Airlift

a technology of airlifting and liquid, applied in the direction of machines/engines, jet pumps, machines/engines, etc., can solve the problems of low lifting efficiency and significant fluctuations in liquid and air flow, and achieve the effect of increasing airlifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

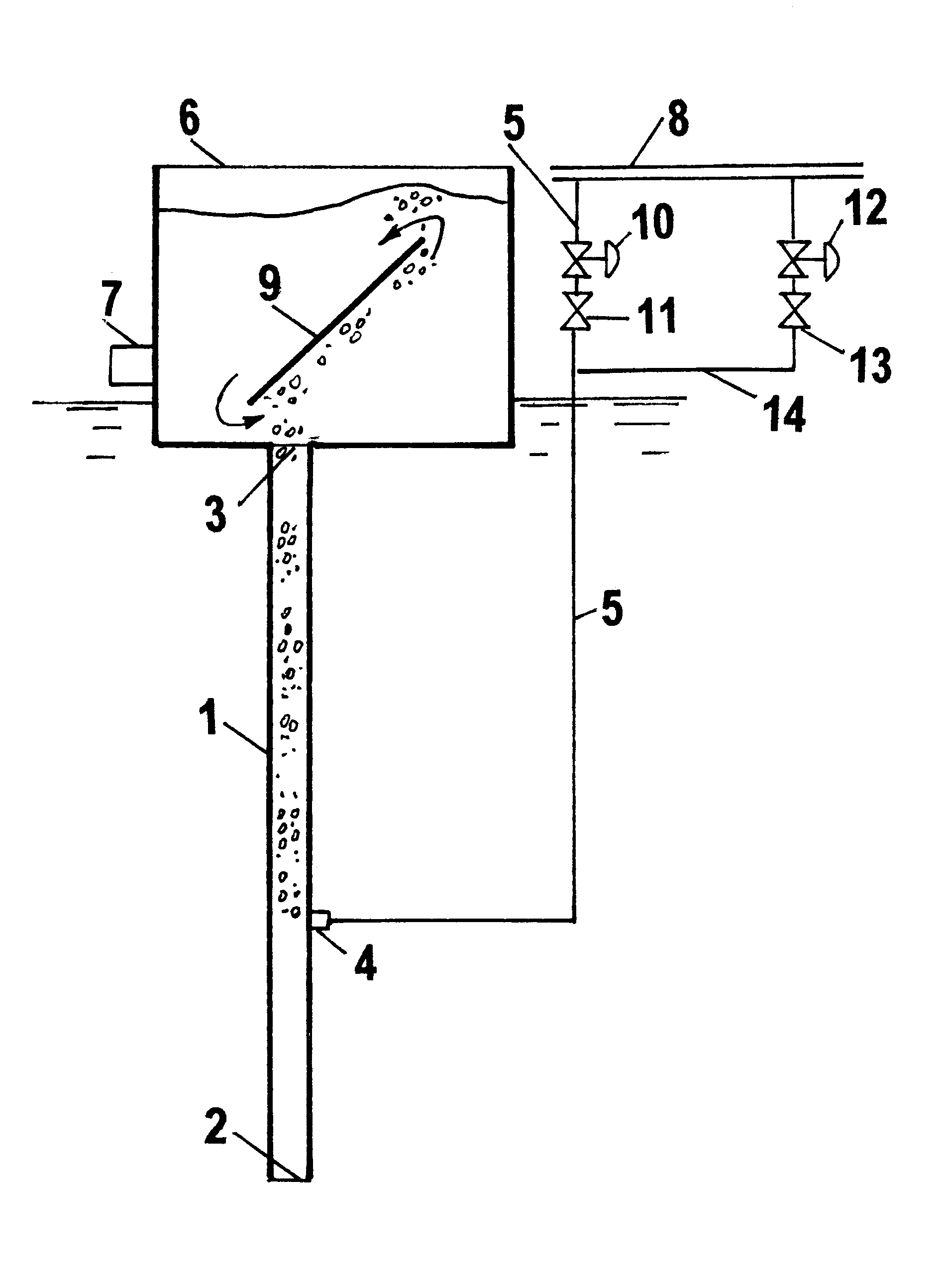

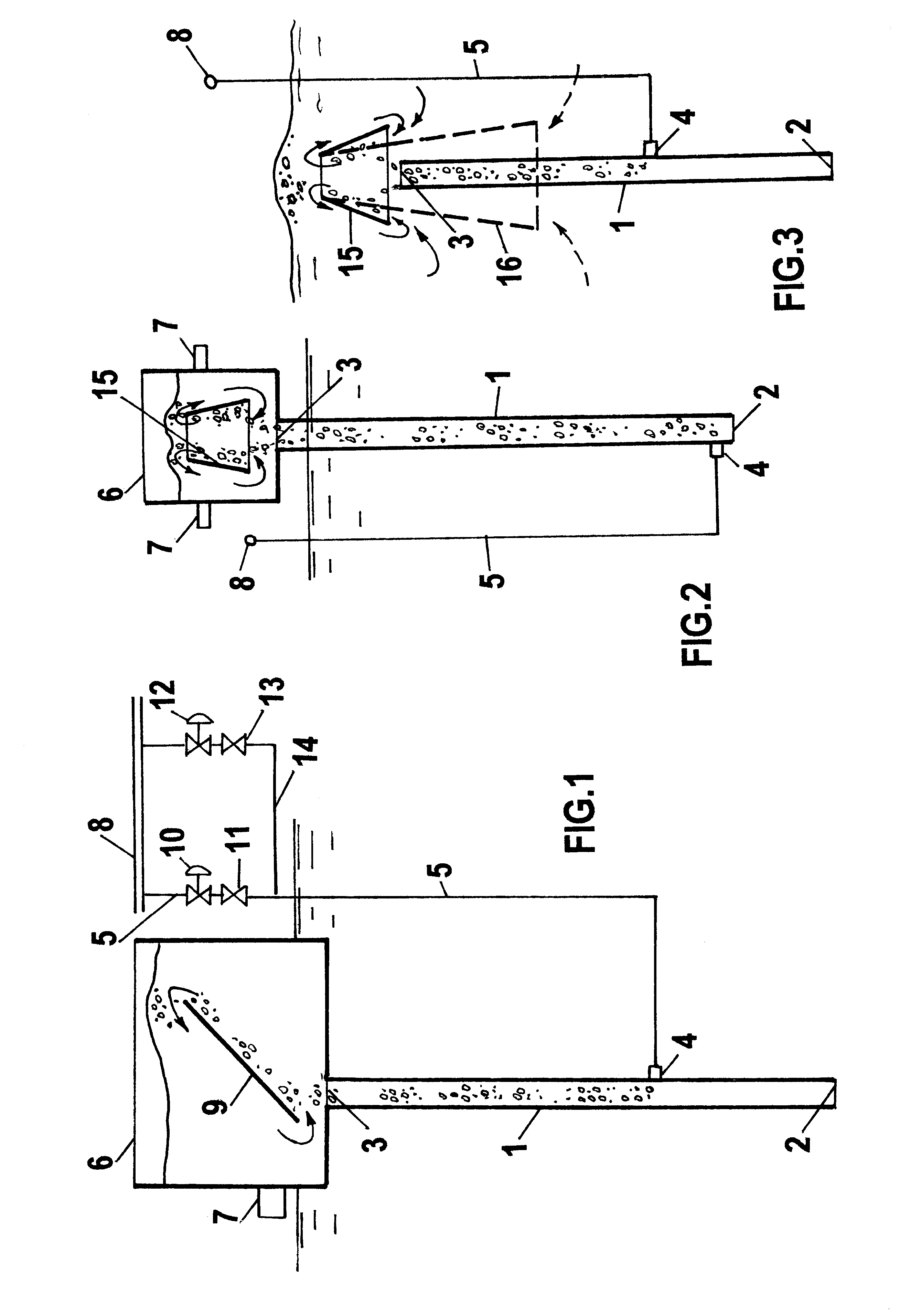

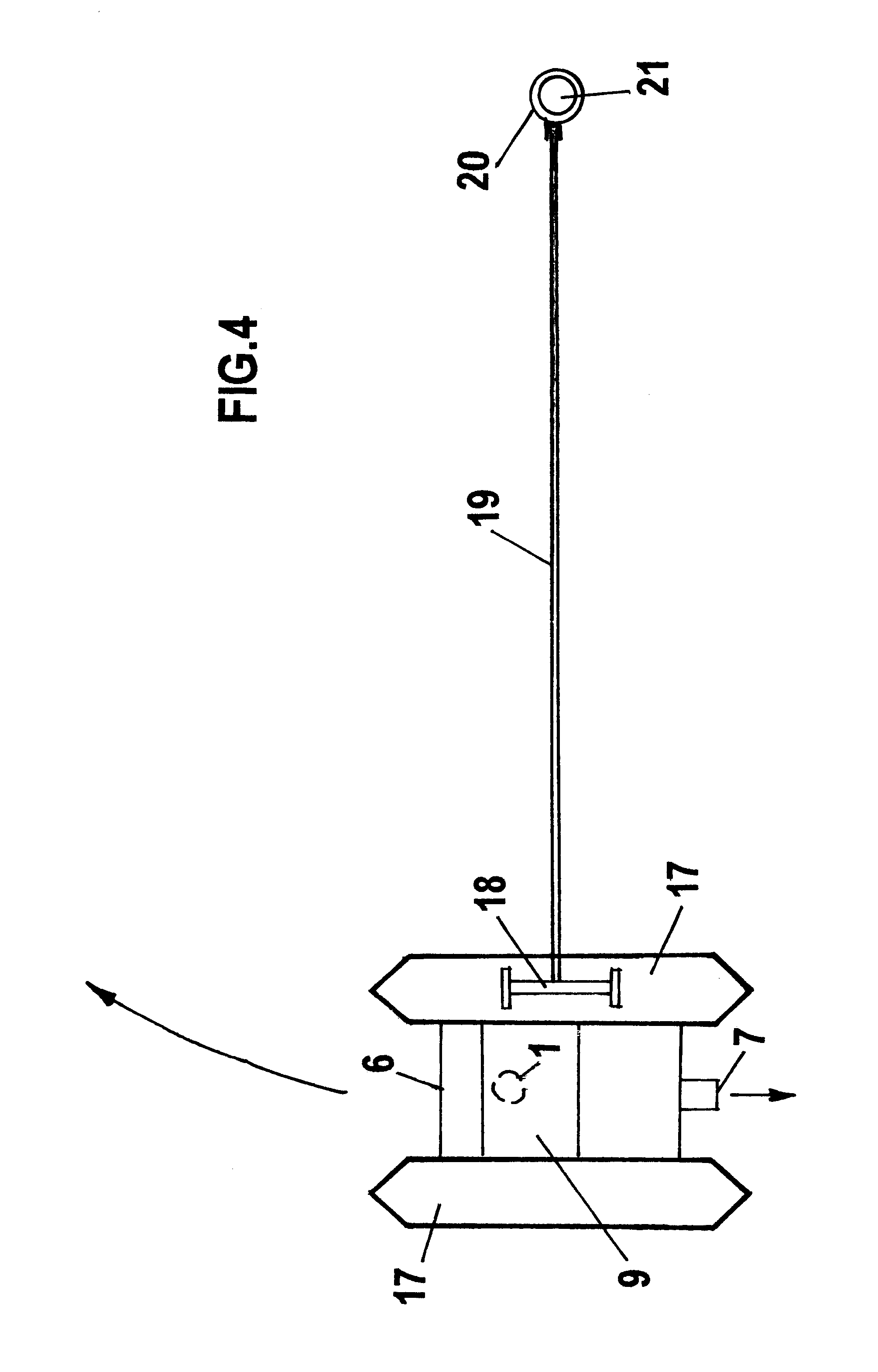

Referring now to FIG. 1, there is shown an airlift comprising a lift pipe 1 having a suction port 2 and disharge port 3, an air main 8 connected to the lift pipe 1 at a port 4. A container 6 is attached to the lift pipe at the port 3. This container has a liquid discharge means 7 and a baffle 9 for inducing flow rotations above the port 3. Optionally, control valve 11 and on / off valve 10 are provided on an air branch 5. Additionally, at least one more optional branch 14 with control valve 13 and on / off valve 12 can also be provided.

Referring now to FIG. 1, the airlift is operated as follows. The air is fed via main 8 and branches 5 and 14 into the lift pipe 1 submerged in liquid. An air-liquid mixture is formed. This mixture has lower density than the non-aerated liquid outside the pipe 1. Accordingly, it floats up in the lift pipe, exits from the port 3 and reaches the flat inclined baffle 9. On the lower (right side in FIG. 1) side of the baffle, the air-liquid mixture continues t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com