Manual input device with force feedback function and vehicle-mounted equipment controller using same

a technology of input device and input lever, which is applied in the direction of electric programme control, program control, instruments, etc., can solve the problems of requiring more power consumption, unable to correct the operation of the gear shifter, and the disagreement between the engagement status of the actual gear and the shift status of the shift lever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fifth embodiment

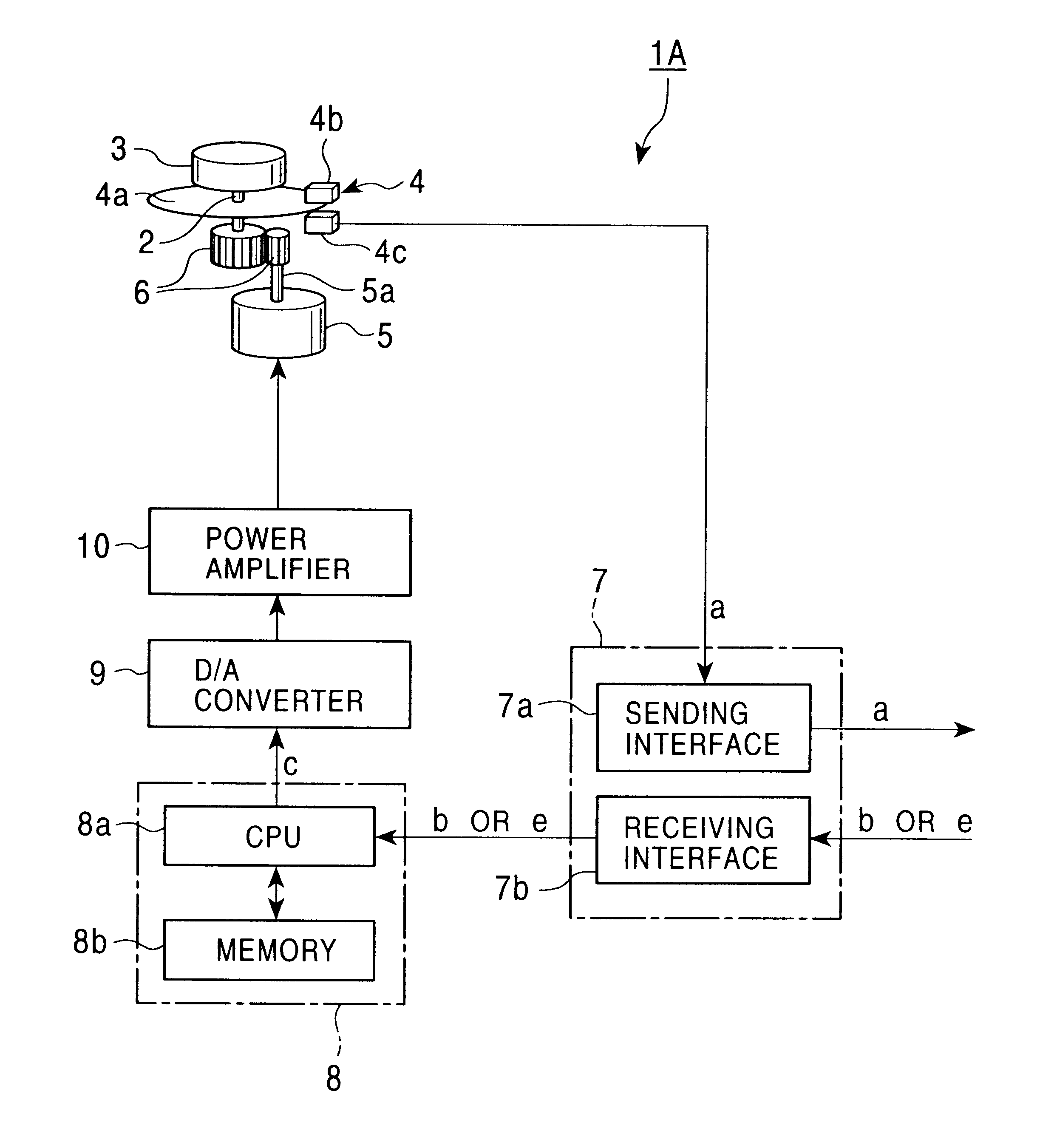

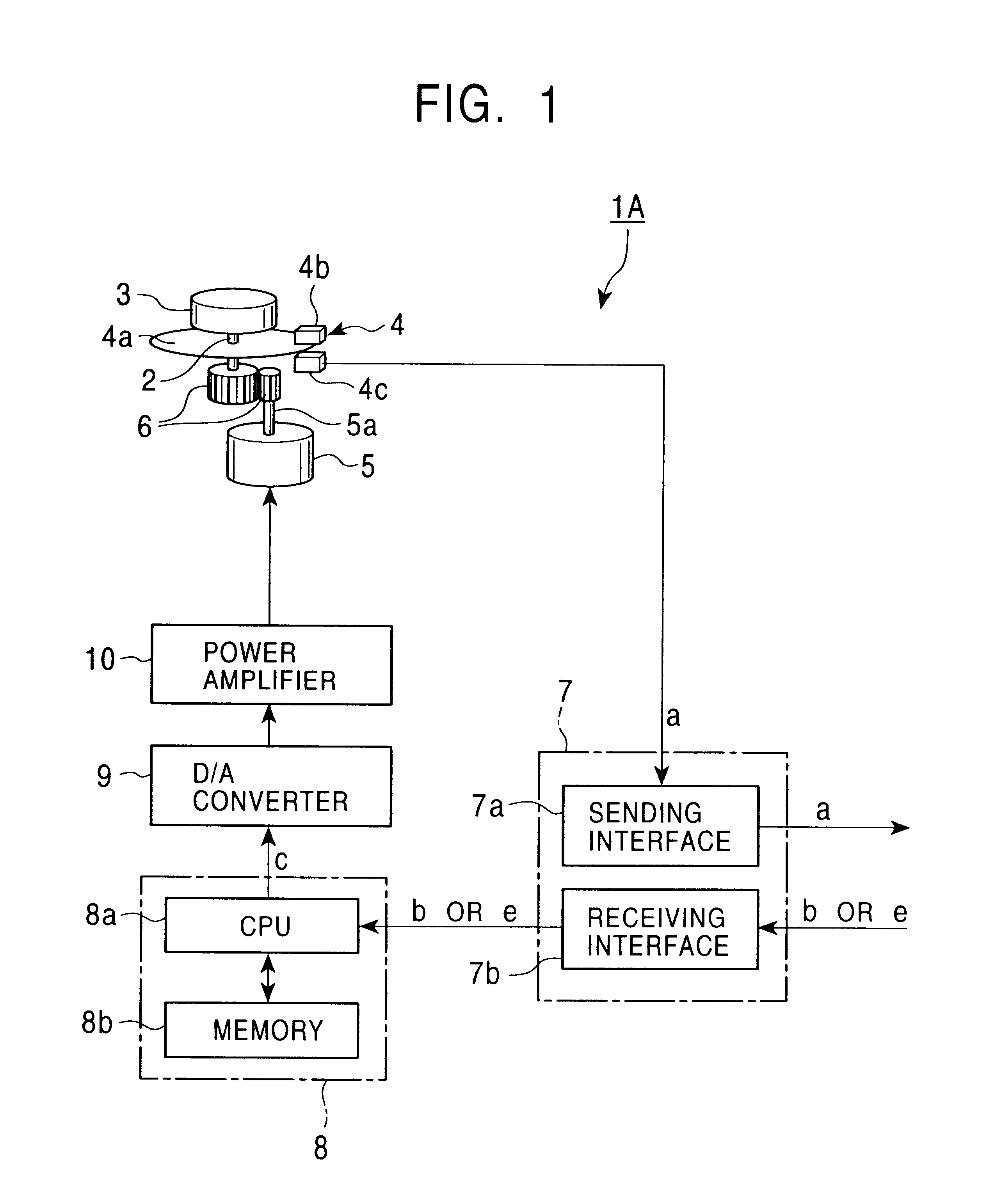

As a first application example of the manual input device, a variable speed controller for an automatic transmission vehicle to which the slide-type manual input device 1E is applied will be described below with reference to FIG. 9.

As shown in FIG. 9, a variable speed controller of this example includes an external device that is connected to the input / output portion 7 of the manual input device 1E. This external device includes a transmission controller 21, a fork driving portion 22 having an actuator such as a solenoid or linear motor which is controlled by the transmission controller 21, and external device sensing means 23 such as an encoder or potentiometer for detecting the driving state of the driving portion 22, and a fork switch 24 which is operated by the driving portion 22. The external device further includes a transmission 25 having gears whose engagement is switched by the fork switch 24, and a revolution sensor 26 for detecting the RPM of the output shaft of the tran...

