Screening module

a technology of material screen and screen, applied in the direction of sieving, solid separation, screening, etc., can solve the problems blockage or blinding of apertures, subjected to further processing, etc., and achieve the effect of facilitating the dislodging of material blinding apertures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

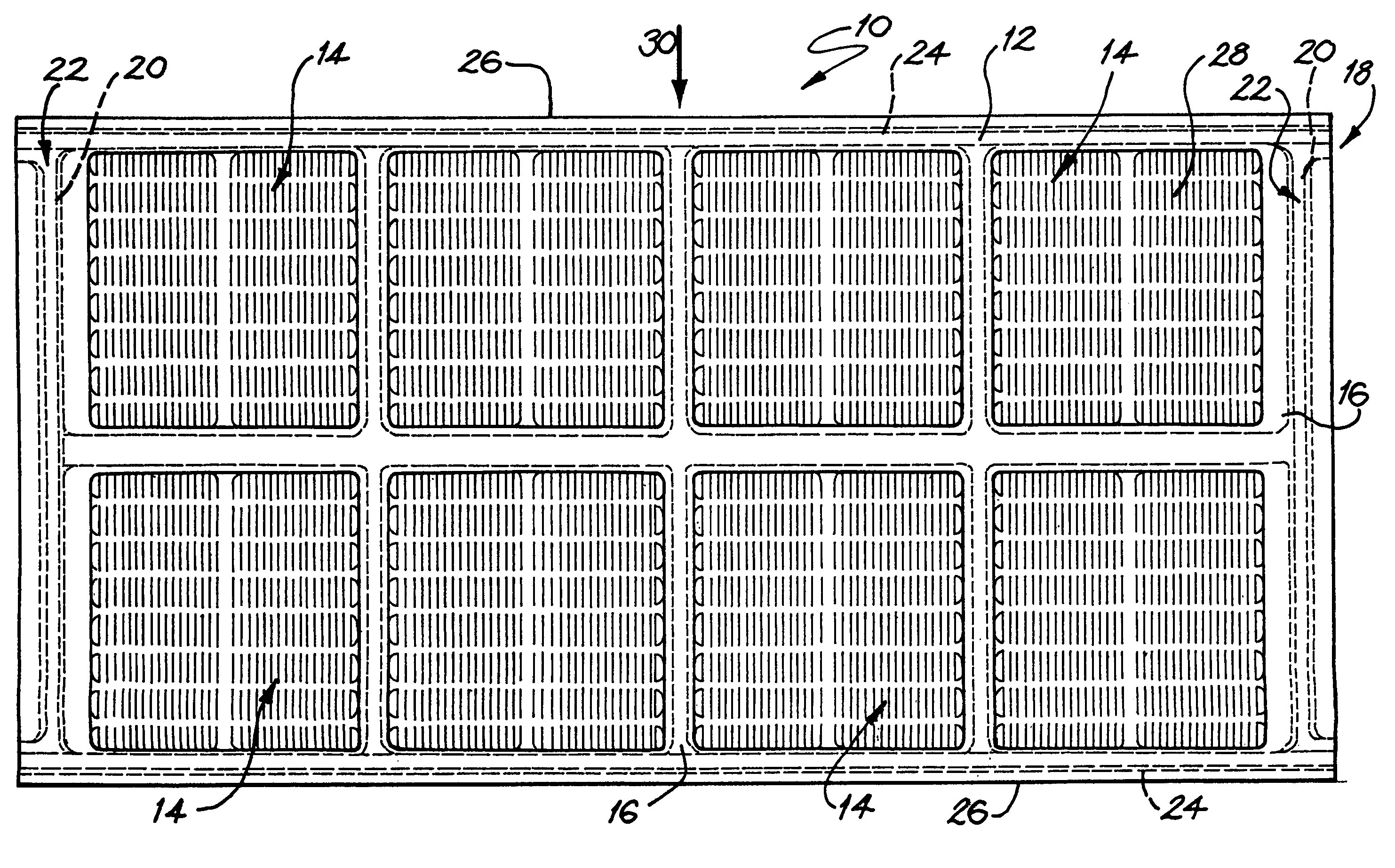

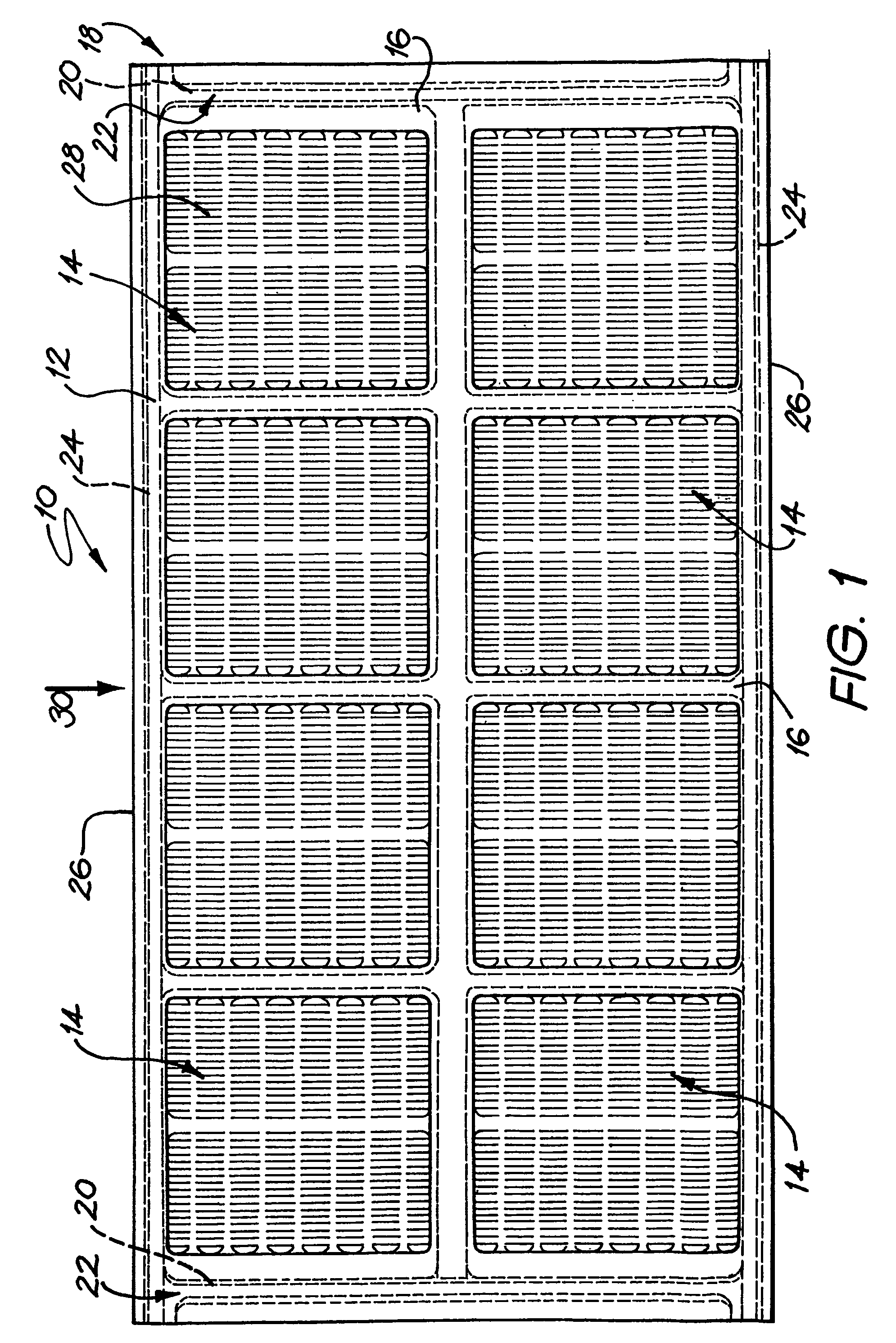

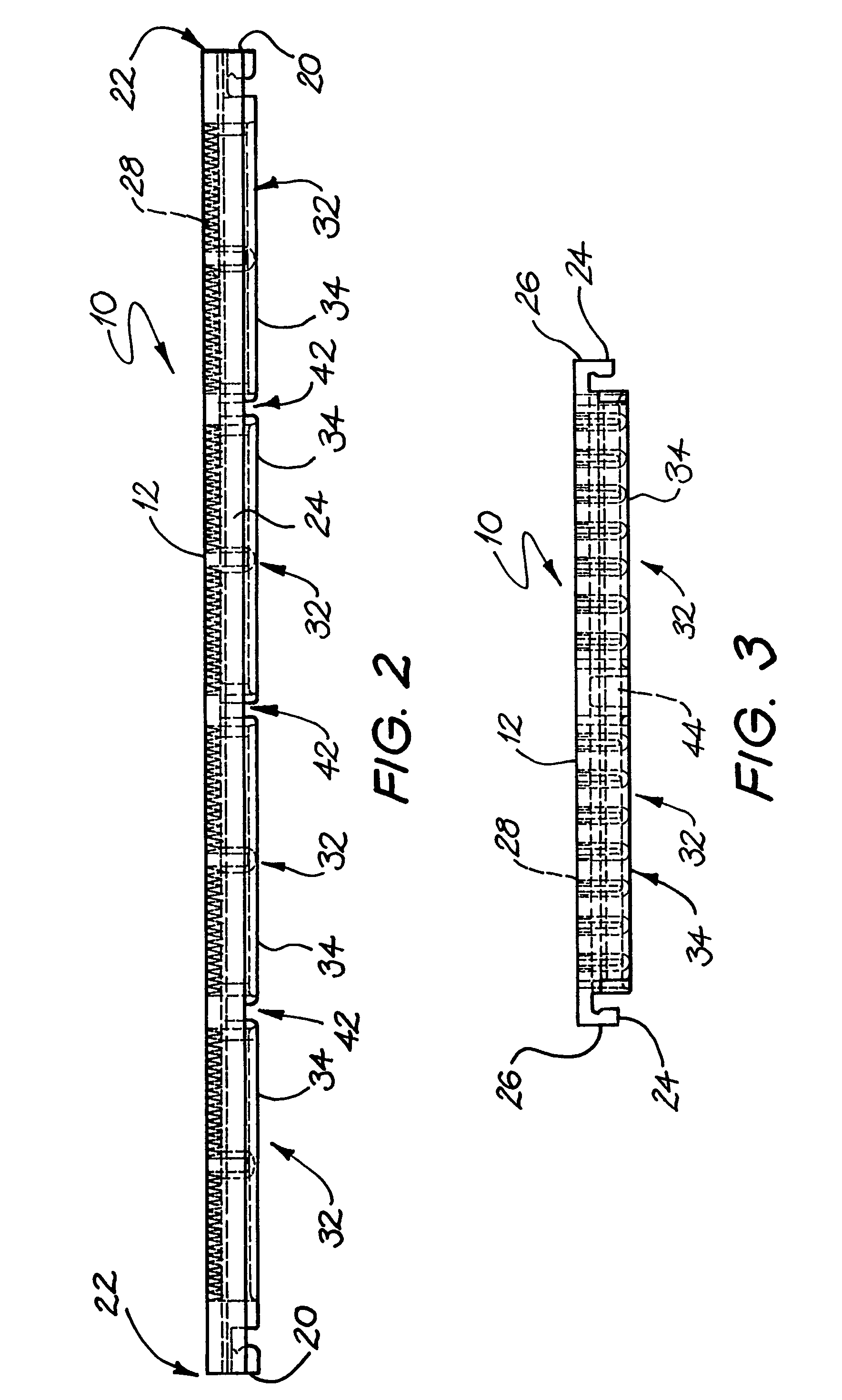

[0030]In the drawings, reference numeral 10 generally designates a screening module, in accordance with an embodiment of the invention.

[0031]The module 10 comprises a panel member 12 defining a plurality of discrete aperture arrays 14. It will be noted that a matrix of aperture arrays 14 is defined in the panel member 12. Each array 14 is separated from its neighbouring array / s by material 16 of the panel member 16.

[0032]The screening module 10 includes a mounting formation 18 in the form of a plurality of clips 20, 24 arranged about a periphery of the panel member 12. A clip 20 is provided at each end 22 of the panel member 12. In addition, a clip 24 is provided along each side 26 of the panel member 12. The panel member 12 is substantially rectangular in shape having shorter ends 22 and longer sides 24. In use, the ends 22 are arranged parallel to a direction of flow of material over the panel member 12 as generally indicated by the arrow 30. It is also to be noted that the apertu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com