Pressure control method for high-pressure regulator to prevent internal leak, and high-pressure shut-off valve

a technology of high-pressure regulator and pressure control method, which is applied in the direction of fluid pressure control, process and machine control, instruments, etc., can solve the problems of inability to prevent and regulate the pressure inside the regulator, and achieve the effects of high reliability, safe and stable use, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, and the present invention is not limited to or restricted by the embodiments.

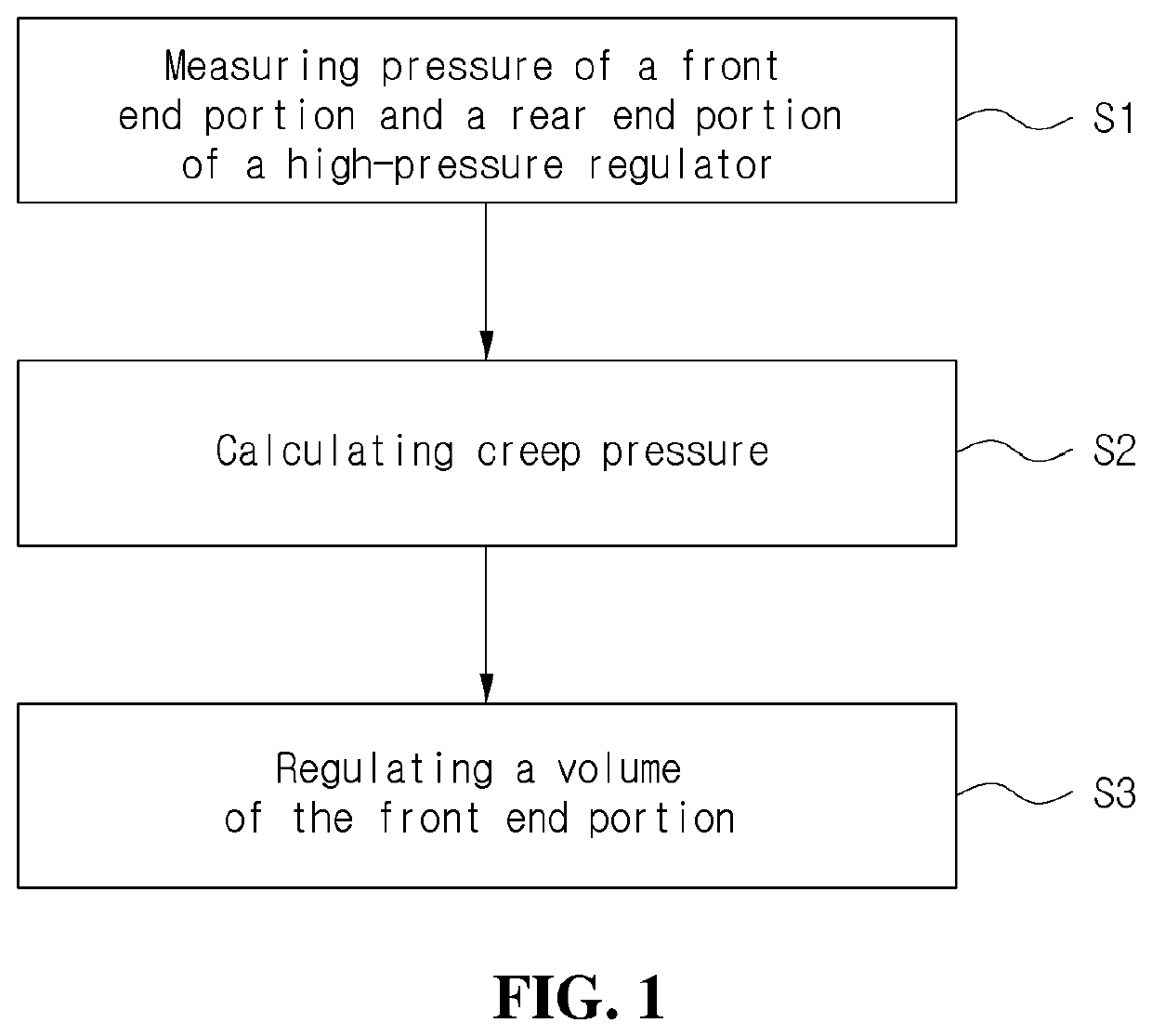

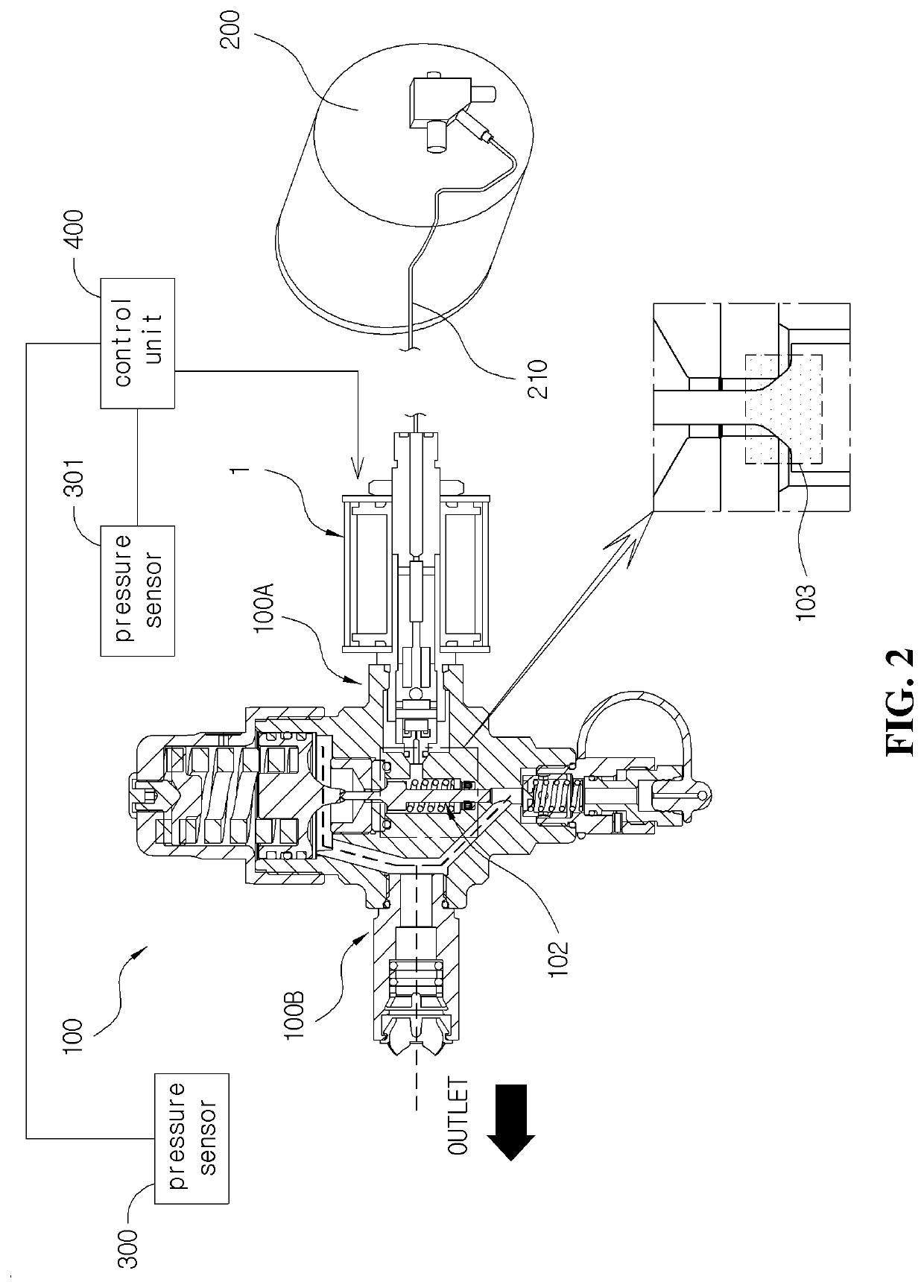

[0046]FIG. 1 is a block diagram for illustrating a pressure control method according to the present invention. FIG. 2 is a conceptual diagram for illustrating a state where the present invention is applied to a high-voltage regulator.

[0047]As shown in the drawings, in general, a typical high-pressure regulator 100 applied to a hydrogen FCEV handles high-pressure hydrogen of about 700 bar, and accordingly stable discharge pressure, sufficient pressure-resistance, and internal airtightness are very important.

