Drive mechanism for oscillatory abrasion and polishing tool

a technology of abrasive bit and drive mechanism, which is applied in the direction of manufacturing tools, edge grinding machines, dental surgery, etc., can solve the problems of abrasive bit recoiling or running away from the nail, difficult for an untrained individual to control such units, and poor acceptance of prior units by consumers, so as to avoid the spread of infection, and achieve the effect of economics and reliably implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

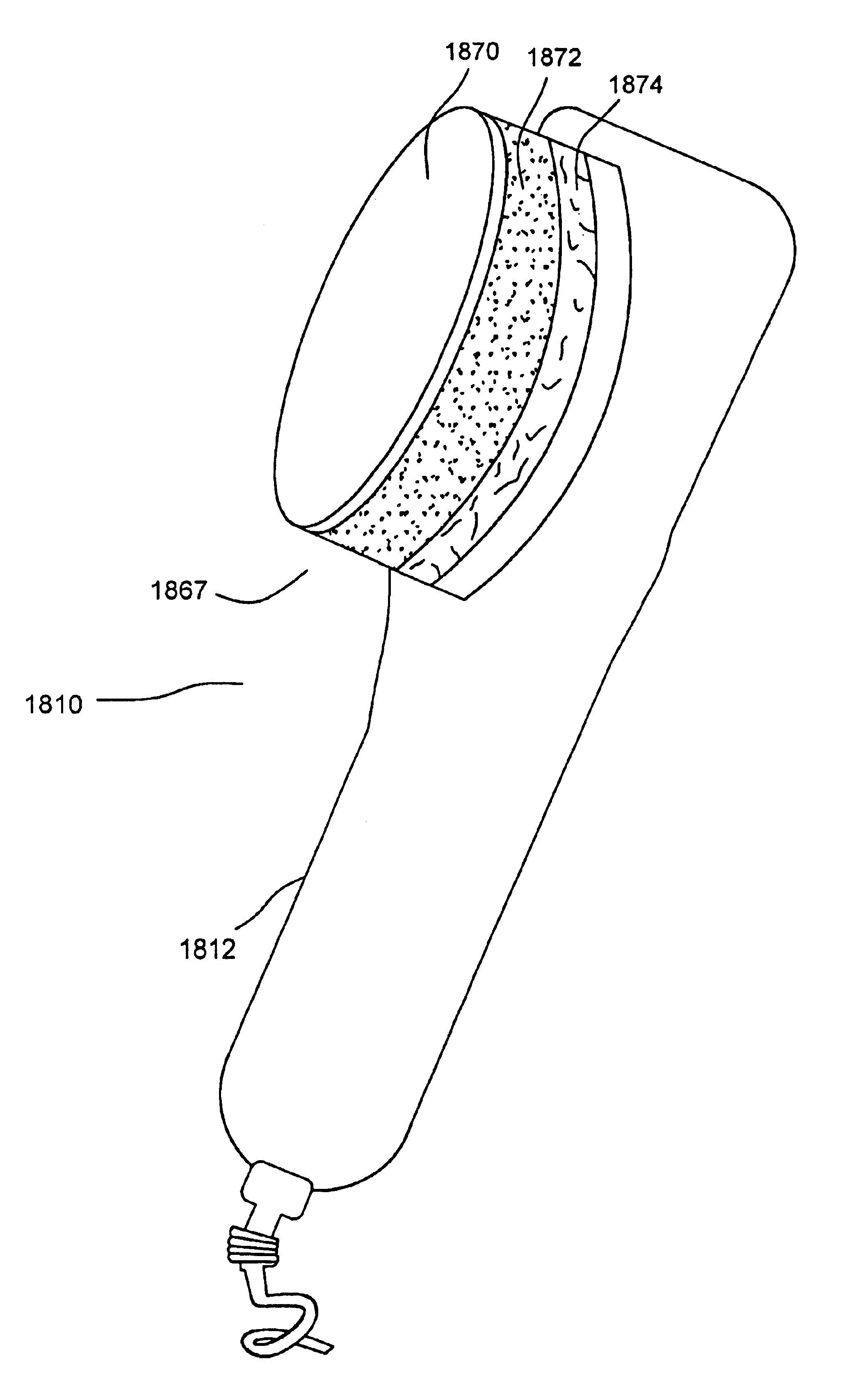

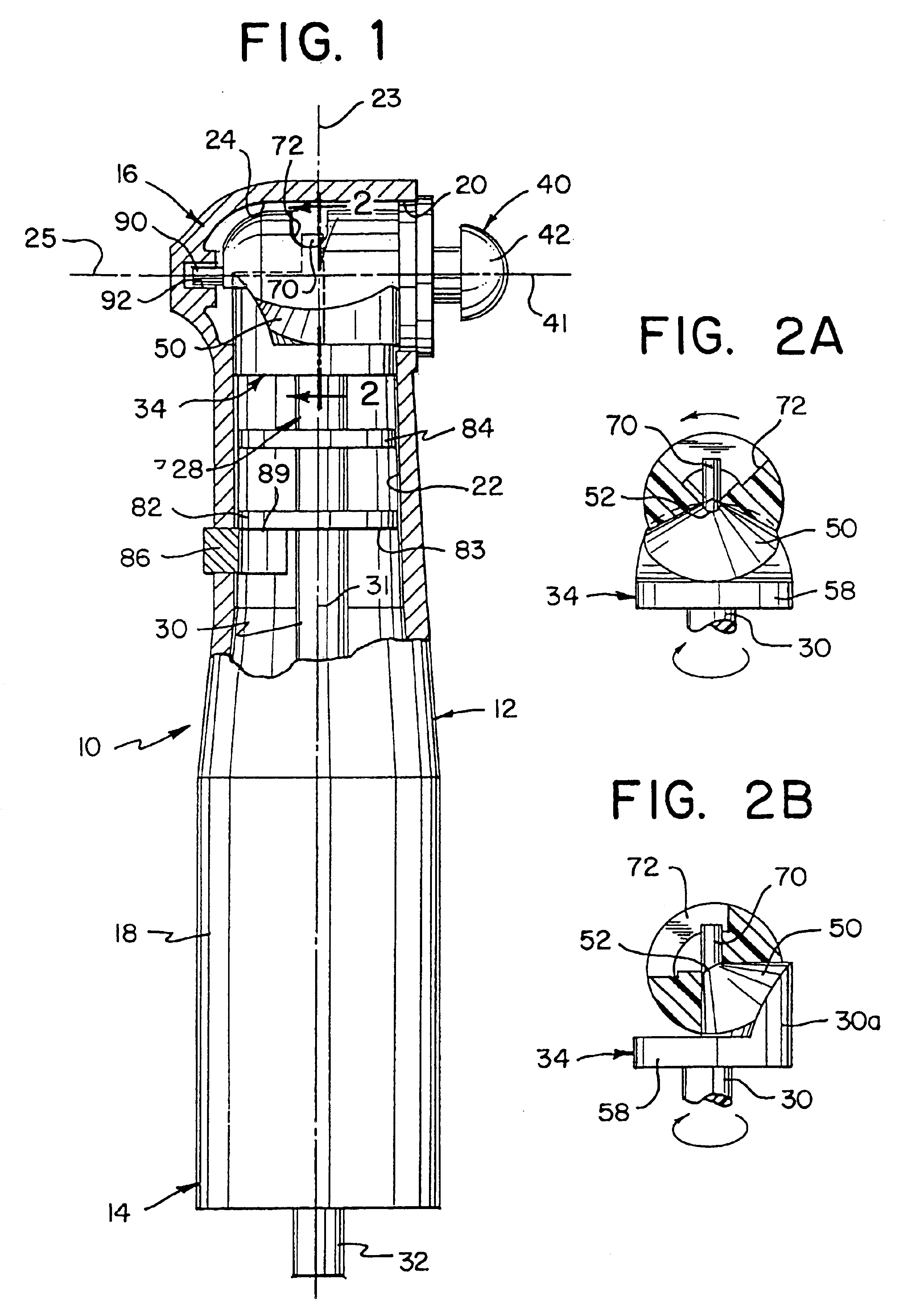

A tool assembly 10, formed in accordance with the principles of the present invention, is shown in FIG. 1. Tool assembly 10 includes a housing 12 having a proximal end 14 and a distal end 16, with main body portion 18 extending therebetween. Proximal end 14 is coupled to a tool hand piece (not shown) known in the art. Distal end 16 has a side opening 20 at which a desired device (not shown) is coupled. However, the preferred embodiment of the tool assembly shown in the Figures is a polishing brush which would be appropriately adjusted for use in buffing nails, or for polishing shoes or furniture and the like. Alternative embodiments replacing the brush with an abrasive surface are also contemplated. It will be understood that any appropriate tool piece known in the art may be used.

