Liquid crystal glare-proof mirror

a technology of glare-proof mirrors and liquid crystals, applied in the direction of optical viewing, instruments, vehicle components, etc., can solve problems such as dark screens, and achieve the effect of low optical transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

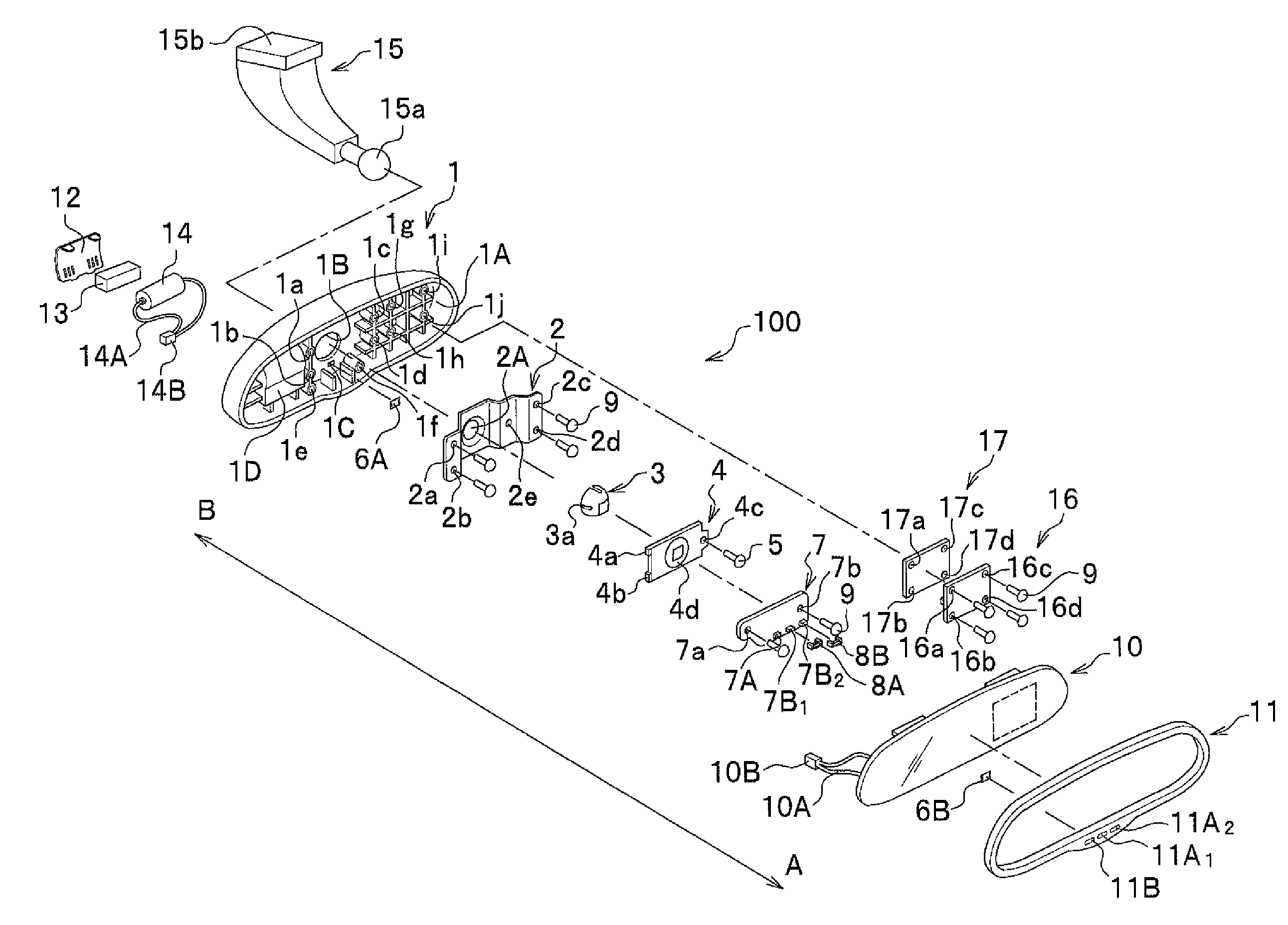

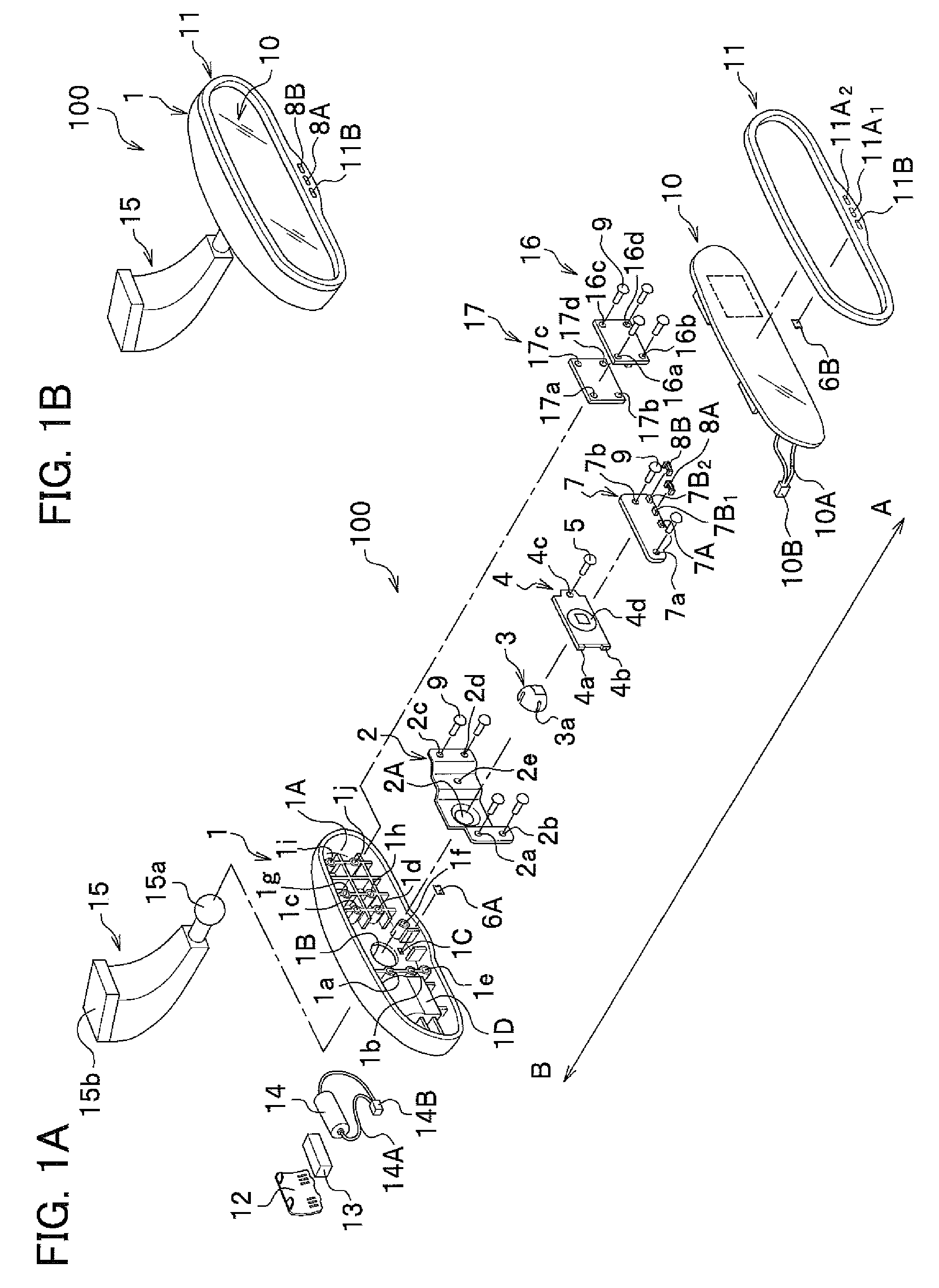

example 1

[0074]The positive electrode of a direct current power supply of which an end is grounded is connected to a switch S1 and a switch S2 via a branch point J1 as shown in FIG. 8. Connected to the switch S1 via a branch point J2 are a branch point J53 and a resistance R1. Connected to the switch S2 via a branch point J52 are an input terminal of a circuit OR1 and an input terminal A of a LSI. The LSI controls the liquid crystal cell 16A and the back light 16E. Terminals of a liquid crystal cell 16A are connected to an output terminal B and an output terminal C of the LSI. The back light 16E is connected to an output terminal D of the LSI. When the switch S2 is on, on receiving input from the input terminal A, the LSI applies voltage to the output terminal B and the output terminal C to set the optical transmission rate of each pixel in the liquid crystal cell 16A according to picture data input by an input terminal F, lights the back light 16E and makes the liquid crystal cell 16A to ej...

example 2

[0093]Similarly to the example 1, in the example 2 the positive electrode of the direct current power supply E of which an end is grounded is connected to the switch S1 and the switch S2 via the branch point J1 as shown in FIG. 9. Connected to the positive electrode of the power supply E is the resistance R1. Connected via the branch point J52 to the switch S2 is the input terminal of the circuit OR1 and the input terminal A of the LSI. The LSI controls the operation of the liquid crystal cell 16A and the back light 16E. Terminals of the liquid crystal cell 16A are connected to the output terminal B and the output terminal C of the LSI. The back light 16E is connected to the output terminal D of the LSI. When the switch S2 is on, on receiving input of the input terminal A, the LSI applies alternating voltage to the output terminal B and the output terminal C to set the optical transmission rate of each pixel in the liquid crystal cell 16A according to picture data input by the input...

modification 1

[0105]In the above embodiments, the liquid crystal glare-proof mirror 100 includes both of the surrounding light sensor 7C and the backward light sensor 7A, however, the liquid crystal glare-proof mirror 100 may include at least one of them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical absorption | aaaaa | aaaaa |

| optical transmission loss | aaaaa | aaaaa |

| internal structures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com