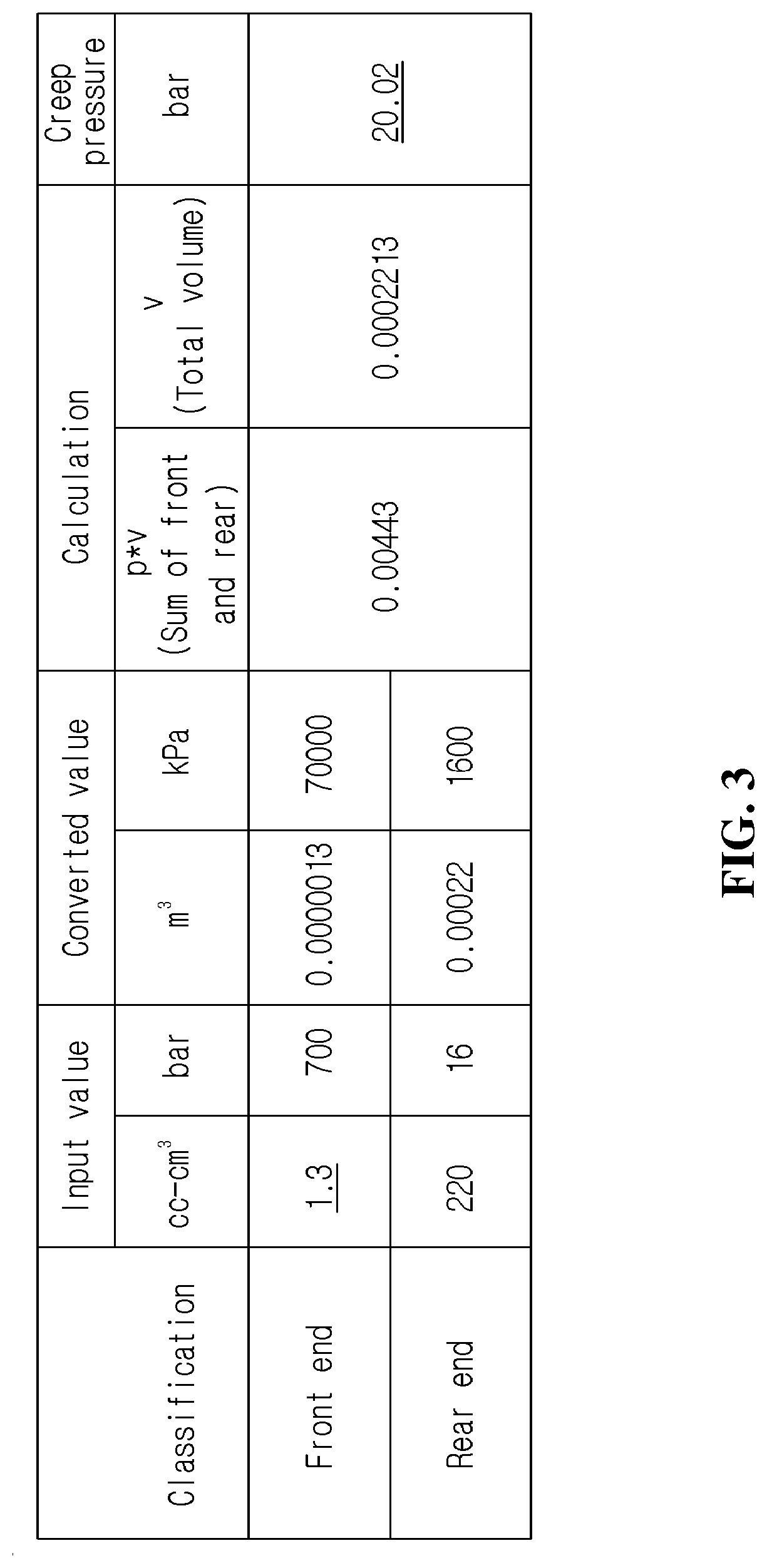

[0048]In other words, a pressure difference and a volume between a front end portion 110 and a rear end portion 120 of the conventional high-pressure regulator 100 are measured as shown in Table 2 of FIG. 7.

[0049]An overpressure relief valve for relieving overpressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com