Manufacturing method for pipe structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

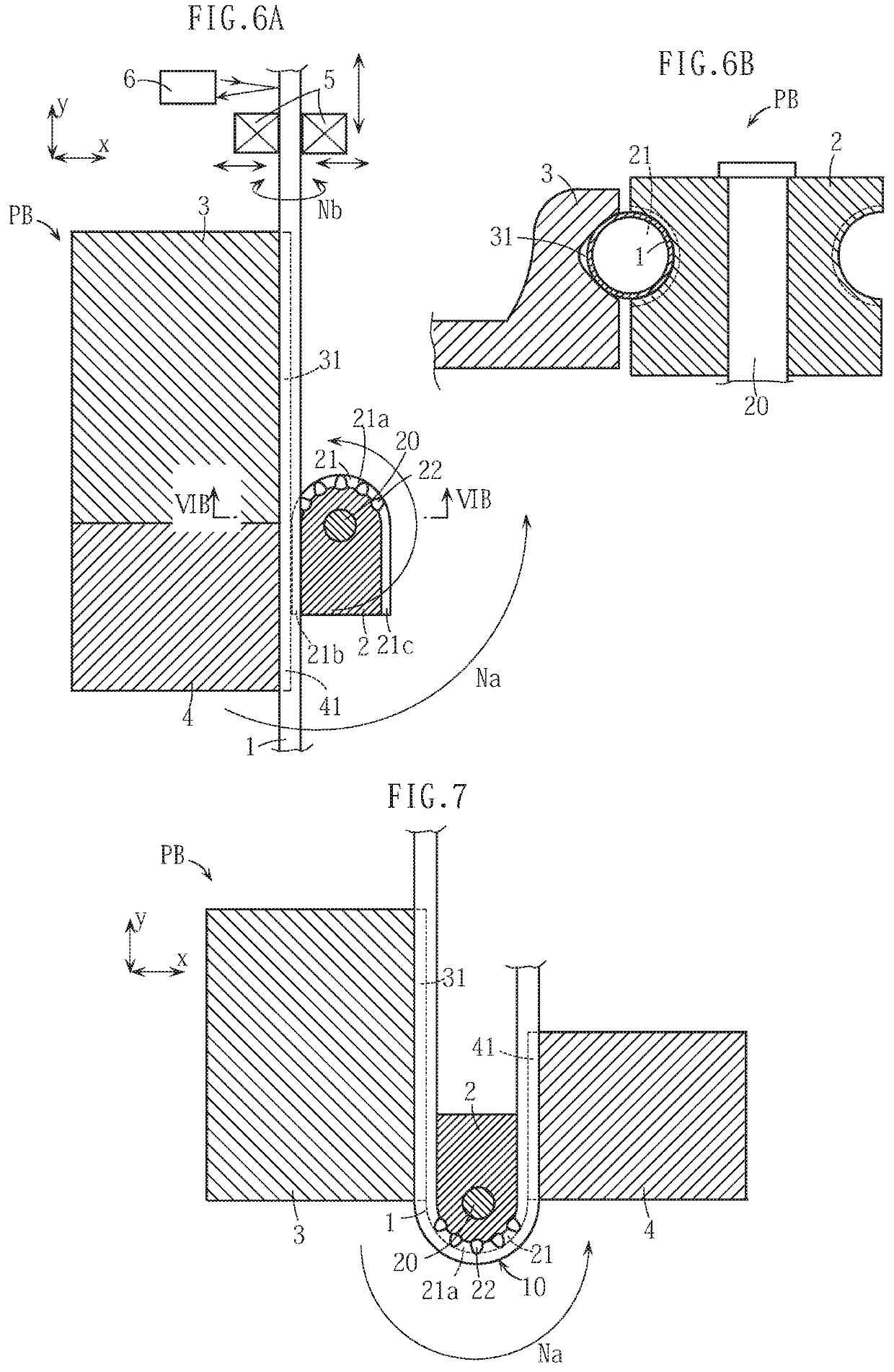

[0037]A preferred embodiment of the present invention will be described specifically below with reference to the figures.

