Extendable beam with slots

a technology of extendable beams and slots, applied in the direction of girders, transoms, walls, etc., can solve the problems of affecting the quality of wood frames, and requiring block repair for removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 110

[0086]Referring to FIGS. 11-18, a system 210 is depicted with the housing 112 may be that as previously described herein. However, the extendable members 31, 32 may be substantially as previously described herein with the addition of the window 134. Rather than the system 10 comprising support members 30, this system 210 embodiment utilizes the same holes 152 and pin 130 wherein from the previous embodiment 110 wherein the pin 130 may act similarly as the support members 30 maintaining the extendable members 31, 32 in place as well as the pin 130 engaging with the proximal wall 38 to act as a stop, as similarly previously described.

[0087]In this embodiment the pin 130 may provide the same strength and stability as the support members 30 but with far less weight allowing for easier manipulation of the system 110 or system 210.

[0088]Referring to FIGS. 19-22, the extendable member 132 may comprise an alternate flange that may comprise an angle. A flange 164 may comprise the same elemen...

first embodiment

[0092]Referring to FIGS. 31-42 similar examples of angled flanges are provided utilizing the extendable members 32 described in the system 10 with the exception of the window 134 also contemplated herein. Similar angles to the previous embodiments are shown with angles of 11°, 22° and 45° respectively. These embodiments may not include the slots 154 as these embodiments may be intended for use with the alternate system 210 but may also be utilized in the first described system 10.

