Assembly of bending machine and support bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

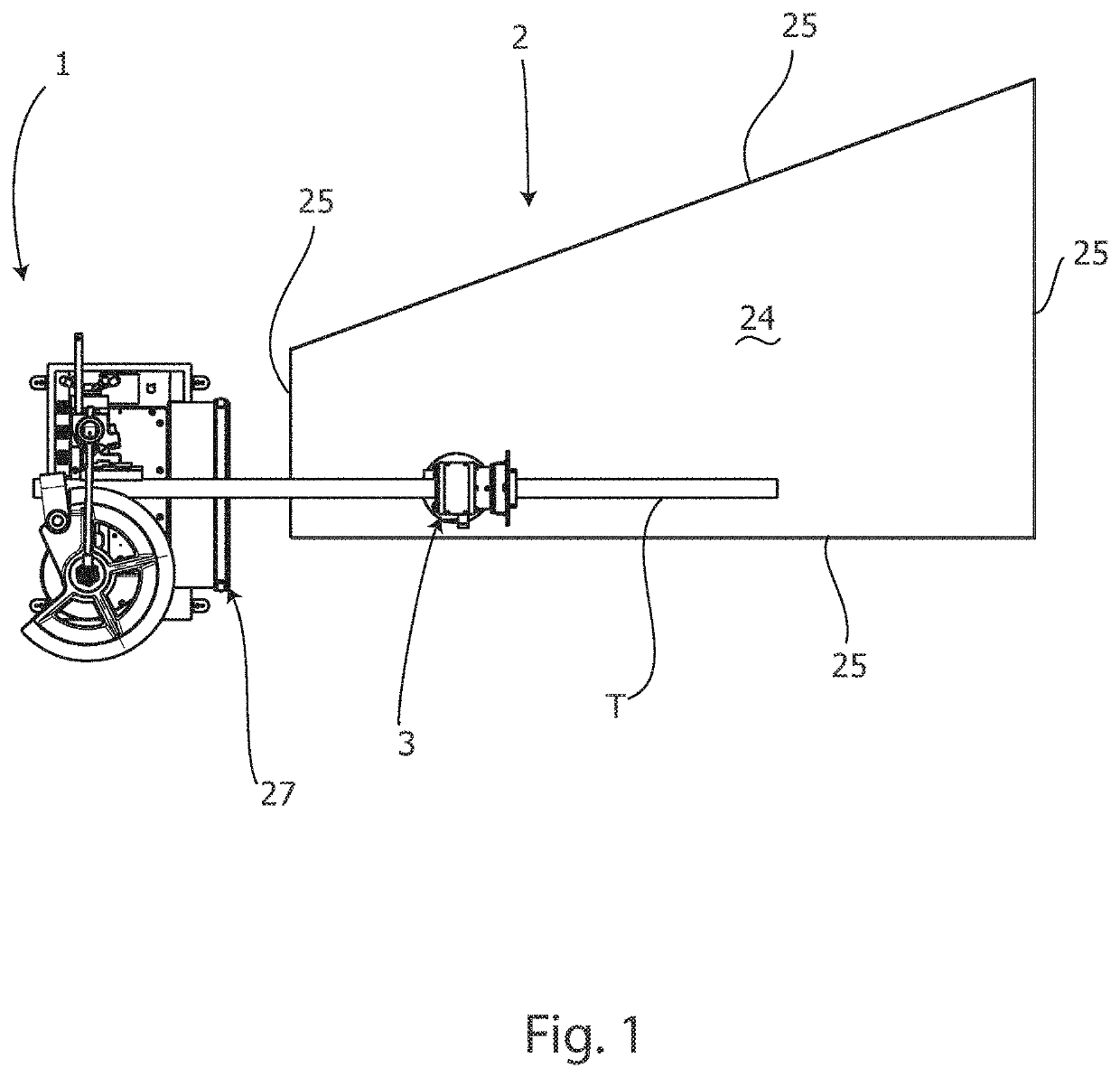

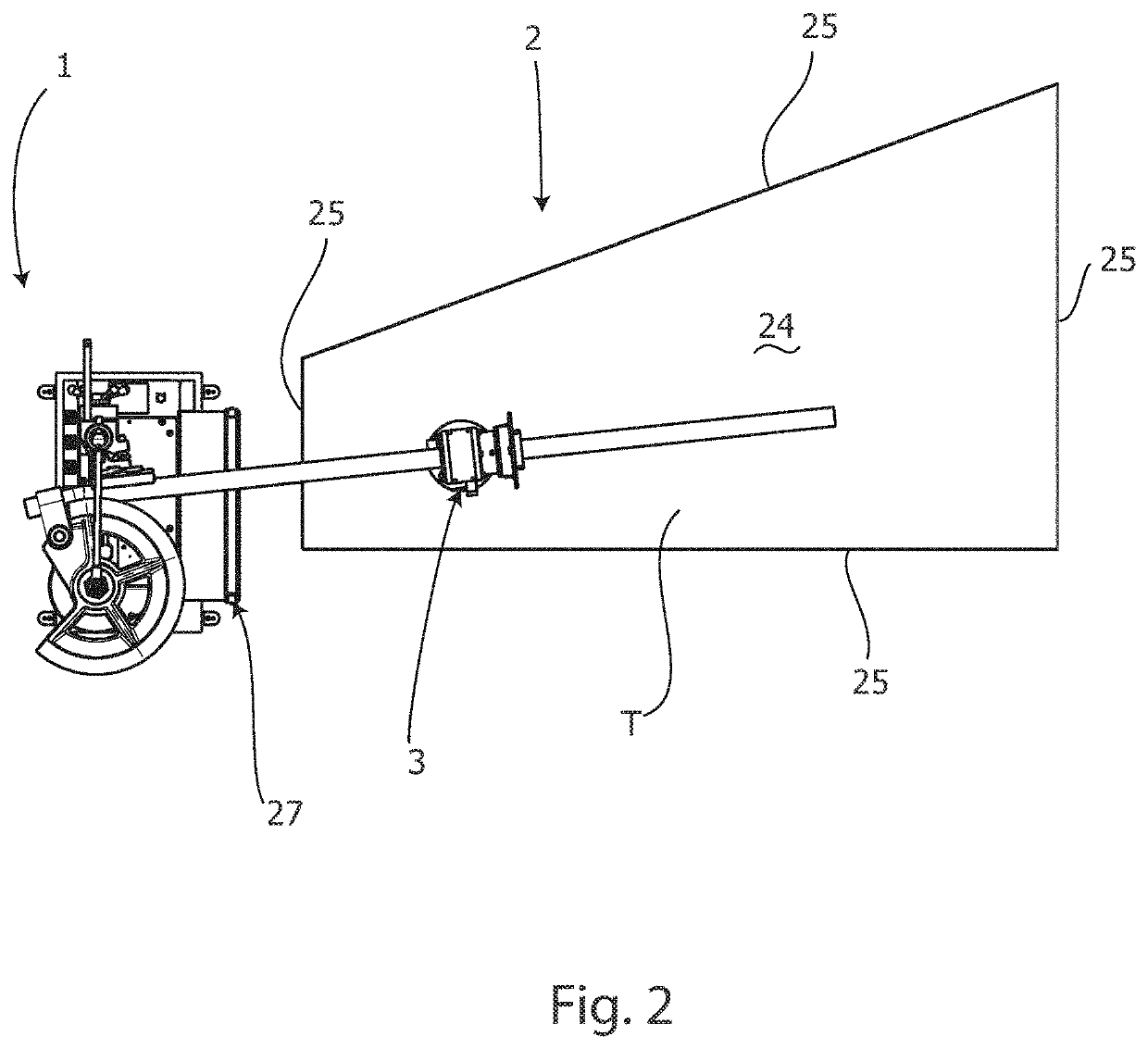

[0023]First of all, reference is made to FIGS. 1 and 2 which are top plan view, in a step preceding the bending and in a start step of bending, respectively, of an assembly of a fixed radius bending machine 1 and a support bench 2 for an elongated piece T to be bent according to a first embodiment of the invention. The elongated piece T to be bent is supported on the support bench 2 by means of a spindle 3. The spindle 3 is provided with at least one spherical support, shown below, so as to slide on the support bench 2, while the elongated piece T is bent. The bending machine 1 and the support bench 2 rest firmly on the ground. The bending machine 1 can be rigidly connected to the support bench 2, if necessary.

