Belt driving apparatus and image forming apparatus

a driving apparatus and belt technology, applied in the direction of electrographic process apparatus, instruments, optics, etc., can solve the problems of affecting the stability the lateral deviation of the belt member, and the liable instability of the frictional force of the contact belt, so as to improve the responsiveness to lateral deviation (movement) of the belt member and enhance the contact stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

(Embodiment 1)

[0025]An image forming apparatus in this embodiment of the present invention will be described.

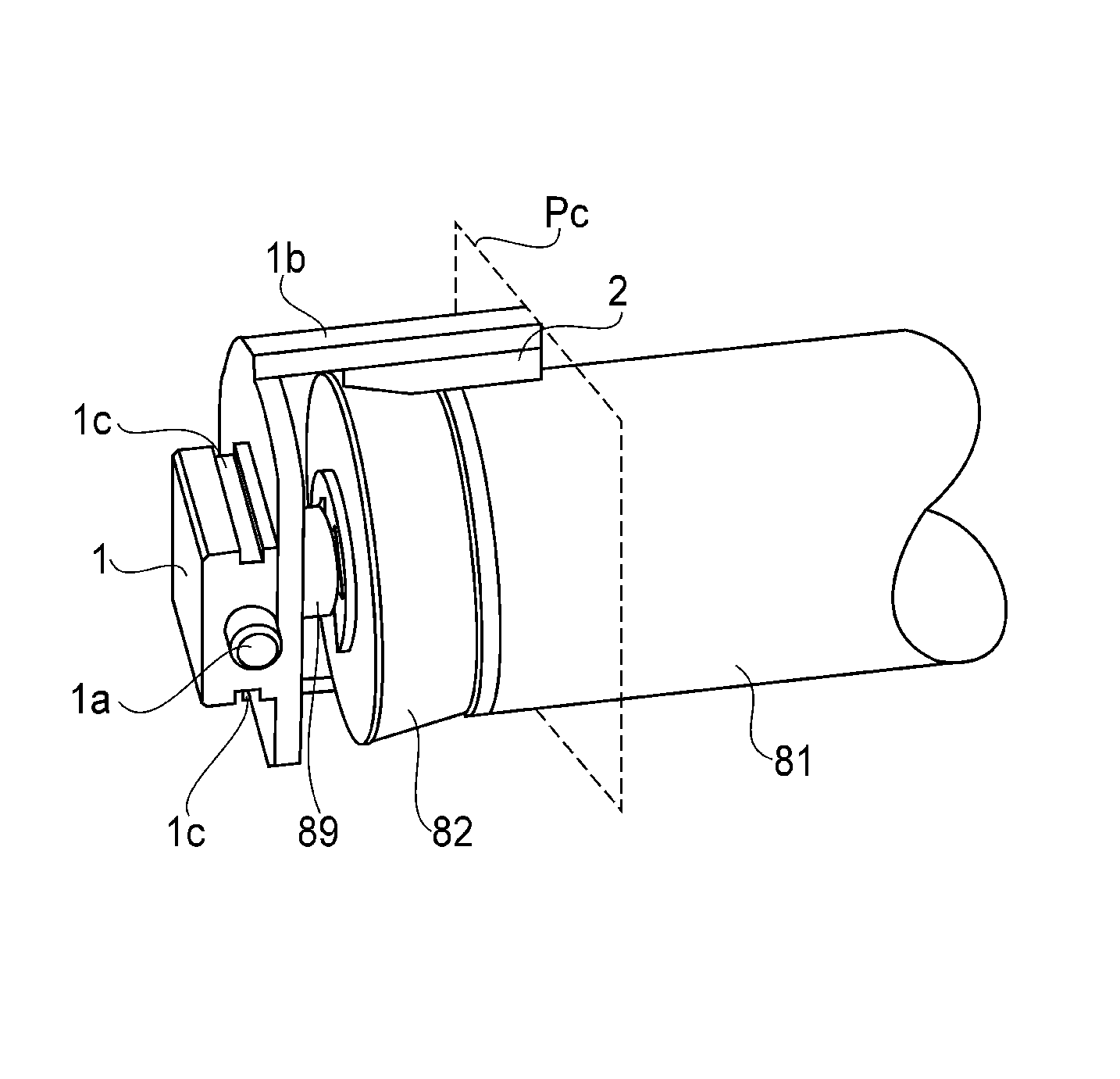

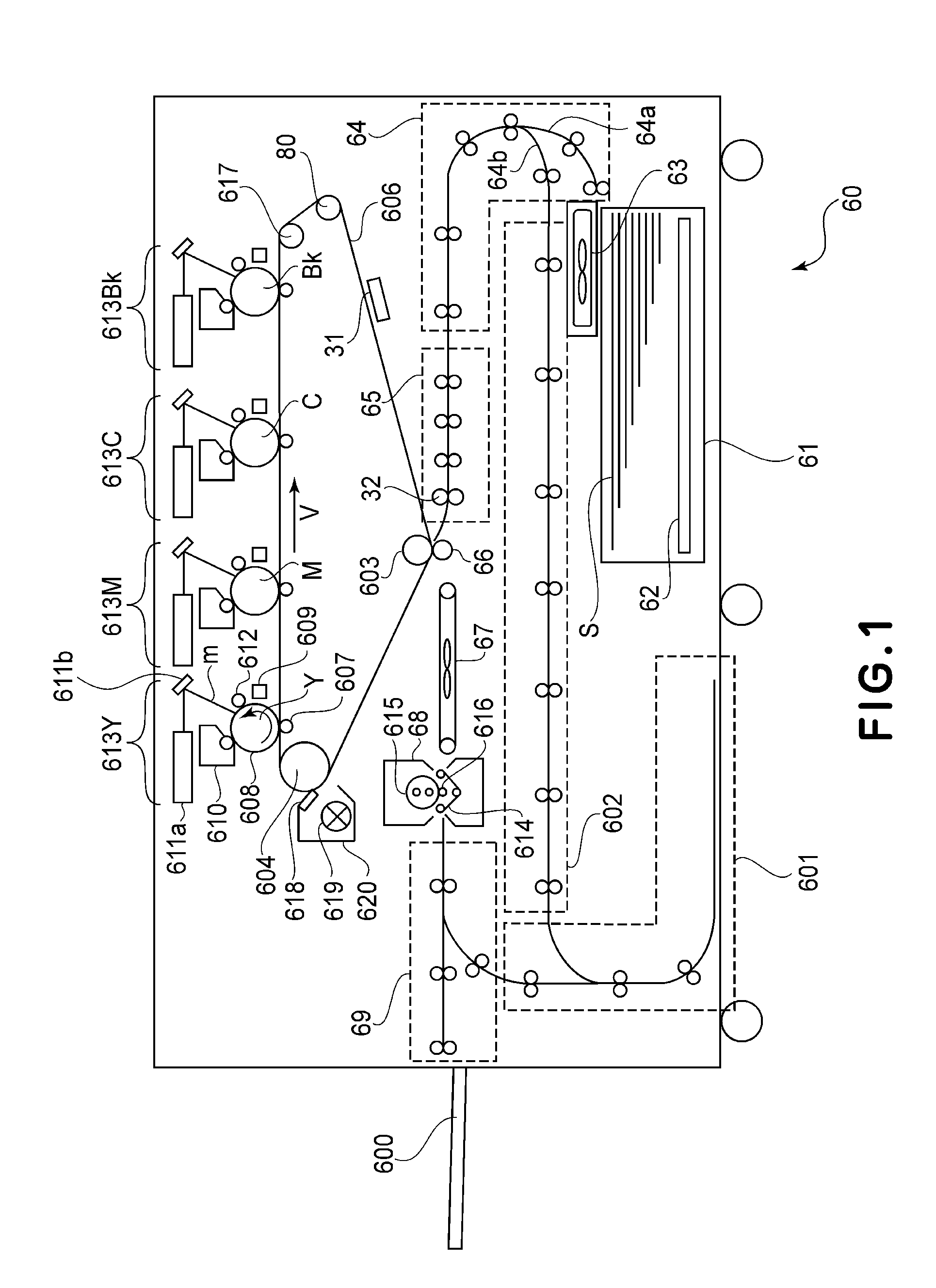

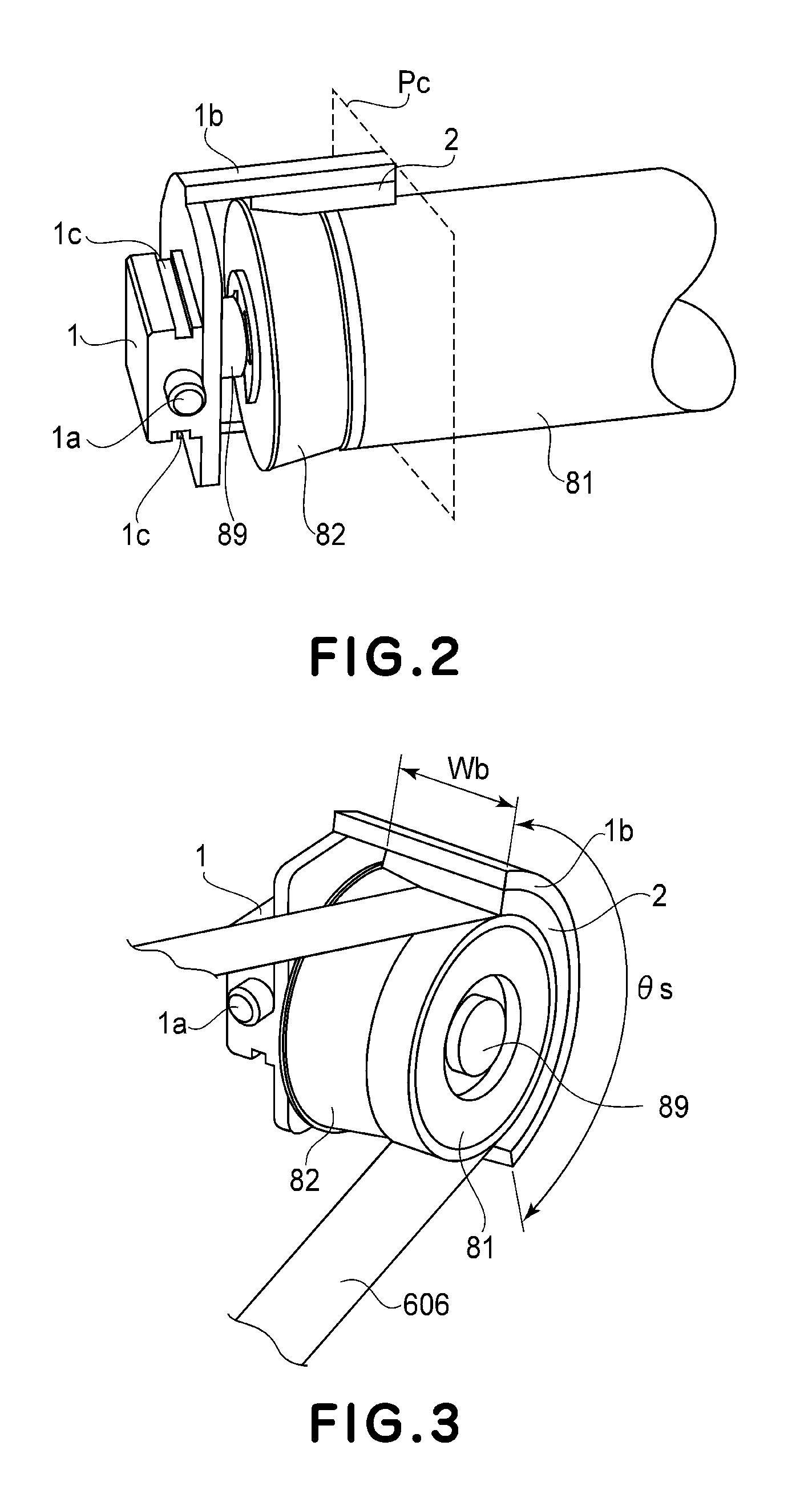

[0026]First, referring to FIG. 1, an operation of the image forming apparatus will be described. Types of the image forming apparatus may include a plurality of types such as an electrophotographic type, an offset printing type and an ink jet type. The image forming apparatus 60 shown in FIG. 1 is a color image forming apparatus of the electrophotographic type. The image forming apparatus 60 is of a so-called intermediary transfer tandem type in which four image forming portions for four