Aircraft flap or slat drive system with redundant drives and shaft drive lines

a technology of shaft drive and drive system, which is applied in the direction of aircraft power plants, transportation and packaging, and actuating personally, etc., can solve the problems of complete loss of the entire functionality of the landing flap and slat system, undesirable and improper behavior of the apparatus, and local overload of the arrangement, so as to maintain at least a partial operability and functionality of the overall apparatus, no and loss of the functionality of the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

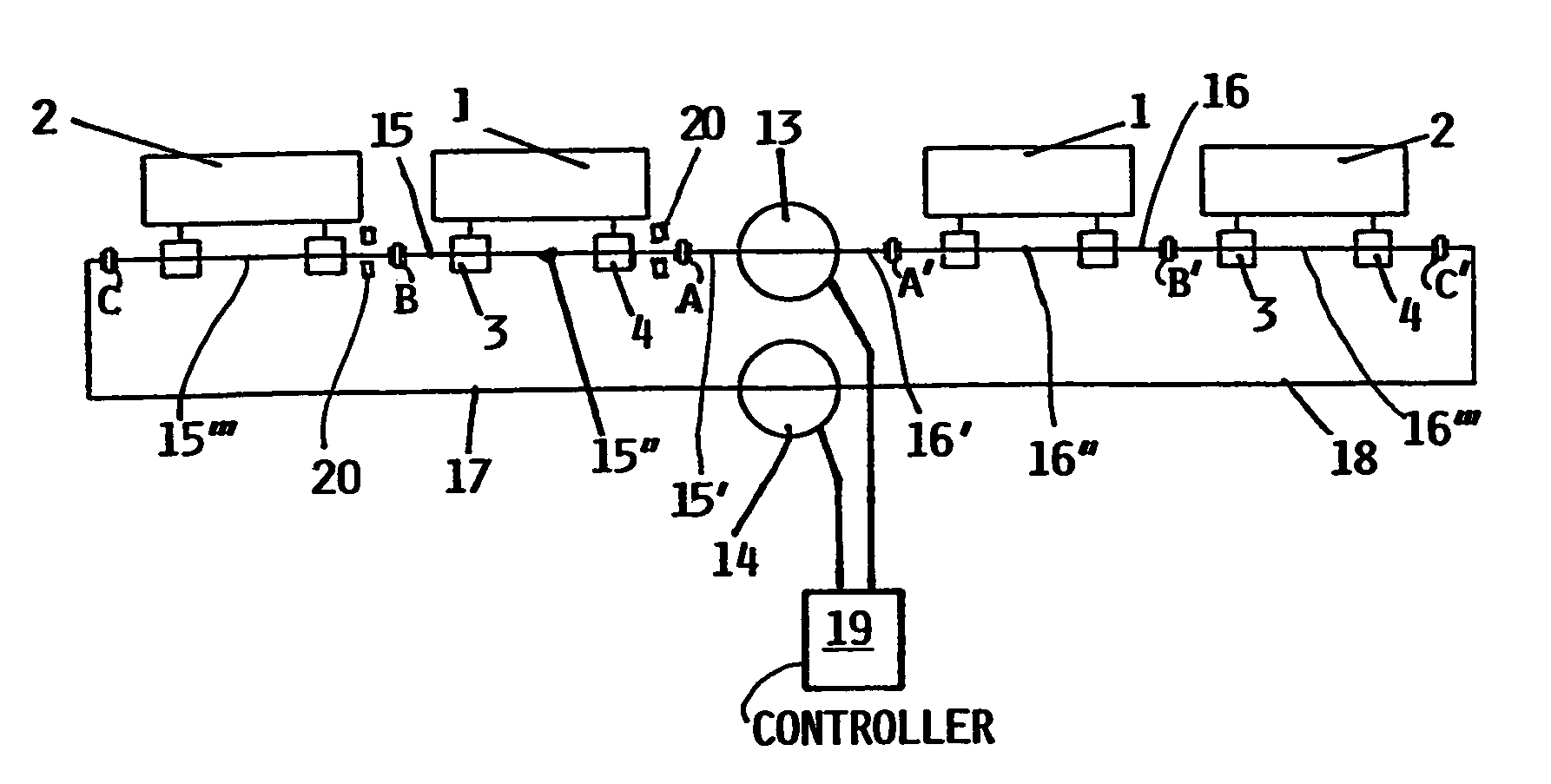

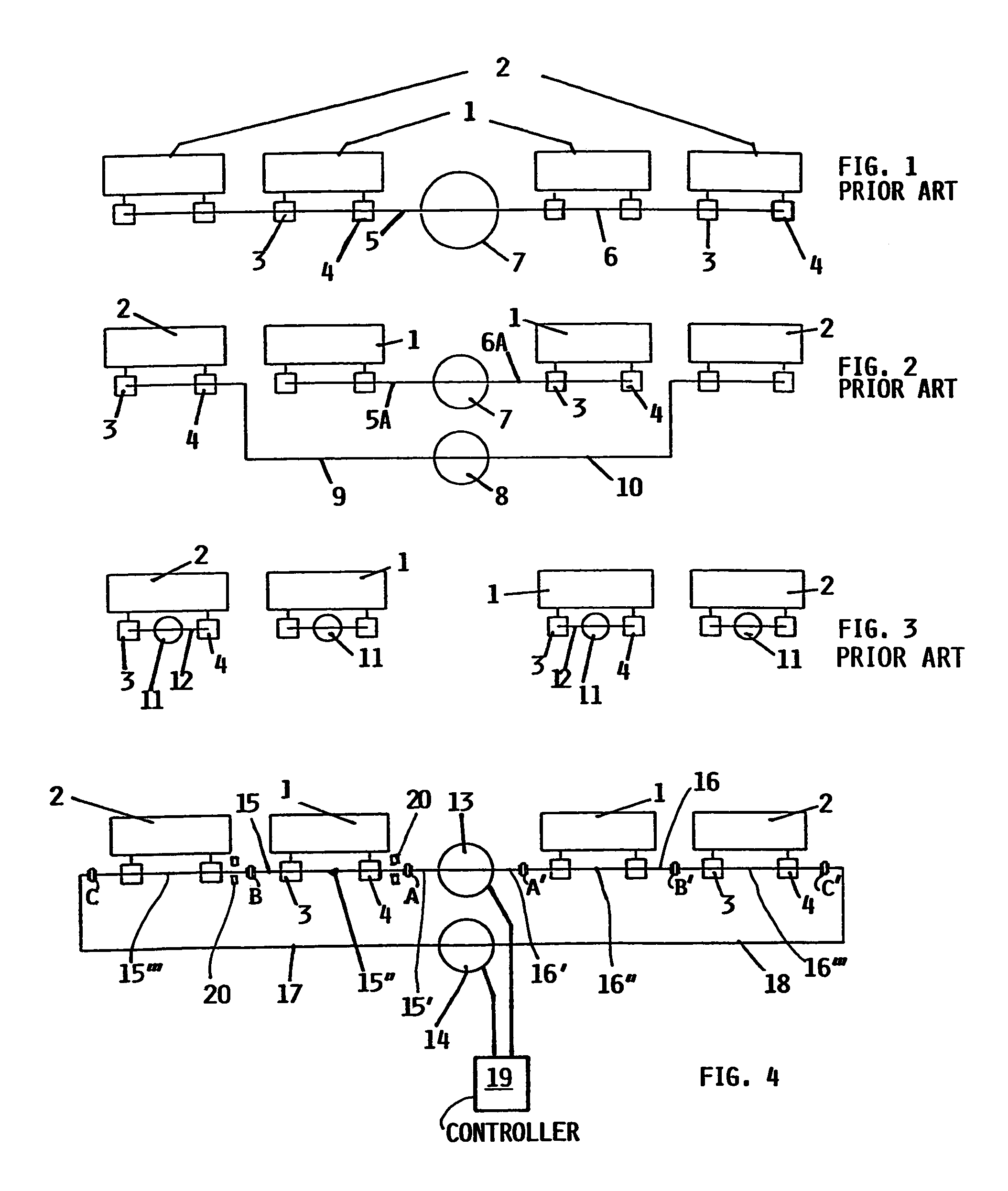

[0024]The conventional systems according to FIGS. 1, 2 and 3 have been described above. The inventive flap or slat drive apparatus according to FIG. 4 is based on some of the same conventional elements as the above described prior art systems. For example, the inventive apparatus according to FIG. 4, in this example embodiment, is for selectively driving or actuating left and right inboard lift enhancing elements 1, and left and right outboard lift enhancing elements 2, which may each be a trailing edge landing flap or a leading edge slat provided on the left and right wings of an aircraft. The final drive or actuation of the lift enhancing elements 1 and 2 is achieved by two actuator mechanisms 3, 4 connected to each one of the lift enhancing elements 1 or 2. The actuator mechanisms 3, 4 can have any conventionally known construction and operation, but basically convert a rotational input drive motion to a translational or deflecting output drive motion that is applied to the respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com