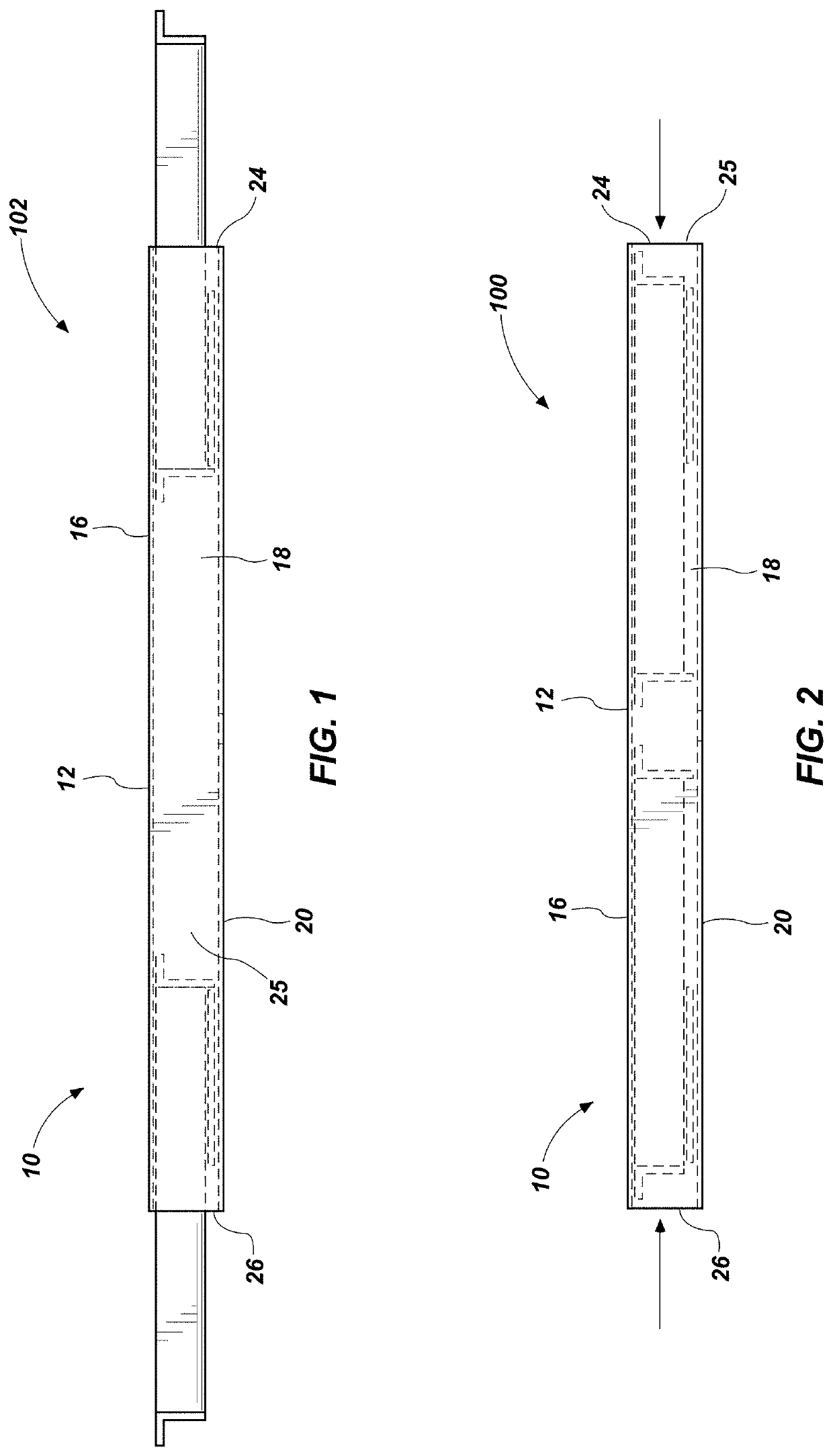

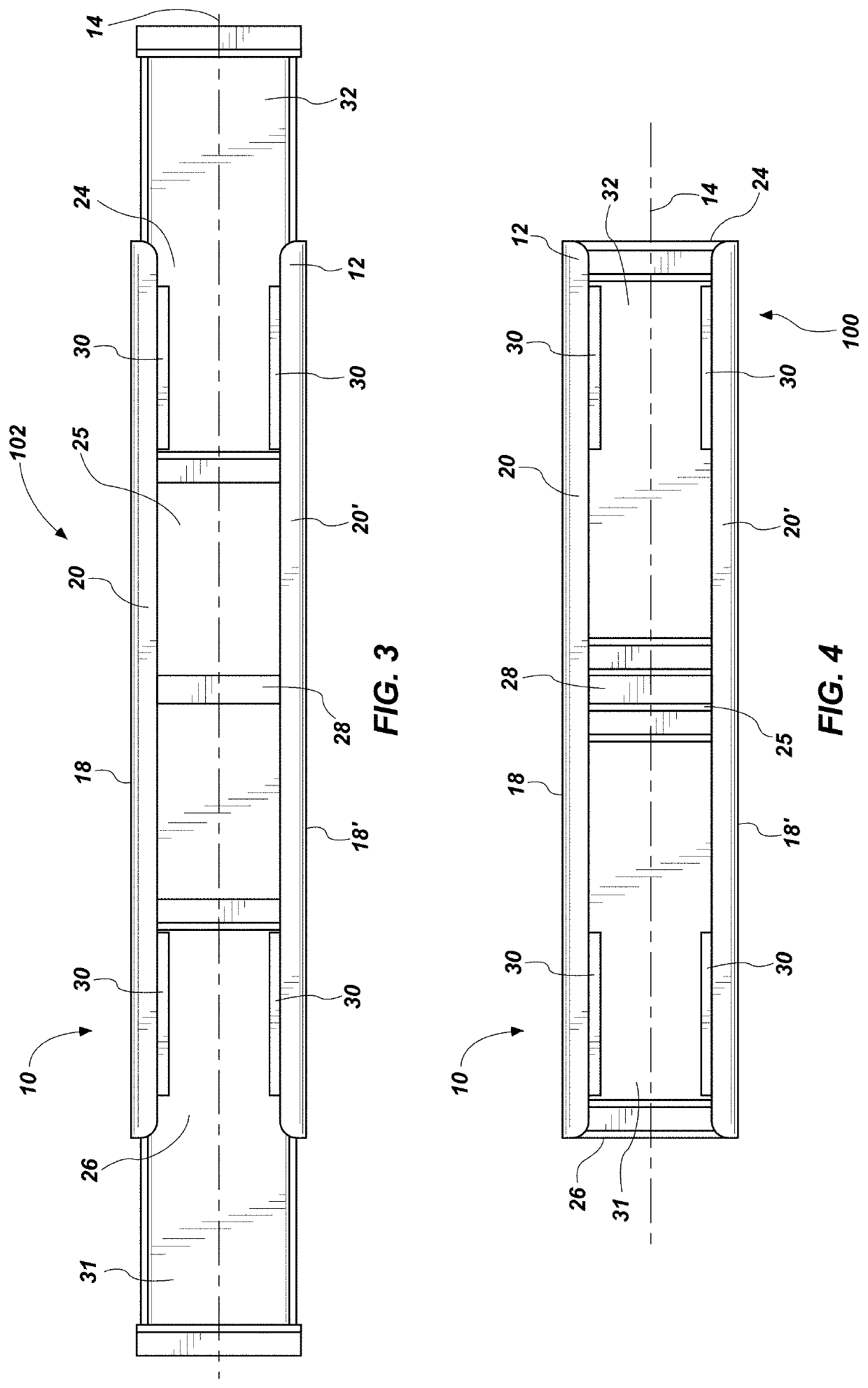

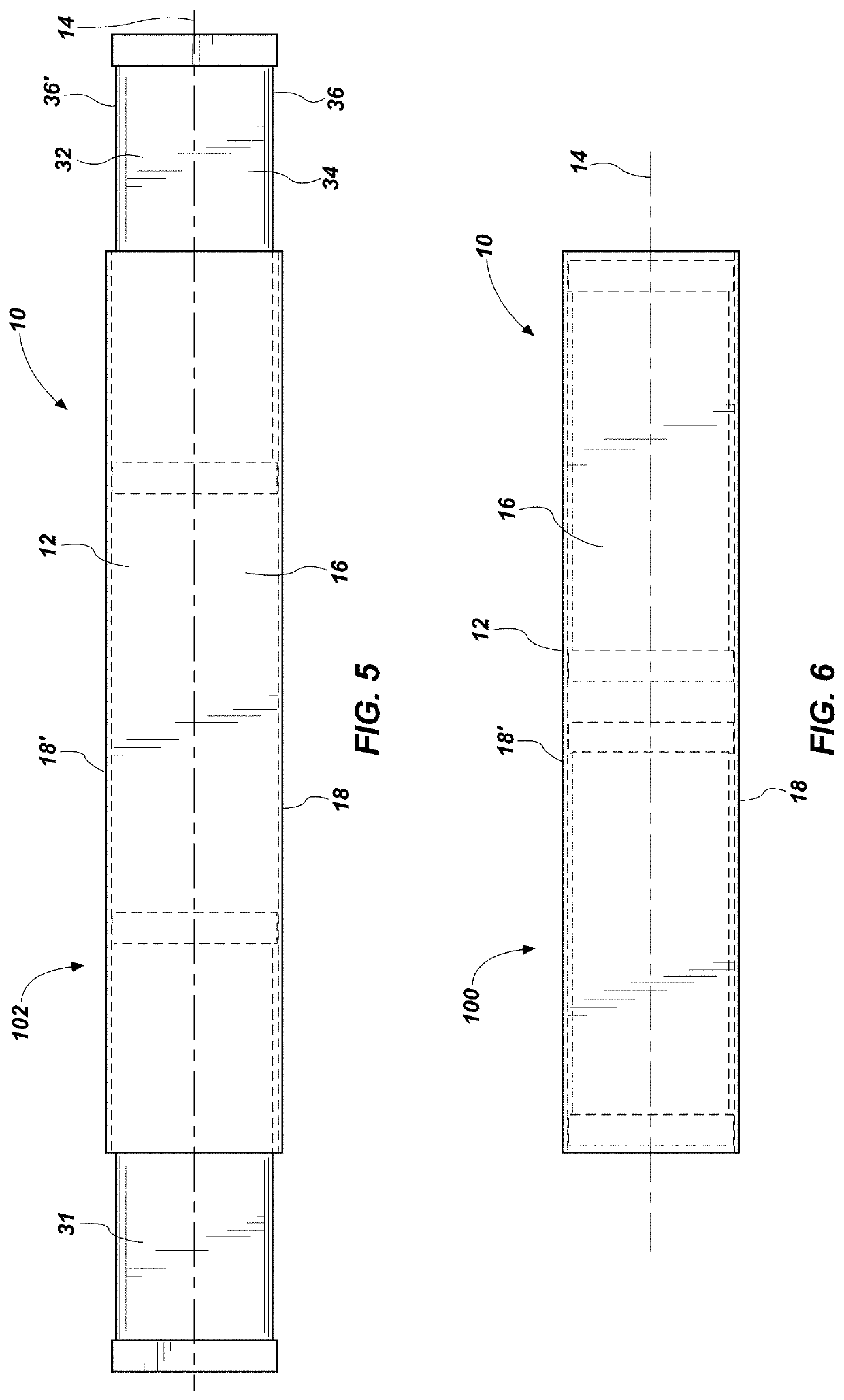

[0093]The dimensions of the system may vary as well. The housing 12 may be anywhere from 2 feet (or roughly 0.6 meters) to 42 feet (or roughly 13 meters) in length. The width of the housing 12 may be 4 to 8 inches (or roughly 10 cm to 21 cm). The height of the housing 12 may be 2 to 4 inches (or roughly 5 cm to 11 cm). The length of the extendable members 31, 32, may vary but may be in the range of 12 to 18 inches (or roughly 30 cm to 46 cm), with the extendable members 31, 32 being capable of extending 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com