colors are arranged side by side on an intermediary transfer belt. FIG. 1 is a sectional view of the image forming apparatus 60 of this type, which goes mainstream from the viewpoints of excellent compatibility with thick paper and excellent productivity.

[0027]Sheets of recording material S are stacked on a lift-up device 62 in a recording material accommodating portion 61. The recording mate...

embodiment 2

(Embodiment 2)

[0062]In this embodiment, the same constitutions as those of the intermediary transfer belt unit 700 and the image forming apparatus 60 including the intermediary transfer belt unit 700 are basically employed. Therefore, the constitution of the image forming apparatus 60 and the operation principle will be omitted from the description and a different portion will be principally explained. Further, in the following, the same portions (members) are represented by the same reference numerals or symbols and will be omitted from the description.

[0063]FIG. 4 is an enlarged view of the end portion of the steering roller for the intermediary transfer belt in this embodiment of the present invention. Specifically, the steering roller has the same constitution as that of the automatic center alignment mechanism described with reference to FIG. 8 and a difference portion is a supporting constitution for supporting an urging (pressing) member 2 which is a feature of the present in...

embodiment 3

(Embodiment 3)

[0070]In Embodiment 3 of the present invention, the image forming apparatus 60 including the intermediary transfer belt unit 700, the arrangement of the steering device is changed from that in Embodiment 1. The arrangement of the driving roller 604 and the steering roller 80 is interchanged. That is, the cleaning blade 618 urges the intermediary transfer belt against the steering roller 80, and the driving roller 604 is disposed between the stretching roller 617 and the inner transfer roller 603. Therefore, the constitution of the image forming apparatus 60 and the operation principle will be omitted from the description and a different portion will be principally explained. Further, in the following, the same portions (members) are represented by the same reference numerals or symbols and will be omitted from the description.

[0071]FIG. 5 is a perspective view for illustrating a relationship between a steering device 800 including the steering roller 80 and a cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com