Production of radio frequency ID tags

a radio frequency identification and tag technology, applied in the direction of noise figure or signal-to-noise ratio measurement, instruments, semiconductor/solid-state device testing/measurement, etc., can solve the problem of requiring a fairly expensive process with narrow tolerances for the initial tuning, and the most fine tuning of semiconductor devices cannot make adjustments over a wide range of ranges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

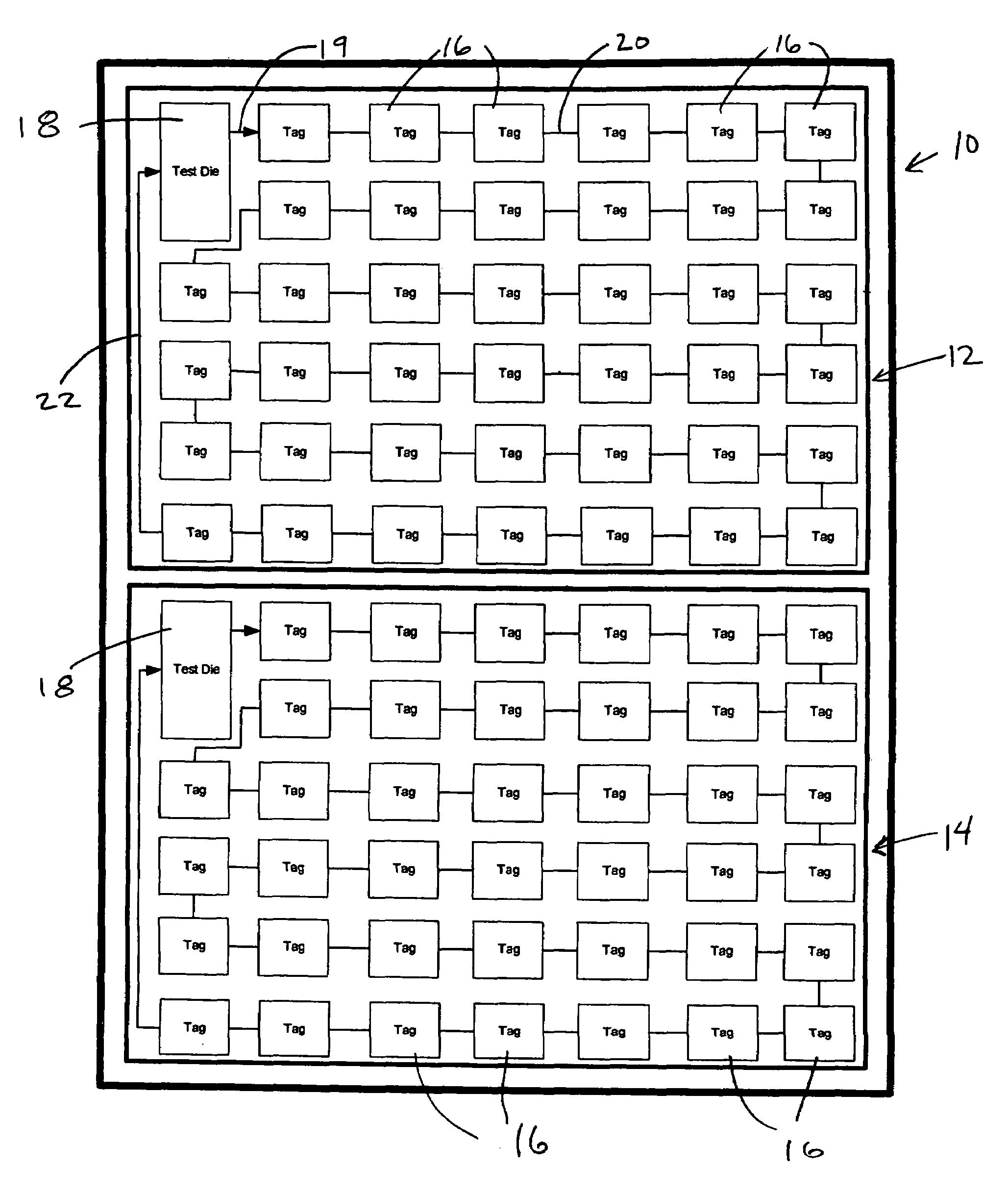

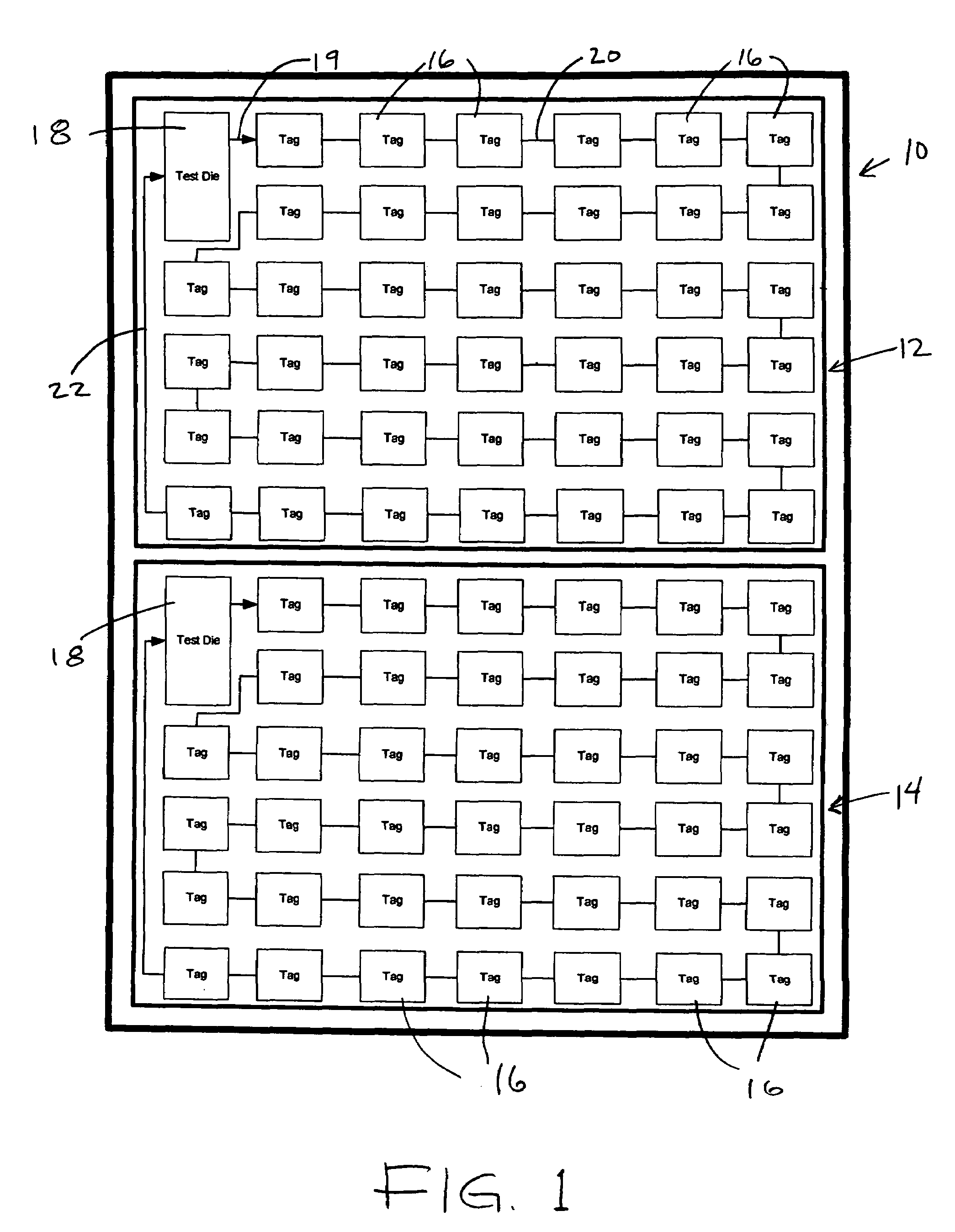

[0017]FIG. 1 shows the reticle field of a semiconductor wafer 10 in the manufacture of RF ID tags, in accordance with one aspect of the invention. In each of two sections 12 and 14 of the wafer, a multiplicity of tag dice 16 are connected in series to a test die 18 for that section. The number of tag dice will be dependent on the size of the tags 16 and the test die 18. The interconnection of all tag dice to the test die in the reticile field enables a tester to make contact only with the test die 18 in order to test all interconnected tag dice within that section of the wafer, without requiring that a probe make contacts with each individual tag dice 16. As indicated, a series of conductors 19 and 20, respectively (each of which may be a bus), connect the test die 18 to the first tag die 16 and the tags serially one to the next, so that through the tags, the test die 18 can connect to each one of the tag dice serially. All tag dice, and the test die 18, can be connected while on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com