Adhesion method using gray-scale photolithography

A technique of grayscale, composition, applied in the direction of originals for photomechanical processing, microlithography exposure equipment, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

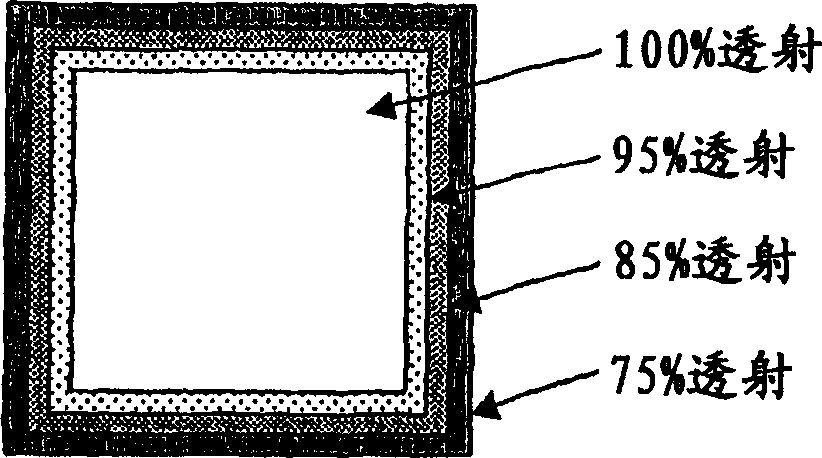

[0108] Repeat Comparative Example 1, except that a standard photomask is used and a grayscale binary photomask is used. The grayscale binary photomask is designed so that the perimeter of the pad receives a reduced amount of radiation during the photolithography process. More specifically, the photomask defines a 5 x 5mm pad as a series of squares whose transmittance drops from 100% to 75%, with each additional square falling in intensity, as figure 1 shown. From 95% to 75% of the intensity is in the 50 micron band, and the intensity in each band is controlled by pixels with a size of 0.5 micron. The intensity was adjusted between the bands by increasing the number of opaque 1 micron pixels randomly placed on each band.

[0109] Compared to Comparative Example 1, the resulting patterned film (ie, mat) has reduced surface non-uniformity (reduced side peaks). Interfacial contact is greater than 80%. Die shear value greater than 20kg.

Embodiment 2

[0112] Comparative Example 2 was repeated, except that a grayscale photomask designed so that the periphery of the pads received a reduced amount of radiation during photolithography was used as in Example 1 . Compared to Comparative Example 2, the resulting patterned film (ie, mat) had reduced surface non-uniformity (reduced side peaks). Interfacial contact is greater than 80%. Die shear value greater than 20kg.

Attached picture

[0113] figure 1 is the grayscale photomask used in Examples 1 and 2 of the present invention.

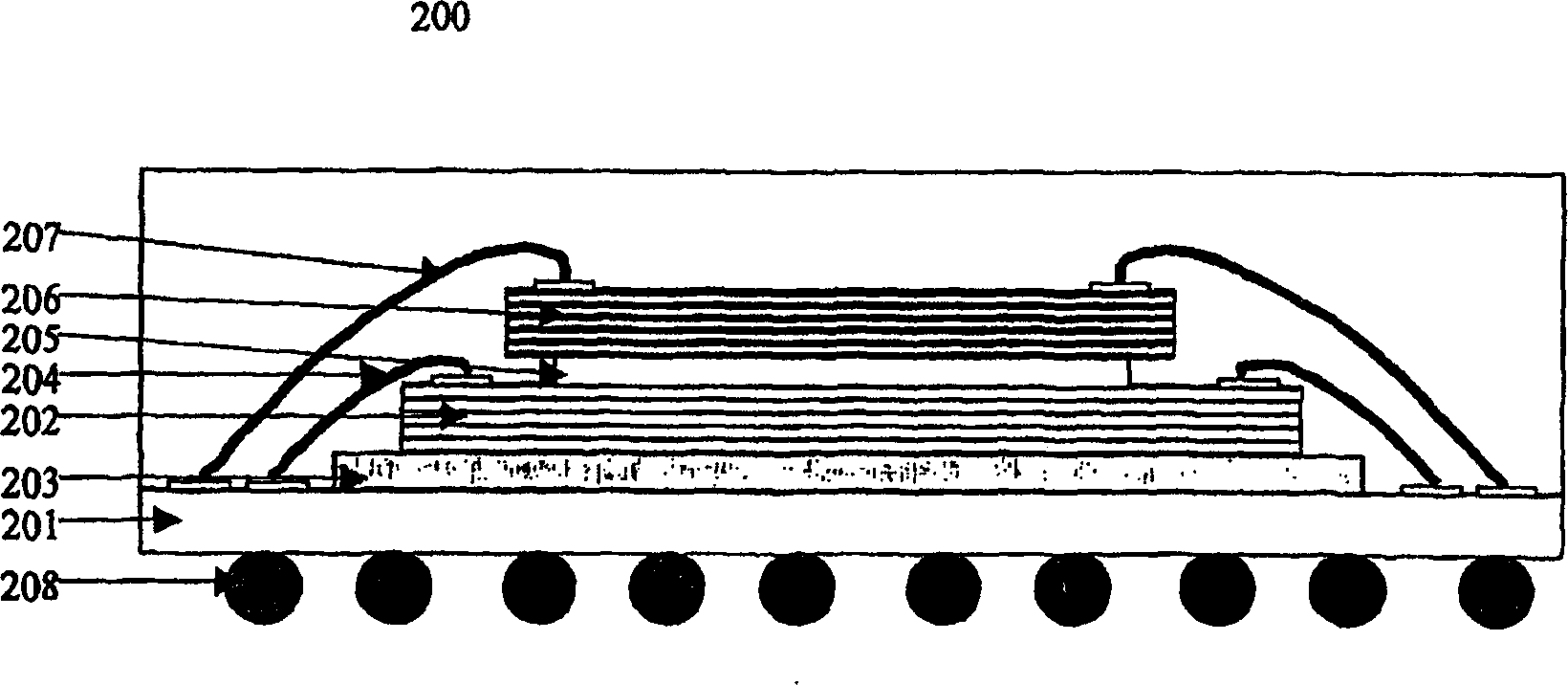

[0114] figure 2 It is a device manufactured by the method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com