Latch with bail-type mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0158]Simultaneously, the remainder of the contact points 192AA, 192BB are secured against the bottom of the panel 32B. The multiple contact points of the clamp 192A, 192AA, 192B, 192BB are used to distribute tension load. In FIGS. 14, 15, 15A through 15E, and 16, the mounting is illustrated, wherein a cradle-type bracket 212 is attached to the housing 102 by any of a variety of attachment means, including self-tapping screws. The attachment screw extends through an aperture 214 in the cradle bracket 212 and a receiving hole in the housing 131. A prepared panel 230 is shown in FIG. 16 to accommodate the bracket 212. The bracket ends 216A, 216B contact the bottom side of the panel 232B, wherein the panel 230 is held in place by the bracket 212, ramps 142A, 142B and the undercuts 151A, 151B. The cutout 234 has 3 notches 234A, 234B and 234C, with the first to on opposite sides and the third at one end.

[0159]In FIGS. 17 through 19, the activation of the latch 100 and ejection of the mod...

first embodiment

[0168]As shown in FIGS. 26 and 26A through 26E, the handle 508 has a body portion 574 with a flat top surface 574A and a contoured bottom surface 574B which converge forward to form a pawl 504. The bottom surface of the handle 574B has a groove 575 wherein the torsion spring 510 is aligned to retard movement when the latch 500 is assembled. As in the first embodiment, the body portion 574 is interrupted midway by a top aperture 584 which allows access to the button member 506. The bottom surface 574A of the body portion 574 extends into the aperture 584 so as to form a lip portion 586.

[0169]As shown in FIGS. 27 and 27A, the continuous flat spring 511 has a hairpin coil 511A and a obtuse coil 511B. The function of the hairpin coil 511A is for mounting on the spring mount 530A wherein the function of the obtuse coil 511B is biasing the movement of the housing 502 when in the panel as will be discussed further below.

[0170]FIGS. 28 and 28A show the torsion spring has a closed end 588 wh...

