Image forming apparatus

a technology of image forming apparatus and photoconductor drum, which is applied in the direction of electrographic process apparatus, instruments, optics, etc., can solve the problems of high cost, difficult to make uniform the pressing balance of the photoconductor drum, and inability to obtain high-quality printed images, etc., and achieve the effect of stably providing electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

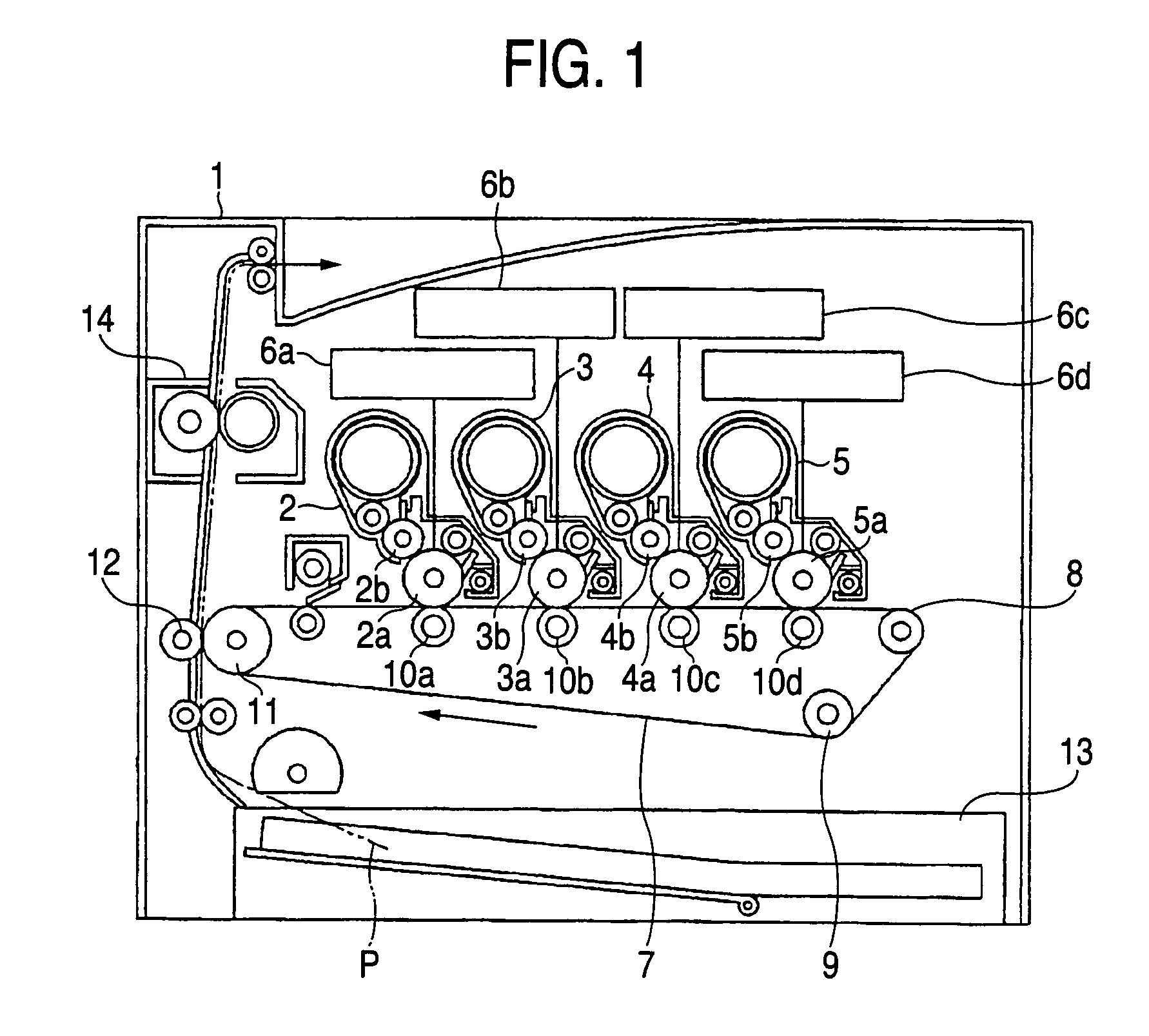

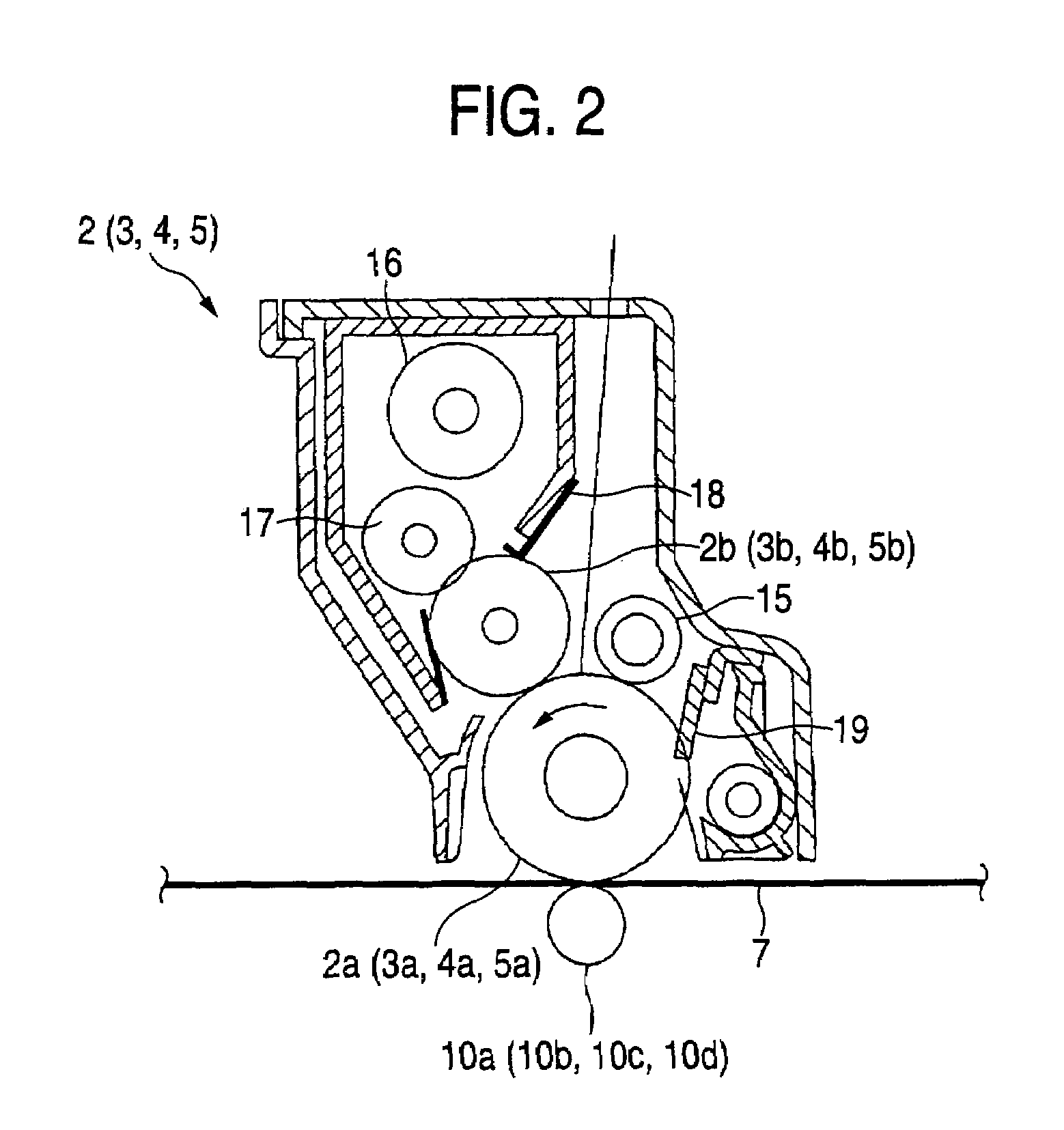

[0045]Referring now to FIGS. 1 to 4, a description will be given of an embodiment of the invention. It should be noted that in these drawings identical members will be denoted by the same reference numerals, and that a redundant description thereof will be omitted.

