Variable-size induction heating plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

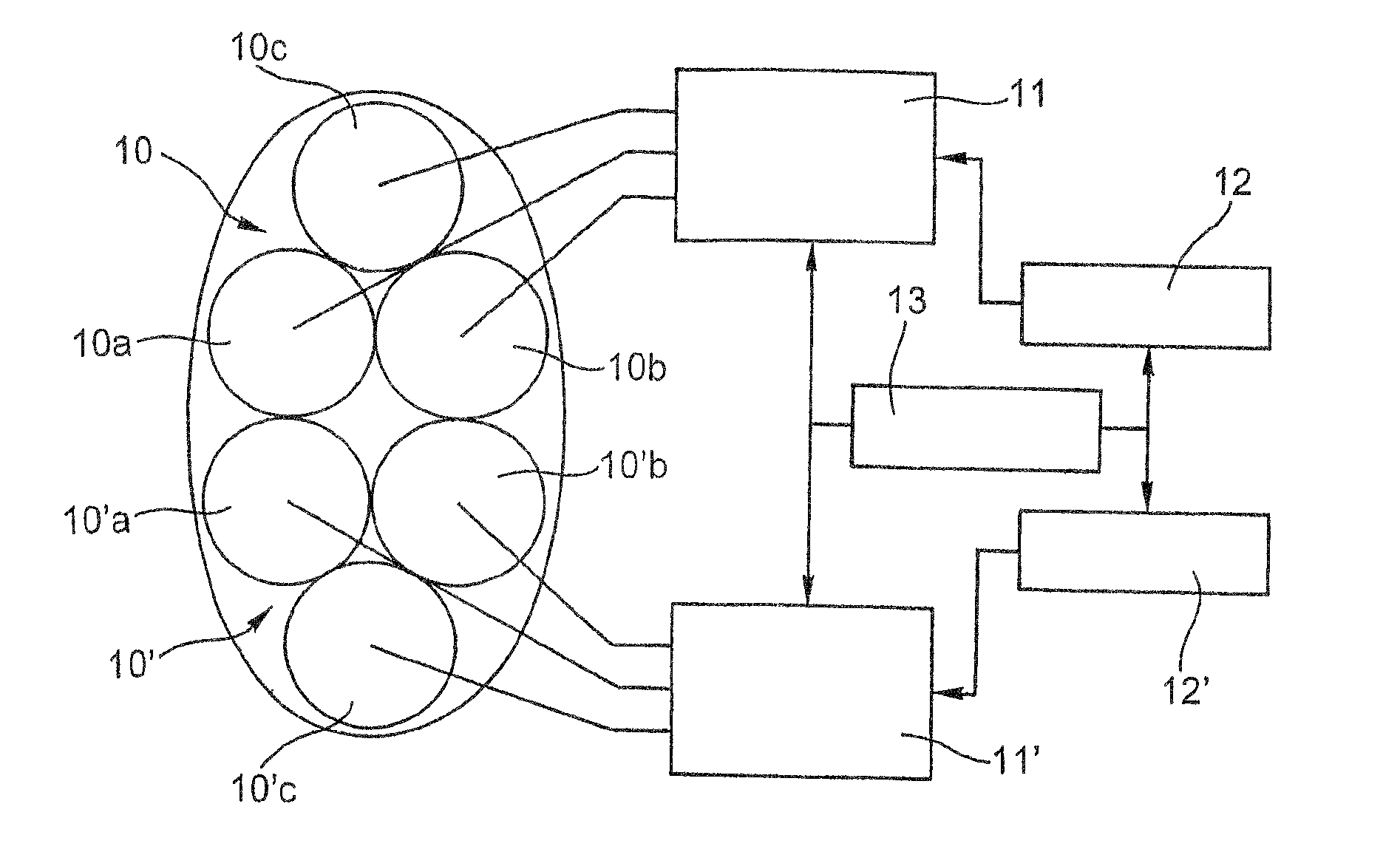

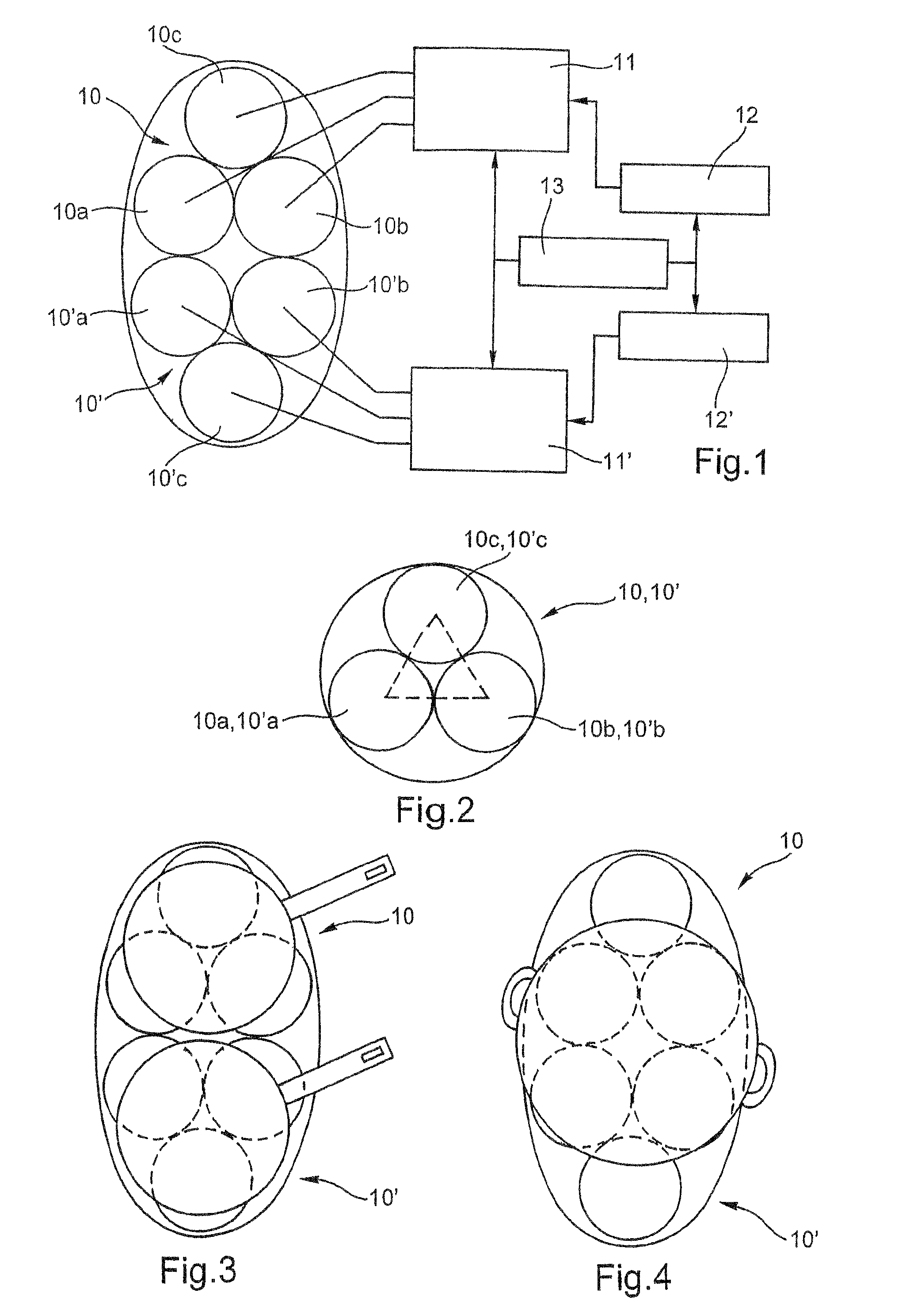

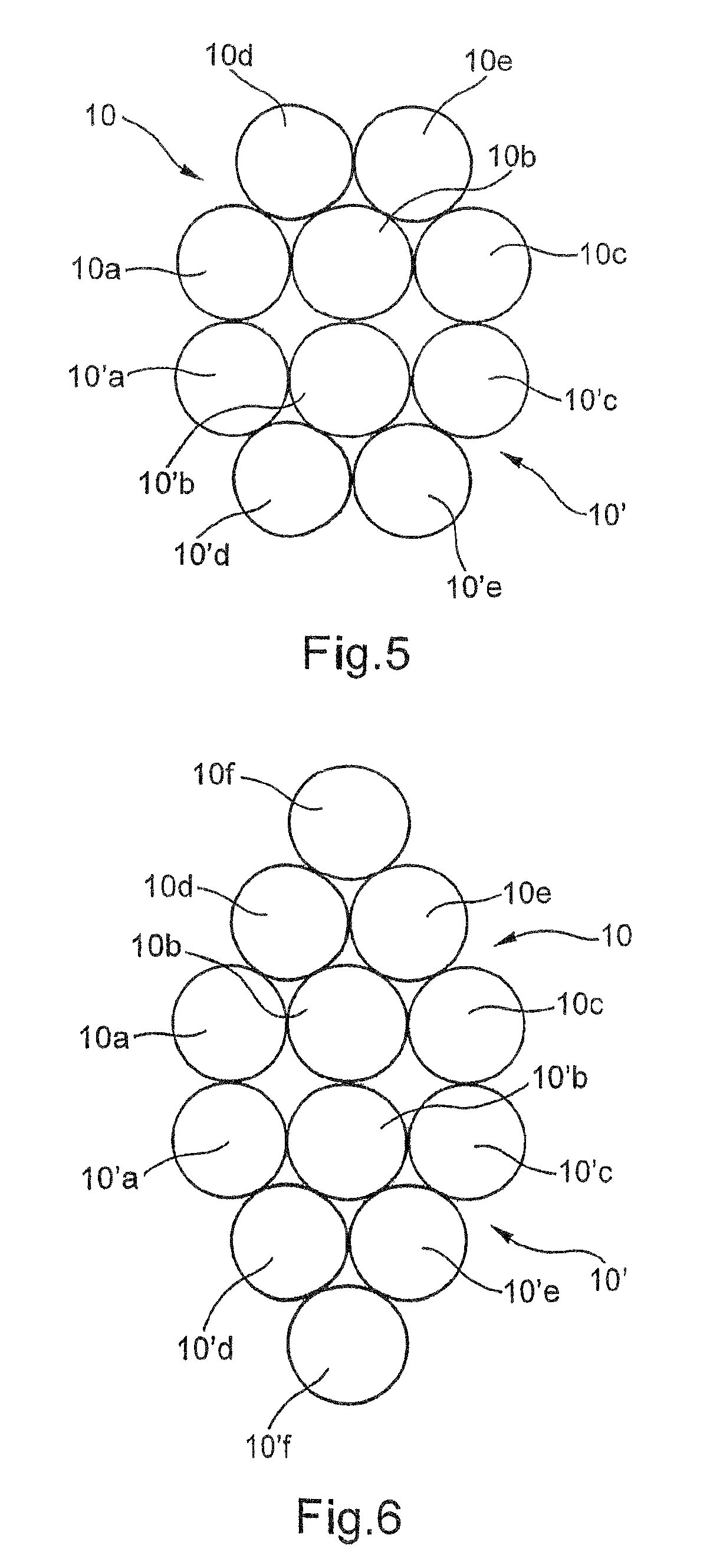

[0033]One embodiment of an induction heading plate of the invention is described next with reference to FIGS. 1 to 4.

[0034]In this embodiment, the heating plate comprises two sets 10, 10′ of a plurality of windings 10a, 10b, 10c, 10′a, 10′b and 10′c, all disposed in a plane parallel to the cooking surface.

[0035]As shown clearly in FIG. 2, each set 10, 10′ includes three windings disposed in a triangle so that each set 10, 10′ includes windings equidistant from each other.

[0036]Thus each set 10, 10′ of three windings is inscribed in a circle, as shown in FIG. 2, in such a manner as to constitute a disc-shaped heating plate particularly suitable for the shape of a cooking vessel.

[0037]In this embodiment, the windings are disc-shaped and tangential to the circle defining the heating plate.

[0038]Each winding consists of an electrically conductive coil.

[0039]In practice, each winding can consist of a flat, spiral coil of multistrand copper wires.

[0040]The electrically conductive coils of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com