Exhaust system conduit with thermal/noise insulation

a technology of exhaust system and conduit, applied in the direction of sleeve/socket joint, mechanical equipment, machine/engine, etc., can solve the problems of undue heat stress, vibration and other movement, and the prior art exhaust system of this type is not completely free of problems, so as to reduce vibration, resist heat transmission, and suppress noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

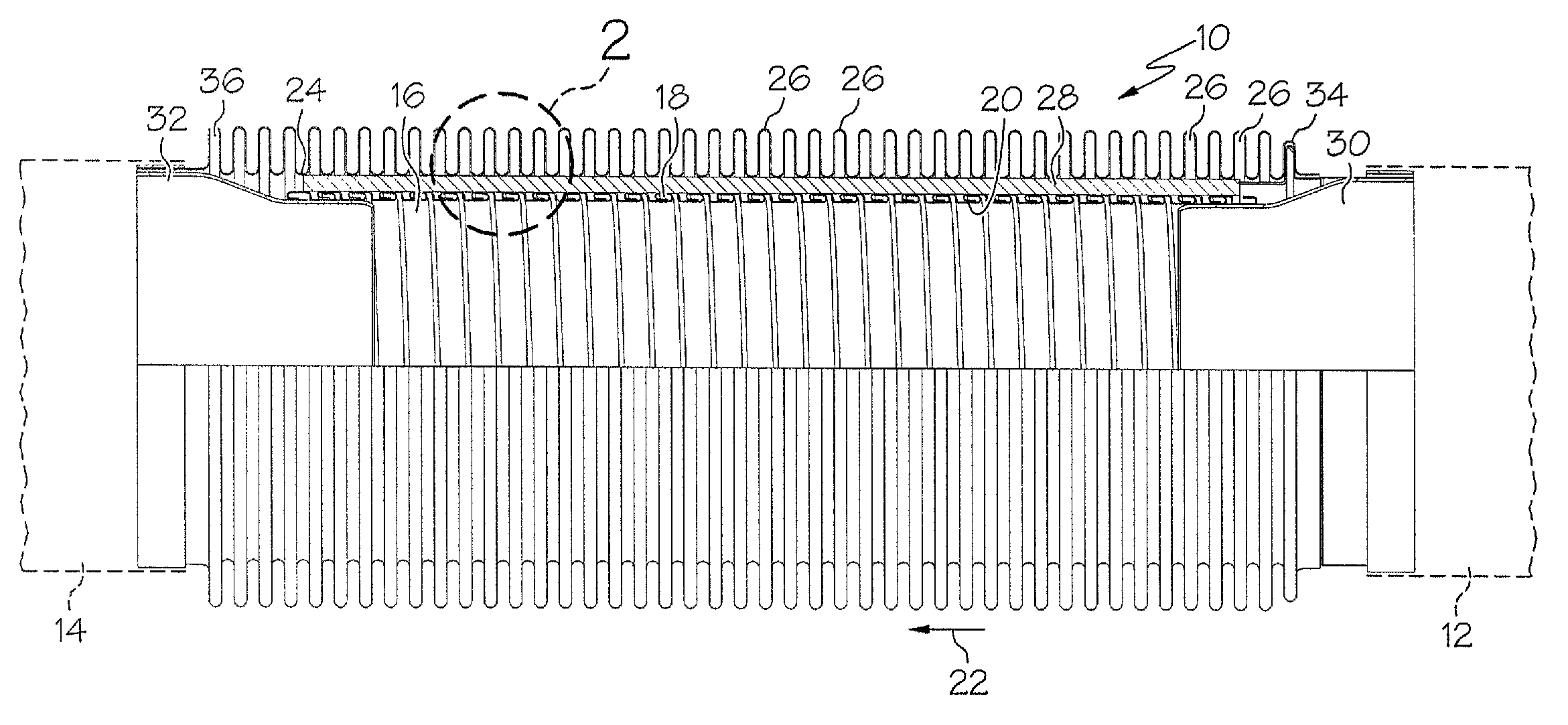

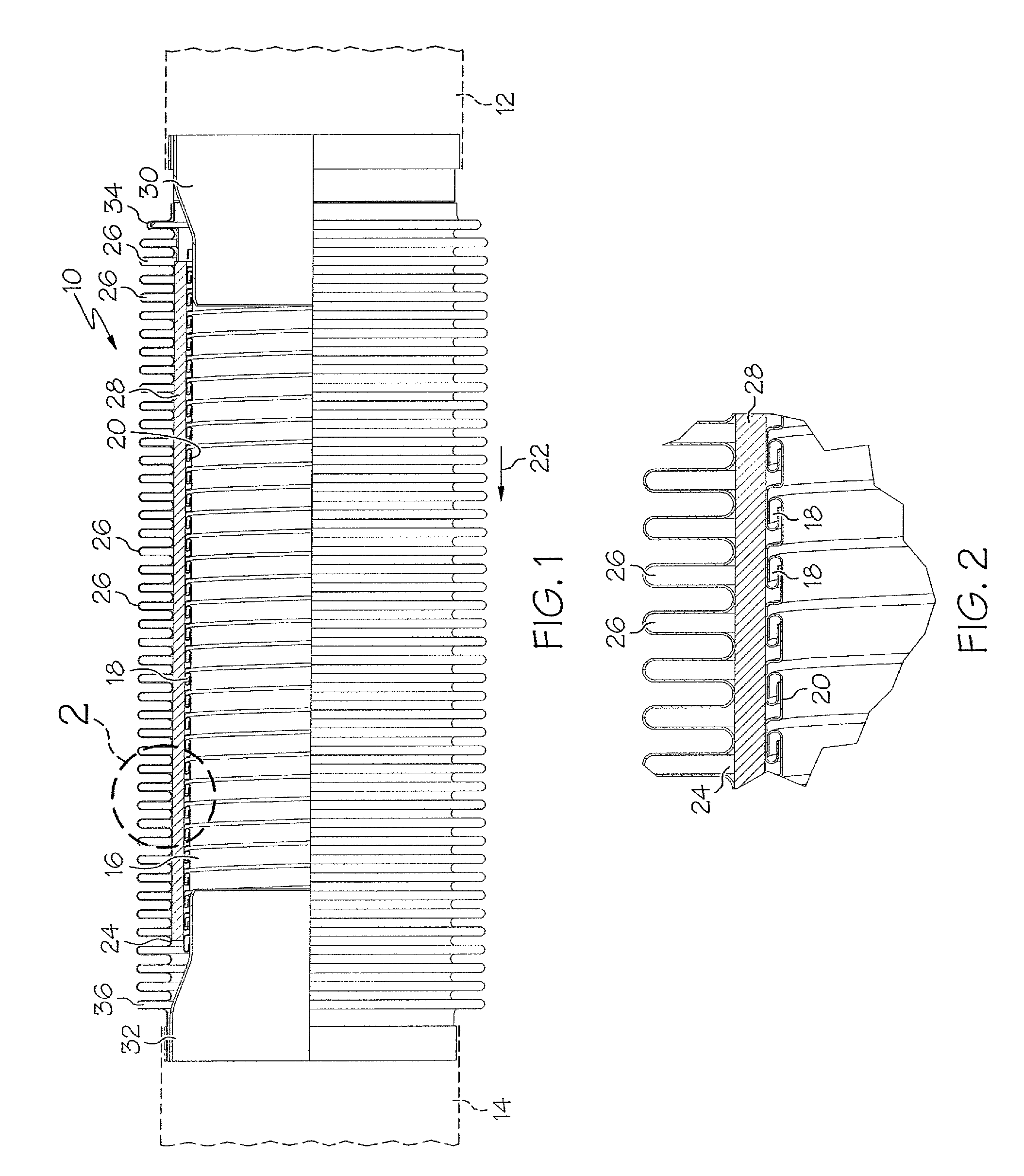

[0014]Referring now to the drawings in more detail and initially to FIG. 1, numeral 10 generally designates a conduit which is constructed according to one embodiment of the present invention. The conduit 10 may couple together a pair of pipes 12 and 14. By way of example, the conduit 10 and the pipes 12 and 14 may be parts of a vehicular exhaust system through which exhaust gases flow.

[0015]The conduit 10 has an inner cylindrical liner portion 16 which may be constructed as a flexible conduit formed by a spirally wound strip 18 having edges of adjacent windings interlocked in the manner described in U.S. Pat. No. 6,427,727 to Thomas which is incorporated by reference. The liner portion 16 has a flexible construction which allows it to flex in a manner to withstand the forces that are applied to it in service. The liner portion 16 provides a cylindrical bore 20 through which the hot vehicular exhaust gases pass from pipe 12 to pipe 14, as shown by the directional arrow 22 in FIG. 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com