Surface acoustic wave oscillator and method of varying frequency thereof

a surface acoustic wave and oscillator technology, applied in the field of surface acoustic wave oscillators, can solve the problems of disadvantageous lower disadvantageous narrowing of the variable frequency range, and difficulty in keeping the sn ratio and cn ratio high, so as to achieve a wider bandwidth of oscillating frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

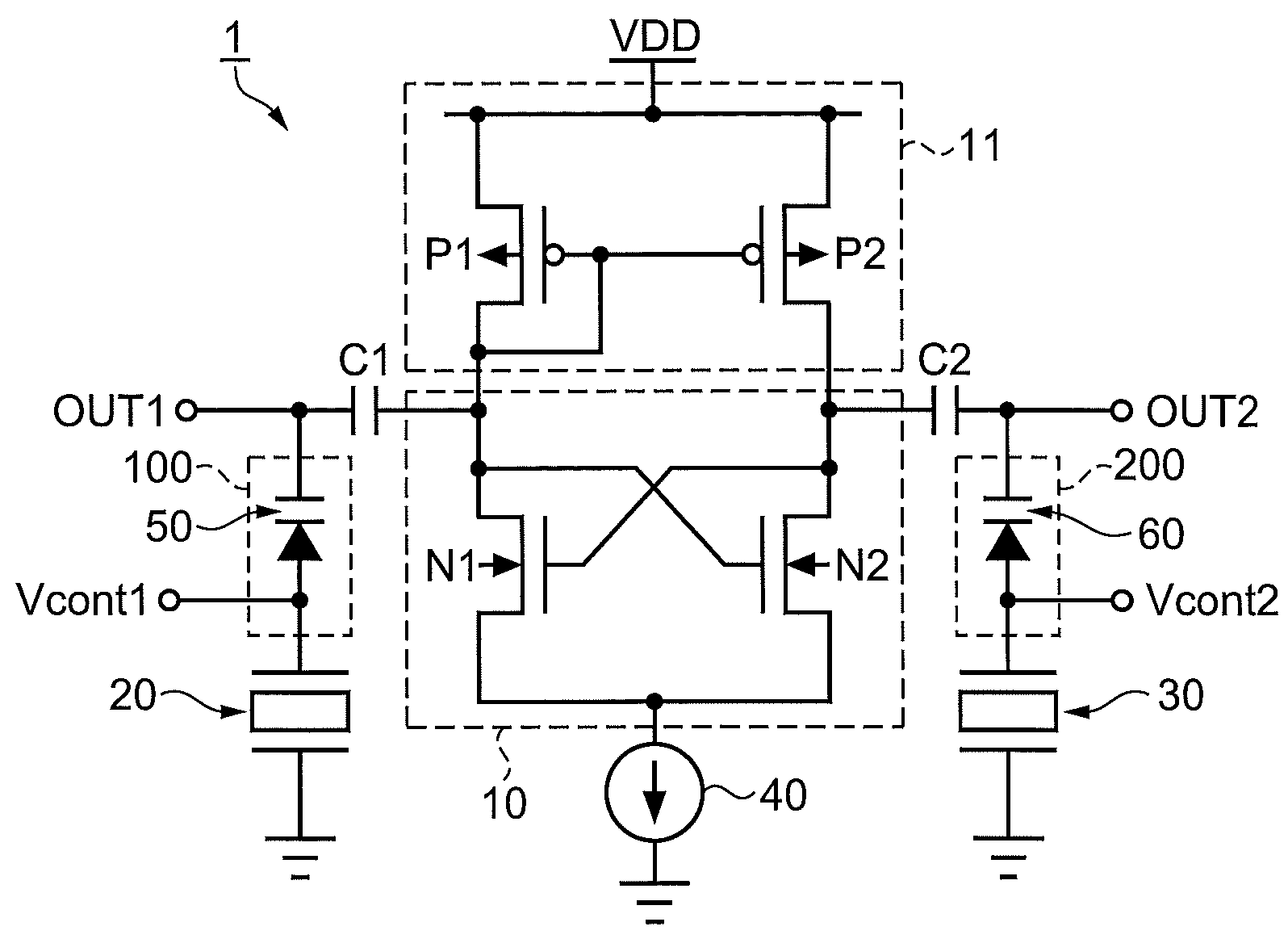

[0036]First, the configuration of the surface acoustic wave oscillator according to this embodiment of the invention will be described with reference to the drawings. FIG. 1 is a circuit diagram illustrating the configuration of the surface acoustic wave oscillator according to this embodiment of the invention.

[0037]As shown in FIG. 1, the surface acoustic wave oscillator 1 includes a cross-coupled circuit 10 and a current mirror circuit 11 each connected to an output terminal OUT1 as a first output terminal and to an output terminal OUT2 as a second output terminal, a first variable capacitance circuit 100 connected to a SAW resonator 20 as a first surface acoustic wave element, to a SAW resonator 30 as a second surface acoustic wave element, and to a control terminal Vcont1 as a first control terminal, and a second variable capacitance circuit 200 connected to a control terminal Vcont2 as a second control terminal.

[0038]The cross-coupled circuit 10 is made up of a Nch transistor N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com