Smoke generator machine

a generator machine and smoke technology, applied in the direction of combustion types, stoves or ranges, instruments, etc., can solve the problems of affecting the quality of smoke, and taking a great deal of time and effort,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

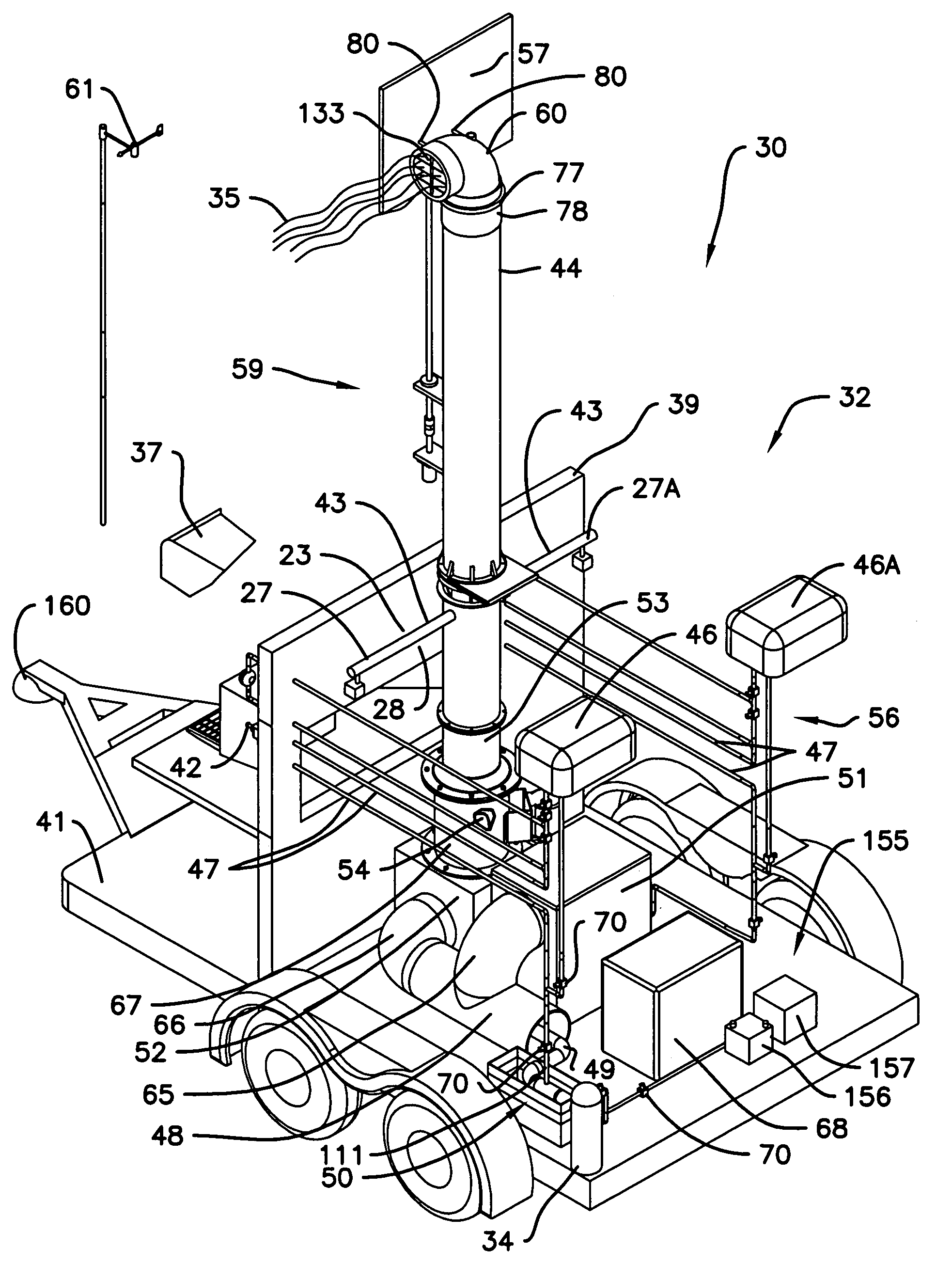

[0068]FIG. 3 is the preferred embodiment illustrating a prospective rear view of the smoke generator (30) with rear doors (31) shown in the open position exposing a portion of the smoke generating components (32), and the side door (33) is shown open to the entrance to the control room (36) separated from the smoke generating component room (32) by a wall (39), with fuel tank (46) and (46A) positioned on top of the trailer cab (37) to provide a gravity-fed head pressure for fuel distribution of the piping system (47), and personnel (38) being tested to visually determine the smoke (35) opacity seated at least fifty yards from the smoke generator (30) during the training session. A wind directional indicator (61) positioned on top of said trailer cab (37) to determine the direction of the prevailing wind.

[0069]FIG. 4 is a front top isometric view of the preferred embodiment with the trailer cover (37) removed to illustrate the control components (5) of the system showing the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com