Metal foil-clad substrate, circuit board and electronic-component mounting substrate

A technology for circuit substrates and electronic components, applied in the direction of circuit substrate materials, printed circuit components, three-dimensional rigid printed circuit boards, etc., can solve the problems of time and energy required for prepreg manufacturing, and achieve the effect of preventing the spread of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

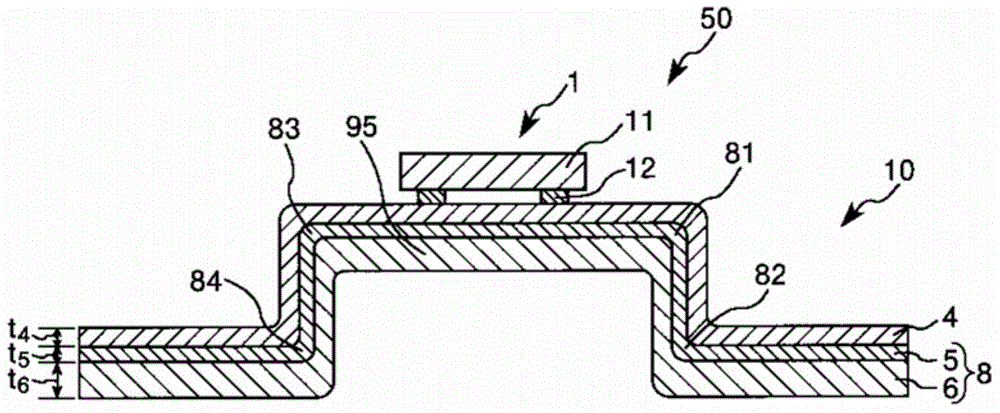

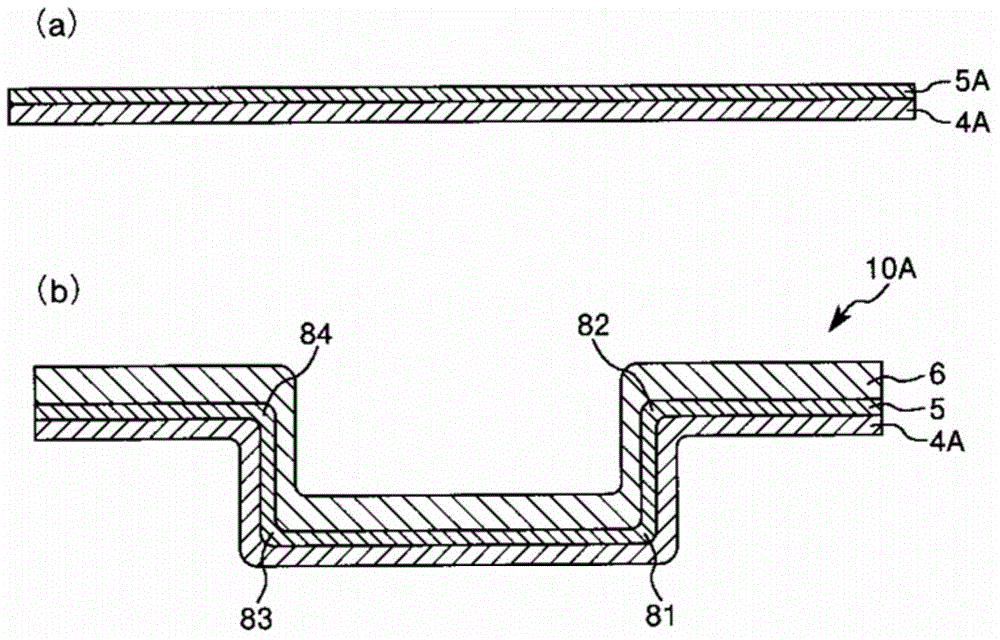

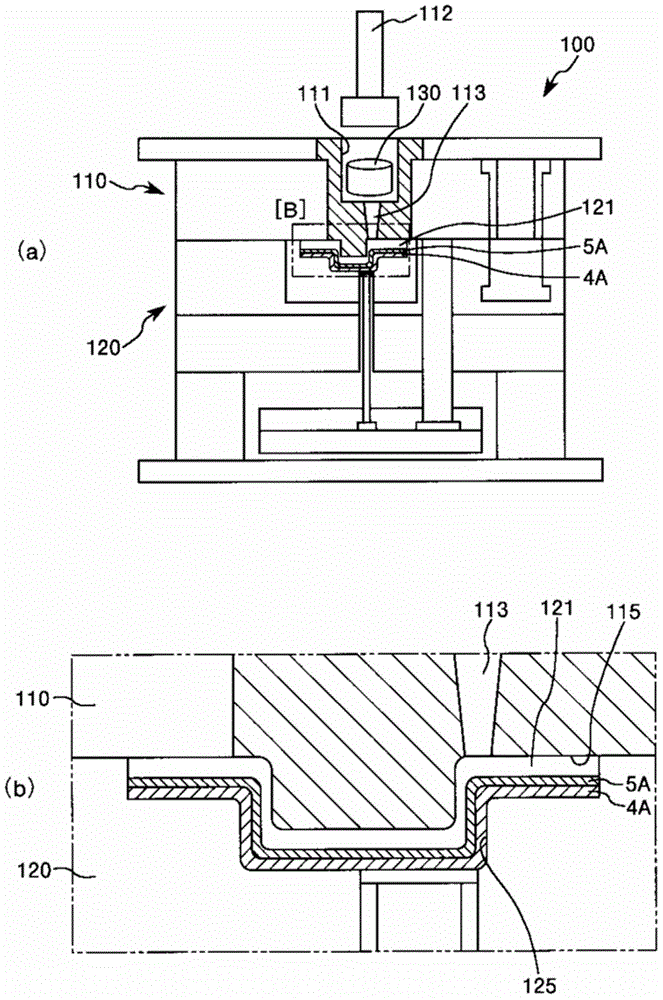

[0050] figure 1 It is a longitudinal sectional view showing the first embodiment of the electronic component mounting substrate of the present invention. It should be explained that in the following, for the convenience of explanation, the figure 1 The upper side in is referred to as "upper", and the figure 1 The lower side in is called "lower", and the figure 1 The right side in is called "Right", and the figure 1 The left side in is called "Left". In addition, each figure shows an exaggerated schematic diagram of an electronic component mounting board and its respective parts, and the sizes and ratios of the electronic component mounting board and its respective parts are greatly different from actual ones.

[0051] figure 1 The illustrated electronic component mounting board 50 has a semiconductor device 1 as an electronic component and a circuit board (circuit board of the present invention) 10 on which the semiconductor device 1 is mounted. It should be noted that, ...

no. 2 Embodiment approach >

[0234] Next, a second embodiment of the electronic component mounting substrate of the present invention will be described.

[0235] Figure 4 It is a vertical cross-sectional view showing a second embodiment of the electronic component mounting substrate of the present invention.

