Tin or tin-alloy plating liquid, bump forming method, and circuit board production method

a technology of tin or tin alloy and plating liquid, which is applied in the manufacture of printed circuits, semiconductor/solid-state devices, and semiconductor/solid-state devices, etc. it can solve the problems of not achieving uniform bump height and 4 plating liquids for substrates, and achieve uniform bump height and plating. good, the effect of suppressing the precipitation of snions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

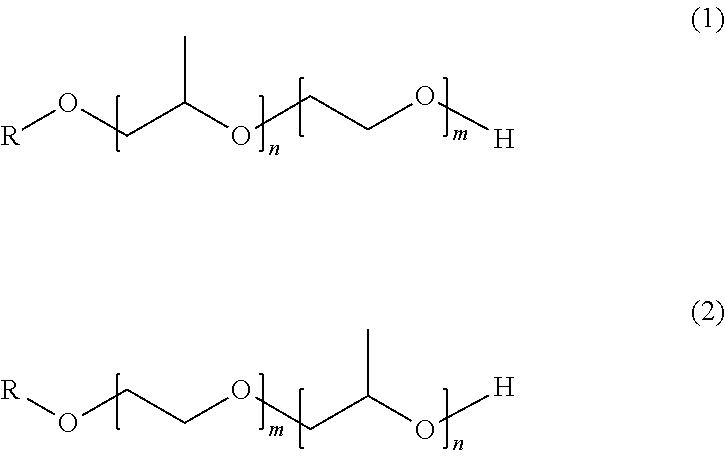

[0075]Methanesulfonic acid as a free acid, hydroquinone as an antioxidant, 1-naphthaldehyde as a leveling agent (D-1), methacrylic acid as a leveling agent (D-2) were mixed with a Sn methanesulfonate aqueous solution to obtain a homogeneous solution. Then, as a surfactant, the above No. C1-6 polyoxyethylene alkyl ether (mass average molecular weight: 500, carbon number in R in Formula (1): 13, number m of polyoxyethylene (EO) groups: 6, and number n of polyoxypropylene (PO) groups: 0), the above No. C2-2 condensate of polyoxyethylene and polyoxypropylene alkyl ether (mass average molecular weight: 530, carbon number in R in Formula (2): 9, number m of polyoxyethylene (EO) groups: 6, and number n of polyoxypropylene (PO) groups: 2) were added. Ion-exchanged water was finally added to initially make-up a Sn plating liquid having the following composition. The Sn methanesulfonate aqueous solution was prepared by electrolyzing a metal Sn plate in a methanesulfonic acid aqueous solution....

examples 3 to 5 , 7 to 9 , 11 , 12

Examples 3 to 5, 7 to 9, 11, 12, and 14 and Comparative Examples 1, 2, 4, 5, 7, 9, 10, 12, 13, 15, 16

[0085]In Examples 3 to 5, 7 to 9, 11, 12, and 14 and Comparative Examples 1, 2, 4, 5, 7, 9, 10, 12, 13, 15, and 16, as the nonionic surfactant (C1) and the nonionic surfactant (C2), the surfactants having the properties shown in Tables 1 and 2 were used and selected as shown in Tables 3 and 4. Except for this, in the same manner as in Example 1, Sn plating liquids of Examples 3 to 5, 7 to 9, 11, 12, and 14 and Comparative Examples 1, 2, 4, 5, 7, 9, 10, 12, 13, 15, and 16 were initially made-up.

Initial Make-Up of SnAg Plating Liquid

example 2

[0086]Methanesulfonic acid as a free acid, catechol as an antioxidant, benzaldehyde as the leveling agent (D-1), methyl methacrylic acid as the leveling agent (D-2) were mixed with the Sn methanesulfonate aqueous solution to dissolve. Further, an Ag methanesulfonate liquid was added and mixed. A homogeneous solution was obtained by mixing. Then, as a surfactant, the above No. C1-6 condensate of polyoxyethylene and polyoxypropylene alkyl ether (mass average molecular weight: 500, carbon number in R in Formula (1): 13, number m of polyoxyethylene (EO) groups: 6, and number n of polyoxypropylene (PO) groups: 0), the above No. C2-3 condensate of polyoxyethylene and polyoxypropylene alkyl ether (mass average molecular weight: 650, carbon number in R in Formula (2): 13, number m of polyoxyethylene (EO) groups: 8, and number n of polyoxypropylene (PO) groups: 2) were added. Ion-exchanged water was finally added to initially make-up a SnAg plating liquid having the following composition. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com