Vortex feature for drug delivery system

a technology of drug delivery system and valve, which is applied in the field of automatic injector, can solve the problems of shortening the time needed to administer a dose of the therapeutic agent, affecting the safety of patients, and long-term storage of the therapeutic agent as a liquid solution, so as to improve the mixing ability, improve the mixing effect of the liquid component and the dry component, and improve the mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

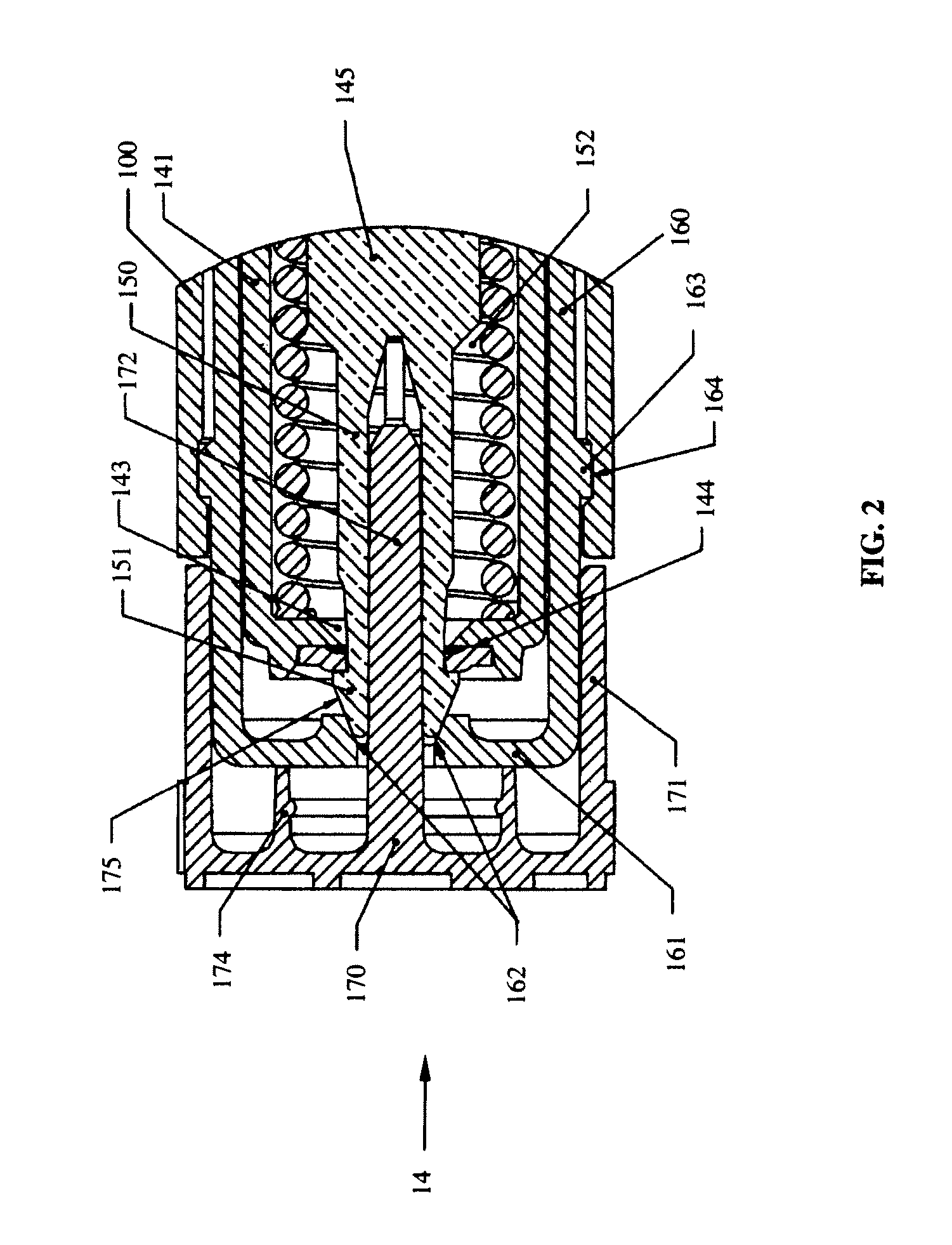

[0045]The results shown in Tables 1 and 2 below demonstrate the improved mixing and dissolution capabilities of the fluid-directing member of the invention.

[0046]Table 1 shows test results of administering a dry component mixed with a liquid component using an auto-injector with a fluid-directing member. Table 2 shows test results of administering a dry component mixed with a liquid component using an auto-injector without a fluid-directing member.

[0047]The tests were done by first loading a sample of a dry component into a wet / dry auto-injector. The auto-injector was then activated, allowing the liquid component to mix with the dry component before being dispensed. The dispensed sample was collected in a container and the dispensed sample and container were weighed. The liquid component was then removed and the dry component and container were weighed. The dispensed solid mass was determined. Also, the mixing / dispensing time was measured.

[0048]

TABLE 1Devices with Fluid-Directing Me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com