Multi-chamber rotating valve

a multi-chamber, valve technology, applied in water supply installation, laboratory glassware, instruments, etc., can solve the problems of not being easily converted to new processes, complex fluid delivery system, system is not easily adaptable to new pre-treatment steps or fluid delivery, etc., to reduce leakage and failure of devices, reduce costs, and be more flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

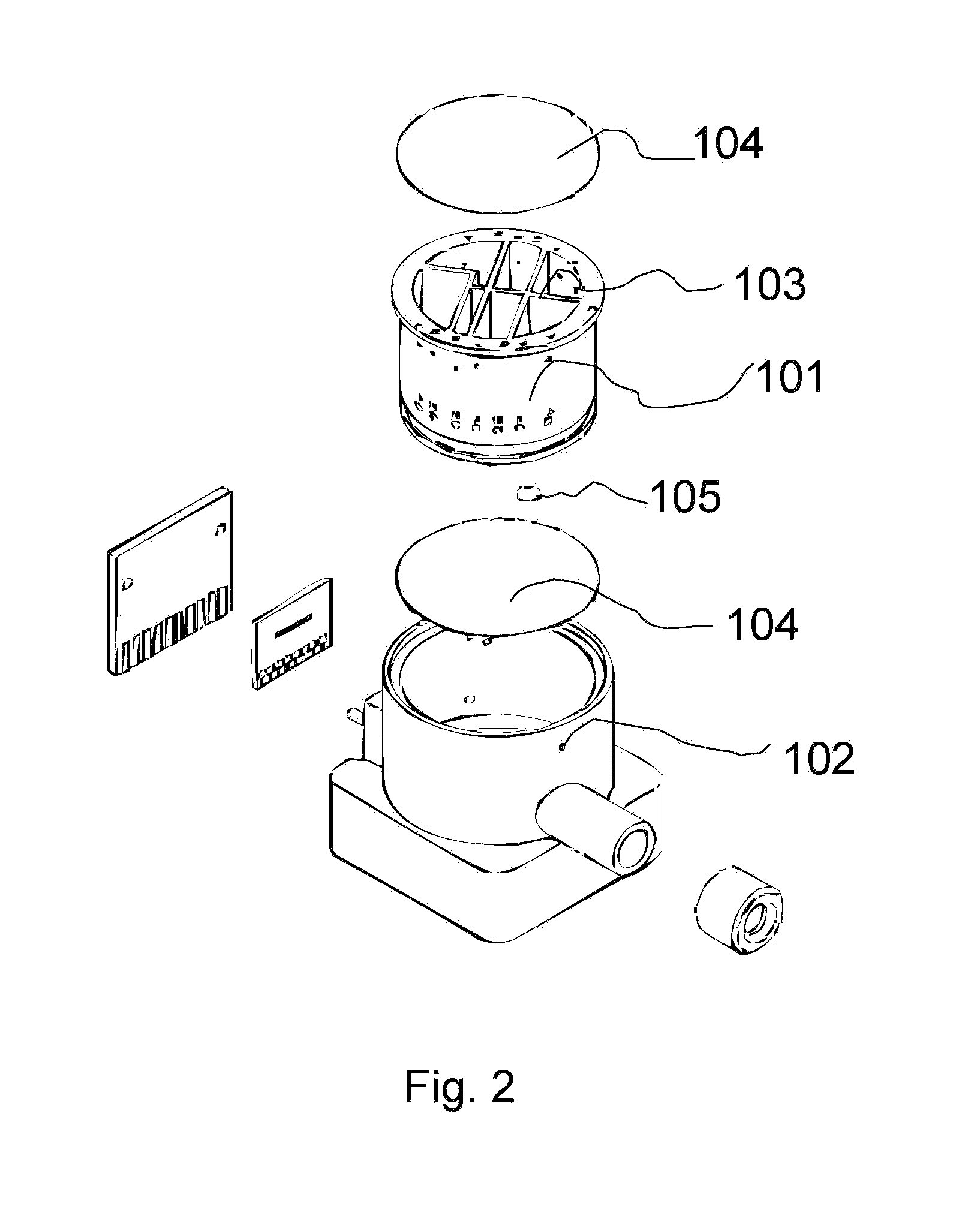

[0032]The rotating valve of the instant invention is a two piece construction capable of various positioning to allow the passage of fluid contained in the reservoirs into the fluid paths. The two piece design allows for easy manufacturing and assembly. The design further allows for the rotating valve to be a disposable piece in instruments requiring a plurality of fluids. In one embodiment, the rotating valve is a single use piece for use in detection devices. The rotating valve contains the necessary fluids for biological testing and further is capable of being injected with a field sample.

