Robotic mechanism with two degrees of freedom

a technology of robotic actuators and actuation mechanisms, applied in the direction of manipulators, joints, manufacturing tools, etc., can solve the problems of large joint weight, low design efficiency, and high cost of strength and stiffness, and achieve the effects of preventing joint separation, substantial stiffness against bending or distortion, and enduring high bending and twisting torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

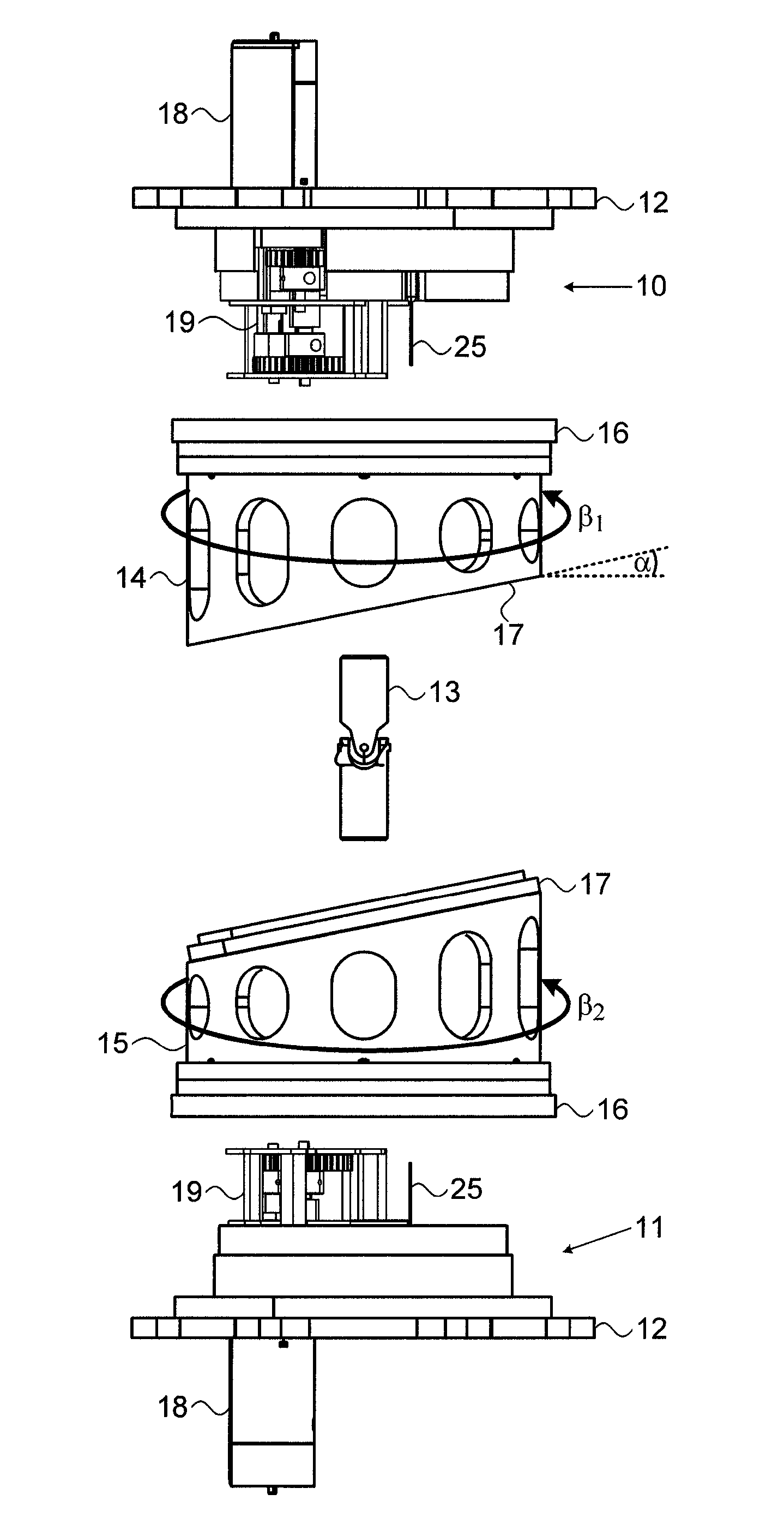