[0236] Hereinafter, the electronic component mounting board 51 of the second embodiment will be described focusing on differences from the electronic component mounting board 50 of the first embodiment described above, and the description of the same matters will be omitted.

[0237] Figure 4 The illustrated electronic component mounting board 51 mounts the semiconductor device 1 on the upper surface of a circuit board 10a having a configuration different from that of the circuit board 10 of the first embodiment, and is similar to figure 1 The illustrated electronic component mounting substrate 50 is the same.

[0238] That is, in the electronic component mounting board 51 according to the seco...

no. 3 Embodiment approach >

[0241] Next, a third embodiment of the electronic component mounting substrate of the present invention will be described.

[0242] Figure 5 It is a vertical cross-sectional view showing a third embodiment of the electronic component mounting substrate of the present invention.

[0243] Hereinafter, the electronic component mounting board 52 of the third embodiment will be described focusing on differences from the electronic component mounting board 50 of the first embodiment described above, and the description of the same matters will be omitted.

[0244] Figure 5 The illustrated electronic component mounting board 52 mounts the semiconductor device 1 on the upper surface of the circuit board 10 b having a configuration different from that of the circuit board 10 of the first embodiment, and is similar to figure 1 The illustrated electronic component mounting substrate 50 is the same.

[0245] That is, in the electronic component mounting board 52 according to the thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com