Light cove

a technology of light coves and coves, applied in the field of light coves, can solve the problems of inability to schedule non-electrical work, need rework, errors, etc., and achieve the effect of simple engaging and disengaging connection and easy disengagemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

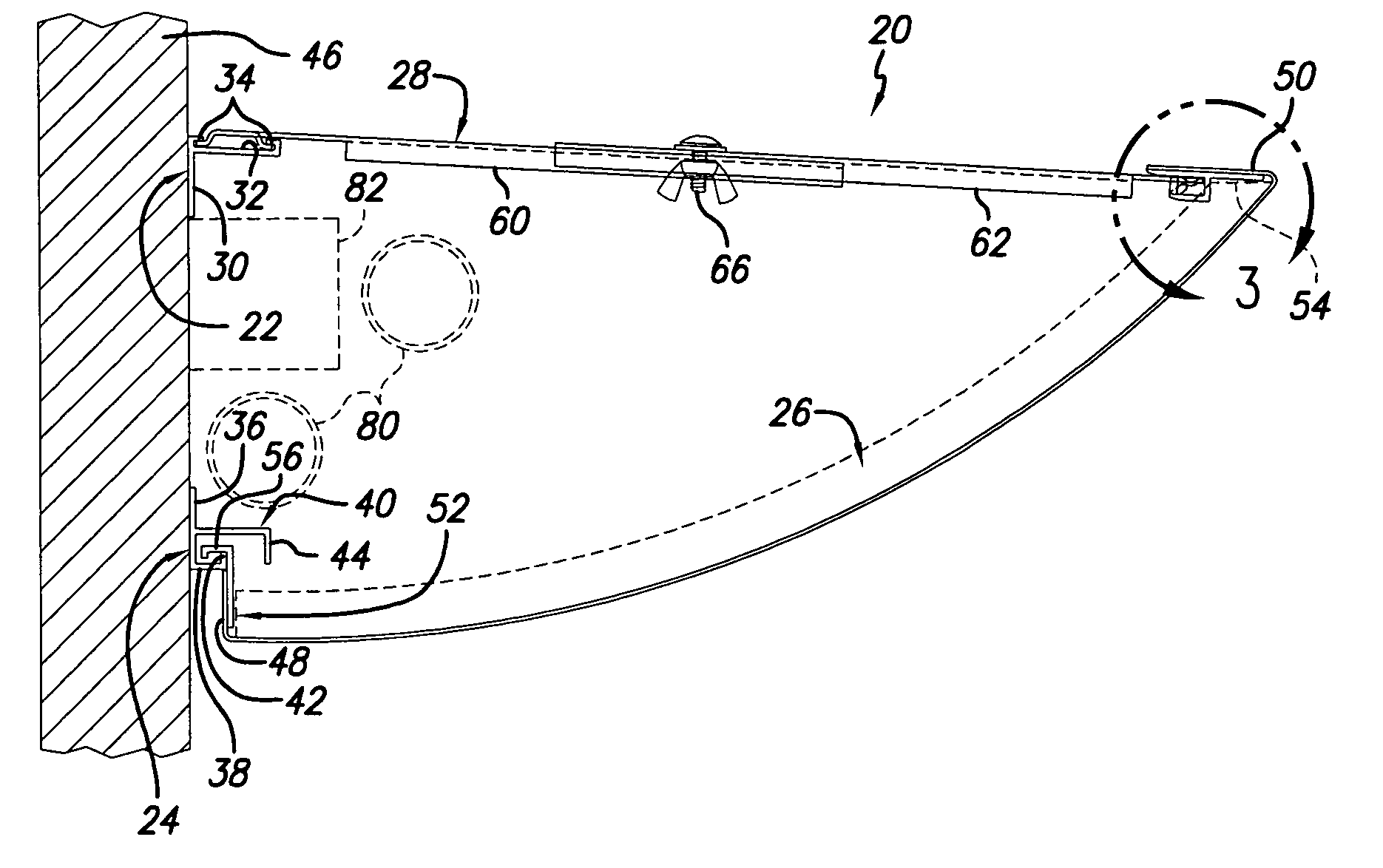

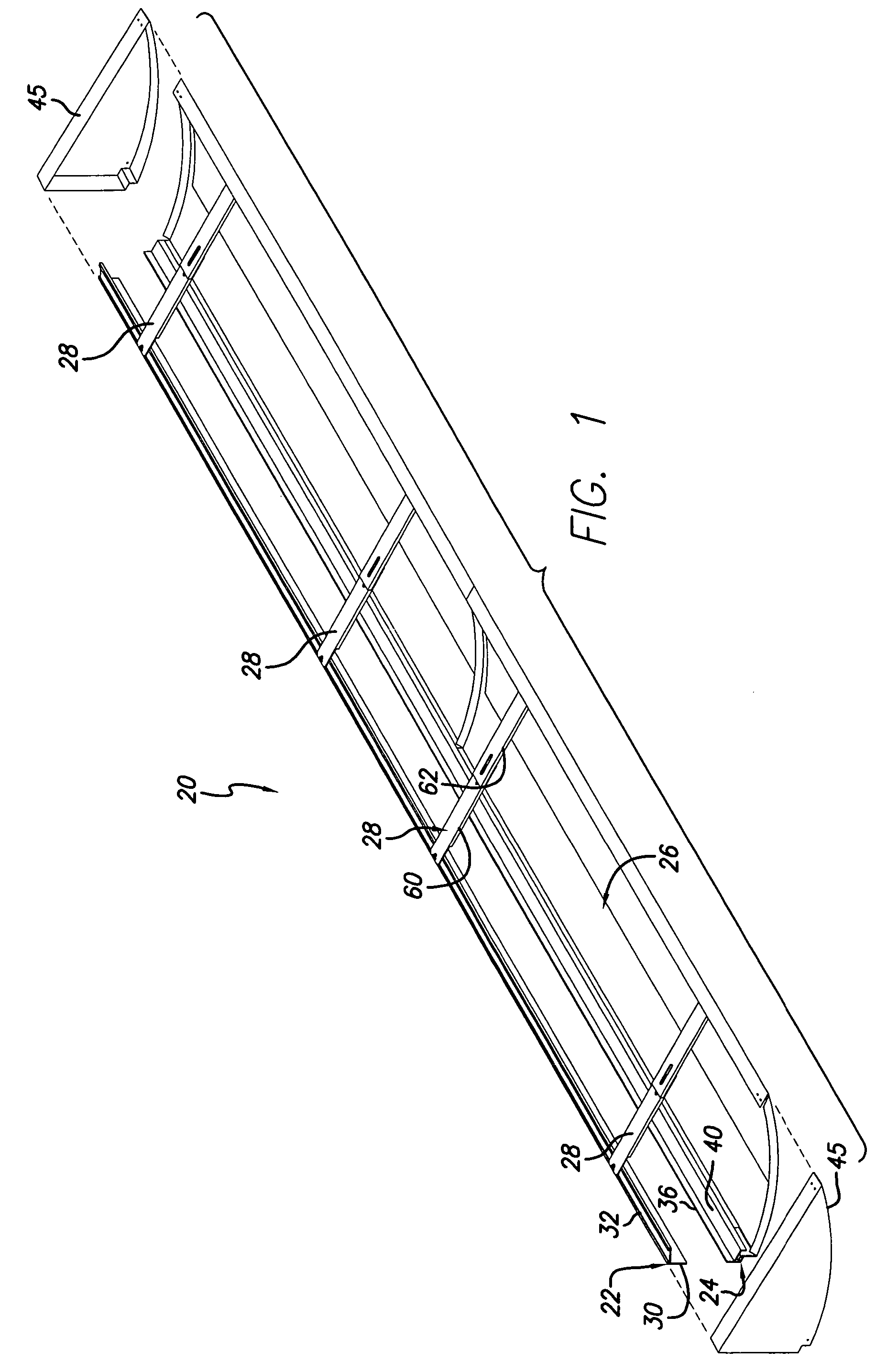

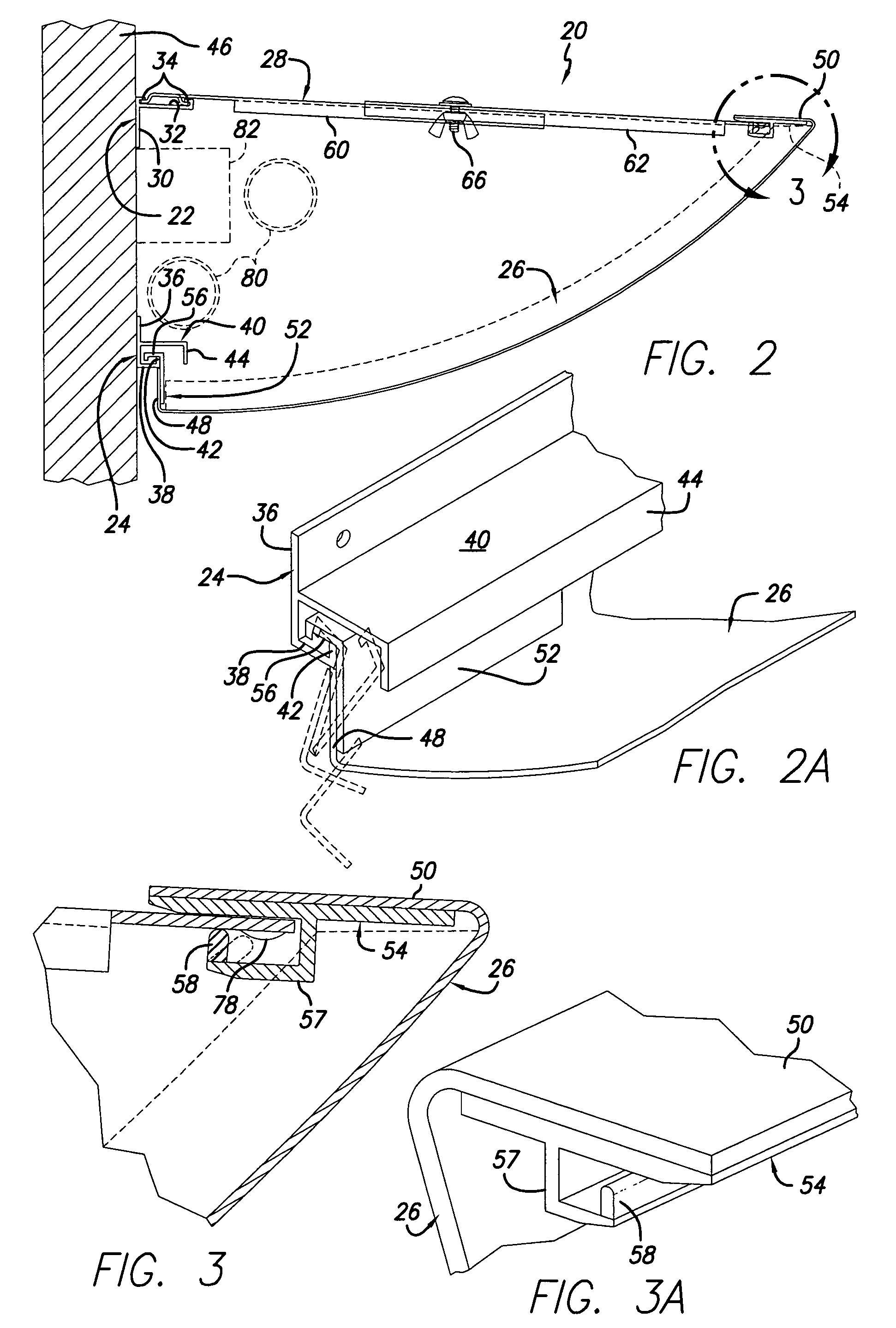

[0020]Accordingly, a light cove 20 includes separate elongated top and bottom fastening devices 22 and 24, a light-transparent panel or shroud section 26, and a plurality of two-piece adjustable supports 28. Top fastening device 22 includes a backing plate 30 and a channel 32 extending perpendicularly therefrom. As best depicted in FIGS. 2 and 2A, channel 32 has a generally U-shaped configuration with a pair of rails 34 extending towards one another. Bottom fastening device 24 includes a backing plate 36, a channel 38 and an overhang 40, both of which extend perpendicularly from backing plate 36. Channel 38 has a generally U-shaped configuration with an upwardly extending rail 42. Overhang 40 has a downwardly extending portion 44 which is disposed to hang over U-shaped channel 38. Both fastening devices 22 and 24 may be formed of extruded aluminum stock. Panel section 26 may comprise a construction including a light-transparent or translucent material which additionally may be modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com