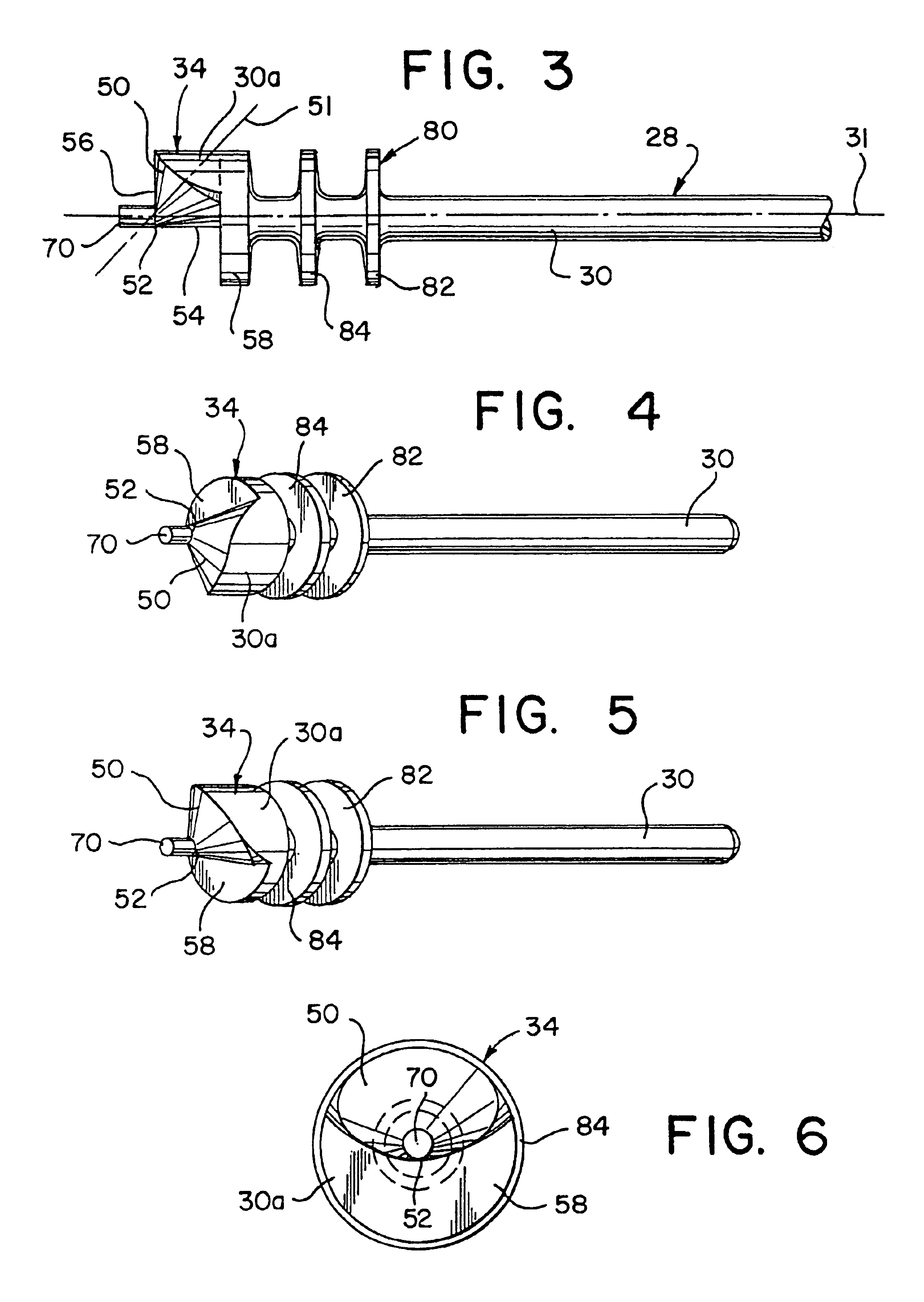

Housing 12 is hollow such that first and second channels 22, 24 are formed therein for housing driving mechanism 28. First, longitudinal channel 22 is formed within main body portion 18 and extends from pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com