Adaptable low voltage electrical box

a low-voltage wiring and adaptable technology, applied in the direction of machine supports, coupling device connections, mechanical equipment, etc., can solve the problems of minimizing stability, minimizing stability, and devices that are not easily mounted to studs in walls, and achieves the effect of stable construction and easy mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

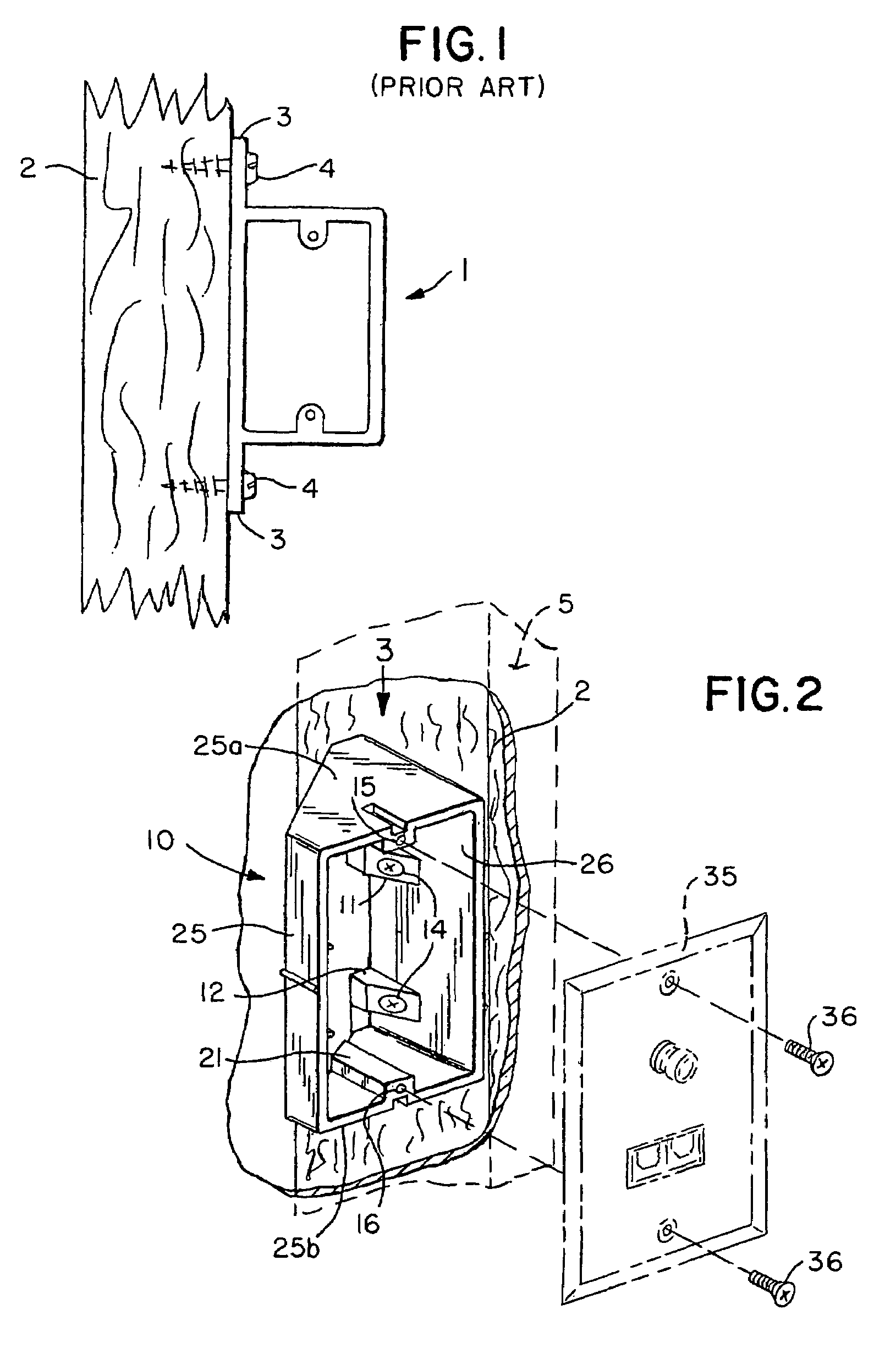

[0059]FIG. 1 shows a prior art low voltage box 1, which is attached to wall stud 2 with screws 4 in brackets 3 protruding from the side of prior art box 1.