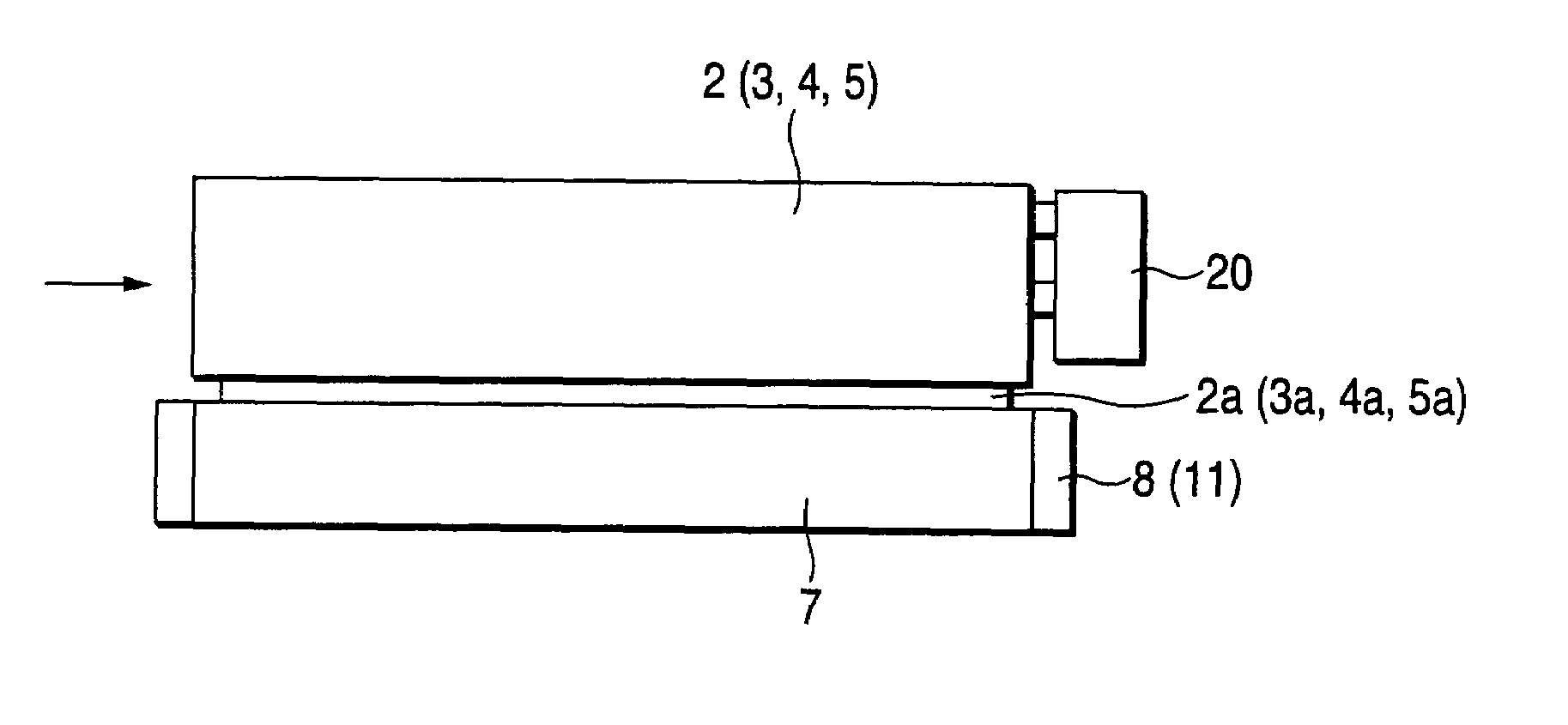

[0046]FIG. 1 is a schematic diagram illustrating the construction of a color image forming apparatus in accordance with the embodiment of the invention. FIG. 2 is an explanatory diagram illustrating in detail image forming units in the color image forming apparatus shown in FIG. 1. FIG. 3 is a perspective view illustrating in extracted form a high-voltage unit, an intermediate transfer belt, and the image forming units in the color image forming apparatus shown in FIG. 1. FIG. 4 is an explanatory diagram illustrating the positional relationship among the image forming units, the high-voltage unit, and the intermediate transfer belt in a state in which the image forming units are installed in the color ima...

second embodiment

[Second Embodiment]

[0062]Referring next to FIGS. 5 to 14, a description will be given of a more detailed construction of the above-described first embodiment as a second embodiment of the invention. Those component parts that are substantially identical to those of the first embodiment will be denoted by the same reference numerals, and a redundant description thereof will be omitted.

[0063]As shown in FIGS. 5 and 6, the photoconductor drum 5a, the developing roller 5b, the charging roller 15, the supply roller 17, a developing-roller biasing metal sheet 105, and a supply-roller biasing metal plate 117 are provided at an end portion of the image forming unit 5 for black on the side away from a grip portion 55. An end portion of the charging roller 15 is in electrical contact with the high-voltage unit 20, and corresponds to one of the terminals 22 in the above-described first embodiment. The developing-roller biasing metal sheet 105 is also in electrical contact with the high-voltage...

third embodiment

[Third Embodiment]

[0074]FIG. 17 is a perspective view illustrating a peripheral structure of the charging means provided in the color image forming apparatus shown in FIG. 1.

[0075]Here, as shown in FIG. 17, the charger 15 is supported by a conductive bearing 720. A coil spring 722 is in pressure contact with the bearing 720, so that the charger 15 is pressed against each of the photoconductor drums 2a to 5a through the bearing 720 by the resiliency of the coil spring 722 acting on the bearing 720.

[0076]A connecting end portion 722a of the coil spring 722 is formed in such a manner as to extend like a rod formed substantially in an L-shape. A main body-side conductive member 721 for carrying electric power from an electric supply means (not shown) abuts against this connecting end portion 722a to electrically connect the two members.

[0077]As shown in the drawing, a distal end of the main body-side conductive member 721 is fitted in a connecting slot member 723 formed in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com