Semiconductor module and mobile apparatus

A semiconductor and conductor part technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problem of inability to effectively suppress noise of circuit components, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

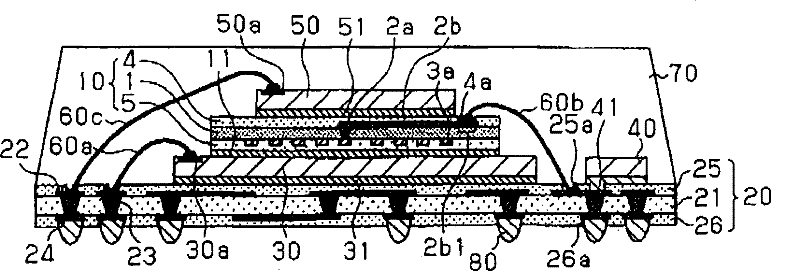

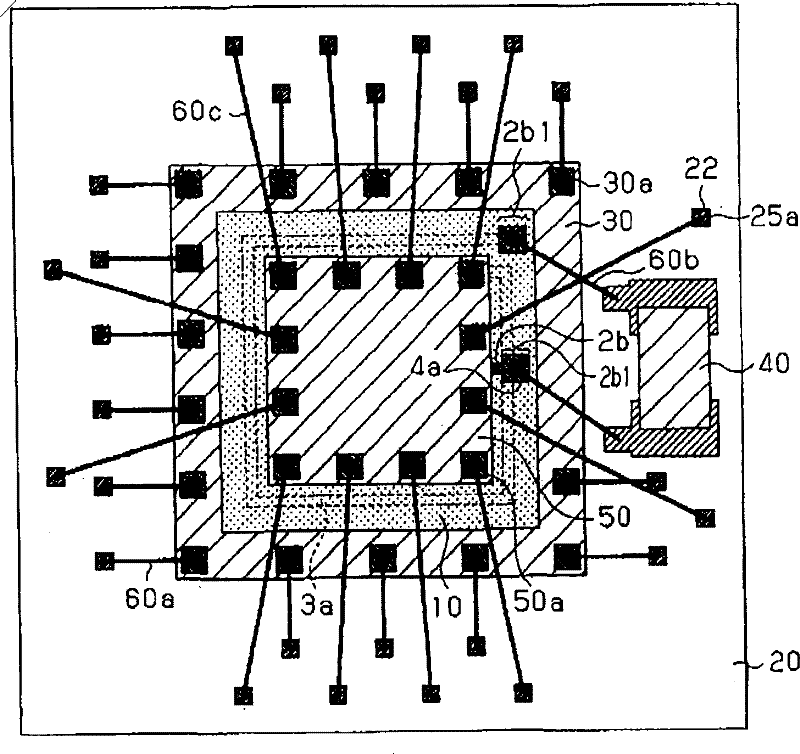

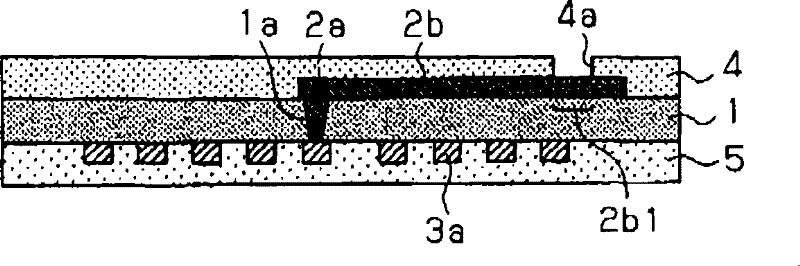

[0047] figure 1 is a cross-sectional view showing the structure of the semiconductor module of the first embodiment, figure 2 It is a plan view (top view) of the semiconductor module of the first embodiment. The semiconductor module of the first embodiment includes: a multilayer substrate 20; a first circuit element 30 mounted on the multilayer substrate 20; a second circuit element 50 stacked on the first circuit element 30; The interposer substrate 10 including the antenna conductor part 3a between the circuit element 30 and the second circuit element 50; the passive element 40 mounted on the multilayer substrate 20 and connected to the antenna conductor part 3a; the seal for sealing each element resin layer 70 .

[0048] The multilayer substrate 20 is, for example, a base substrate with a two-layer wiring structure, and has a wiring layer 22 and a wiring layer 24 on its upper and lower surfaces, respectively, with an insulating layer 21 interposed therebetween. The wiri...

no. 2 Embodiment approach

[0091] Figure 9 It is a design drawing of the antenna conductor part of the interposer board|substrate of 2nd Embodiment. The difference from the first embodiment is that the antenna conductor portion 3a1 of the interposer board 10 is changed from a spiral-shaped wiring pattern to a meander-shaped (Miander-shaped) wiring pattern. Here, the outer edge (dimension) of the antenna conductor portion 3a1 is the same as that of the first embodiment, and the outer edge of the common area (area within the dotted line) S where the first circuit element 30 and the second circuit element 50 overlap is viewed from above. (Size) is large, and the antenna conductor part 3a1 overlaps so that the whole common area S may be covered. Other than that, it is the same as the above-mentioned first embodiment. In addition, the antenna conductor part 3a1 is an example of the "conductor part" of this invention.

[0092] The interposer board 10 having such an antenna conductor portion 3a can be form...

no. 3 Embodiment approach

[0097] Figure 10 It is a design drawing of the antenna conductor part of the interposer board|substrate of 3rd Embodiment. The difference from the first embodiment is that the antenna conductor portion 3a2 of the interposer board 10 partially includes at least one of the first circuit element 30 and the second circuit element 50 in the common area S and becomes a source of noise. circuit area ( Figure 10 The area enclosed by the dotted line) overlaps the configuration in a selective coverage manner. Other than that, it is the same as the above-mentioned first embodiment. In addition, the antenna conductor part 3a2 is an example of the "conductor part" of this invention, and the circuit area N is an example of the "circuit area" of this invention.

[0098] Such an antenna conductor part 3a2 is in Figure 7 In the patterning step of the copper plating layer 3 shown in (F), it can be easily produced by changing its design.

[0099] According to the semiconductor module of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com