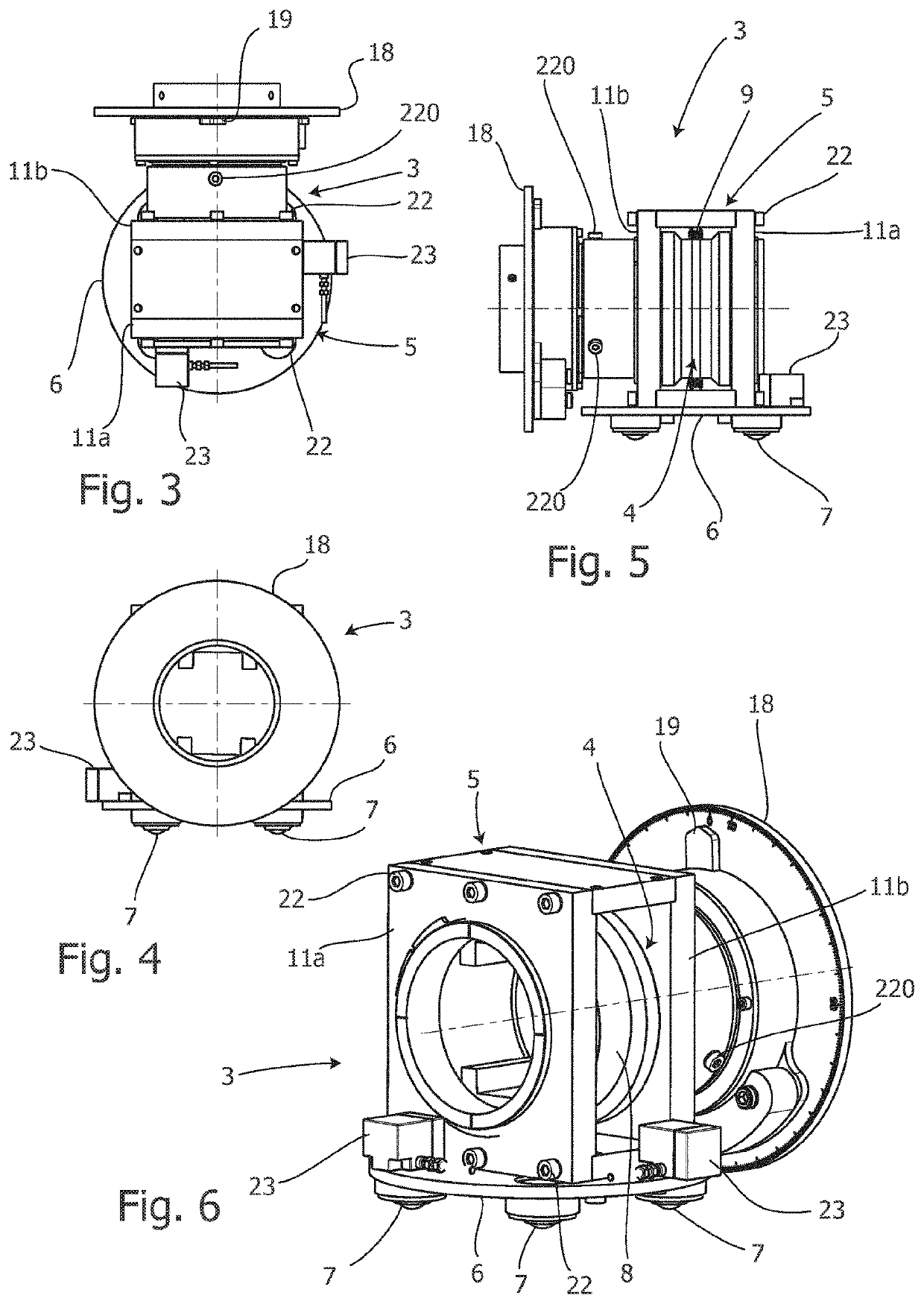

[0024]Reference is therefore made to FIGS. 3 to 7 which are a top plan view, a rear view, a side view, a perspective view and an exploded view of the spindle 3, respectively. The spindle 3 comprises a sleeve member 4 adapted to be connected to the elongated piece T to be bent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com