Control scheme for coordinating variable capacity components of a refrigerant system

a technology of variable capacity and control scheme, which is applied in the field of refrigerant systems, can solve problems such as the difficulty of controlling a refrigerant system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

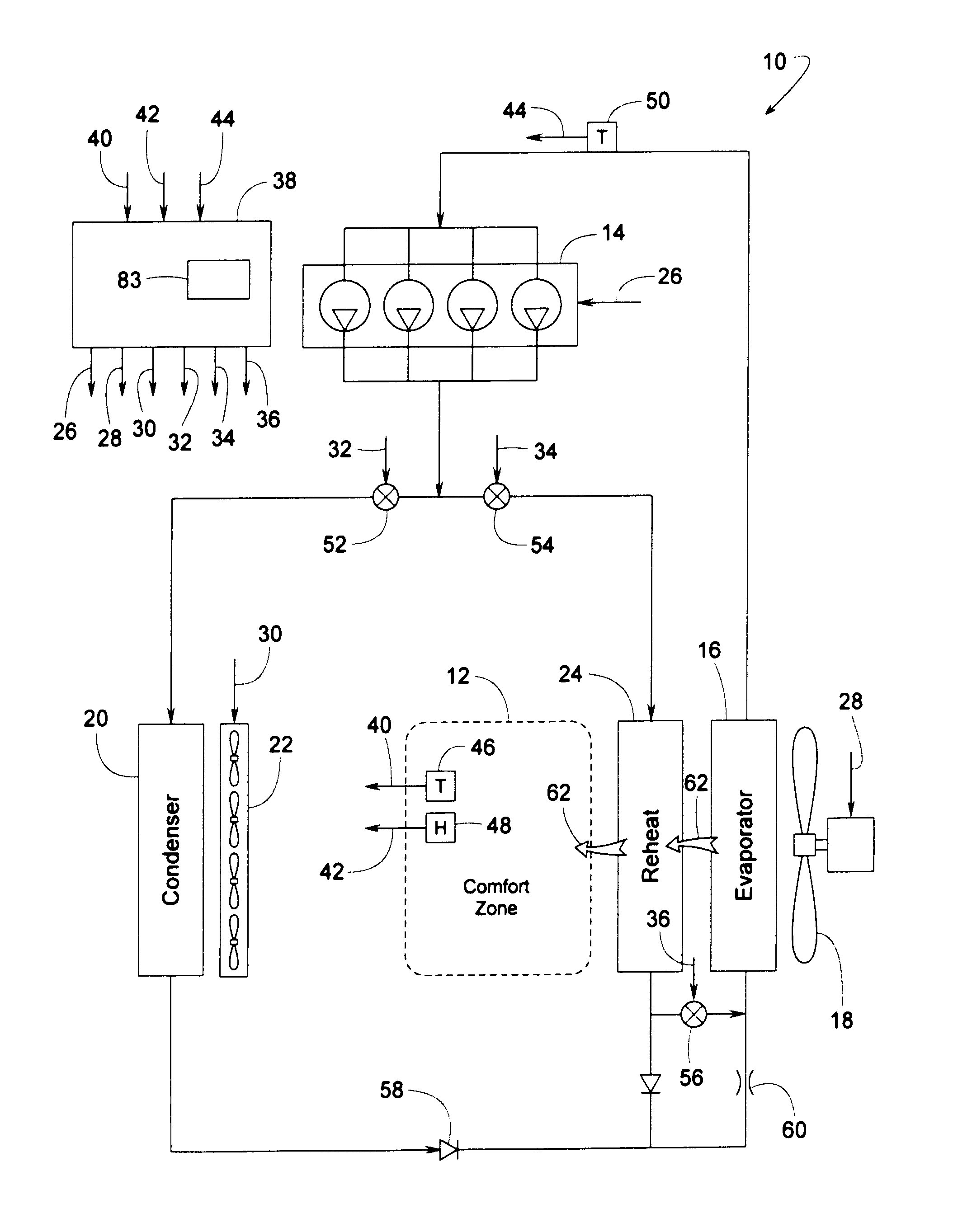

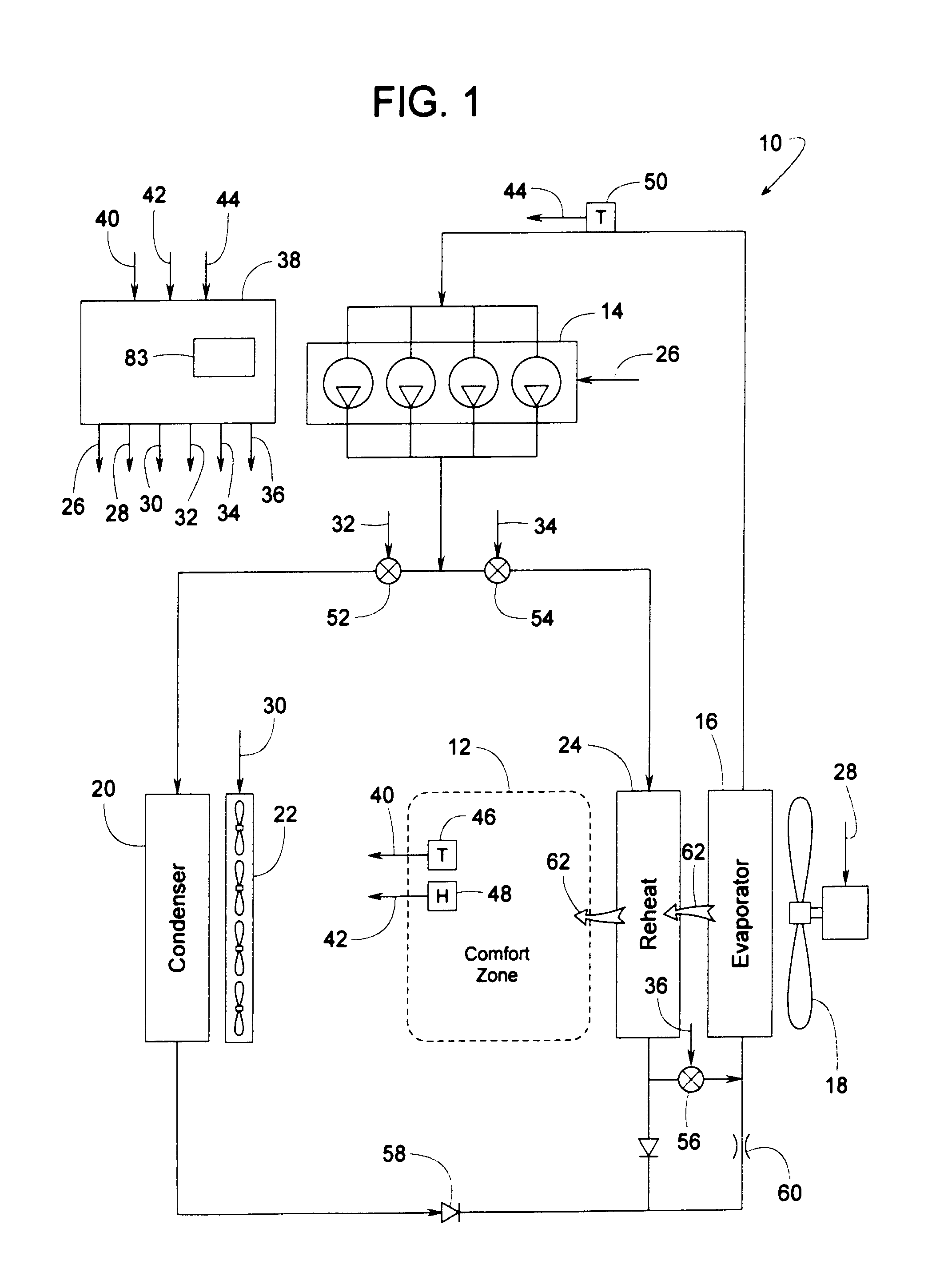

[0015]FIG. 1 schematically illustrates a refrigerant cooling system 10 for controlling the temperature and humidity of a comfort zone 12, such a room or area of a building. To meet the comfort zone's varying demand for cooling or dehumidification, system 10 includes a compressor system 14 with variable compressor capacity (in terms of refrigerant mass flow rate), an evaporator 16 associated with an evaporator fan system 18 with variable evaporator fan capacity (in terms of standard airflow volume across evaporator 16), a condenser 20 associated with a condenser fan system 22 with variable condenser fan capacity (in terms of standard airflow volume across condenser 20), and an optional reheat coil 24 that can be used for heating the cooled air exiting evaporator 16 when system 10 is needed for dehumidifying without sensible cooling.

[0016]It is well known to those of ordinary skill in the art that there are countless ways of varying the operating capacities of individual compressor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com