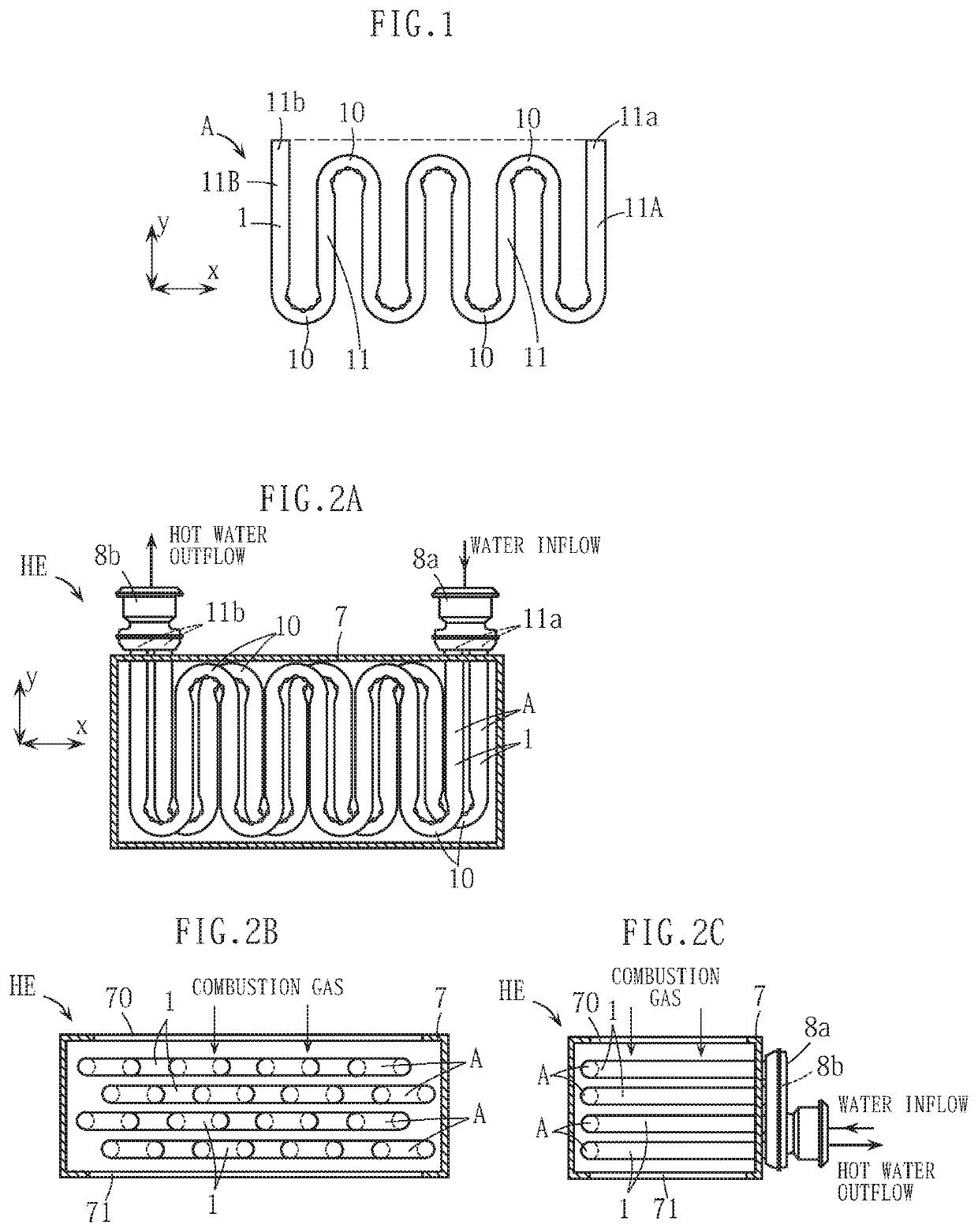

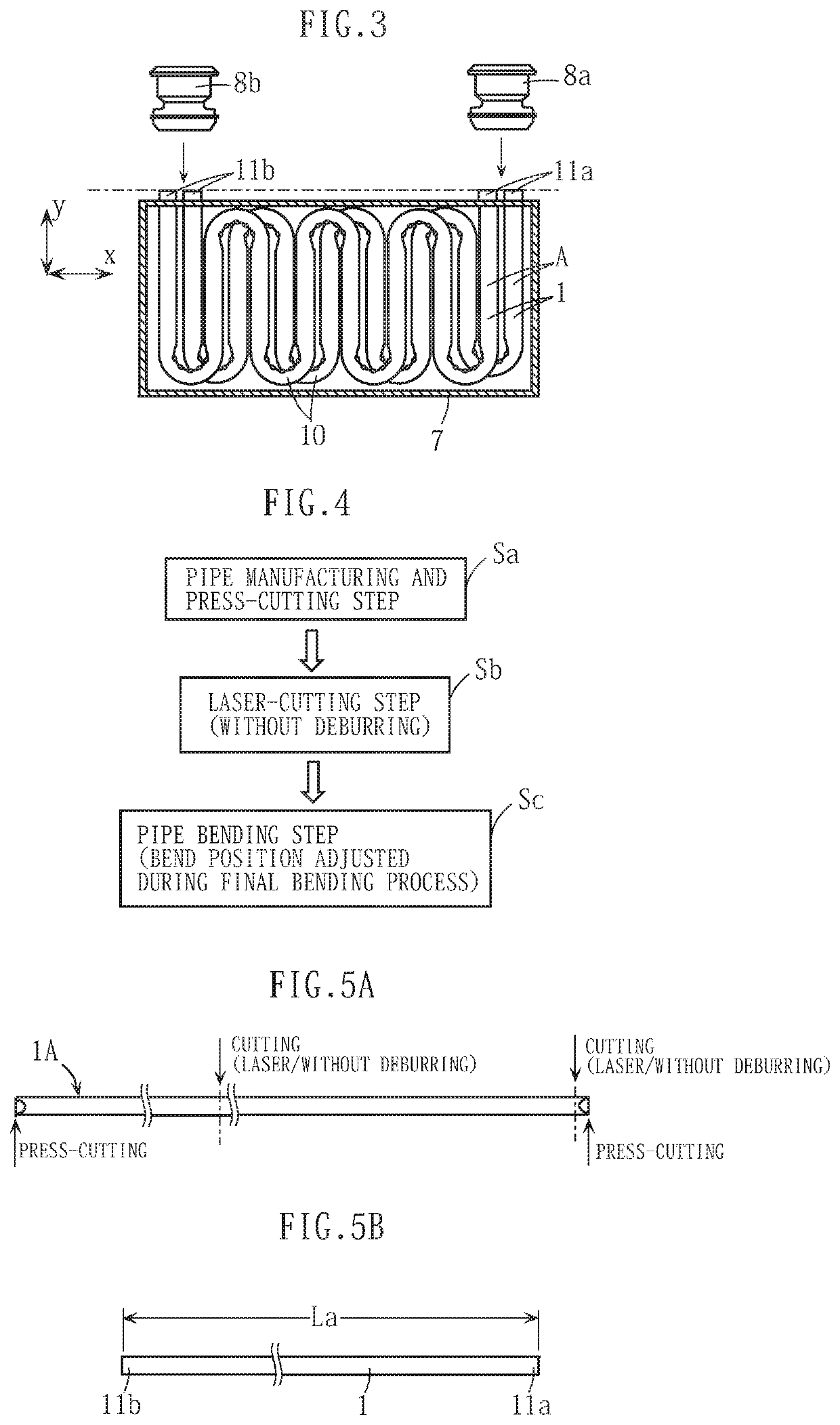

[0038]The manufacturing subject of the manufacturing method for a pipe structure according to this embodiment, similarly to the prior art described above, is the meandering pipe body A shown in FIG. 1. Accordingly, identical or similar elements to the prior art have been allocated identical reference symbols to the prior art.

[0039]First, the meandering pipe body A will be described.

[0040]As described above, the meandering pipe body A is constructed by forming the stainless-steel pipe 1, for example, in a meandering shape, and includes the plurality of bend portions 10, each of which has a bend angle of 180 degrees, and a plurality of straight portions 11 connected via the plurality of bend portions 10. The regions 11A, 11B near the respective end portions of the pipe 1 are separated from each other in the x direction, which is a horizontal width direction in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com