Ejection head for ejecting alignment film forming composition

a technology of alignment film and composition, which is applied in the field of liquid crystal display technology, can solve the problems of affecting easy to form problems, and achieve the effect of avoiding large droplets and greatly enhancing the quality of alignment film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

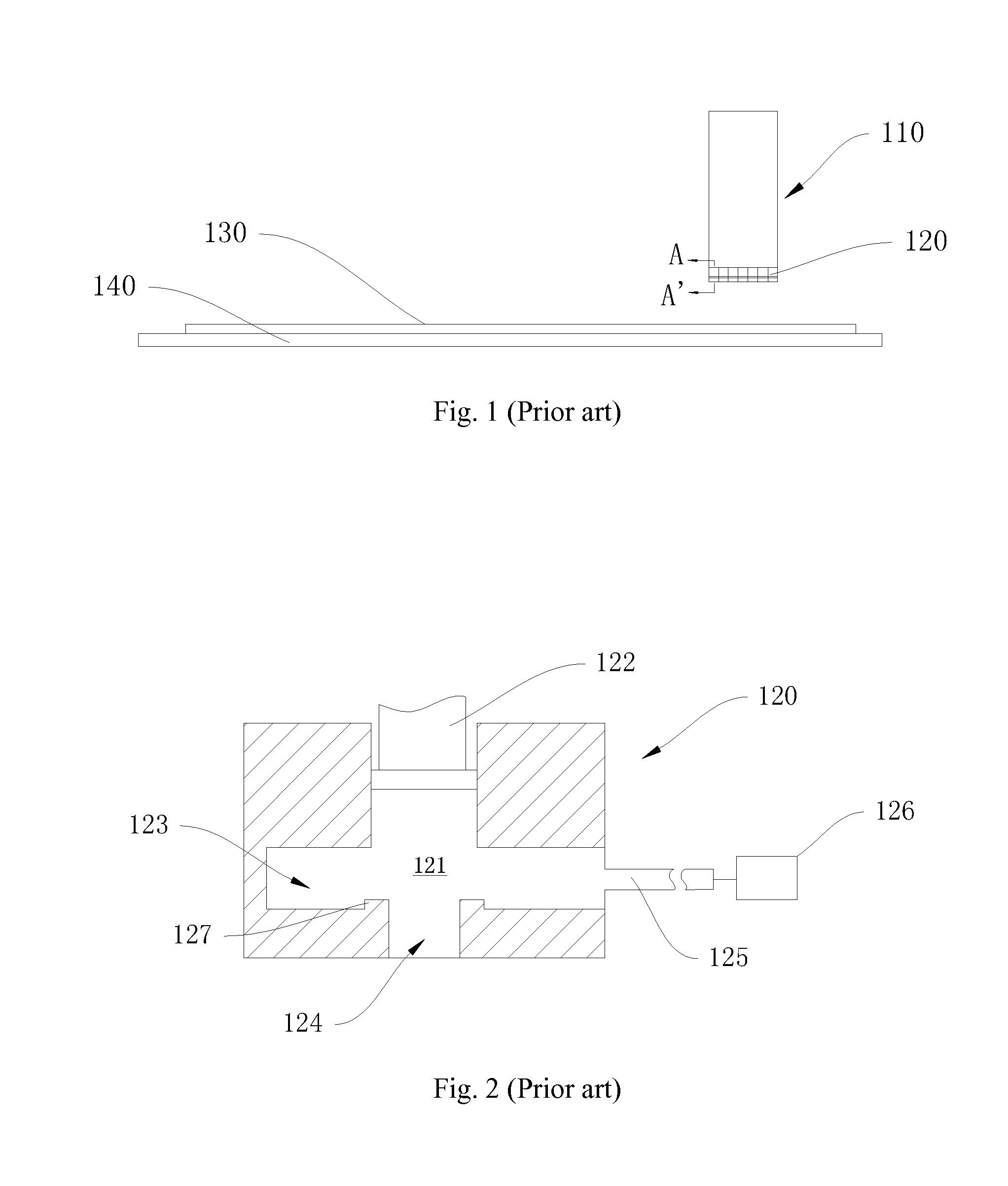

[0029]The accompanying drawings are included to provide a further understanding of the invention, and are incorporated in and constitute a part of this specification. The drawings illustrate embodiments of the invention and, together with the description, serve to explain the principles of the invention.

