Positioning device having dynamically isolated frame, and lithographic device provided with such a positioning device

a positioning device and dynamic isolation technology, applied in the field of precision motion stages, can solve problems such as reducing the frequency response of the stage, and achieve the effect of reducing unwanted moments of force (i.e., torque)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

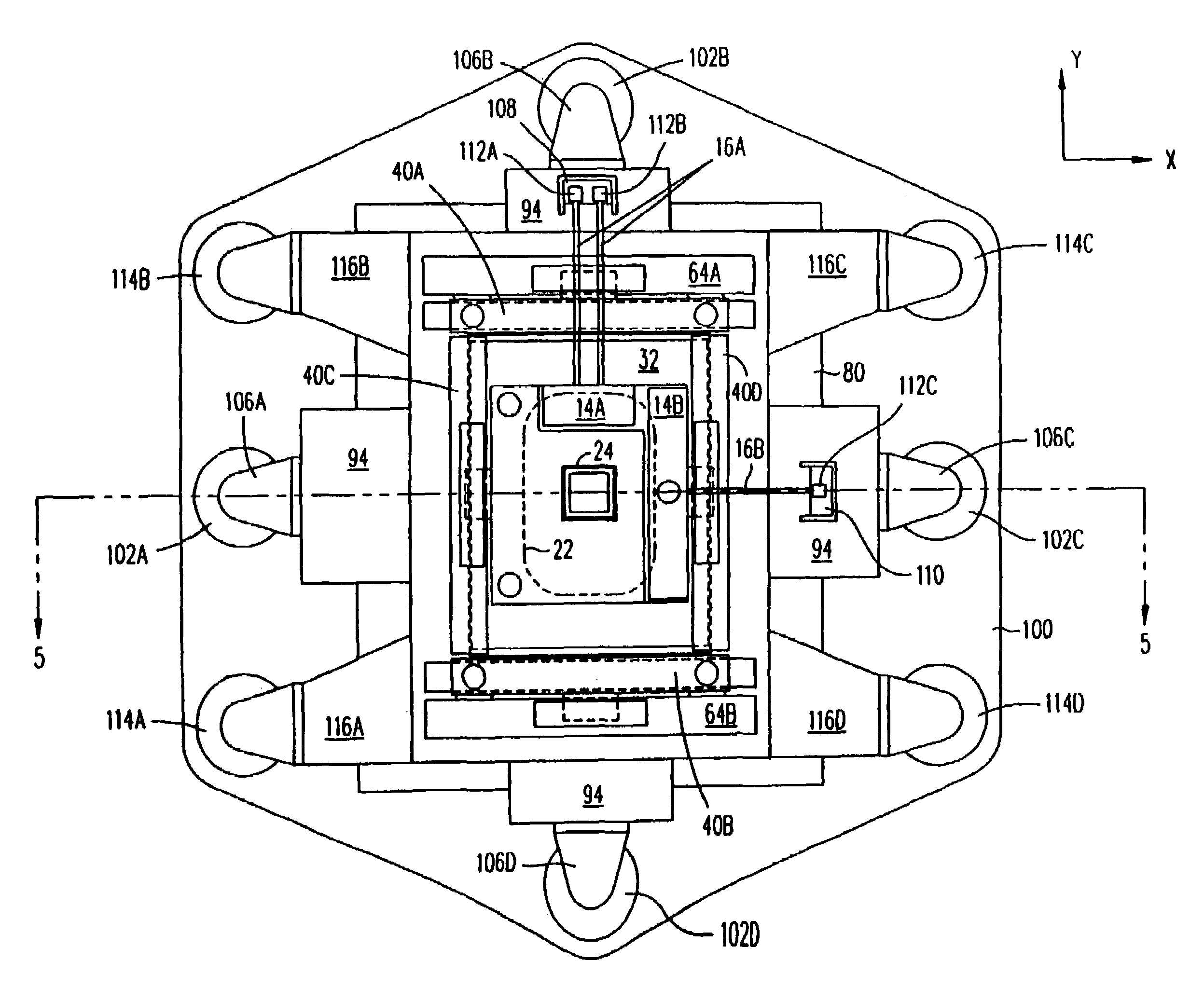

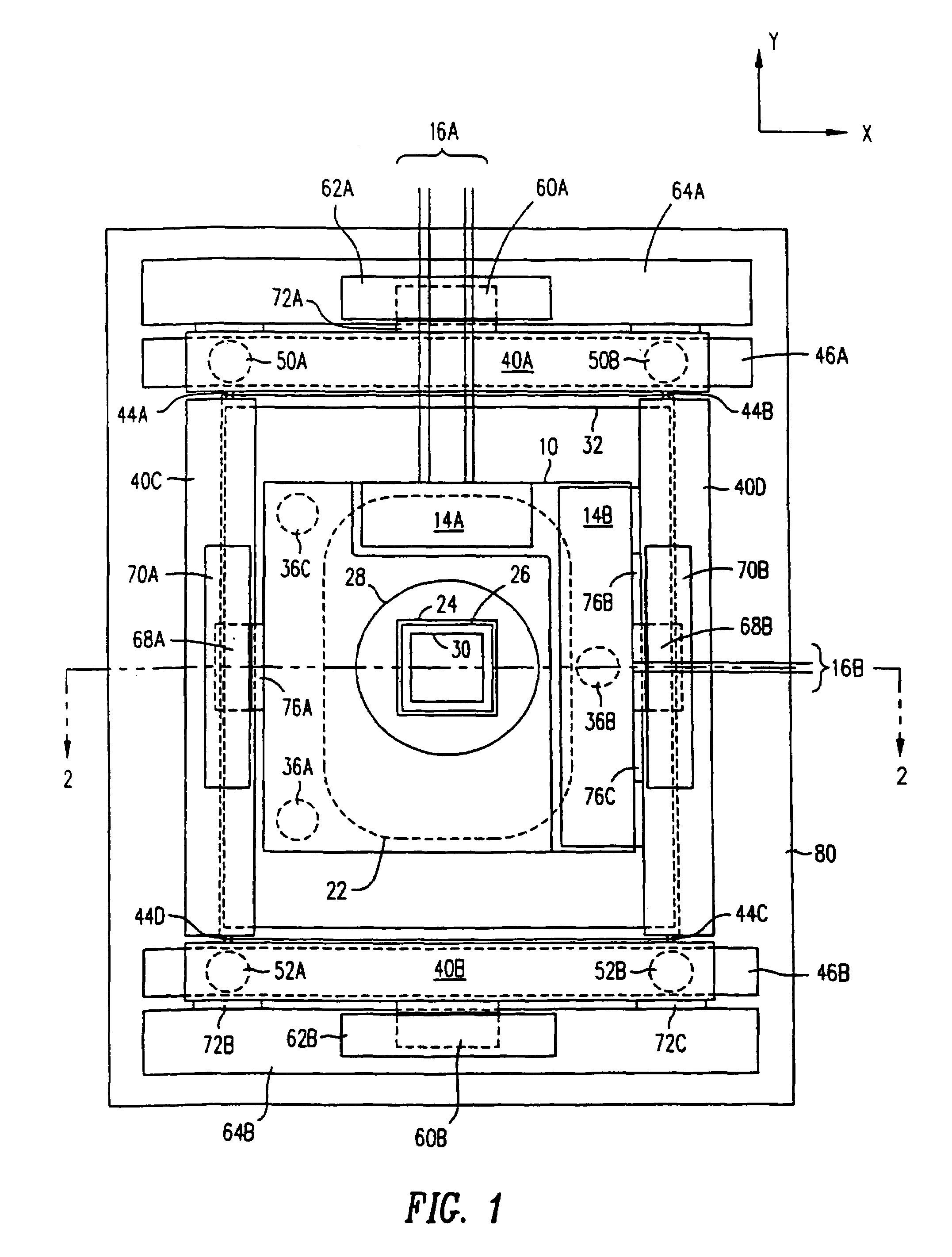

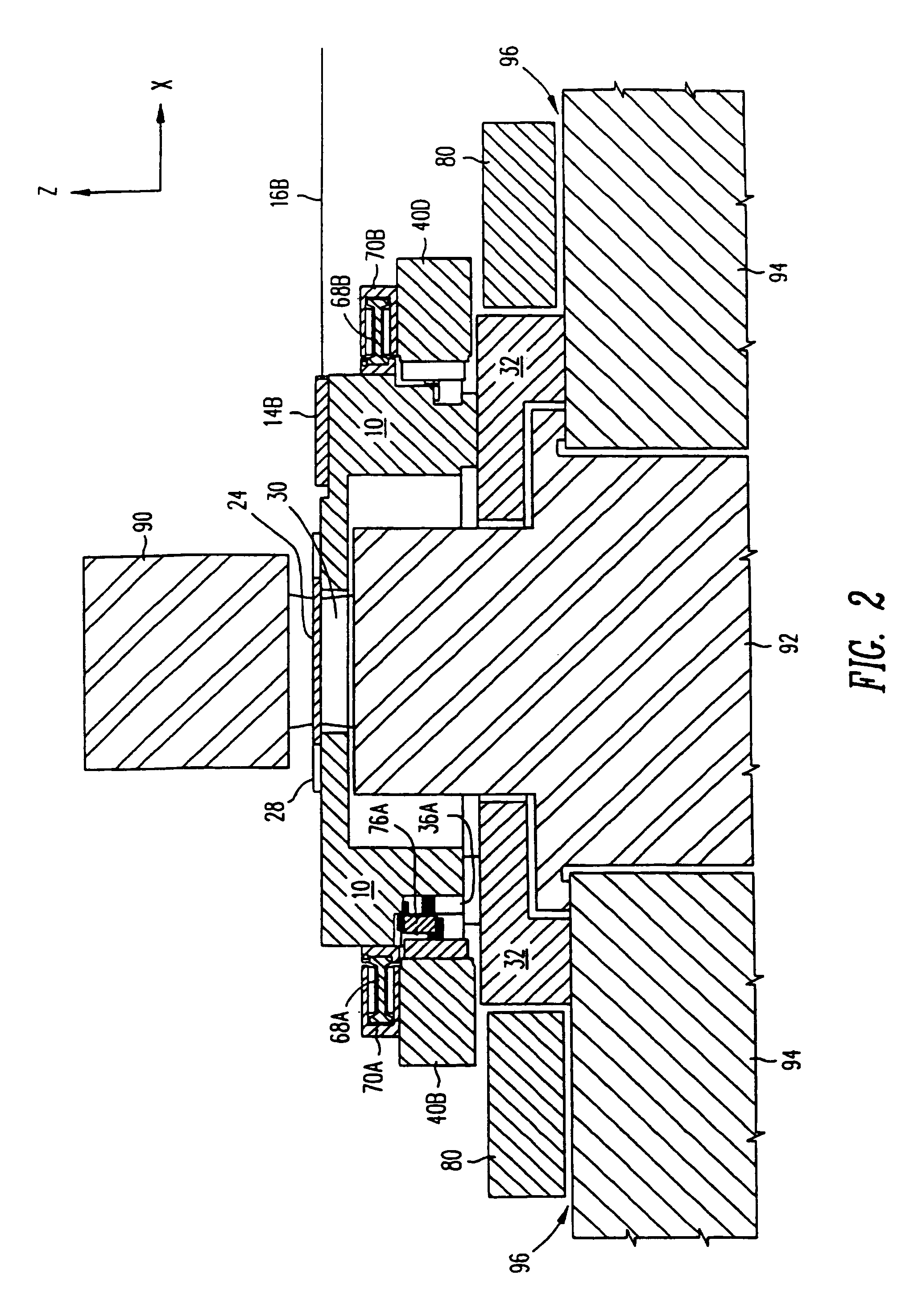

[0037]FIG. 1 shows a top view of a stage mechanism in accordance with the invention. See also copending commonly owned and invented U.S. patent application Ser. No. 08 / 221,375 entitled “Guideless Stage with Isolated Reaction Stage” filed Apr. 1, 1994, which is incorporated herein by reference and shows a related method of supporting elements of a stage mechanism so as to isolate reaction forces from the projection lens and other parts of a photolithography apparatus.

[0038]The detailed description from U.S. patent application Ser. No. 08 / 221,375 is reproduced below. FIGS. 1–11 of that application have been renumbered respectively as FIGS. 7–17, and the reference numerals have been increased by 200 in order to avoid the use of duplicate reference numerals for different elements.

[0039]While it will be appreciated by those skilled in the art that the guideless stage, with or without its isolating reaction frame, has many applications to many different types of instruments for precise po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com