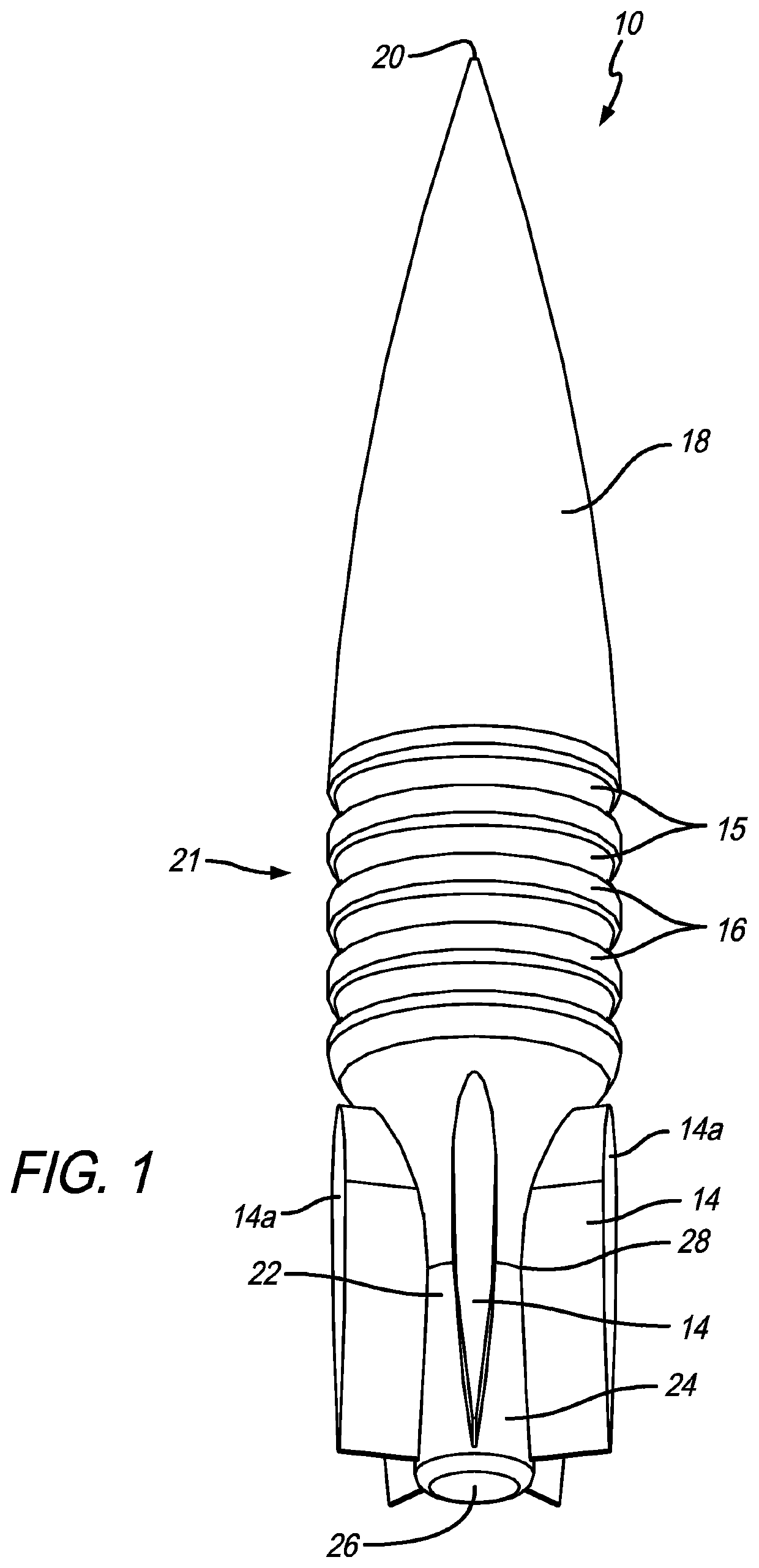

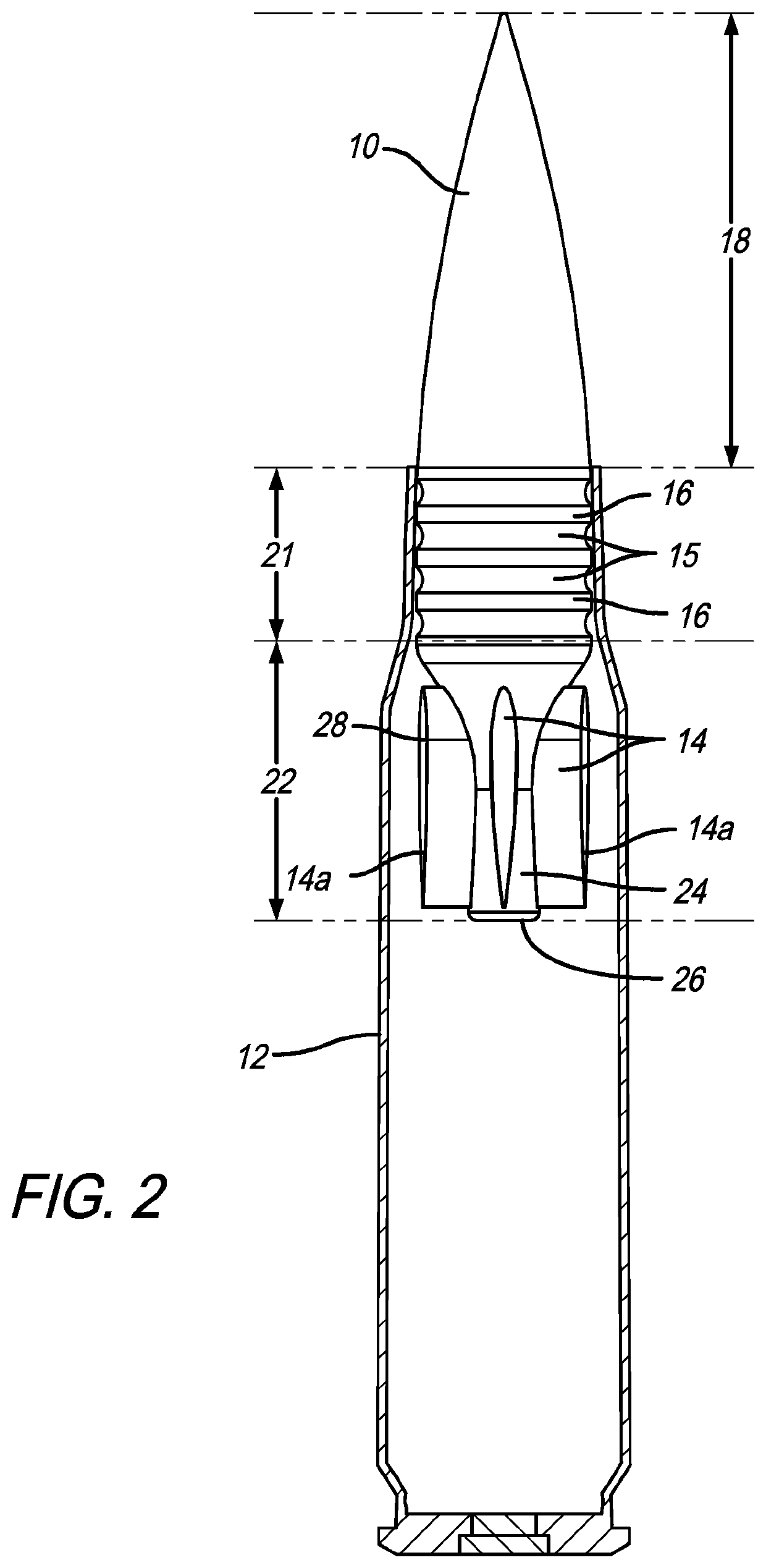

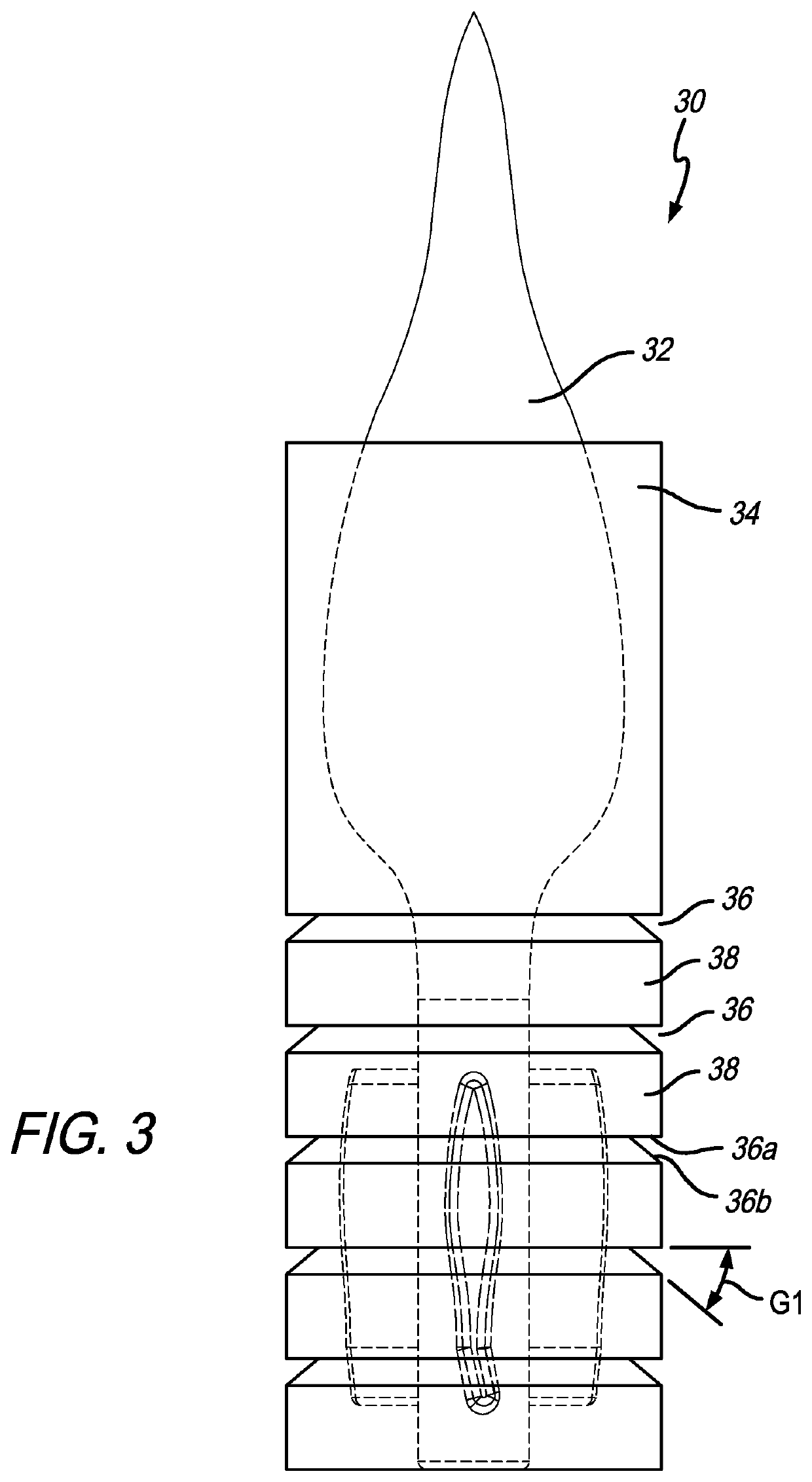

[0005]In accordance with a first aspect of the present invention there is provided a covered projectile that includes a projectile having a nose portion, a middle portion, a rear portion, and a plurality of fins extending outwardly from the rear portion, and a jacket that surrounds at least a portion of the projectile and includes an exterior surface and an interior surface. The jacket includes a front cone. A plurality of annular grooves are defined in the exterior surface of the jacket. In a preferred embodiment, the middle portion has a greater diameter than the nose portion and the rear portion. Preferably, the projectile defines a projectile axis, each fin includes a front portion that defines a front portion axis and a tail portion that defines a tail portion axis. The front portion axis of each fin extends parallel to the projectile axis, and the tail portion axis of each fin defines an acute angle with the front portion axis.

[0006]In a preferred embodiment, the interior surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com