[0030]An object of the present invention is to solve problems caused by the conventional nozzle, such as occlusion and drop condensation.

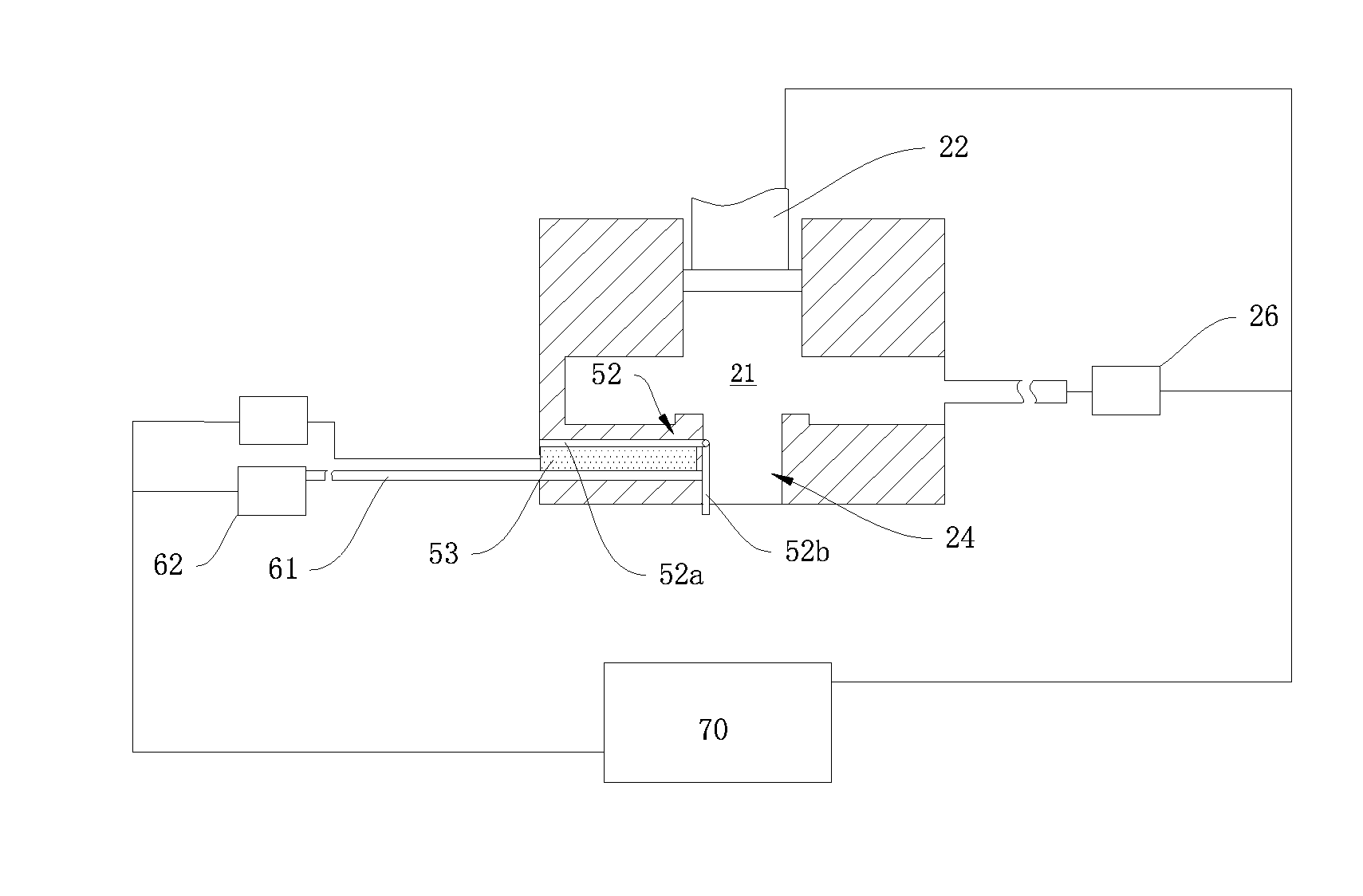

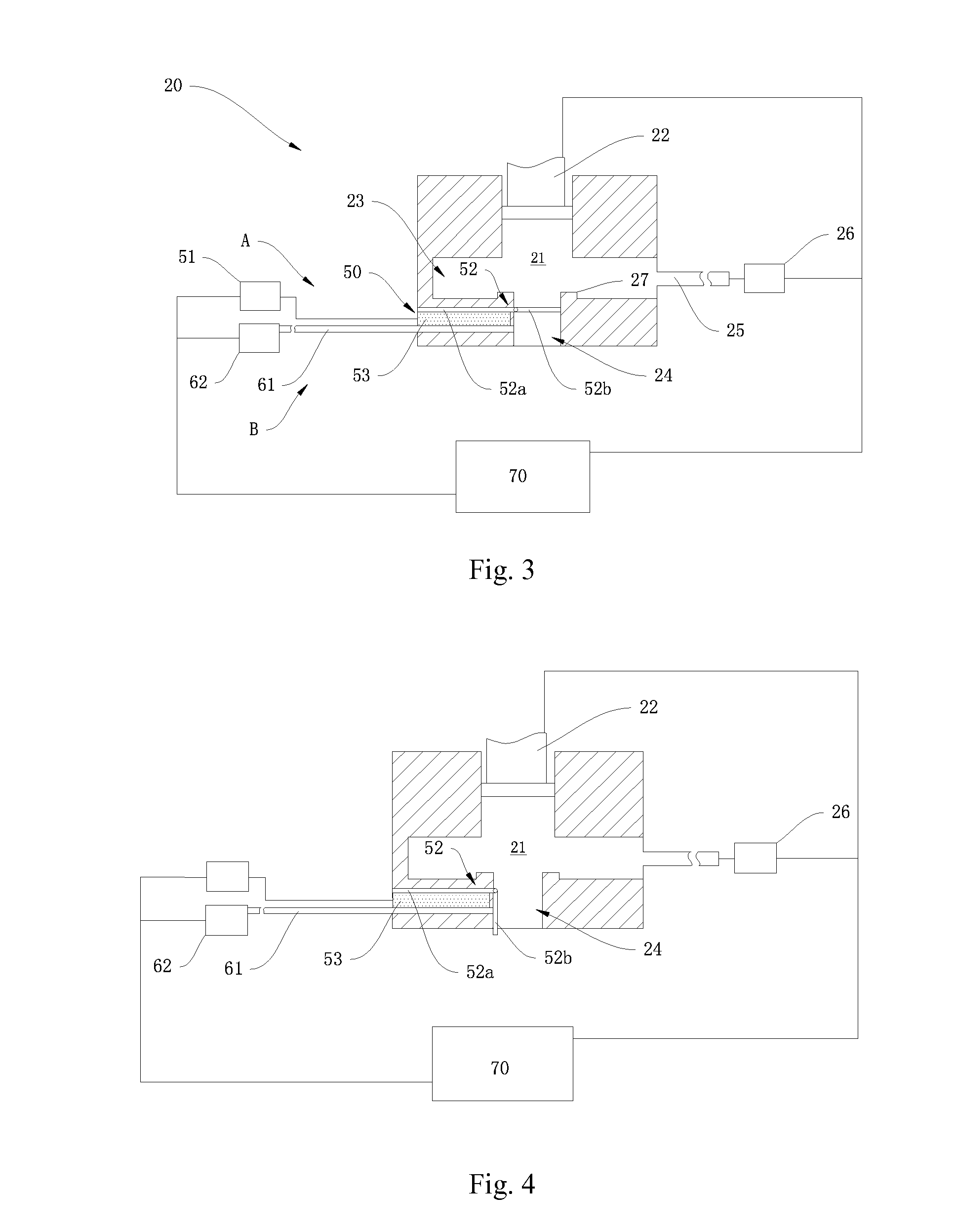

[0031]The ejection head in the present embodiment comprises a plurality of nozzles 20. The structure of the nozzle 20 is improved. FIG. 3 shows the internal structure of the nozzle 20. Each of the plurality of nozzles 20 comprises a chamber 21 and a composition source 26.

[0032]A liquid transportation pipe 24 and a pusher 22 are disposed on the bottom of the chamber 21 and the top of the chamber 21, respectively. The liquid transportation pipe 24 and the pusher 22 correspond with each other. The pusher 22 is used to push the alignment film forming co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| magnetic forces | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com