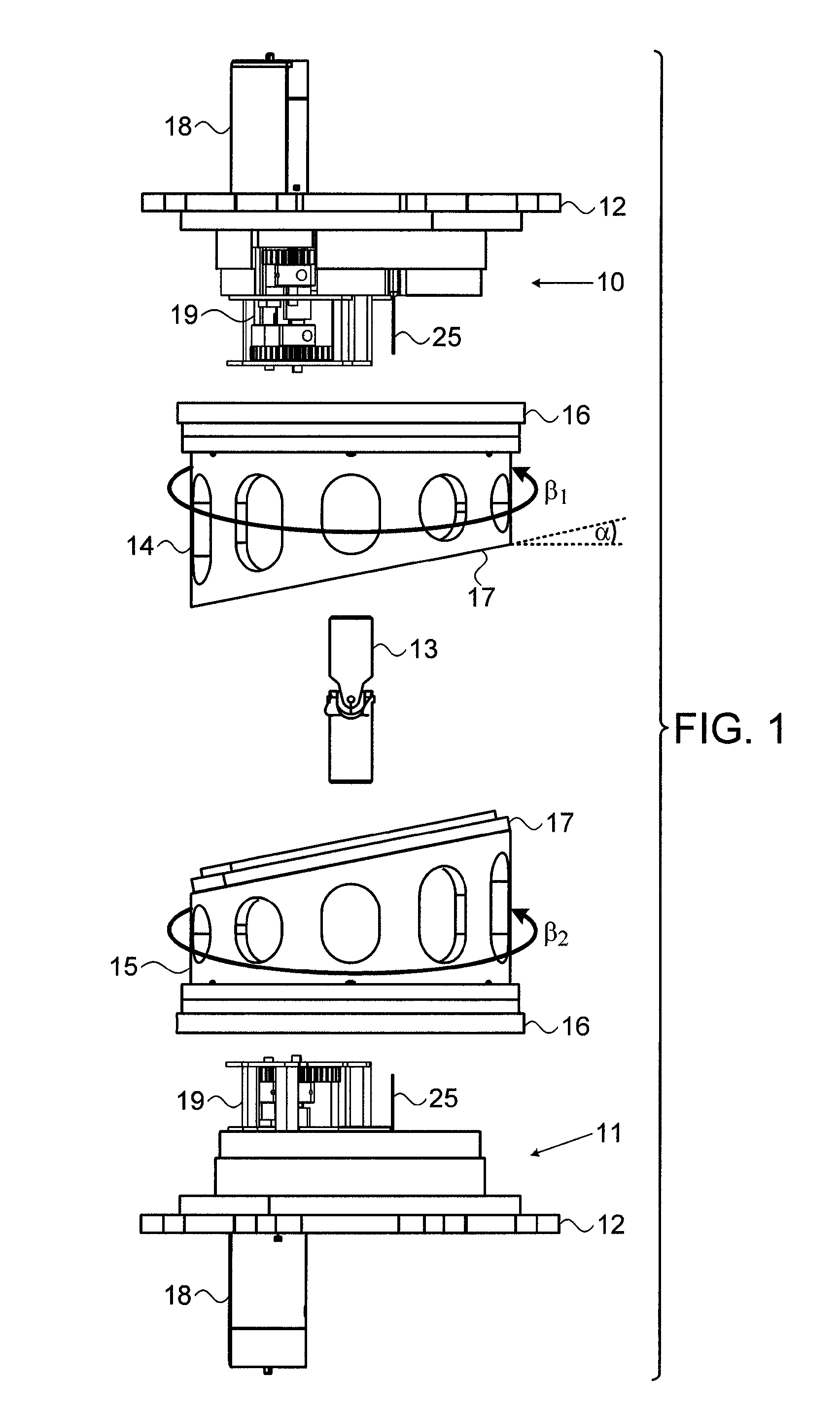

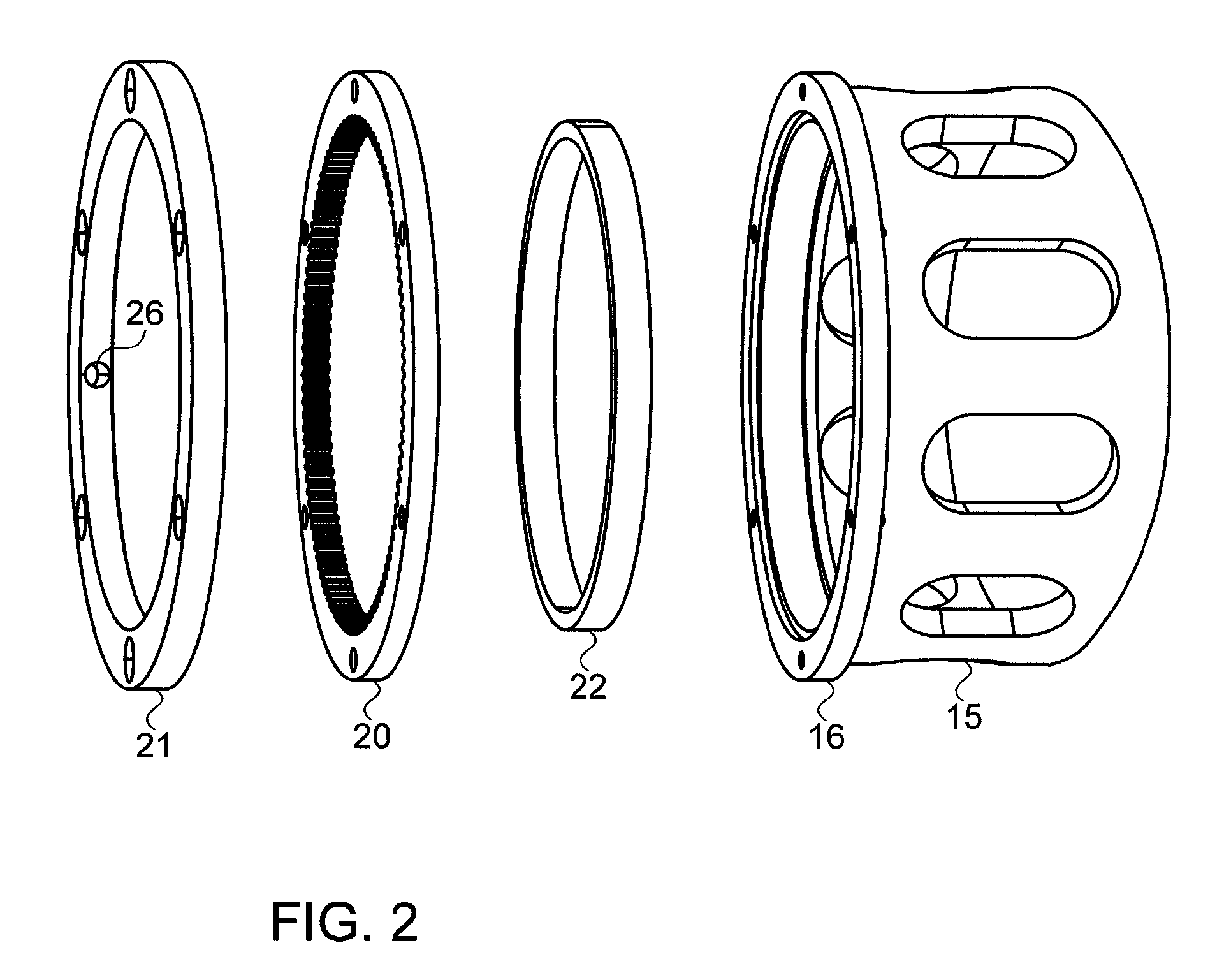

[0043]Reference is now made to FIG. 1 of which illustrates an exploded view of one exemplary implementation of a robotic actuator device having a link mechanism of the type described in the present disclosure. The device comprises a pair of base elements 10, 11, shown constructed on base flanges 12, the two base elements 10, 11, representing what is termed in common parlance as the static base and the actuated robotic platform of the robotic mechanism. Since the device is symmetric, the definition of which base element is the “static” base and which is the actuated output platform is nominal, since either end can be considered to be able to fulfill either function, depending on the specific use to which the robotic link is put. The base elements are connected together by a flexible joint 13 shown in FIG. 1 as a mechanical universal joint providing two degrees of freedom, though it could be any other form of flexible shaft. The universal joint is connected rigidly at its ends to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com