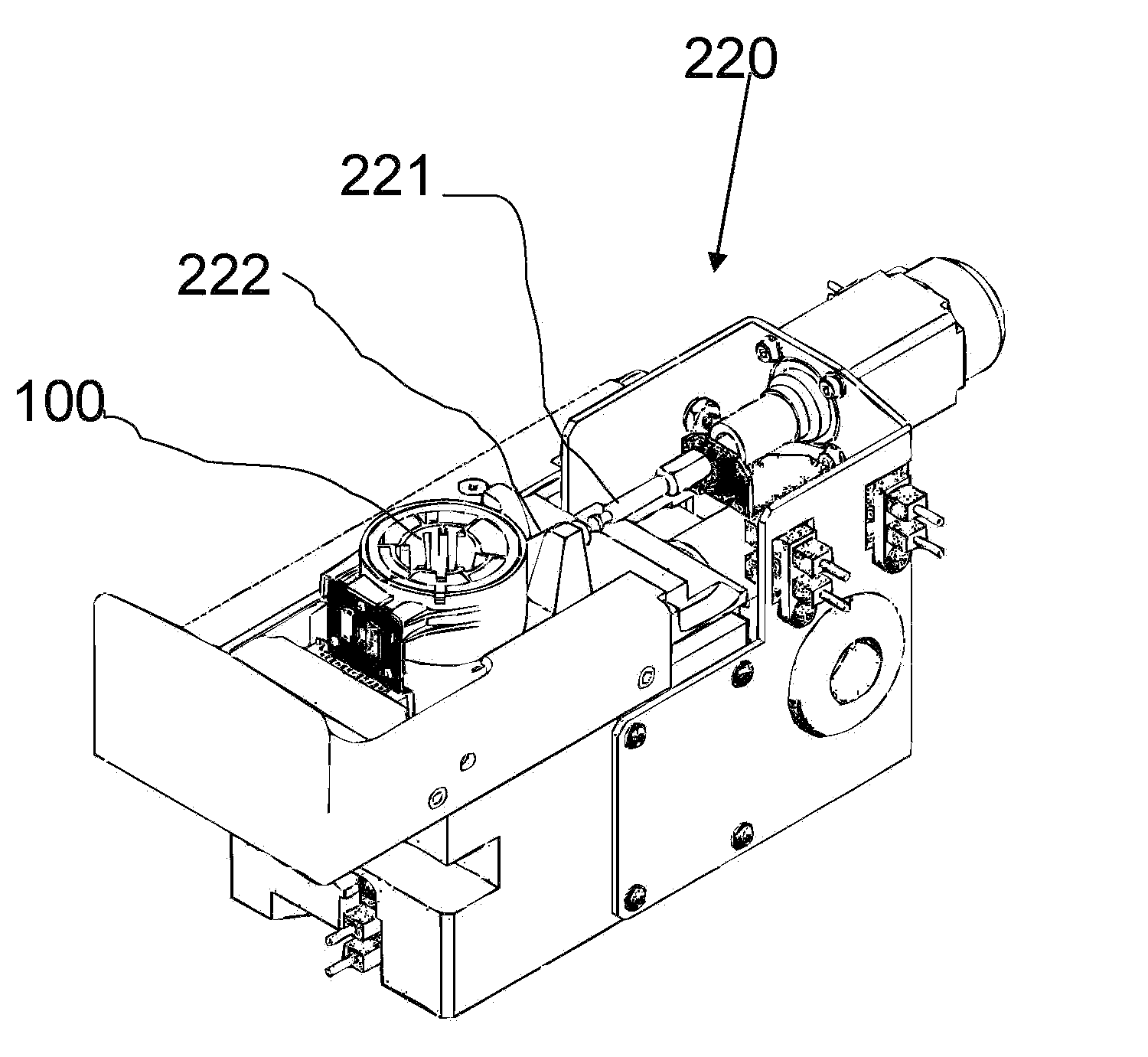

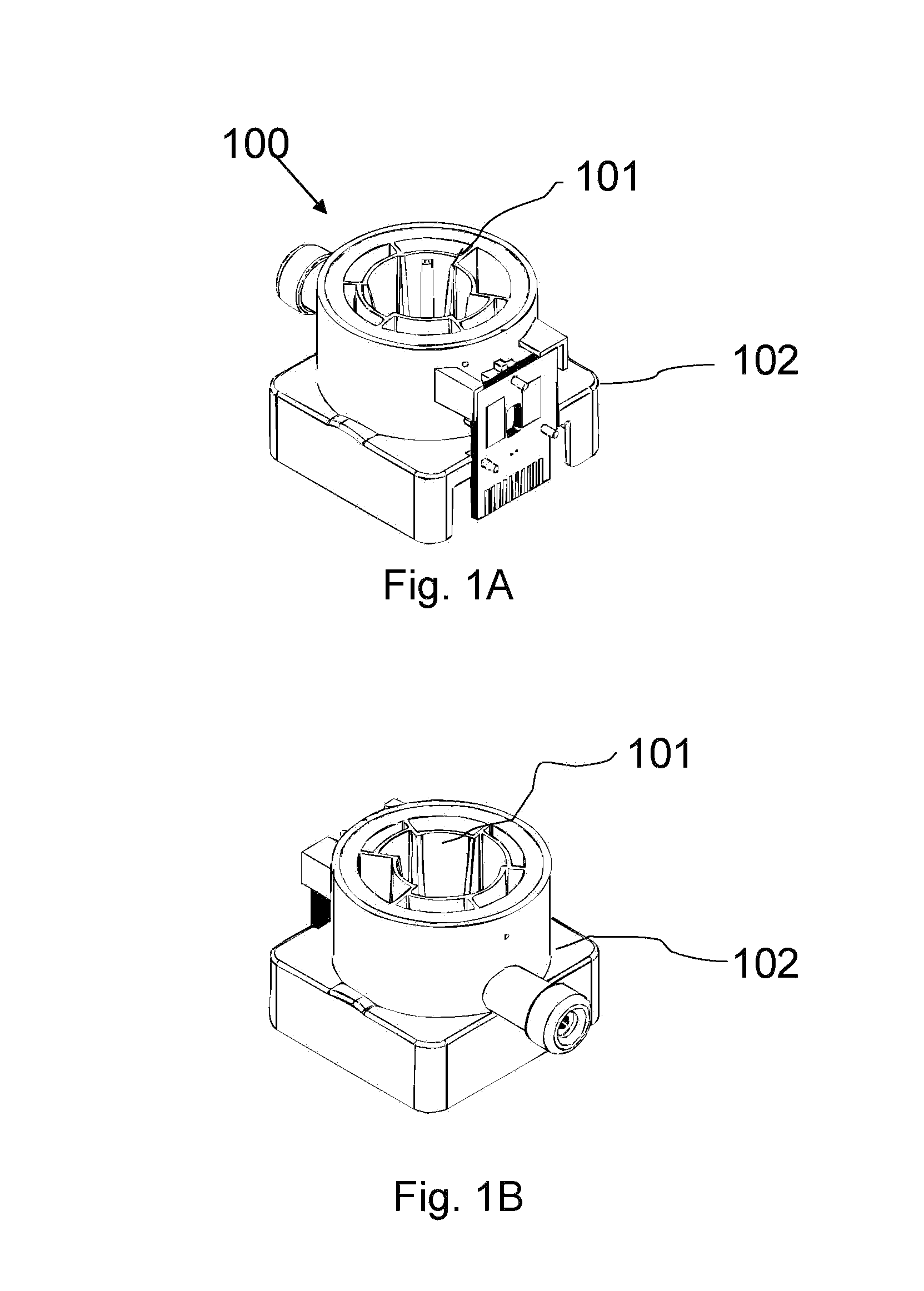

[0033]Referring to FIGS. 1A-1B there is shown an assembled rotating valve of the instant invention. The rotating valve comprises two main components. The reservoir insert 101 is contained within the cartridge body 102. The rotating valve 100 is a disposable component containing a plurality reservoirs capable of storing a plurality of fluids. In one embodiment, the reservoir insert 101 and the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com