second application example

of Manual Input Device

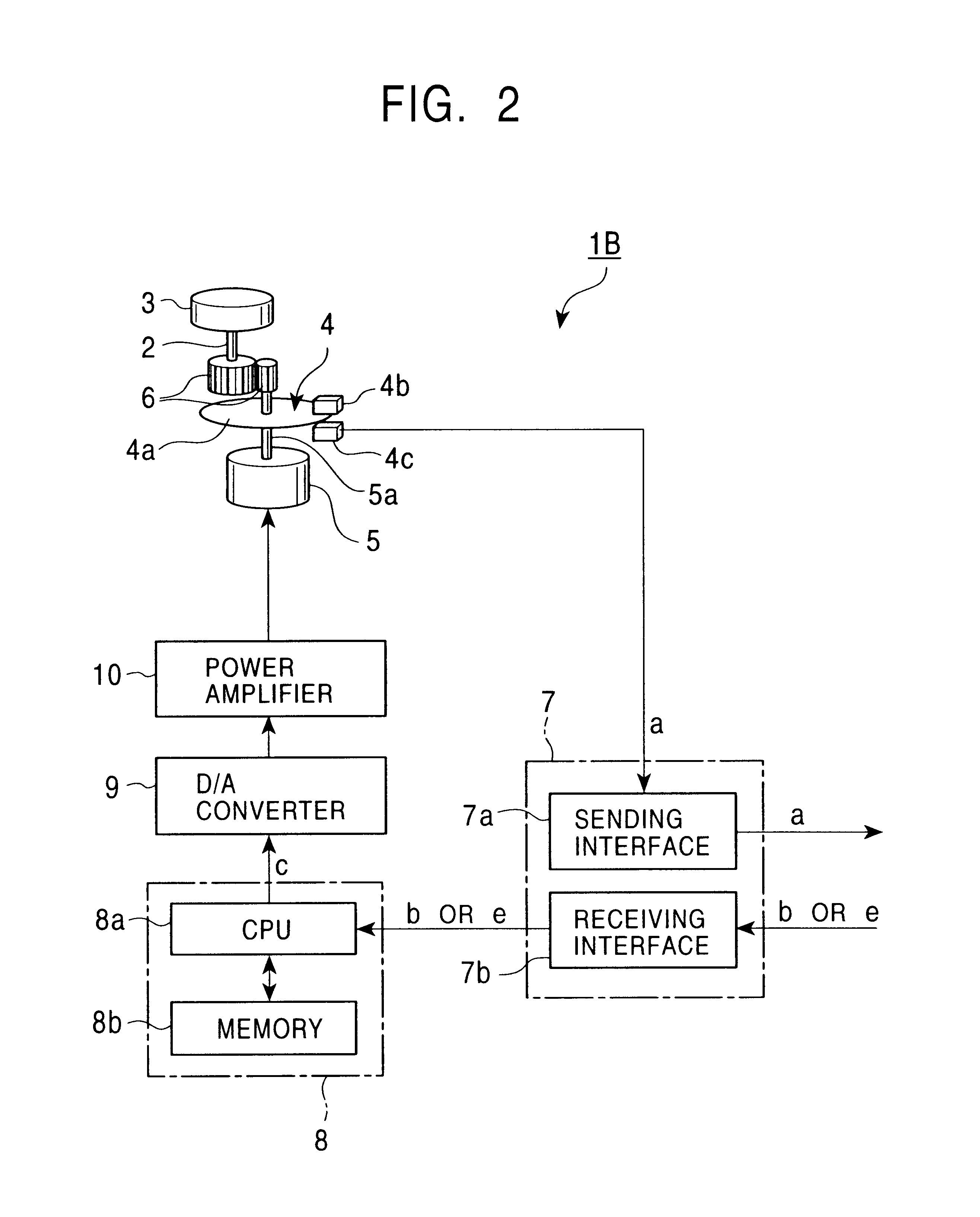

The second application example of the manual input device will now be described with reference-to FIG. 10. In this example, the slide-type manual input device 1E according to the fifth embodiment is also applied to the variable speed controller of an automatic transmission vehicle. However, unlike the first application example in which the external signal b1 and b2 are transmitted from the external device control portion 28 to the control portion a, this second example is characterized in that the raw detection signal a and the external signals b1 and b2, or the external signals b1 and b2 are converted to control information e that is simpler in data structure, and the control information e is sent to the control portion 8.

Thus, the memory 28b of the external device control portion 28 contains a conversion program for converting the detection signal a and the external signals b1 and b2, or the external signals b1 and b2, which are inputted to the CPU 28a, into ...

third application example

of Manual Input Device

A third application example of the manual input device will now be described with reference to FIG. 11. In this application example, the manual input device 1H according to the eighth embodiment is applied to the variable speed controller of an automatic transmission vehicle, and is characterized in that the control signal c for the actuator 5 is transmitted from the external device control portion 28 to the manual input device 1H.

Thus, the memory 28b of the external device control portion 28 stores the data and program for analyzing the detection signal a and the external signals b1 and b2, or the external signals b1 and b2, which are inputted to the CPU 28a, as well as the driving data and driving program for the actuator 5. The CPU 28a repeatedly activates the driving program to generate the control signal c, corresponding to the inputted detection signal a and the external signals b1 and b2, or the external signals b1 and b2, for the actuator 5, and then ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com