third embodiment

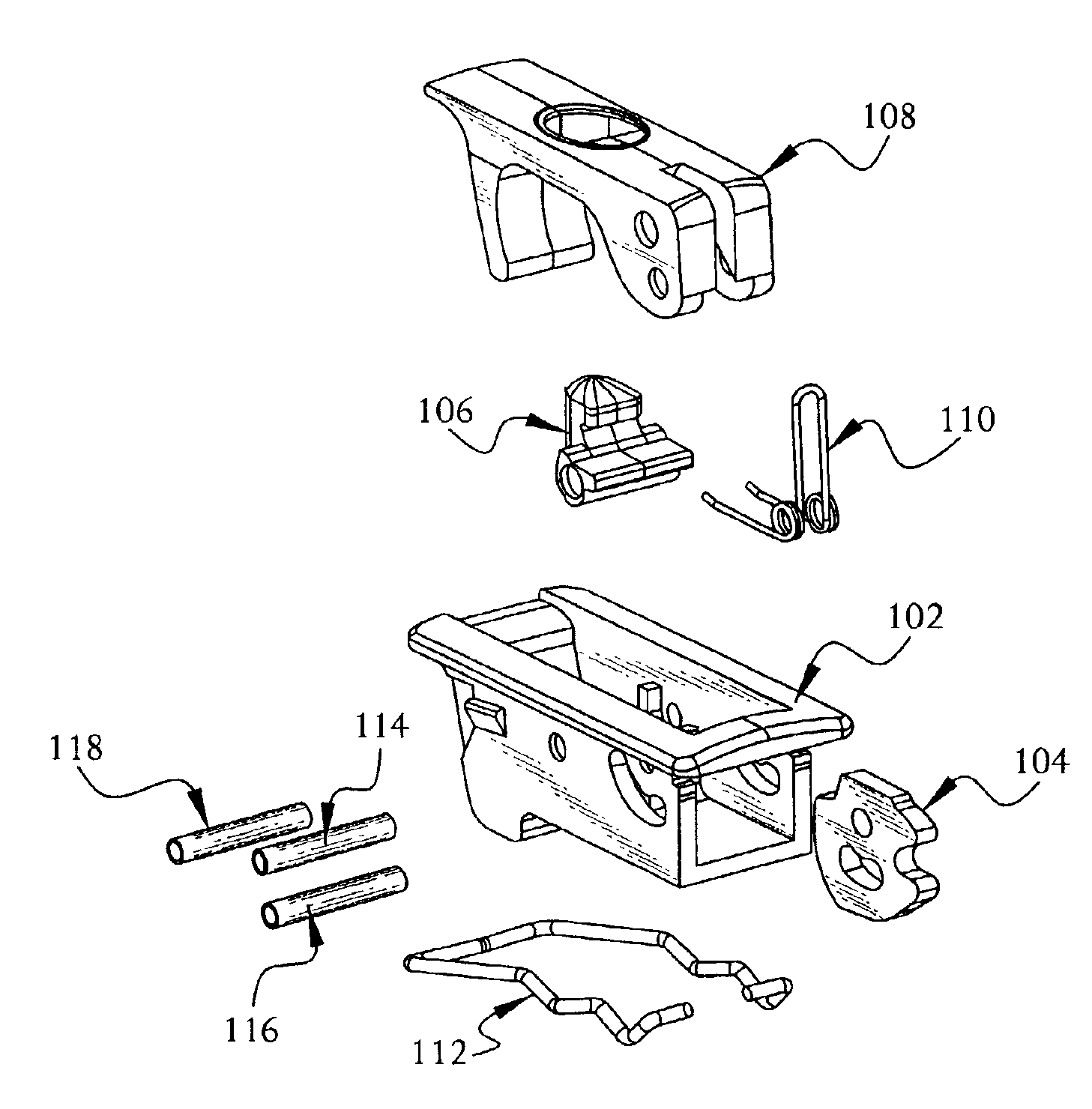

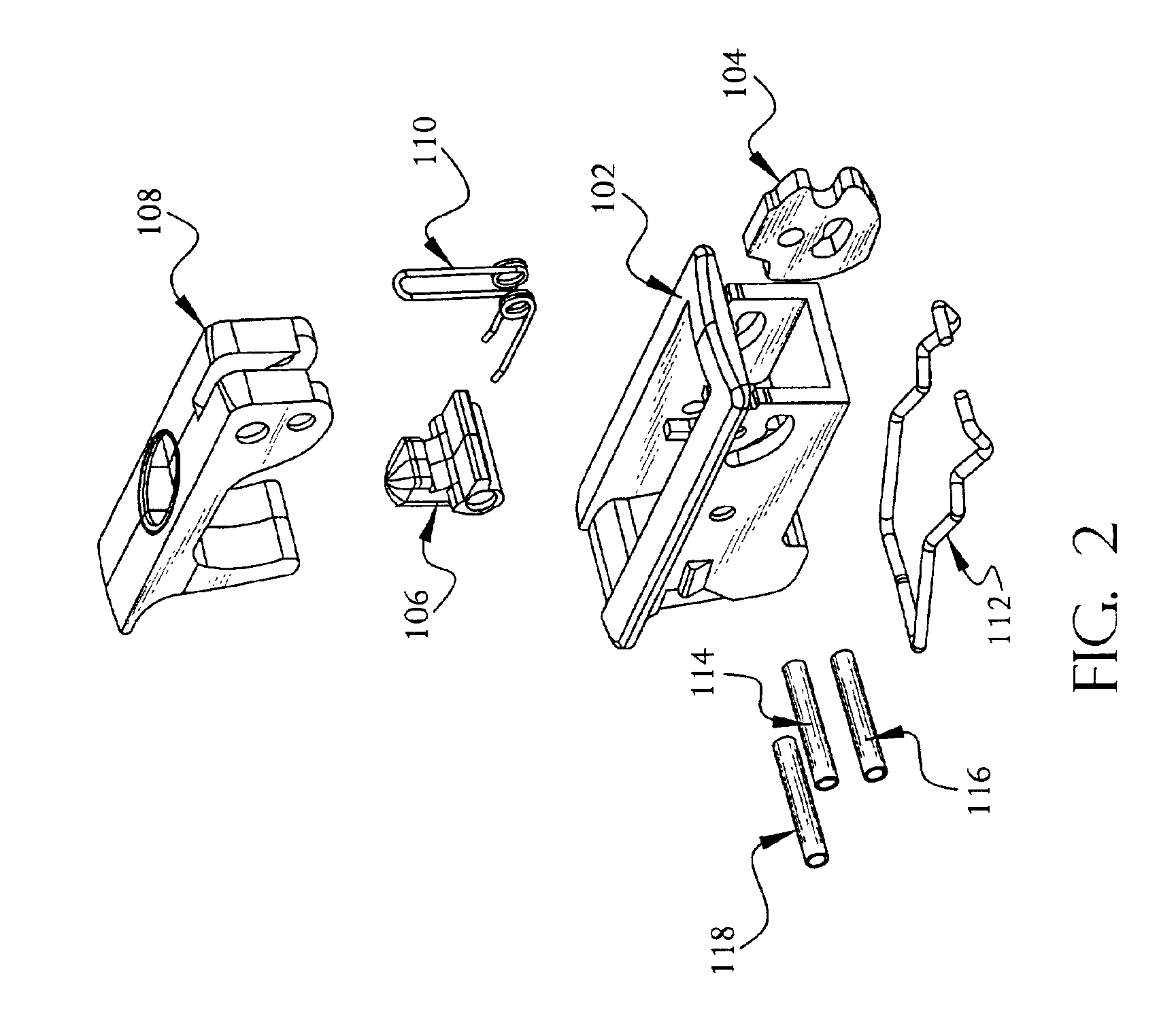

[0174]Referring to FIGS. 35, 35A through 35E, and 36, the third embodiment latch 700 in the closed position. This latch 700 includes a housing 702, a pawl member 704, a button member 706, a handle 708, a torsion spring 710, and pin members 714, 716, 718 and 719. The pawl member has a longitudinal aperture 756 and an rear aperture 754 which are shaped so as to limit the rotation of the handle 708 after disengagement from the button member 706.

[0175]Shown in FIGS. 37 to 41, latch 700 activation is accomplished as in the preferred embodiment 100 and the second embodiment 500 wherein the button member 706 disengages the handle member 708. The latch 700 is driven by the torsion spring 710 to a first position as guided by the shape of the longitudinal pawl member 756. The forward pin member 716 is stopped at the first curved portion 756A. Further rotation by the operator will bring the forward pin member 716 to the second curved portion 756B wherein it will stop until further rotation by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com