[0060]FIG. 1 also shows that it would be not be possible to mount prior art box 1 to stud 2 through a rectangular hole in wall sheet rock the size of the box face. Box 1 is therefore used in new construction and is mounted before wall sheeting is installed. It would not be used for retrofit work where an existing wall must be penetrated.

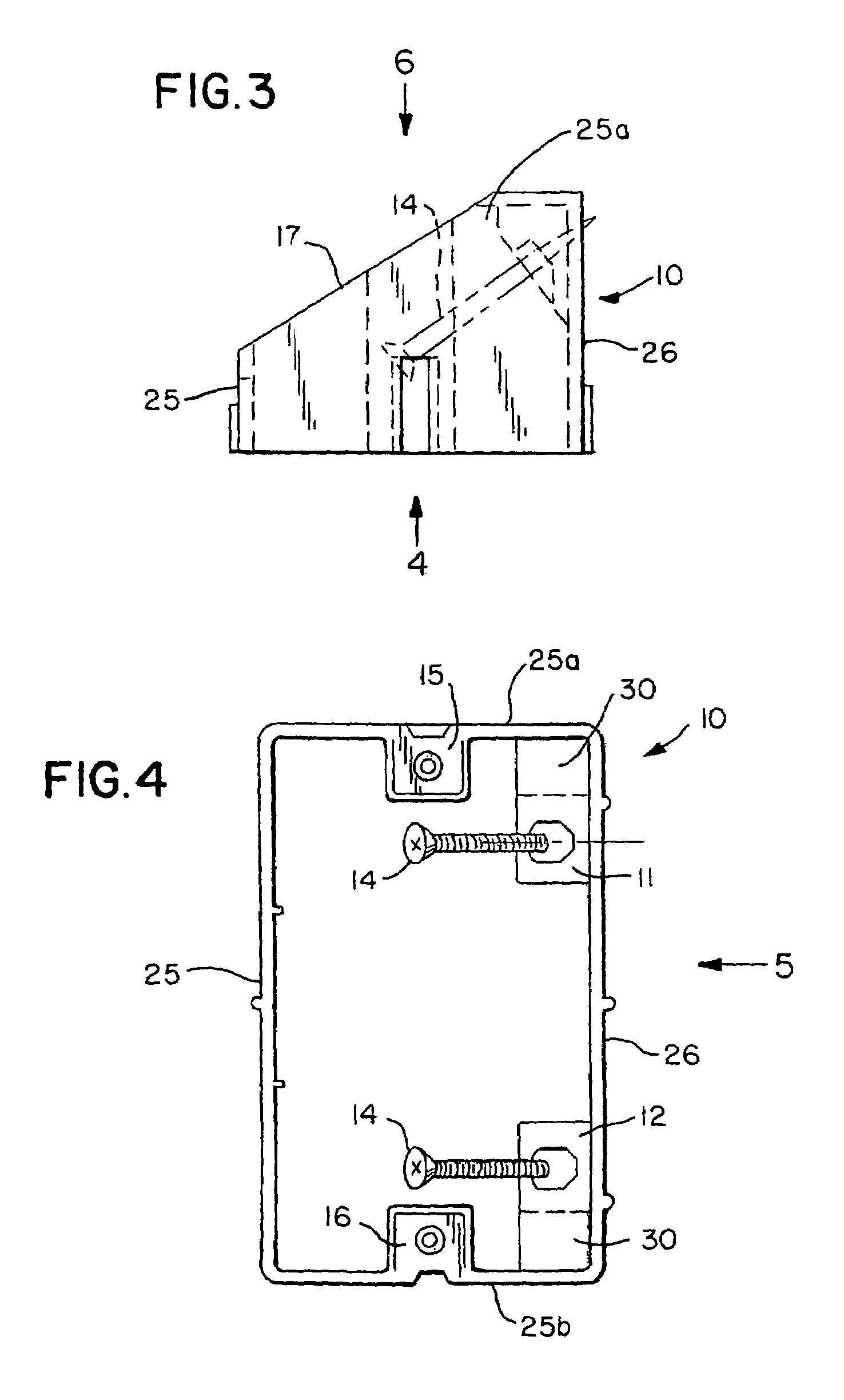

[0061]Low voltage box 10 of this invention, as depicted in the various views of FIGS. 2 through 6, is equally useful for new construction as well as retrofit work.

[0062]As shown in FIG. 2, low voltage box 10 includes primarily a vertically extending fastener wall 26 having a depth deeper than a cantilevered ring edge casing portion, such as horizontally top wall 25a joined by vertically extending distal side wall 25 to lower wall 25b, in a three sided C-shape configuration. Top wall 25a and bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com