Sectionalized surfboard

a sectionalized, surfboard technology, applied in the field of sectionalized surfboards, can solve the problems of easy theft of surfboards and sailboards, easy to be stolen by someone, and easy to deteriorate the plastic of boards in sunligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

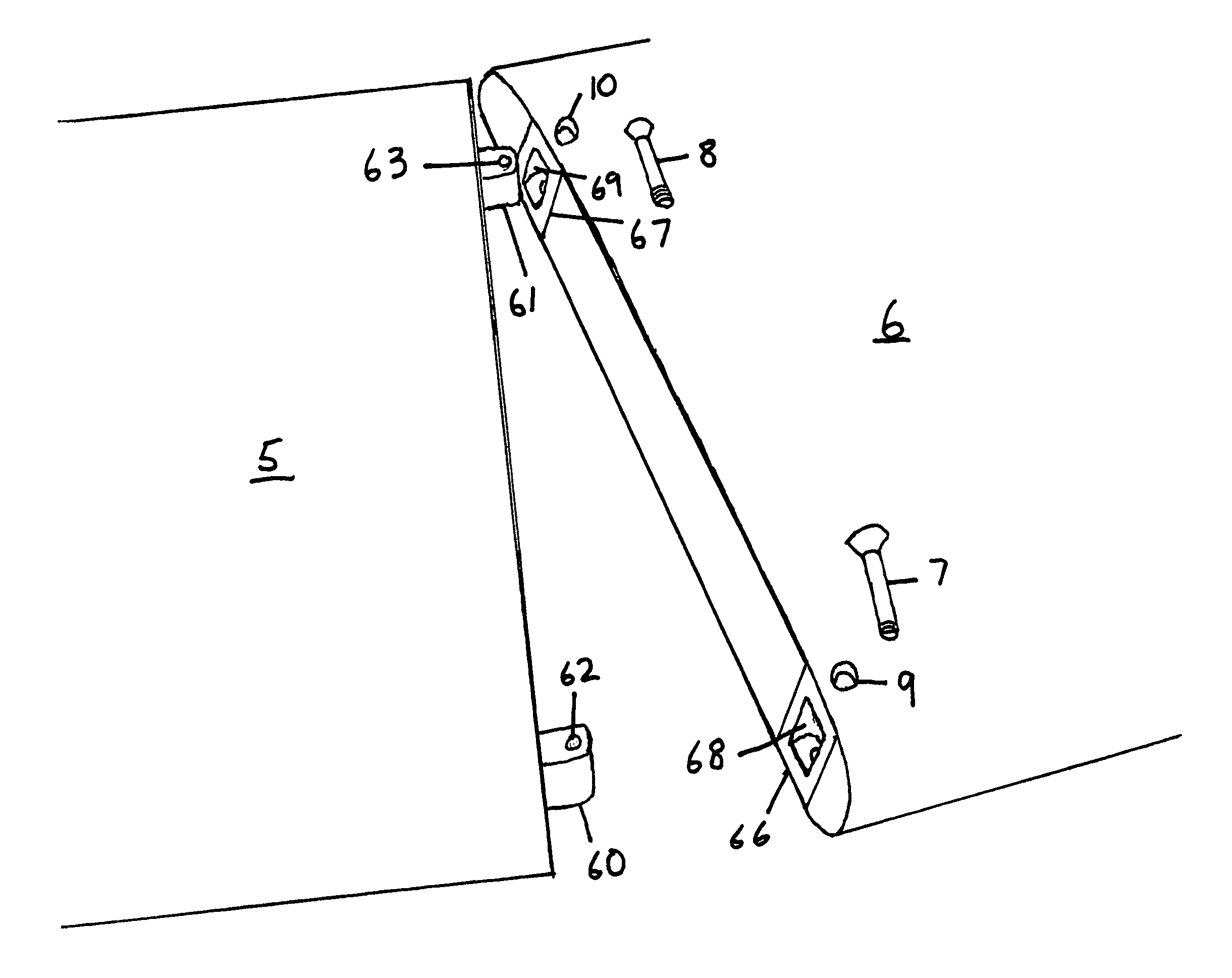

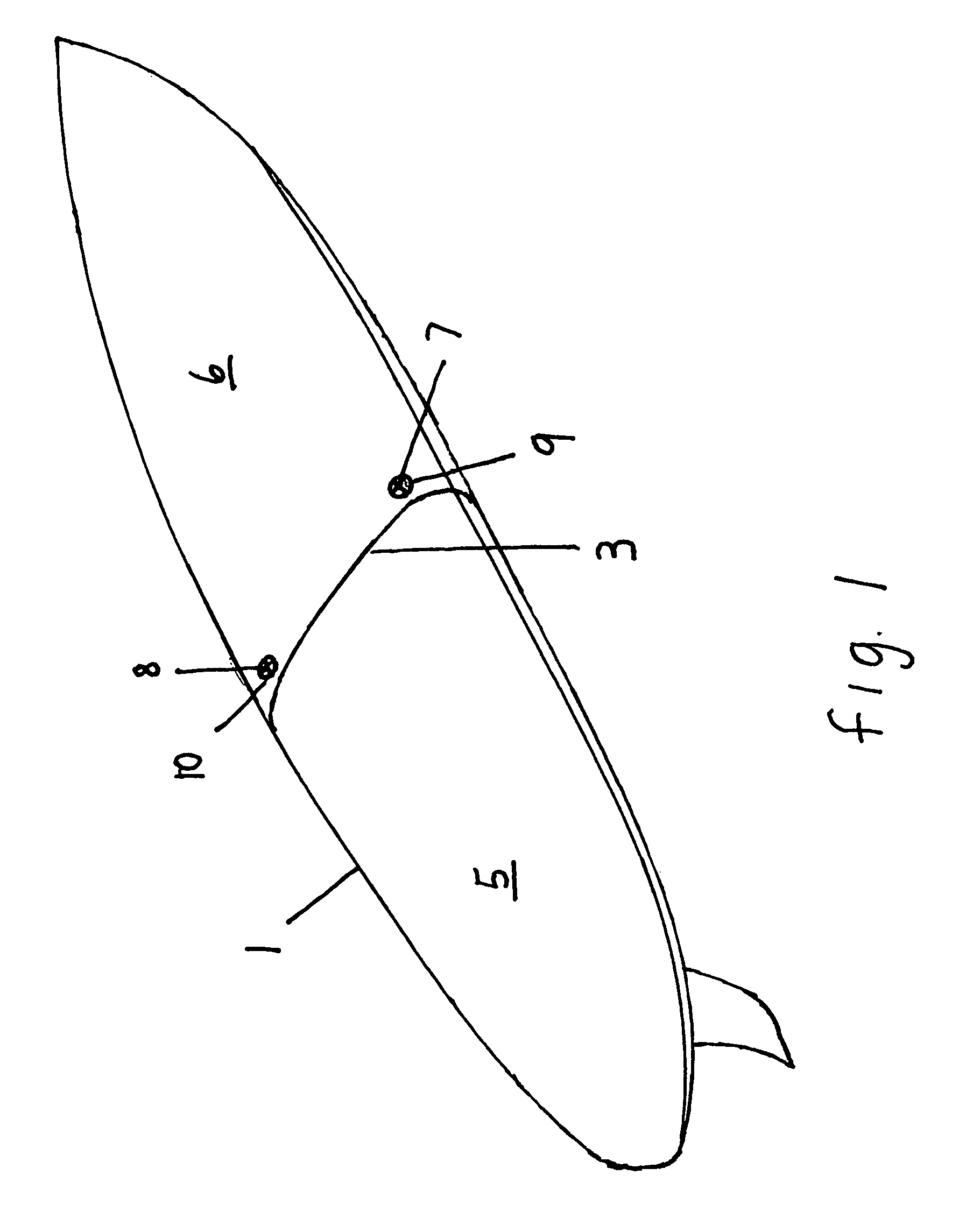

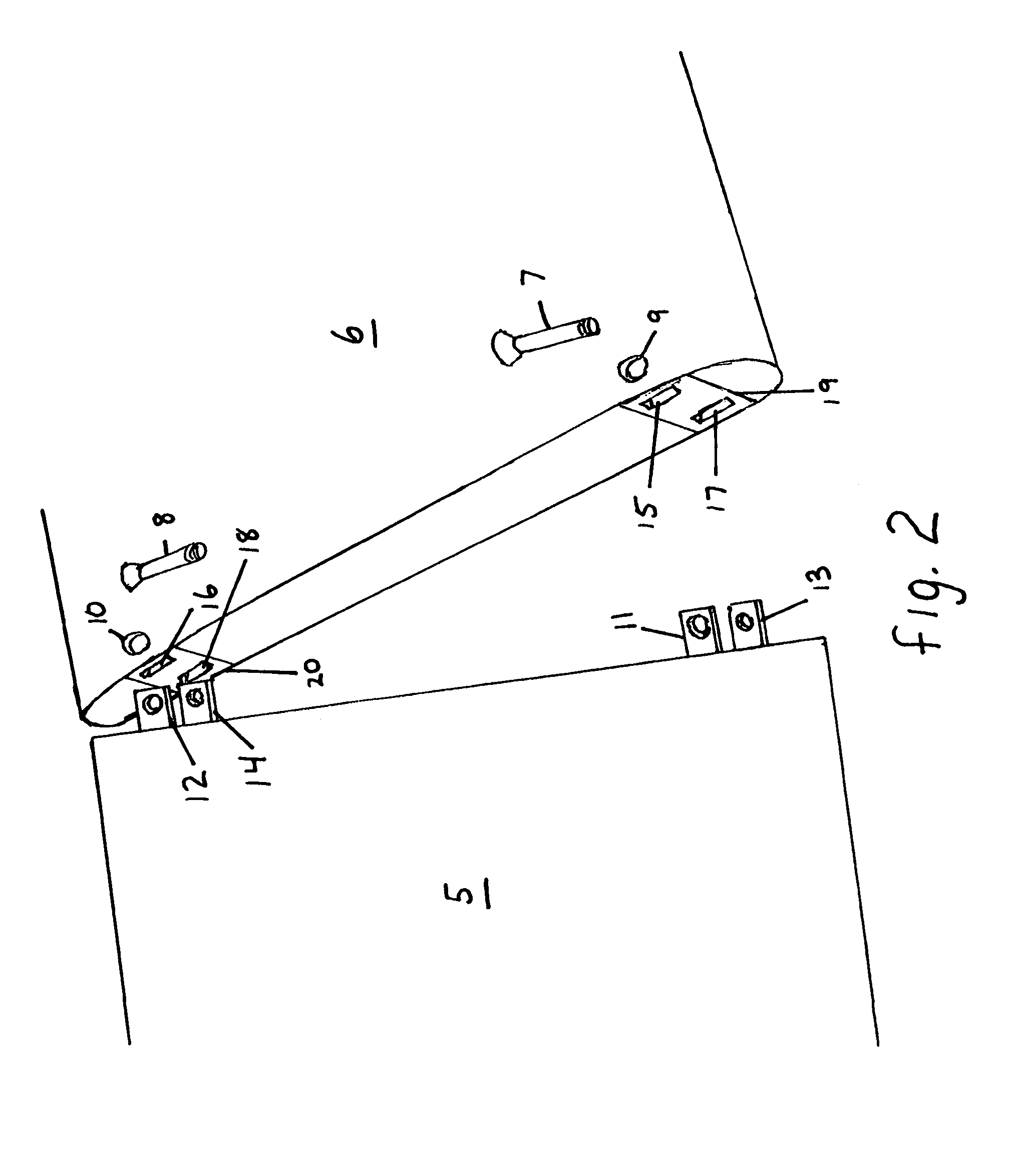

[0050]An embodiment of the present invention will now be described with reference to the drawings. An example of a surfboard divided into two sections will be used to illustrate this embodiment. The invention is not limited to dividing board into two sections. There can be as many sections as desired. The surfboard described is divided near the middle into two sections. Boards made with a similar construction method such as some paddleboards and sailboards could also be adapted to include the first embodiment. A surfboard with more than two sections can be carried in a suitcase for traveling.

[0051]FIG. 1 shows the assembled surfboard 1 in accordance with the present invention includes a front section 6, a back section 5, and a joining bolts 7 and 8 (The head of bolt 7 and 8 are recessed respectively into holes 9 and 10 so only the heads of bolts 7 and 8 are visible). A dividing line 3 shows where the board sections separate when disassembled. To separate the sections bolts 7 and 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com